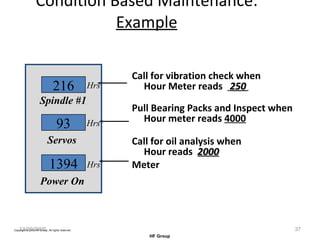

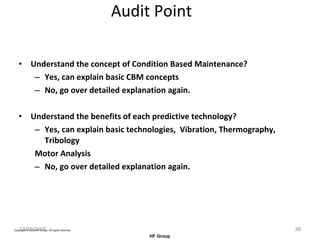

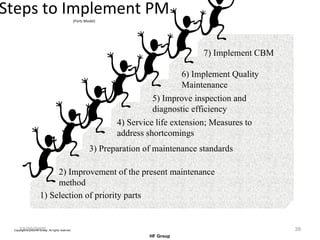

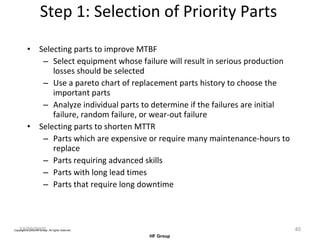

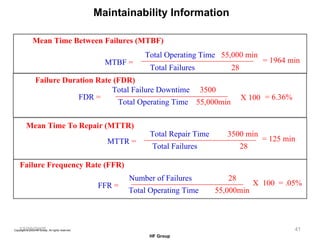

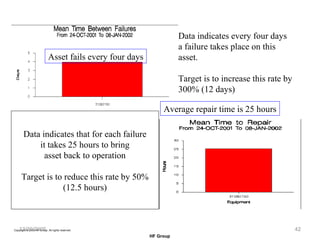

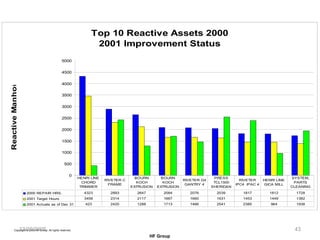

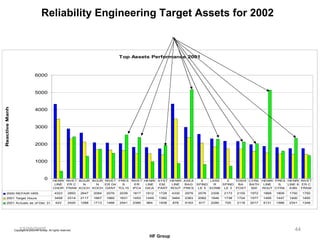

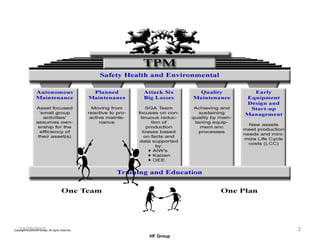

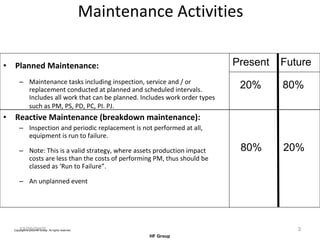

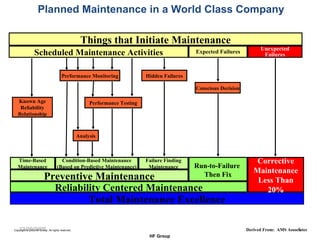

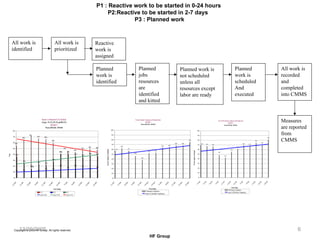

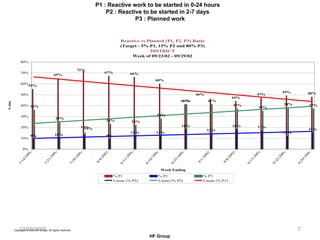

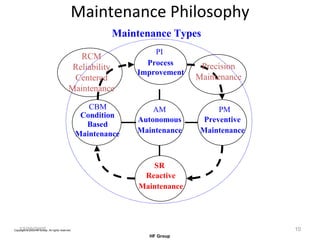

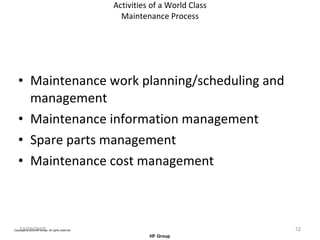

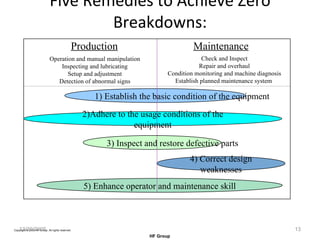

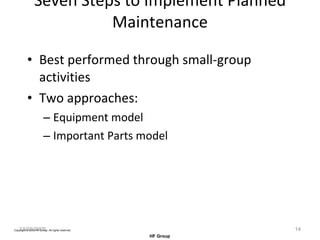

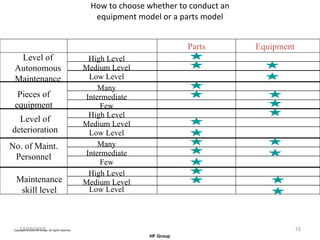

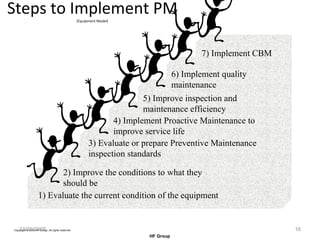

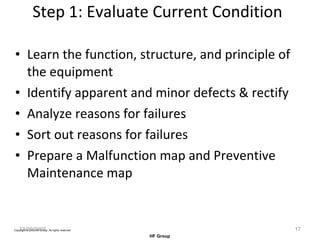

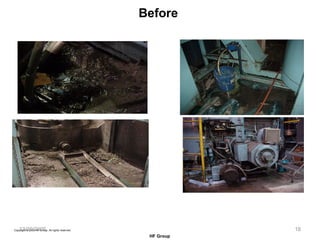

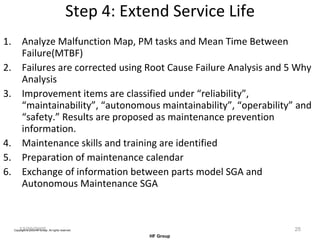

The document discusses techniques for achieving zero equipment failures through planned maintenance. It describes the differences between planned and reactive maintenance. Planned maintenance involves scheduled inspections and repairs, while reactive maintenance only addresses unplanned breakdowns. The document outlines seven steps to implement a planned maintenance program using either an equipment model or parts model approach. This includes evaluating current equipment conditions, improving conditions, developing inspection standards, extending service life, and implementing condition-based maintenance.

![12/20/2005 Concept of Condition Based Maintenance Appropriate time for maintenance or replacement Deterioration curve Time [Service life of part] Equipment failure quality defects Too early: over-maintenance Too late: equipment outside manufacturing specification BAD [Start of deterioration] [Appropriate time to take Action] Control limits Periodic maintenance CBM](https://image.slidesharecdn.com/12480plannedmaintenancenewppt-13171552294151-phpapp02-110927152932-phpapp02/85/Planned-Maintenance-31-320.jpg)