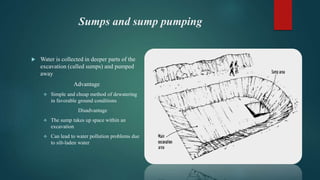

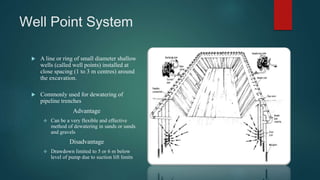

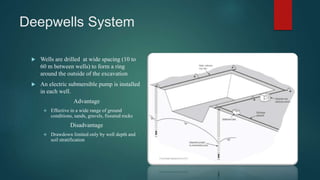

Dewatering is the process of controlling groundwater levels during construction by pumping water out of excavation sites. There are several techniques used for dewatering including pumping methods like sump pumping, well points, and deep wells. Exclusion methods prevent water from entering sites using techniques like ground freezing, sheet piling, slurry trench cut-off walls, and grouted cut-offs. The appropriate dewatering method depends on factors such as ground permeability, excavation size and depth, and proximity to existing structures. Common pumping techniques are sump pumping, well points, and deep wells which use pumps in shallow wells, closely spaced shallow wells, or widely spaced deep wells respectively. Exclusion methods form impermeable