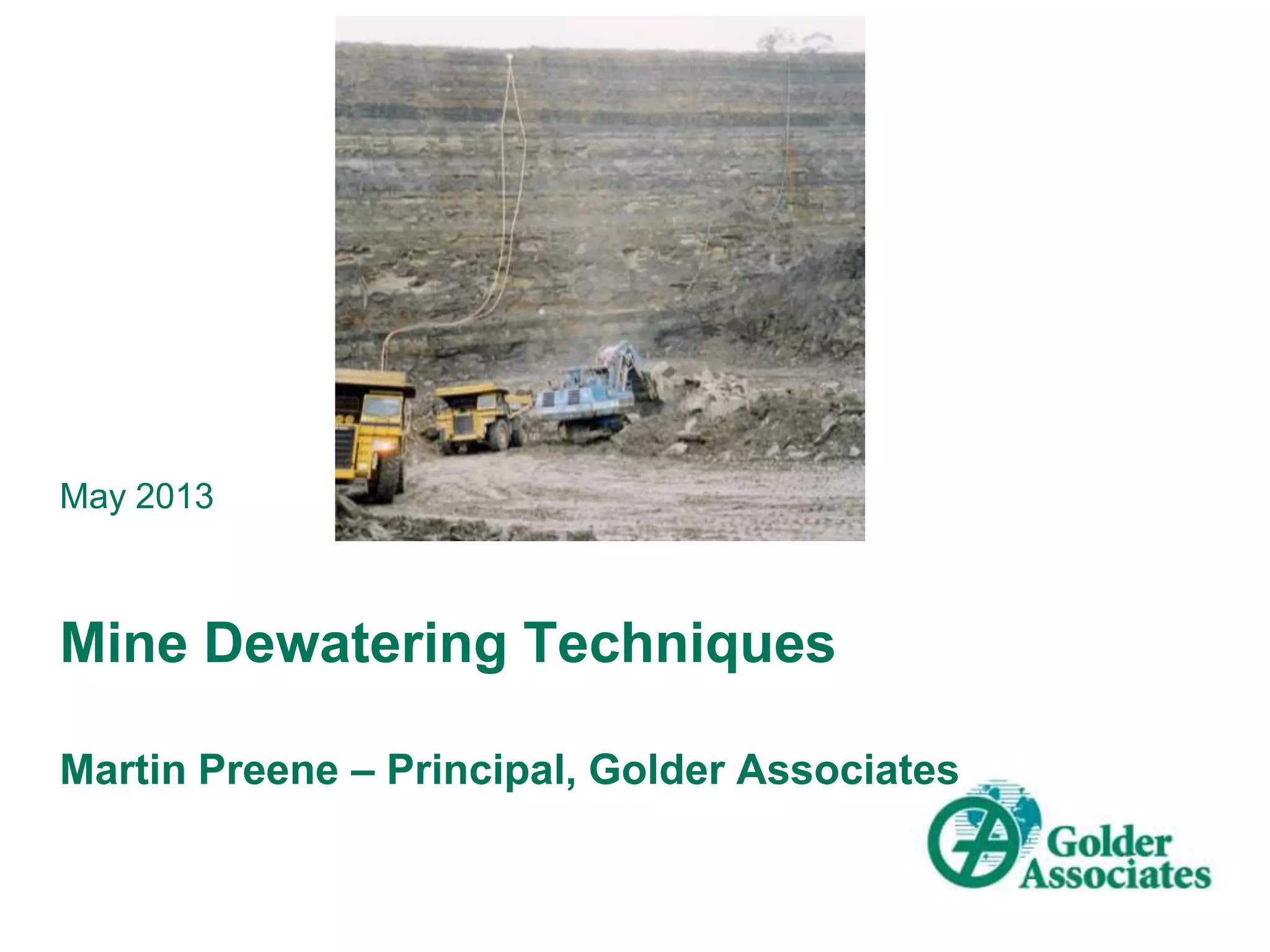

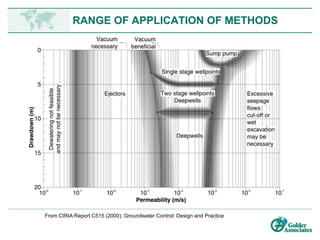

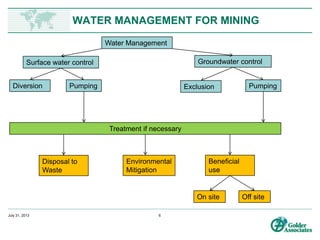

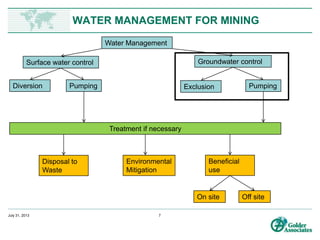

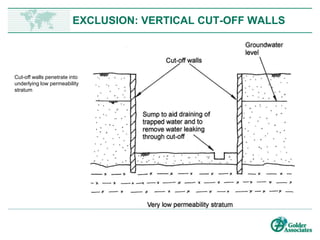

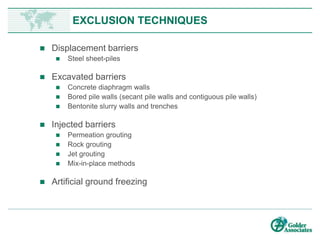

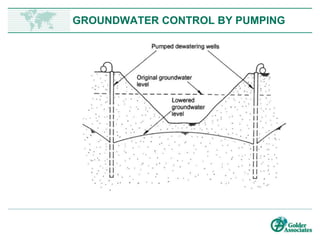

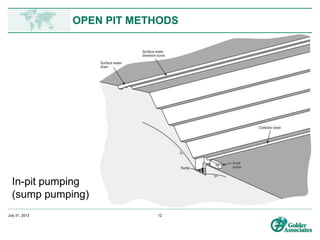

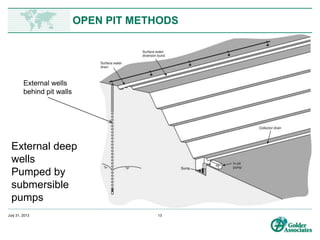

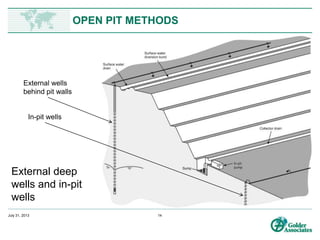

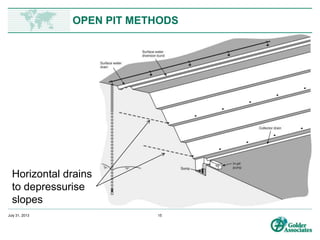

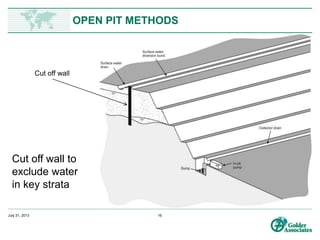

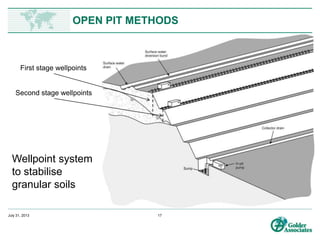

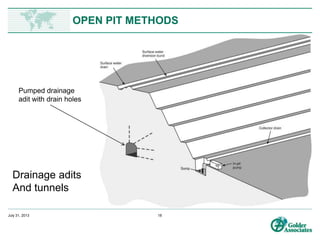

This document discusses mine dewatering and groundwater control. It describes various approaches to dewatering such as exclusion methods using cut-off walls or grouting, and pumping methods using wells, drains or sumps. Both open pit and underground mines are addressed. The key aspects of successful mine dewatering projects are explained as understanding the hydrogeology, appropriate dewatering technology, and environmental considerations.