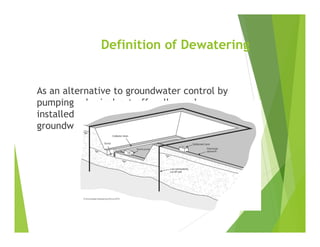

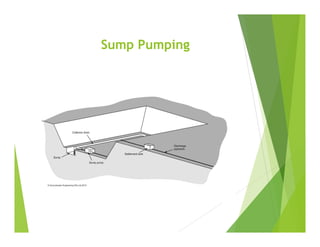

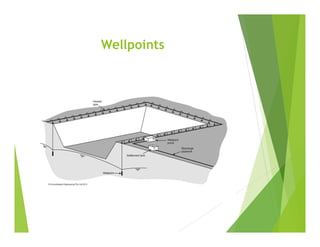

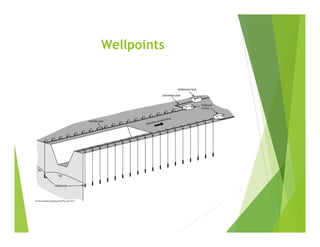

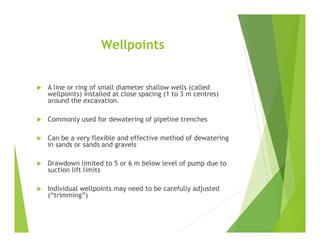

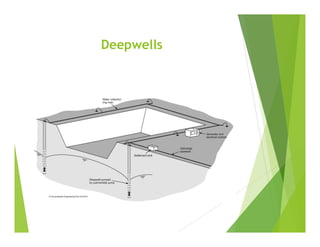

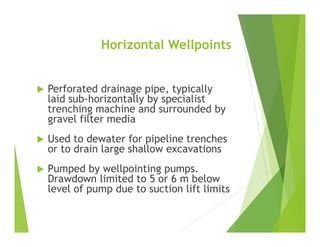

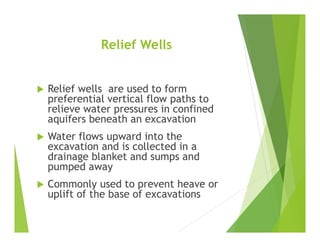

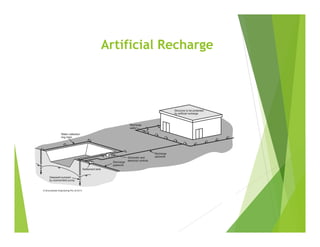

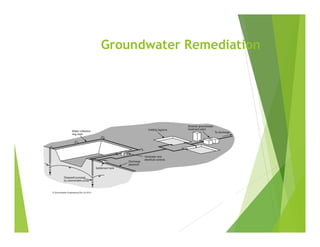

The document provides an overview of construction dewatering, defining it as the control of groundwater through pumping to create dry excavation conditions. It discusses various techniques for both dewatering and surface water control, including commonly used methods like sump pumping and wellpoints, as well as less frequently employed ones like relief wells and artificial recharge. The document also highlights the importance of managing surface water to prevent flooding and soil erosion during construction operations.