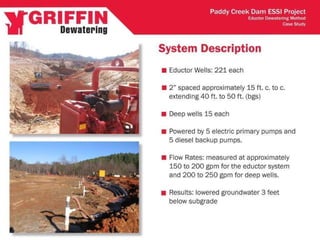

Griffin specializes in dewatering and groundwater control for challenging construction projects using techniques like wells, wellpoints, and relief wells to separate water from soil and control groundwater levels. Proper dewatering is important as it allows for safer and more efficient construction by improving soil properties and intercepting water, while improper dewatering can have consequences like unstable excavations and increased costs. The document then provides details on dewatering methods, considerations for selecting a system, and several case studies of Griffin's dewatering work on large infrastructure projects.