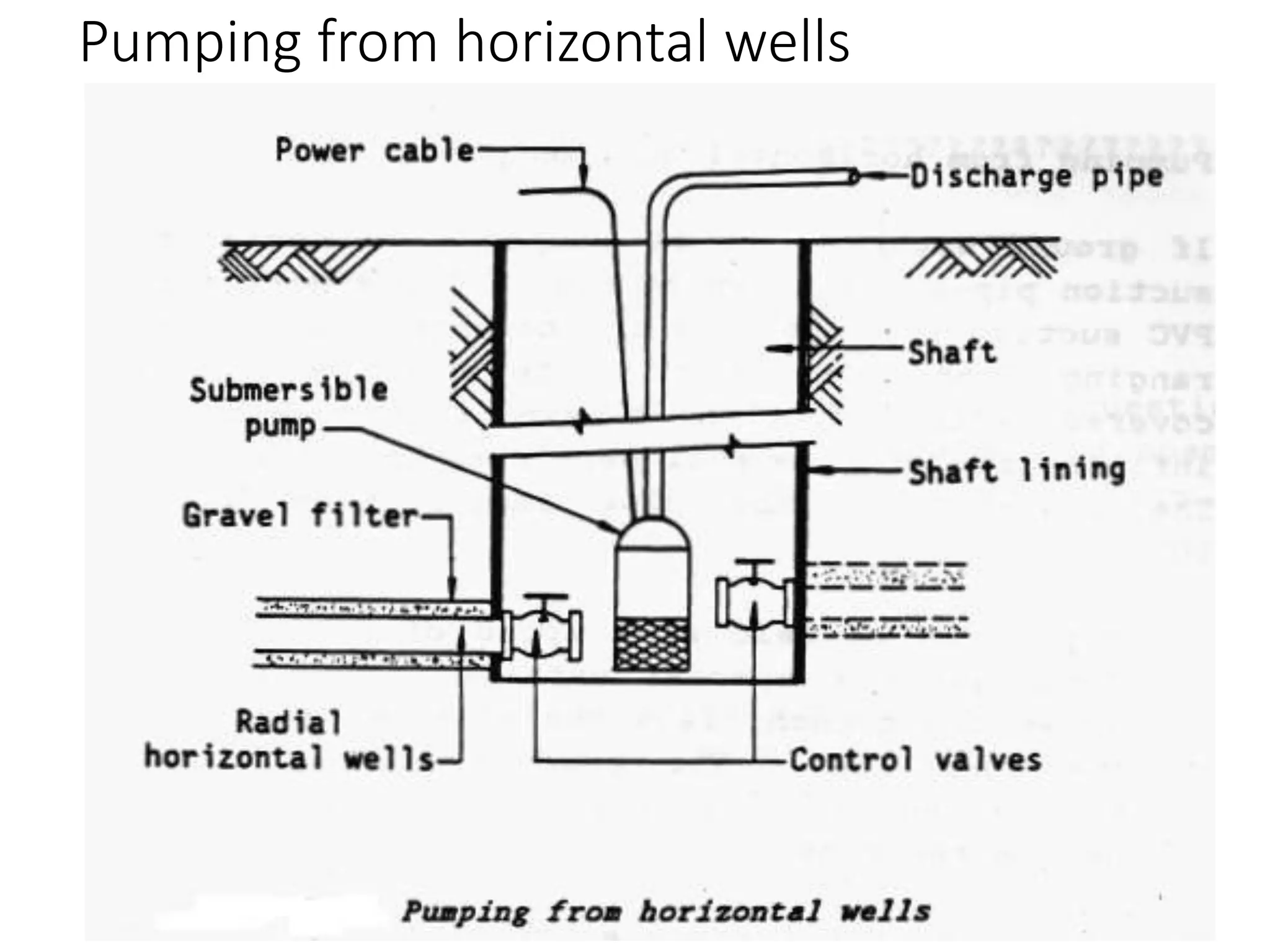

This document summarizes different types of excavation including topsoil excavation, rock excavation, muck excavation, and earth excavation. It then discusses various purposes of excavation such as cut and fill excavation, trench excavation, basement excavation, and dredging excavation. Finally, it covers topics related to controlling groundwater and surface water during excavation projects through methods like pumping, cutoff walls, and special techniques.