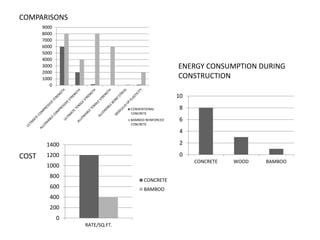

Bamboo is an evergreen, perennial plant in the grass family with significant economic and cultural importance in Asia, valued for its strength and versatility as a construction material. It requires careful preservation and skilled construction techniques due to its susceptibility to moisture and pests, making various joint methods and processing techniques crucial for effective use. Bamboo scaffolding has been historically important in construction, with multiple benefits over traditional materials including strength, sustainability, and lower environmental impact.