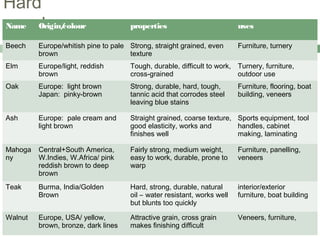

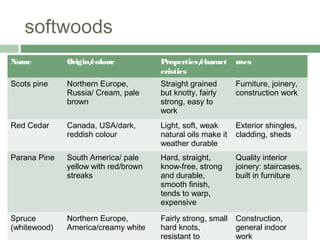

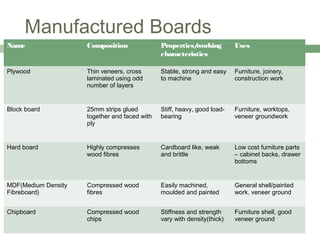

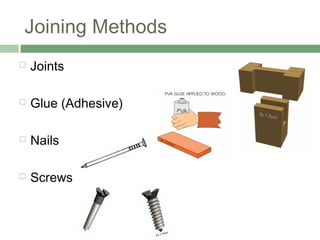

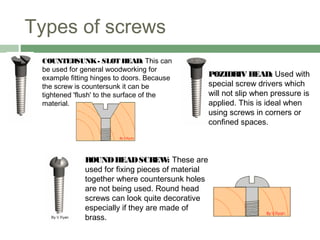

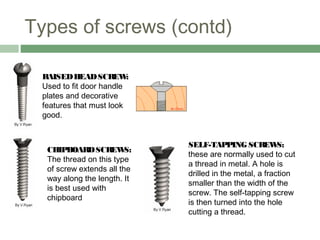

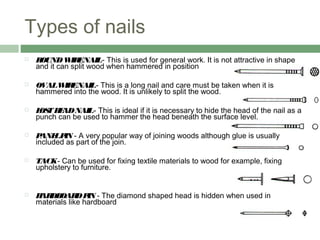

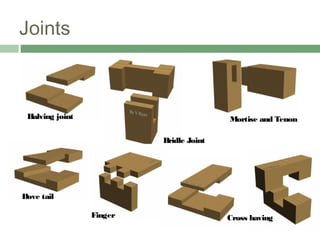

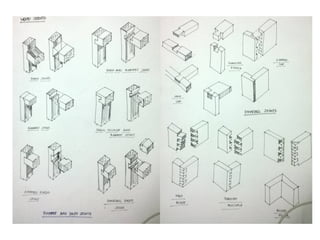

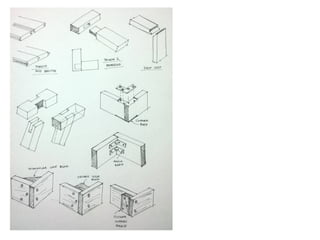

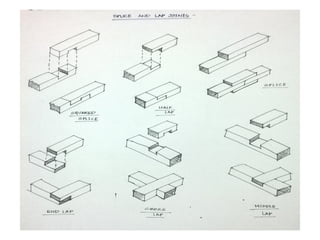

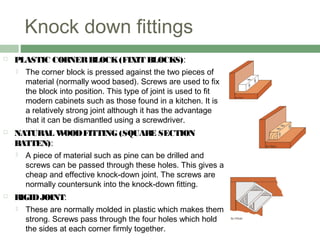

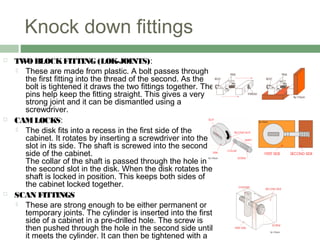

The document discusses the characteristics and uses of different types of wood, classifying them into hardwoods, softwoods, and manufactured boards, each with distinct properties. It details various wood species, their origins, and suitable applications in furniture and construction, alongside joining methods involving adhesives, screws, and nails. Additionally, the text covers knock-down fittings, emphasizing their utility in assembling flat-pack furniture and providing strong yet removable joints.