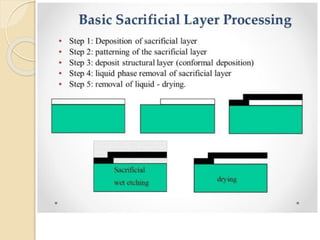

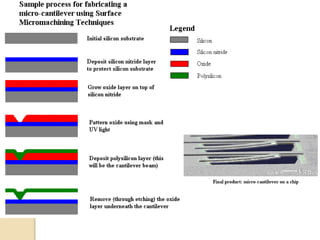

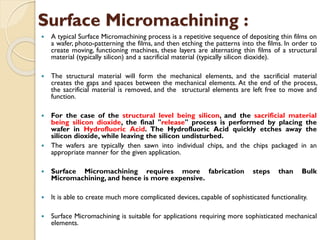

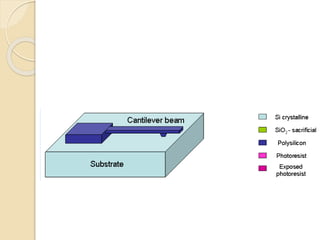

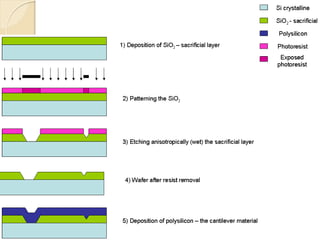

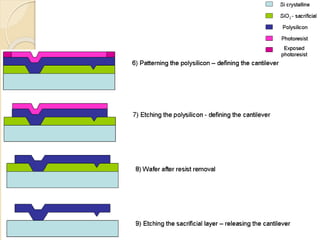

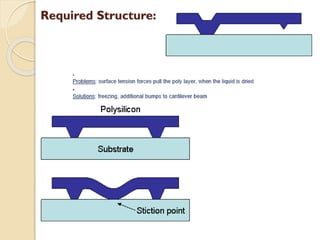

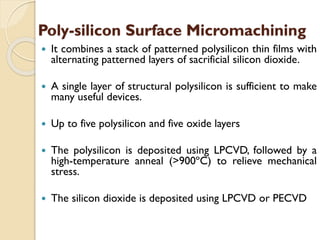

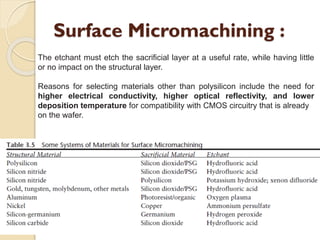

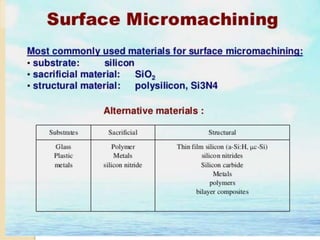

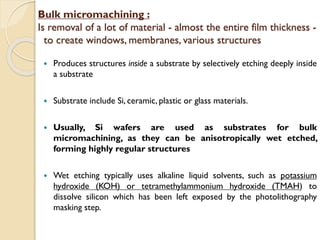

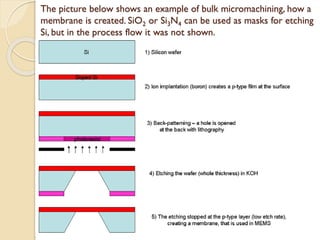

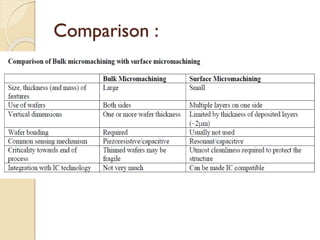

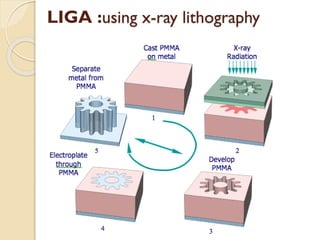

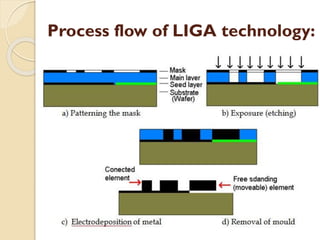

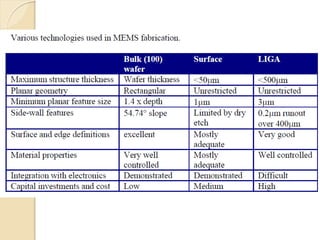

The document covers the fabrication and manufacturing processes involved in MEMS devices, detailing both surface and bulk micromachining techniques. Surface micromachining allows for complex mechanical elements through layer-by-layer construction using polysilicon and sacrificial materials, while bulk micromachining involves deeper etching of silicon wafers to create simpler structures. Additionally, it introduces LIGA technology for high-aspect-ratio microstructures, comparing its x-ray and UV methods, highlighting their respective advantages and challenges.