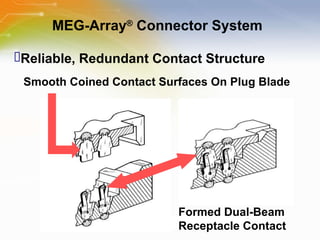

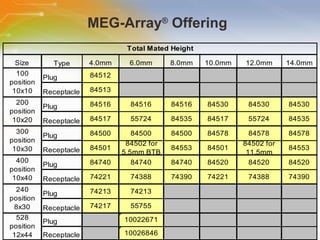

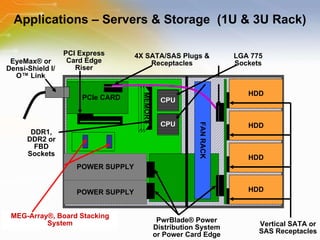

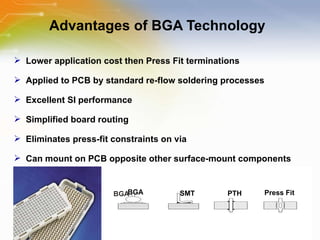

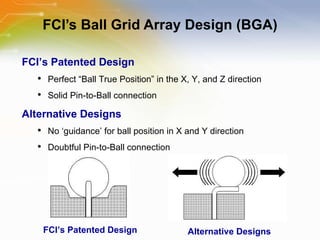

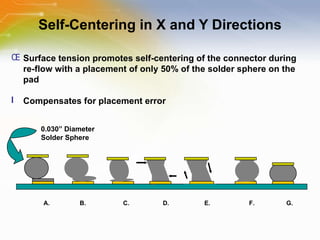

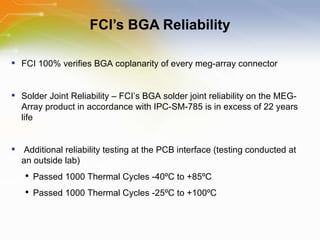

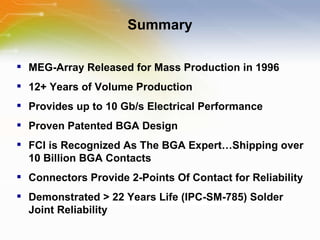

The document introduces FCI's MEG-Array connector system, which uses ball grid array (BGA) attachment. Key features include providing bandwidth of up to 5GHz for differential pairs, demonstrated solder joint reliability of over 22 years, and applications in servers, storage, switching, transmission, and industrial/medical equipment. FCI's patented BGA design provides perfect ball position and self-centering/leveling during reflow soldering to compensate for placement errors and ensure reliable connections.