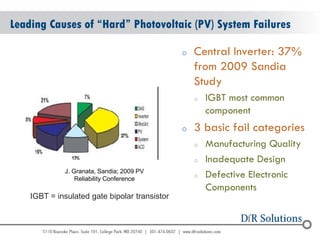

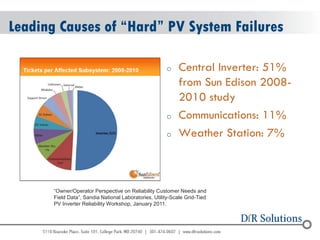

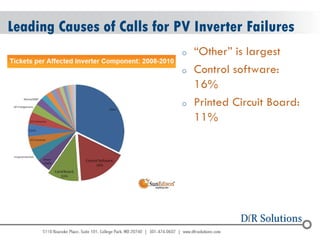

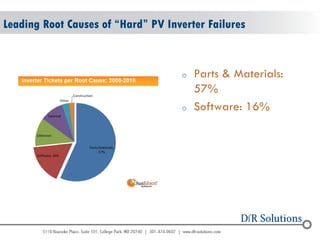

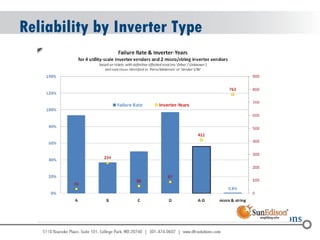

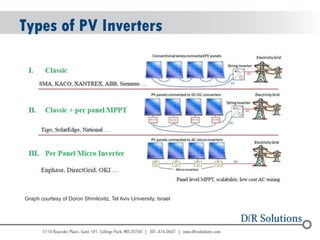

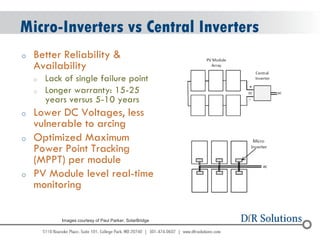

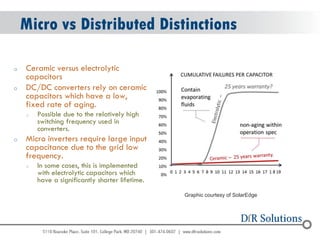

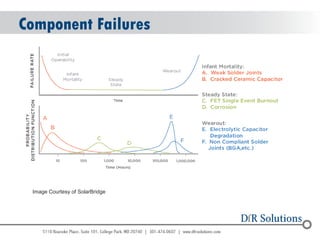

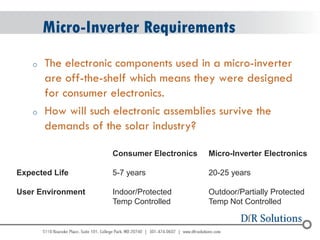

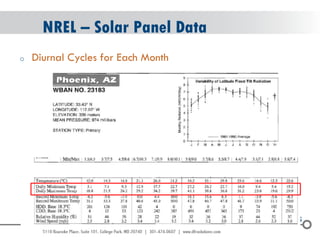

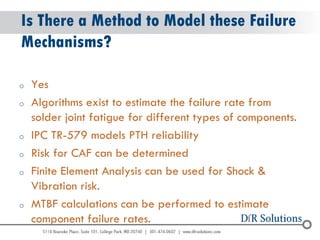

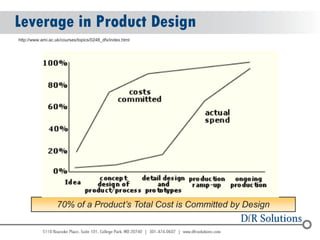

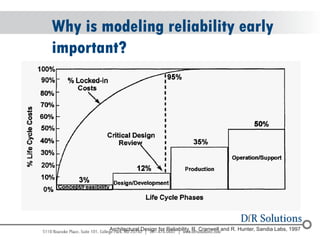

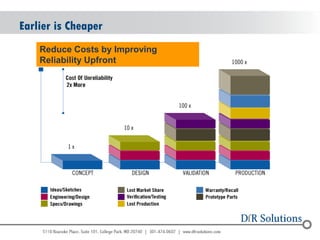

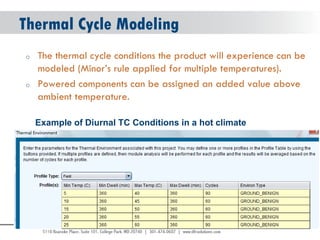

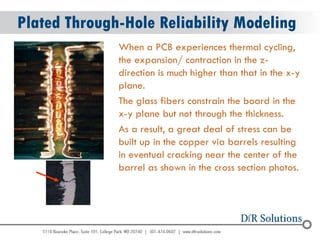

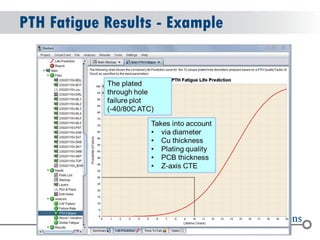

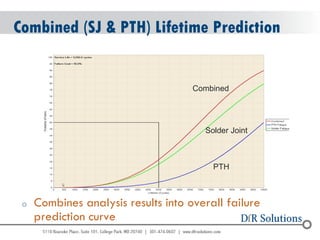

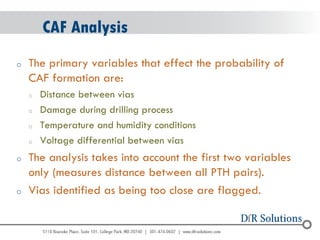

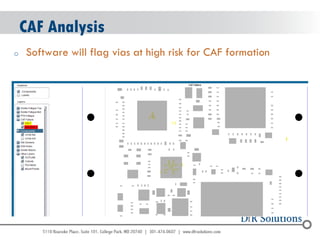

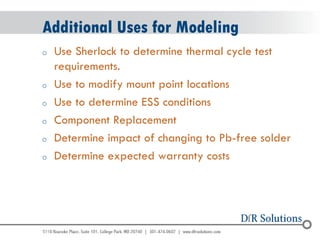

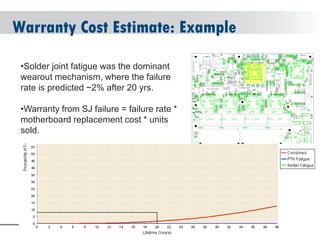

This document discusses reliability challenges for solar electronics, particularly inverters, that must last for 25 years. It notes that central inverters and their components like IGBTs are leading causes of failures. Micro-inverters and power optimizers are presented as alternatives that improve reliability by distributing the electronics over many individual modules rather than having a single point of failure. The document discusses various failure modes for electronic components like solder joints and methods to improve reliability through design choices, testing, and modeling lifetime under stress conditions.