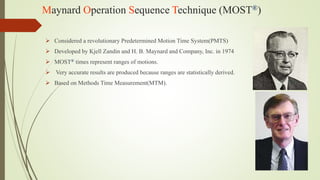

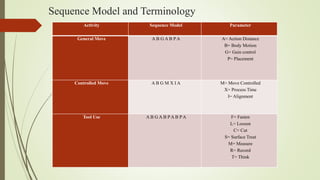

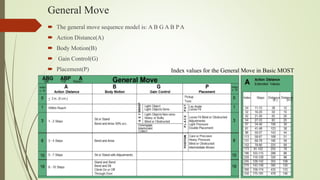

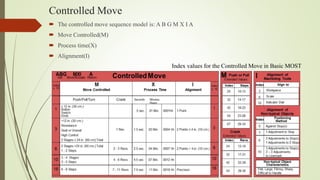

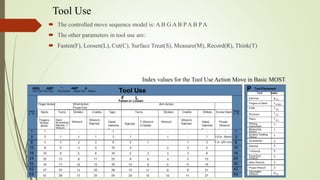

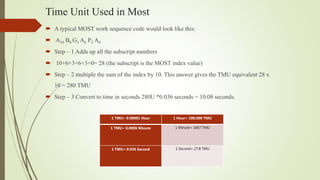

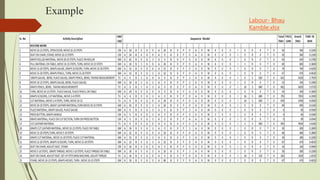

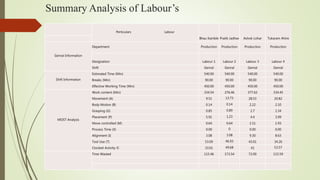

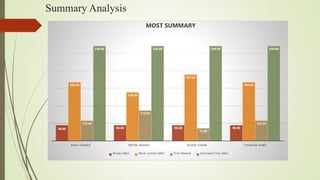

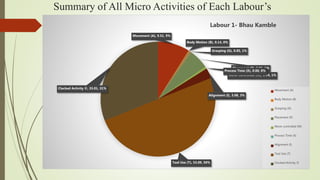

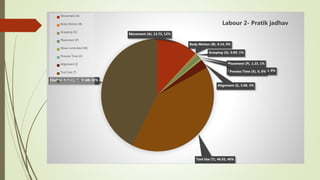

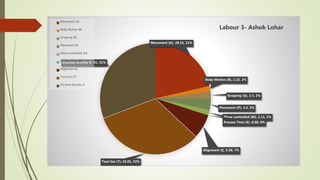

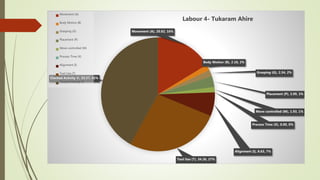

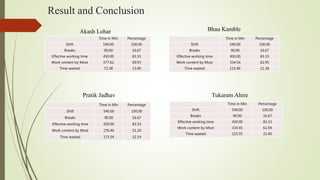

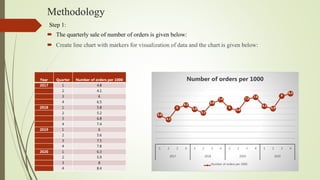

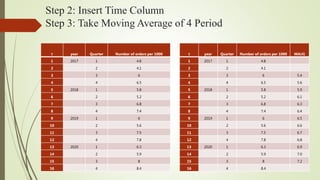

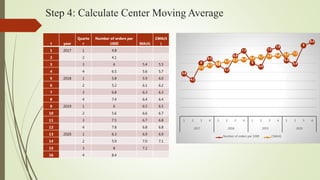

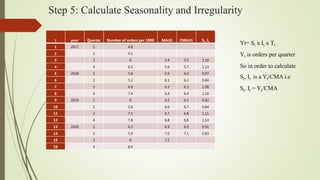

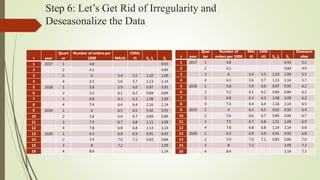

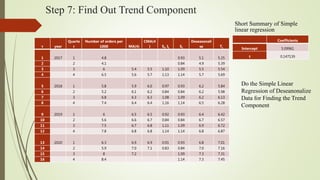

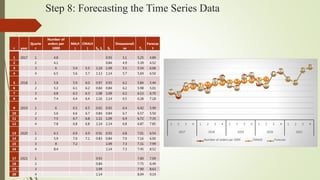

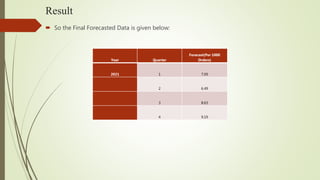

The document discusses productivity improvement through Maynard's Operation Sequence Technique (MOST) and time series forecasting, detailing the methodology for time studies, standard work content measurement, and workload analysis for labor across various tasks. It includes a summary of individual laborers' work effectiveness, their time wastage, suggestions for improvement, and a time series analysis of quarterly order data with trends and seasonality. The findings emphasize the importance of efficient workflow, minimizing waste, and forecasting to enhance productivity in a production setting.