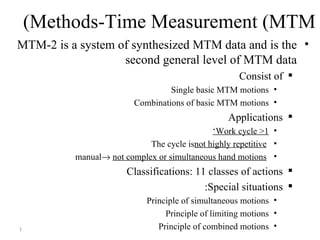

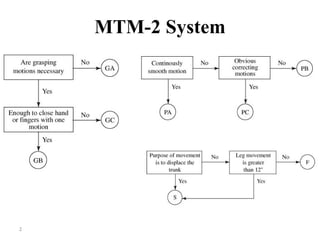

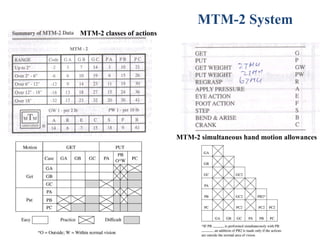

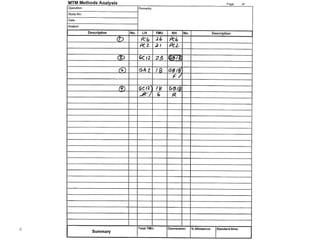

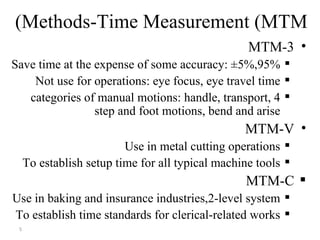

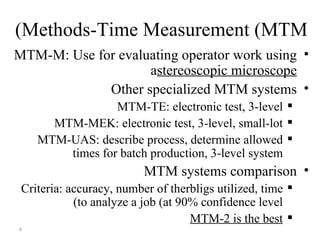

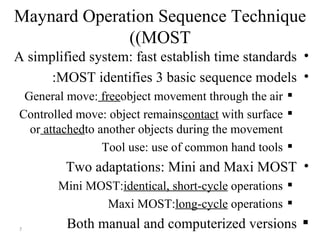

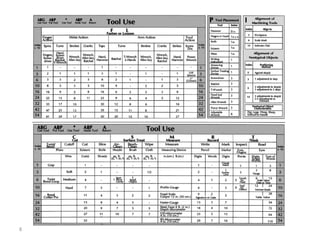

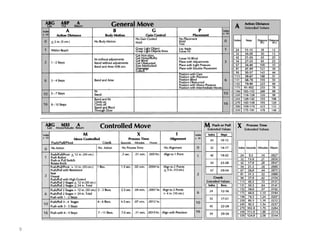

The document discusses several time measurement systems including Methods-Time Measurement (MTM). MTM-2 is the second general level of MTM data that uses basic motions and their combinations to analyze work cycles over 1 minute. The document also describes MTM-3, MTM-V, MTM-C and other specialized MTM systems. It compares different MTM systems based on accuracy, number of elements used, and time to analyze a job. The Maynard Operation Sequence Technique (MOST) is also summarized as a simplified time measurement system that identifies basic sequence models.