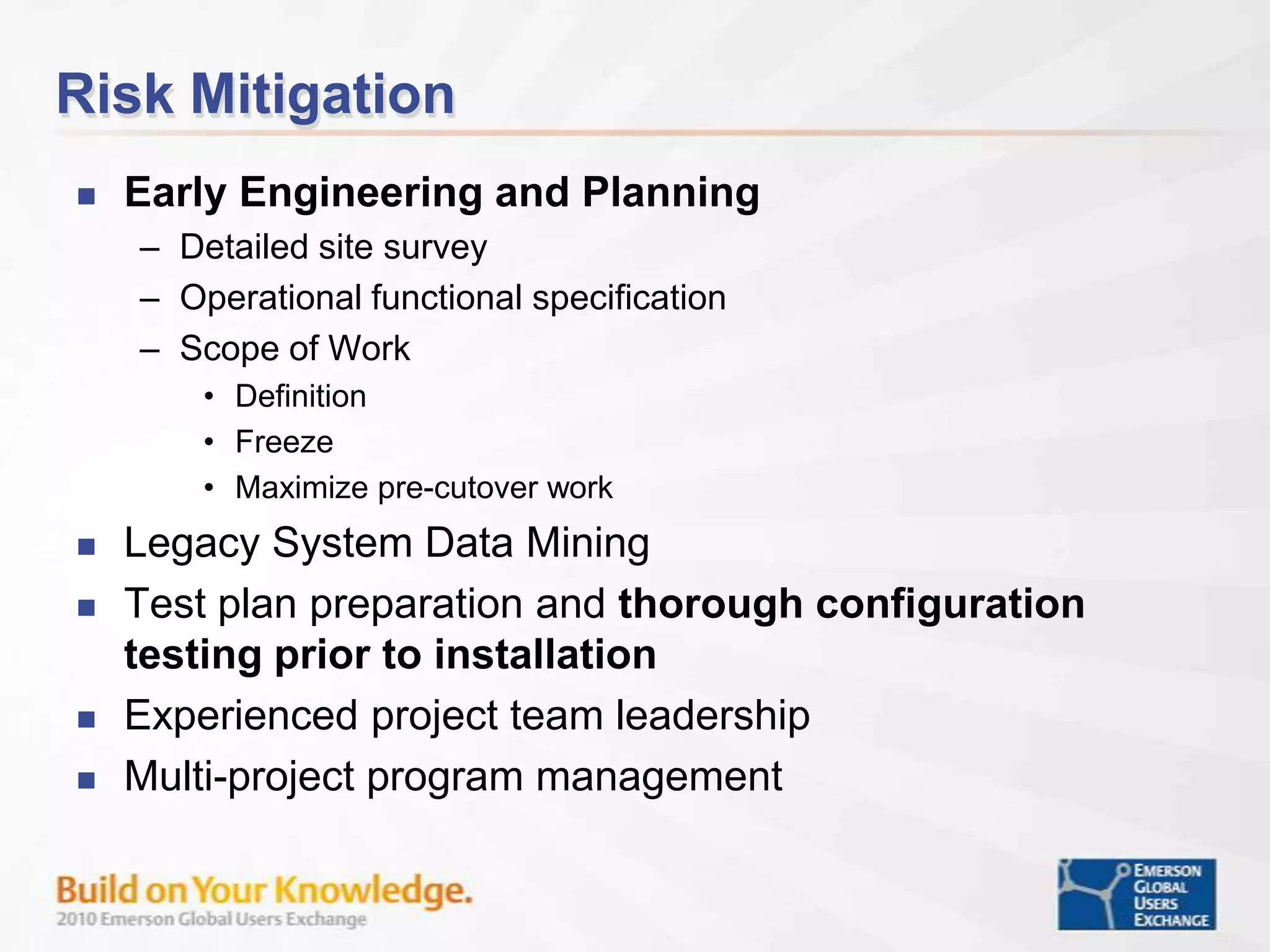

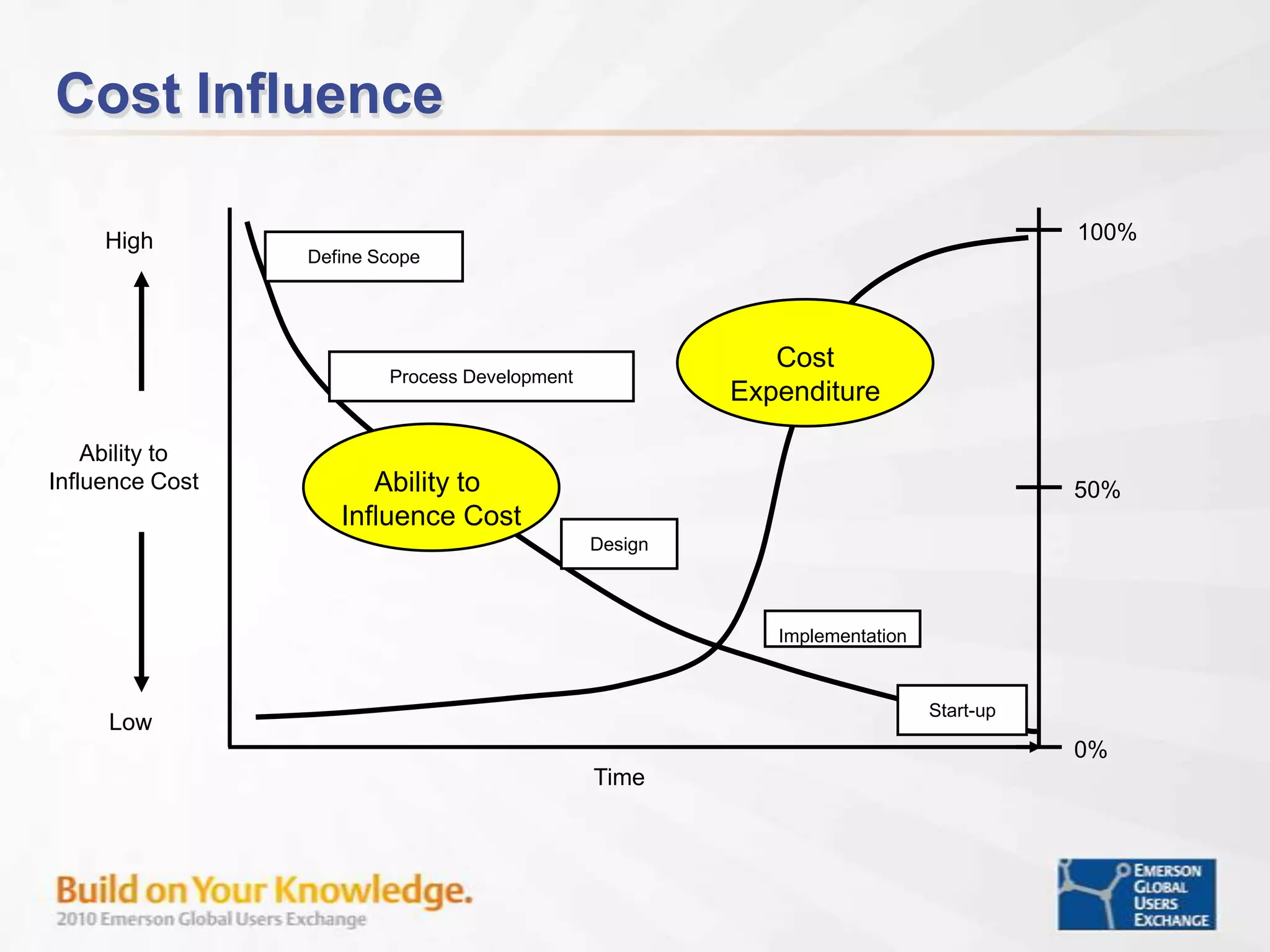

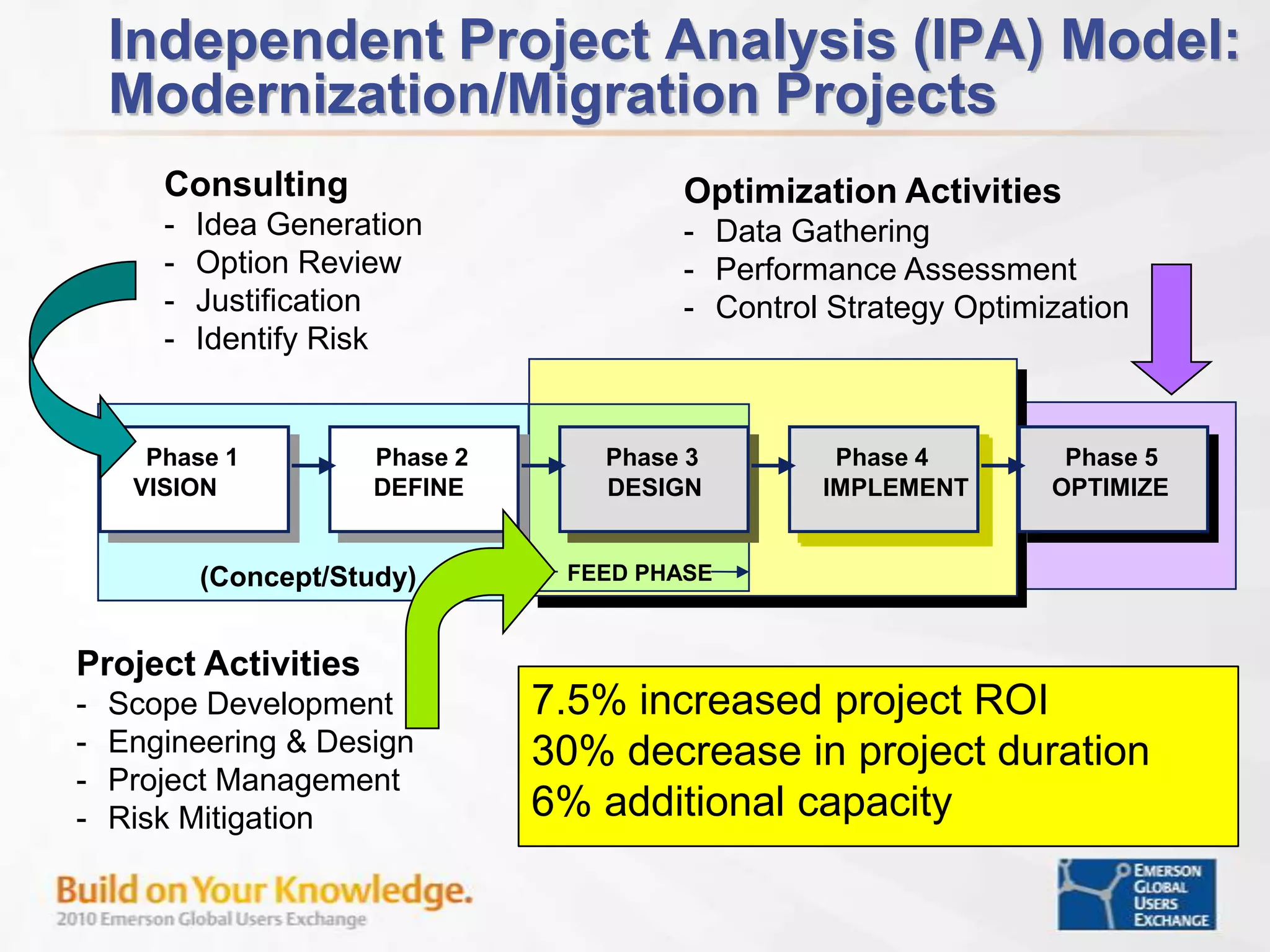

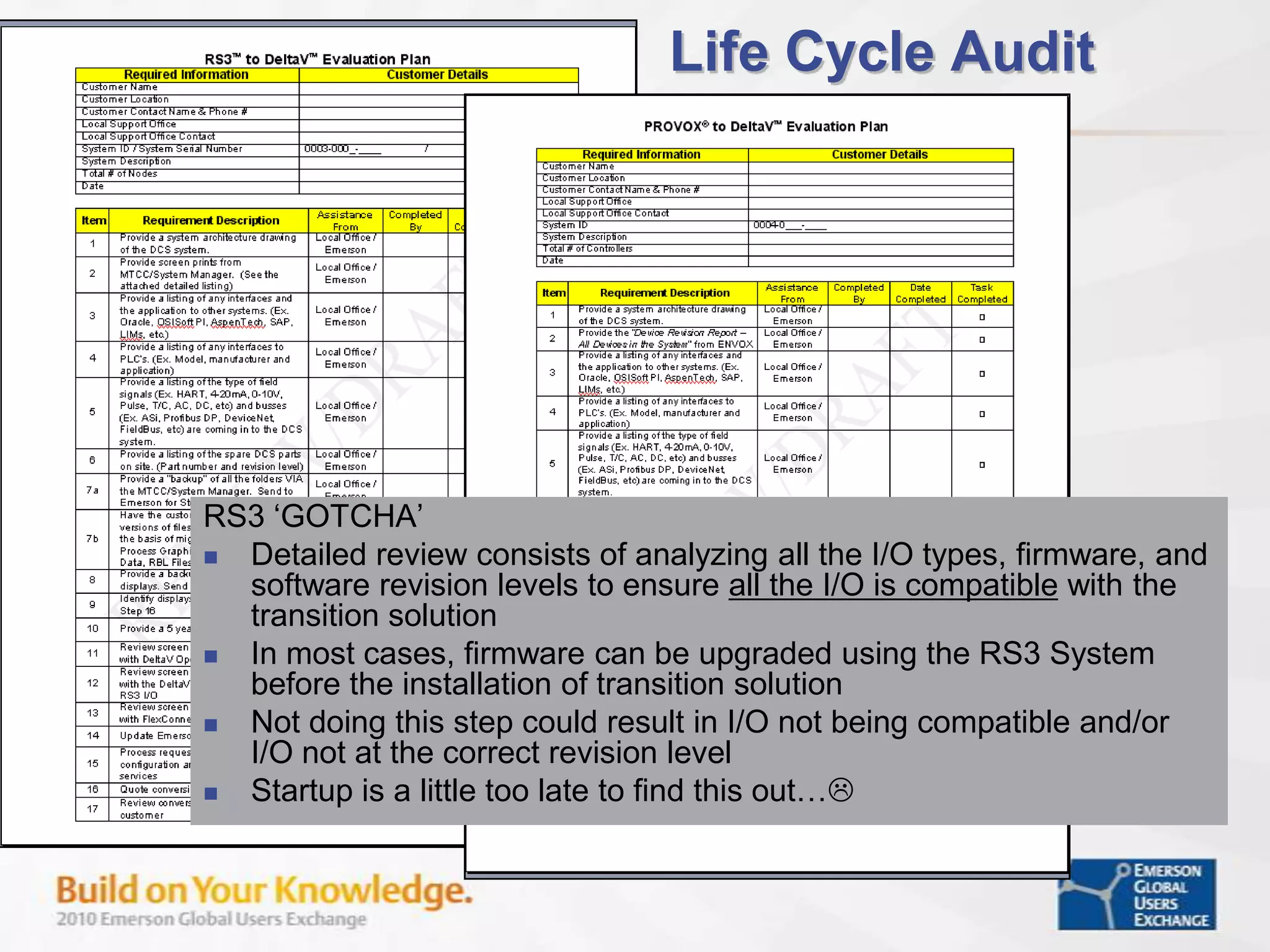

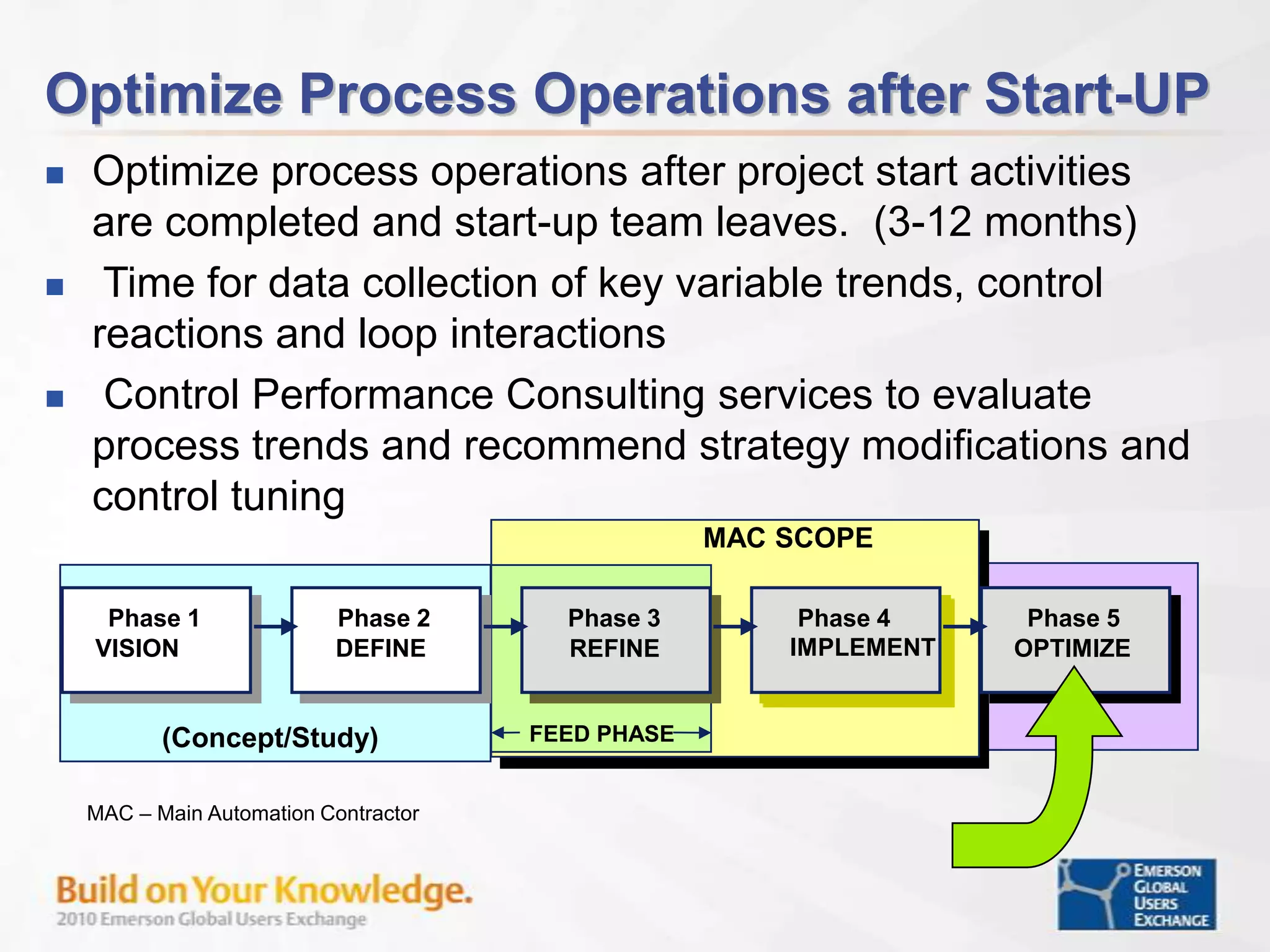

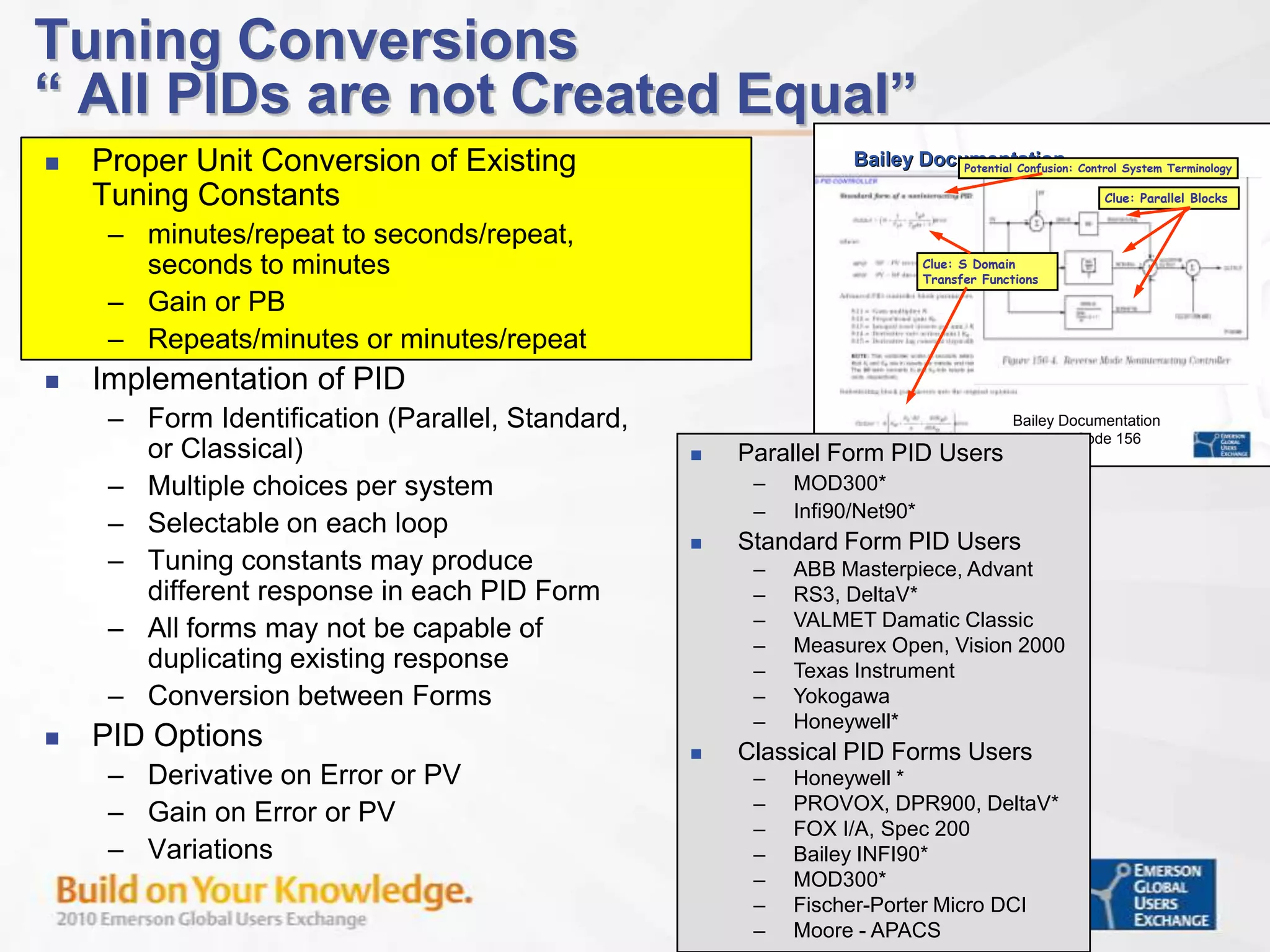

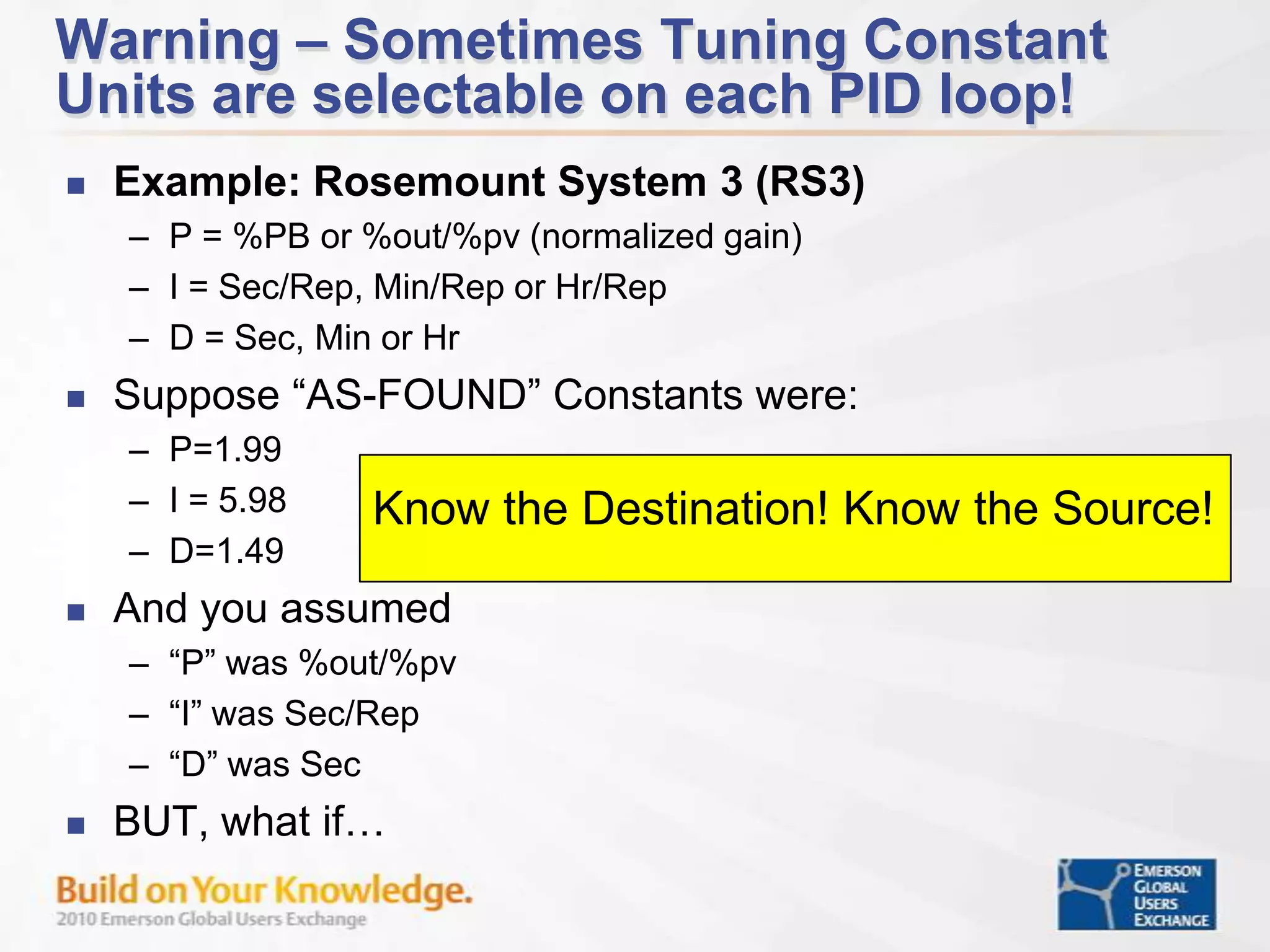

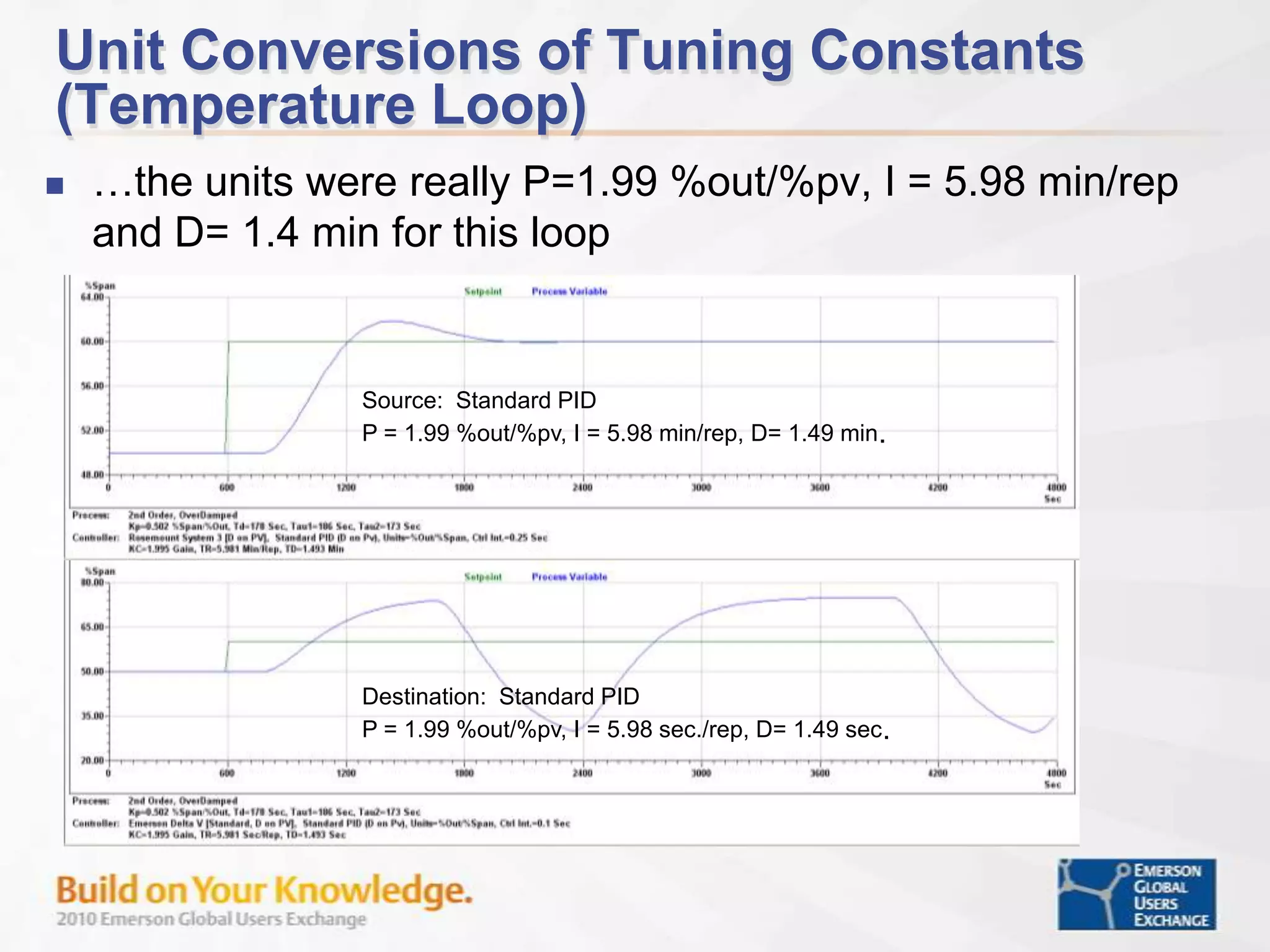

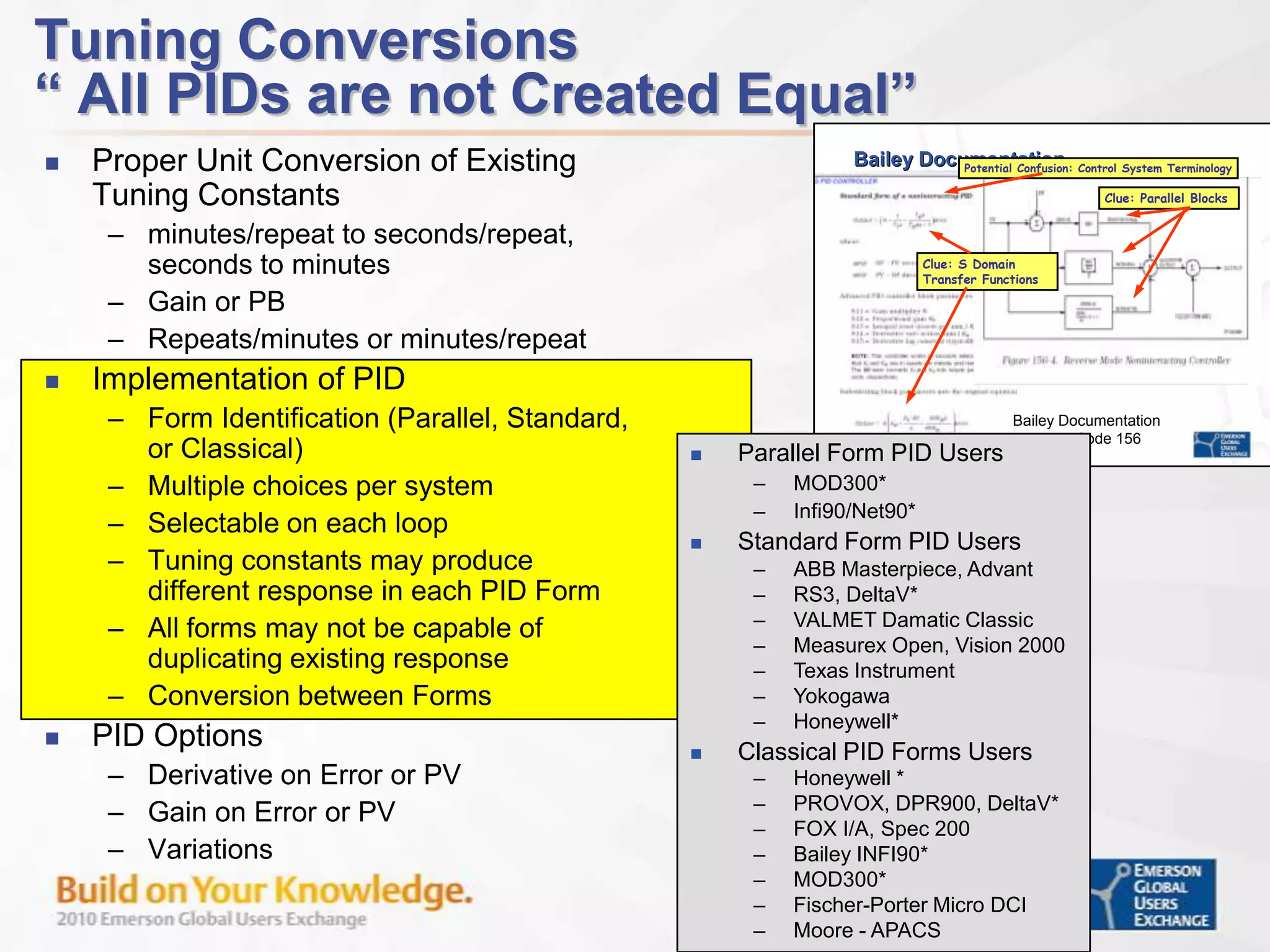

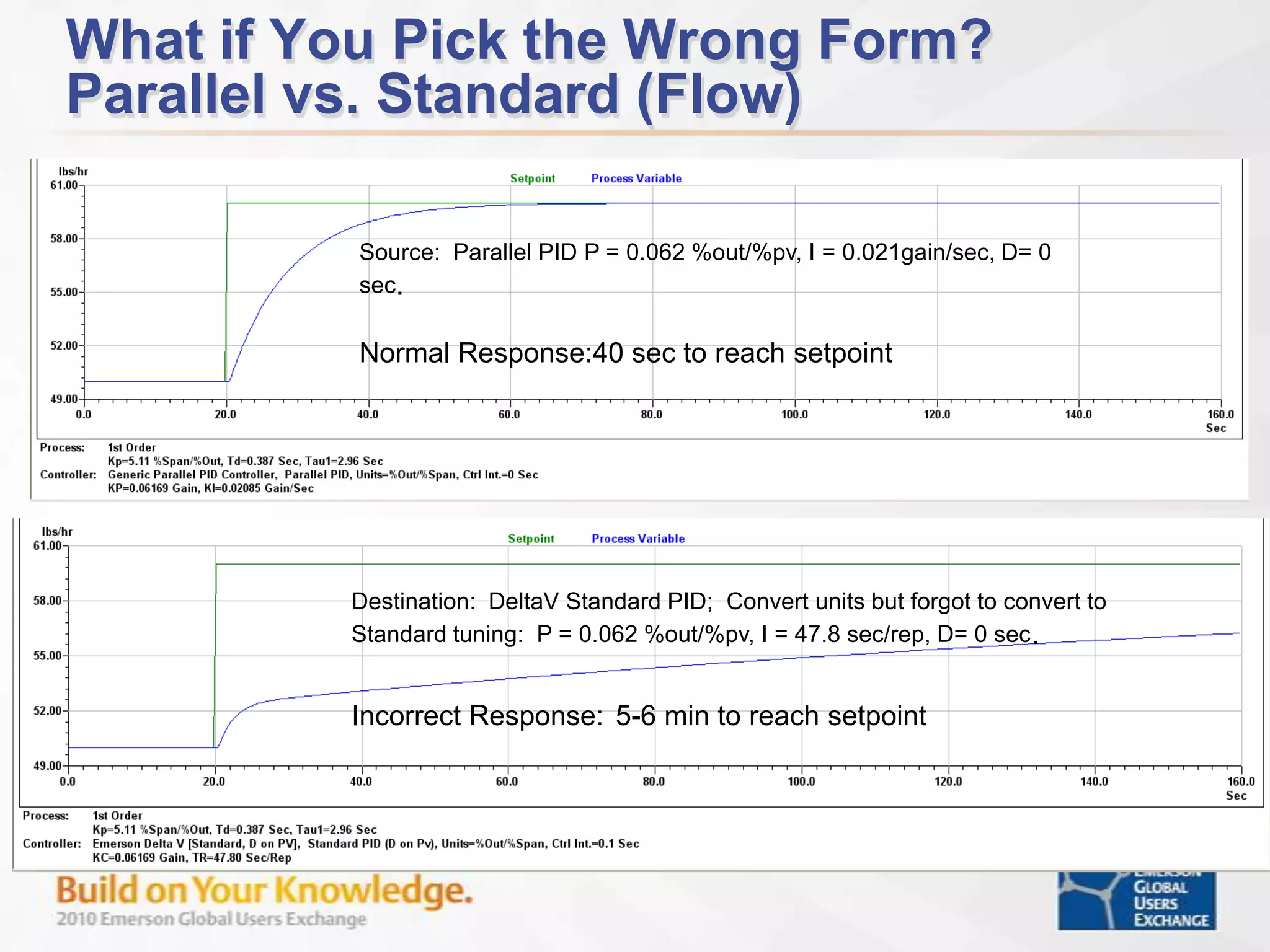

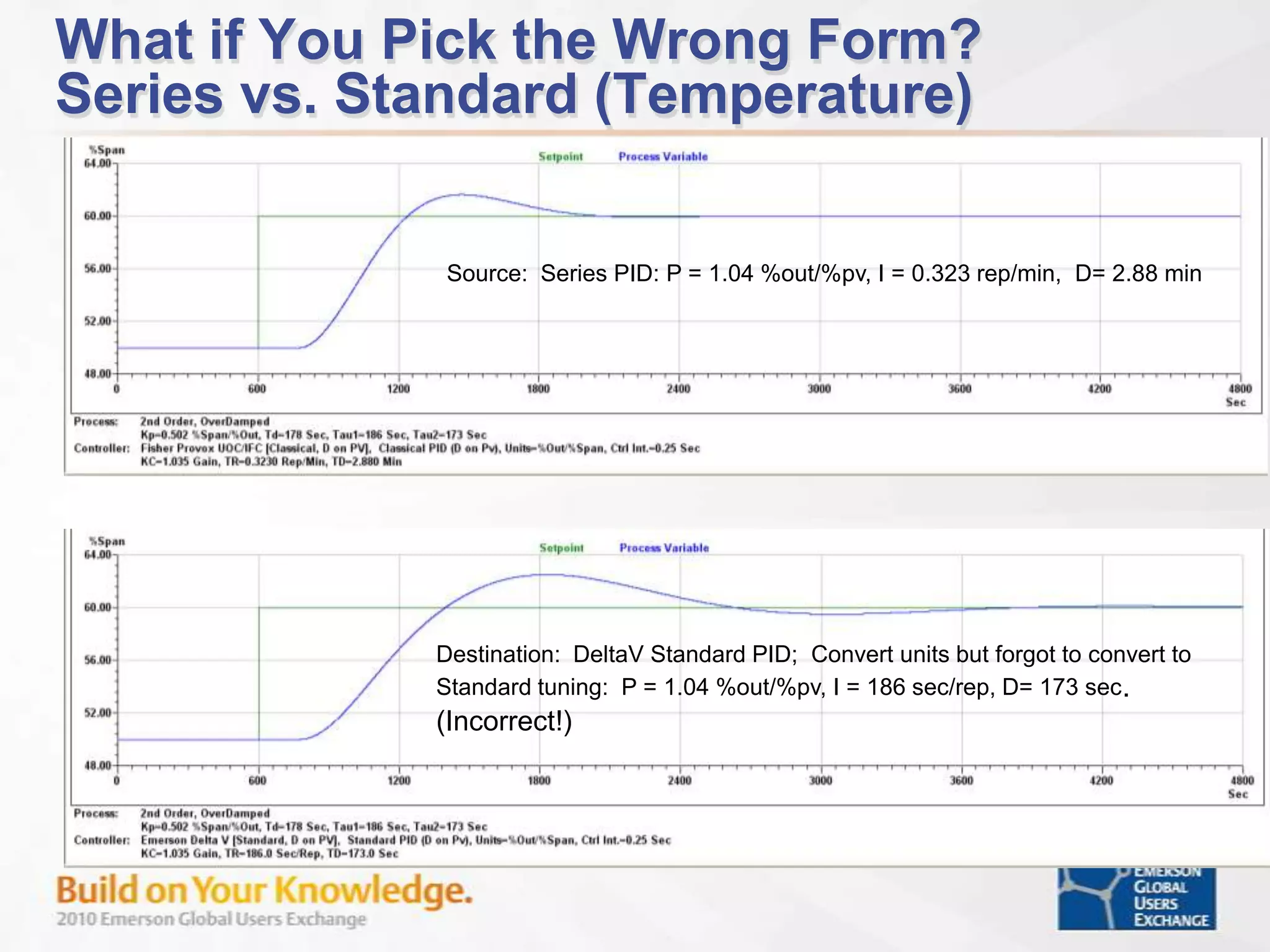

This document discusses lessons learned from modernization and migration projects. It emphasizes the importance of thorough planning to mitigate risks. Key risks include control issues after cutover and schedule delays. To reduce risks, the document recommends early engineering, scope definition, legacy system data mining, and thorough testing. It also stresses experienced project leadership and independent analysis to optimize costs and schedule. Proper conversion of tuning parameters between control systems is also highlighted to avoid unexpected control responses.