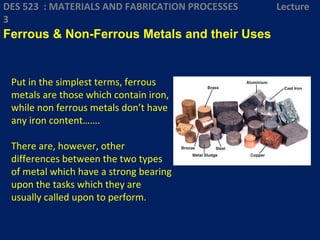

This document outlines the course structure and content for DES 523: Materials and Fabrication Processes. The course covers 6 units that examine materials like metals, ceramics, glass and plastics as well as manufacturing processes. Additional topics include joining techniques, automation, product design principles, sustainable manufacturing, and an overview of ferrous and non-ferrous metals and their common uses. Lectures provide details on concurrent engineering, design for manufacturing, principles for economic production, and product lifecycles.