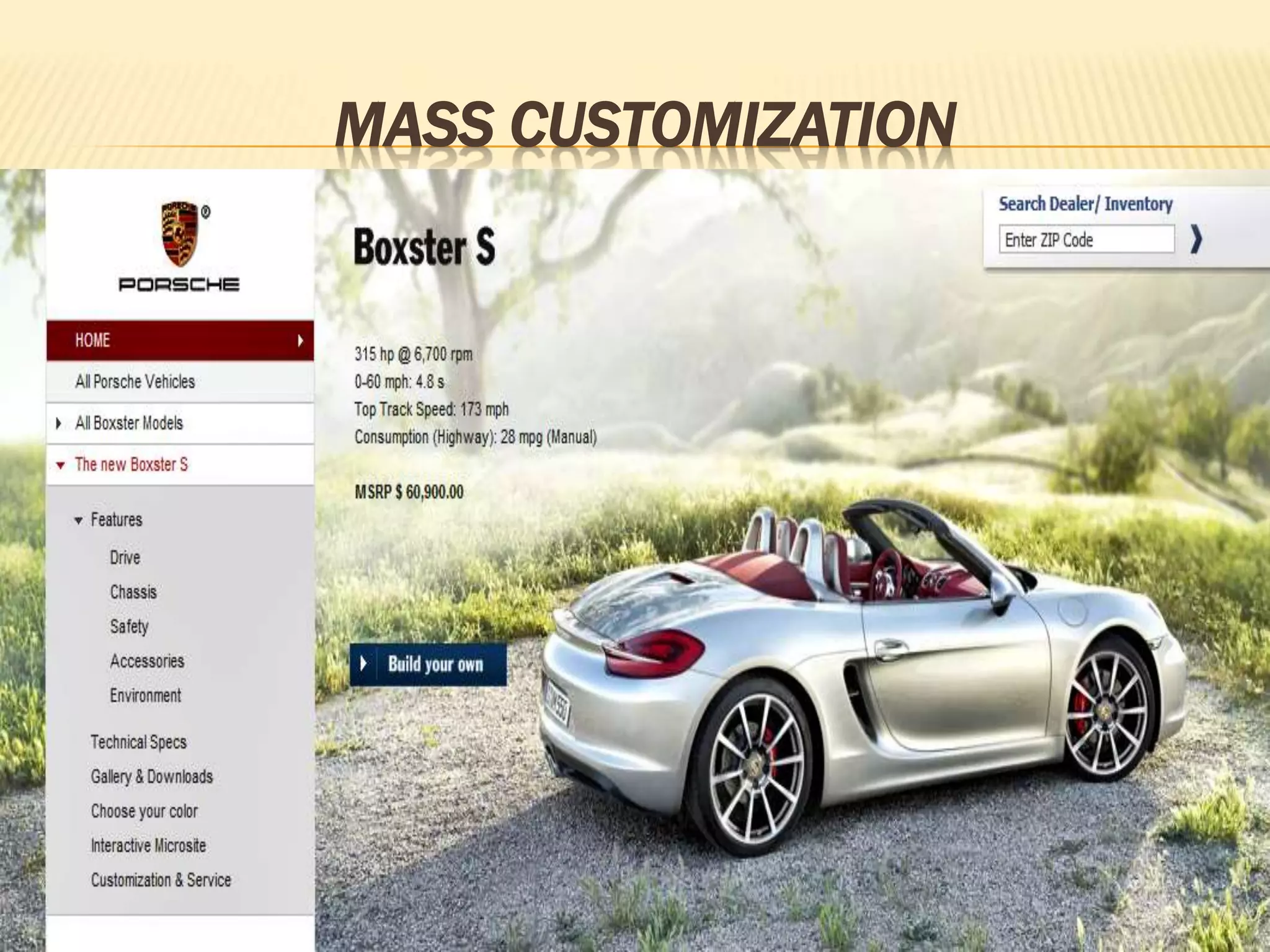

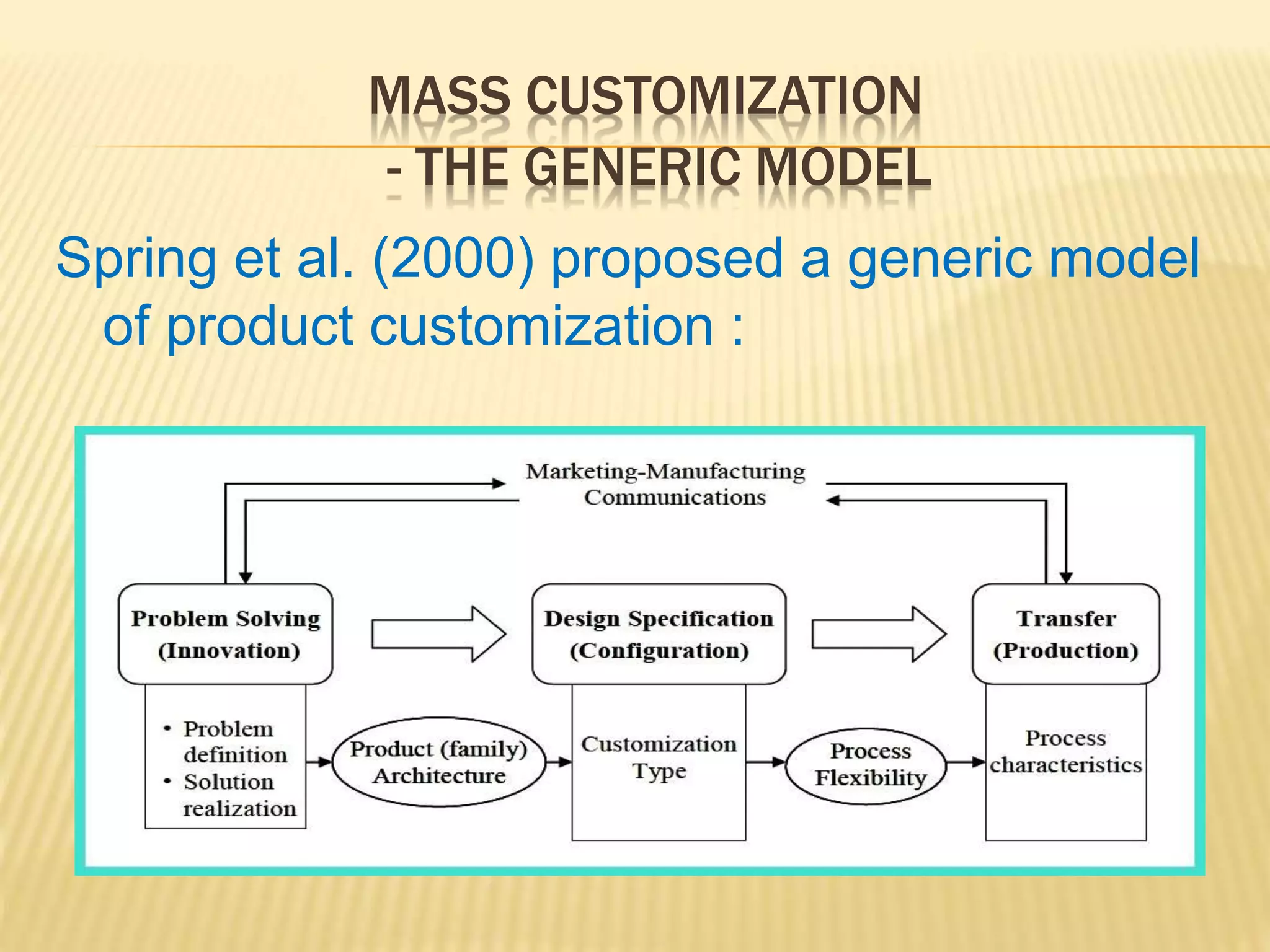

Mass customization aims to deliver customized products and services to individual customers at a cost near that of mass production. It uses information technology, flexible processes and organizational structures. There are four types of mass customization: collaborative, adaptive, transparent and cosmetic. Mass customization provides advantages like maximized customer satisfaction, reduced costs and inventory, increased cash flow and responsiveness to customer needs.