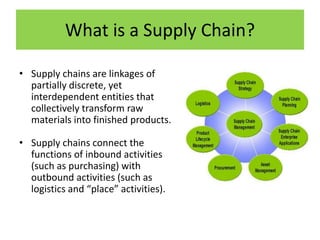

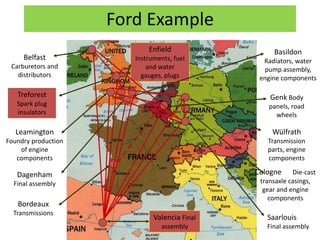

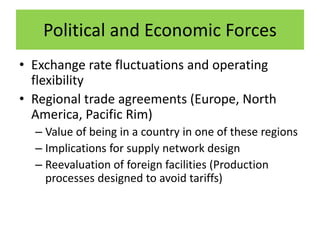

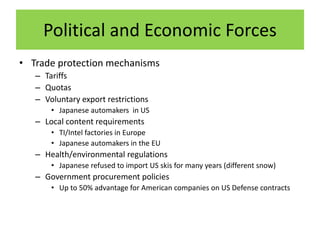

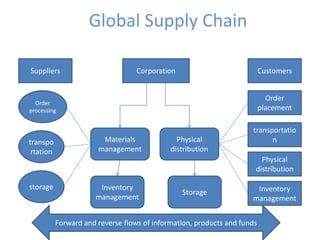

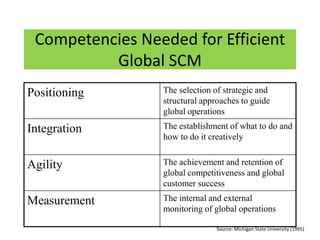

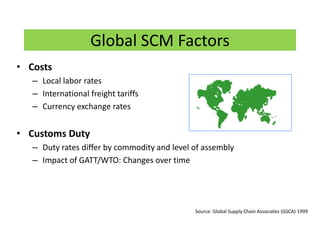

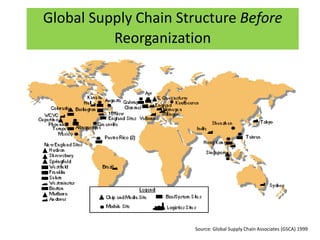

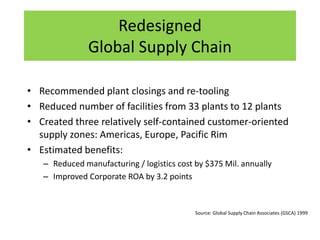

Global supply chain management involves coordinating activities across countries. A global supply chain connects organizations worldwide to source materials and produce goods for customers. Managing such a complex network introduces challenges like long distances, currency fluctuations, and differing business environments. However, companies also benefit from expanded markets, lower costs, and competitive advantages. To operate efficiently, firms must integrate worldwide operations and have the agility to respond to various global factors. For example, a large computer company redesigned its supply chain from 33 plants across many countries to 12 plants within 3 regional zones, reducing costs and improving profits.