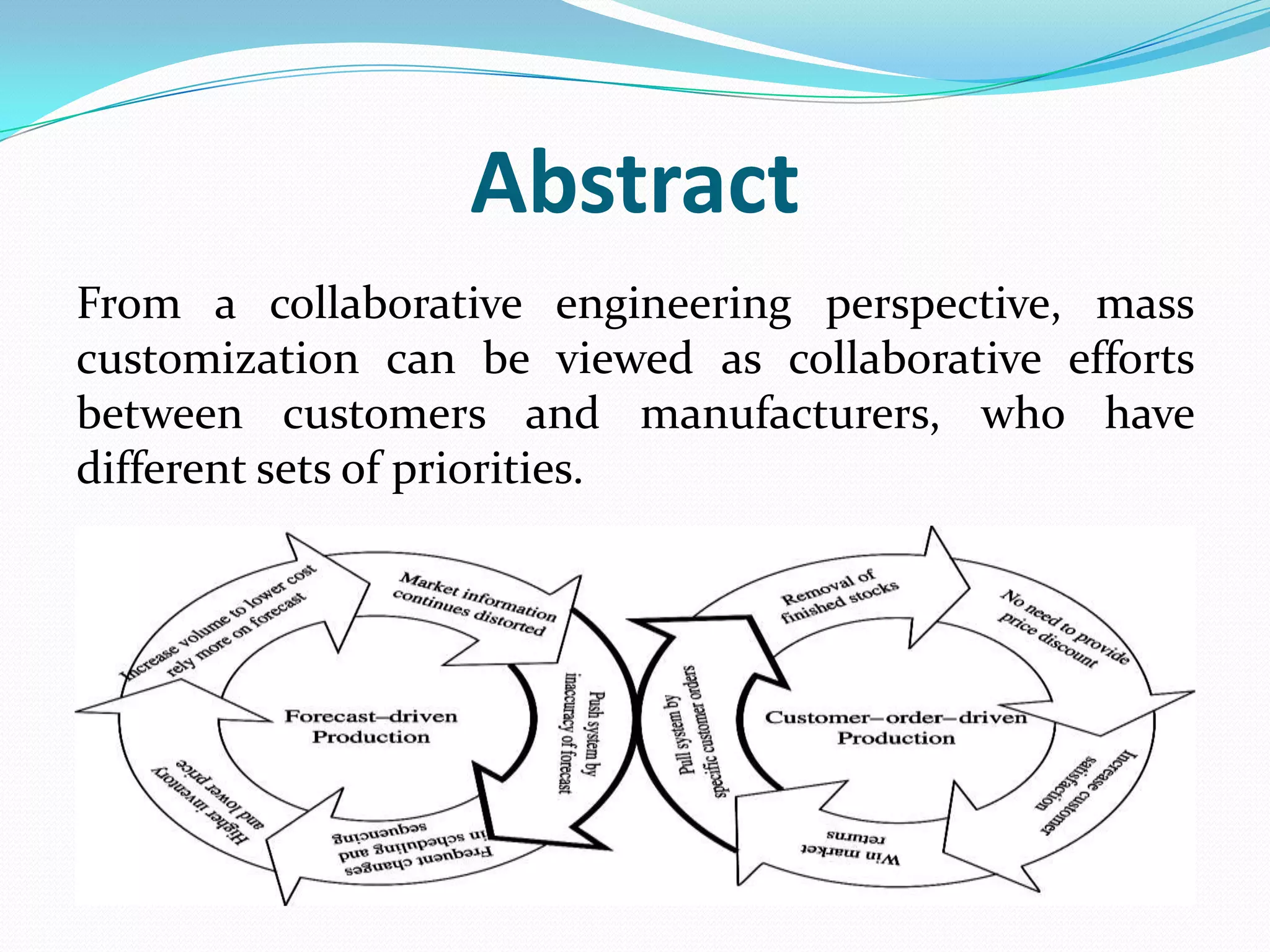

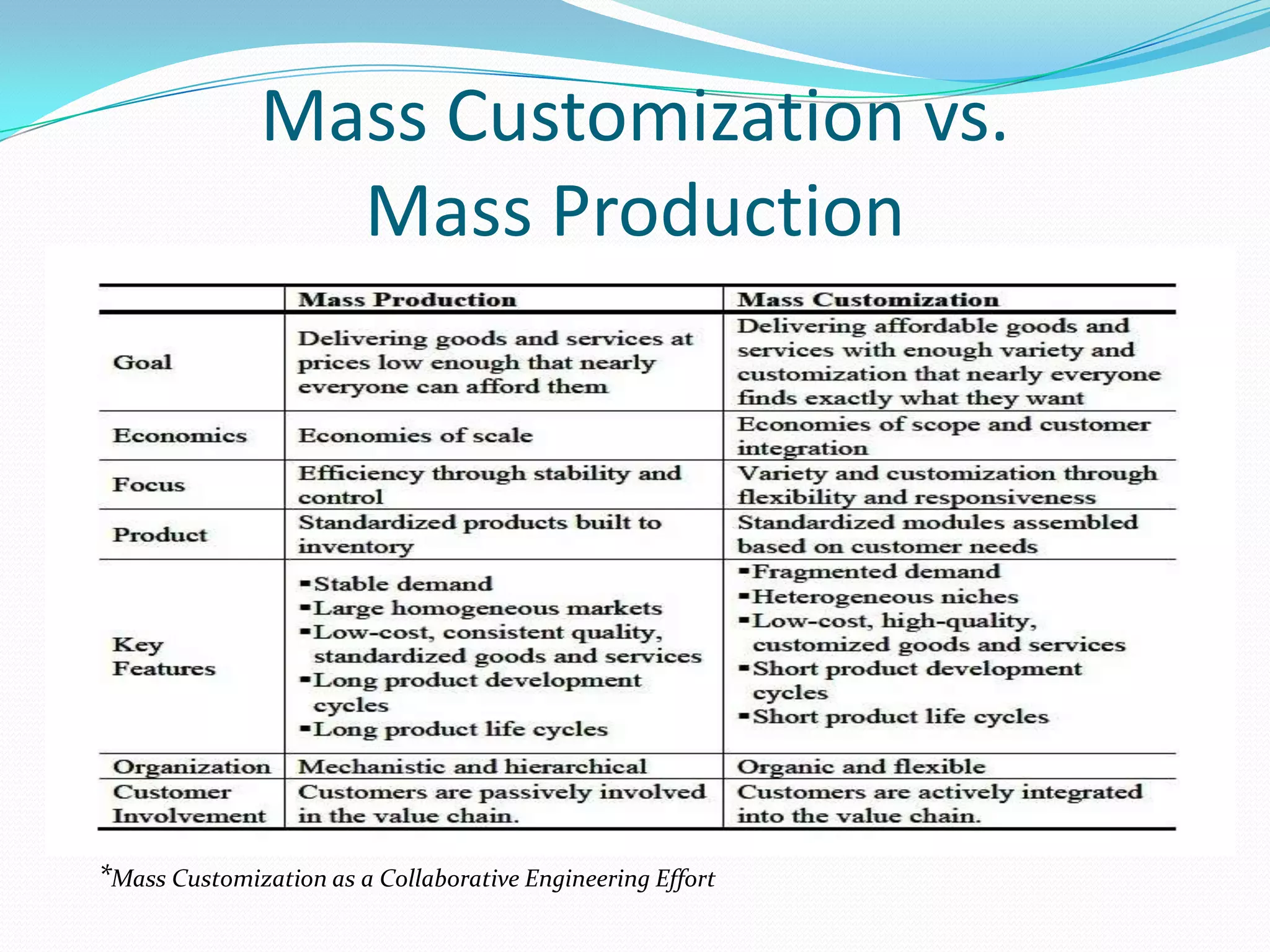

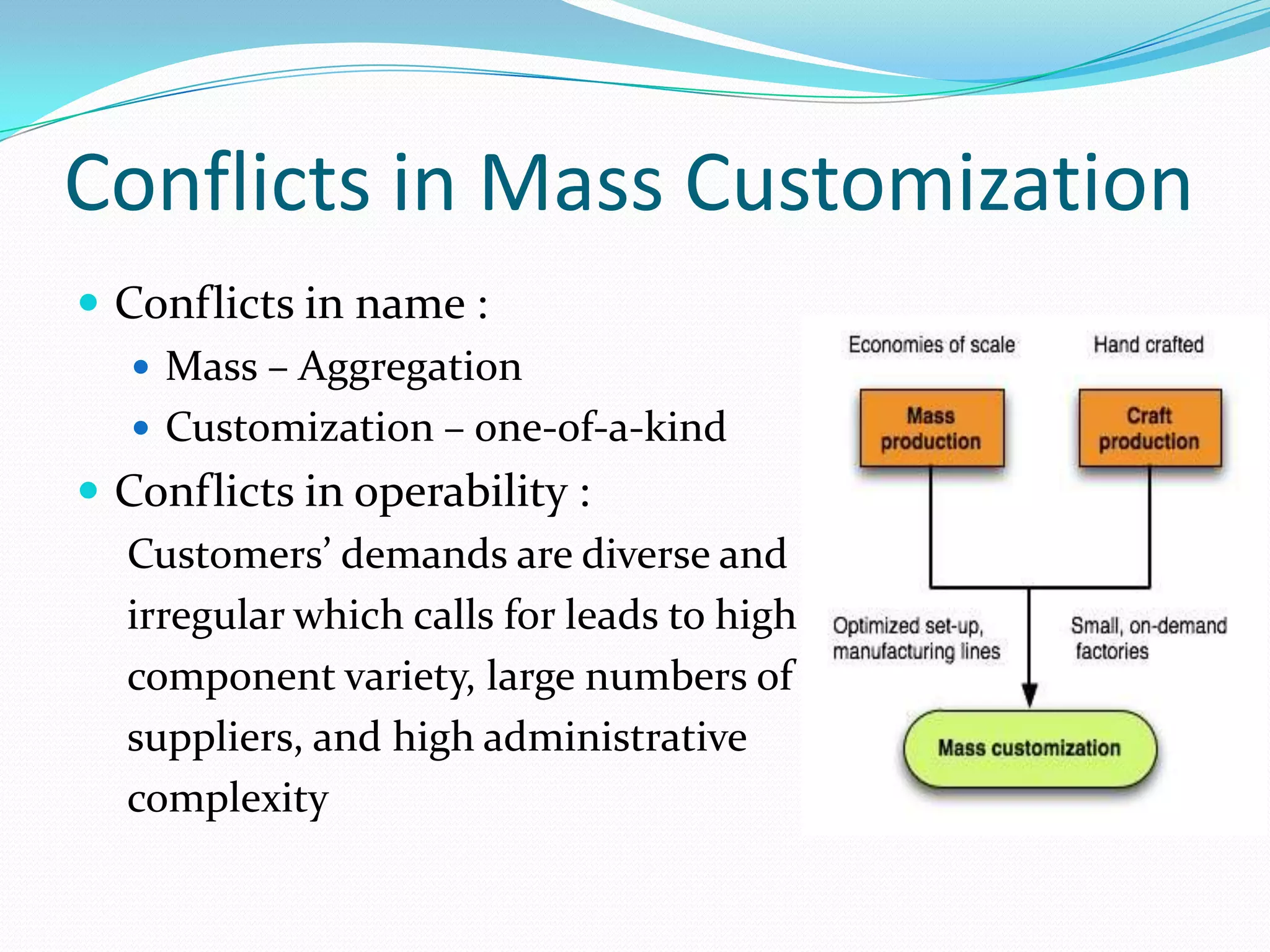

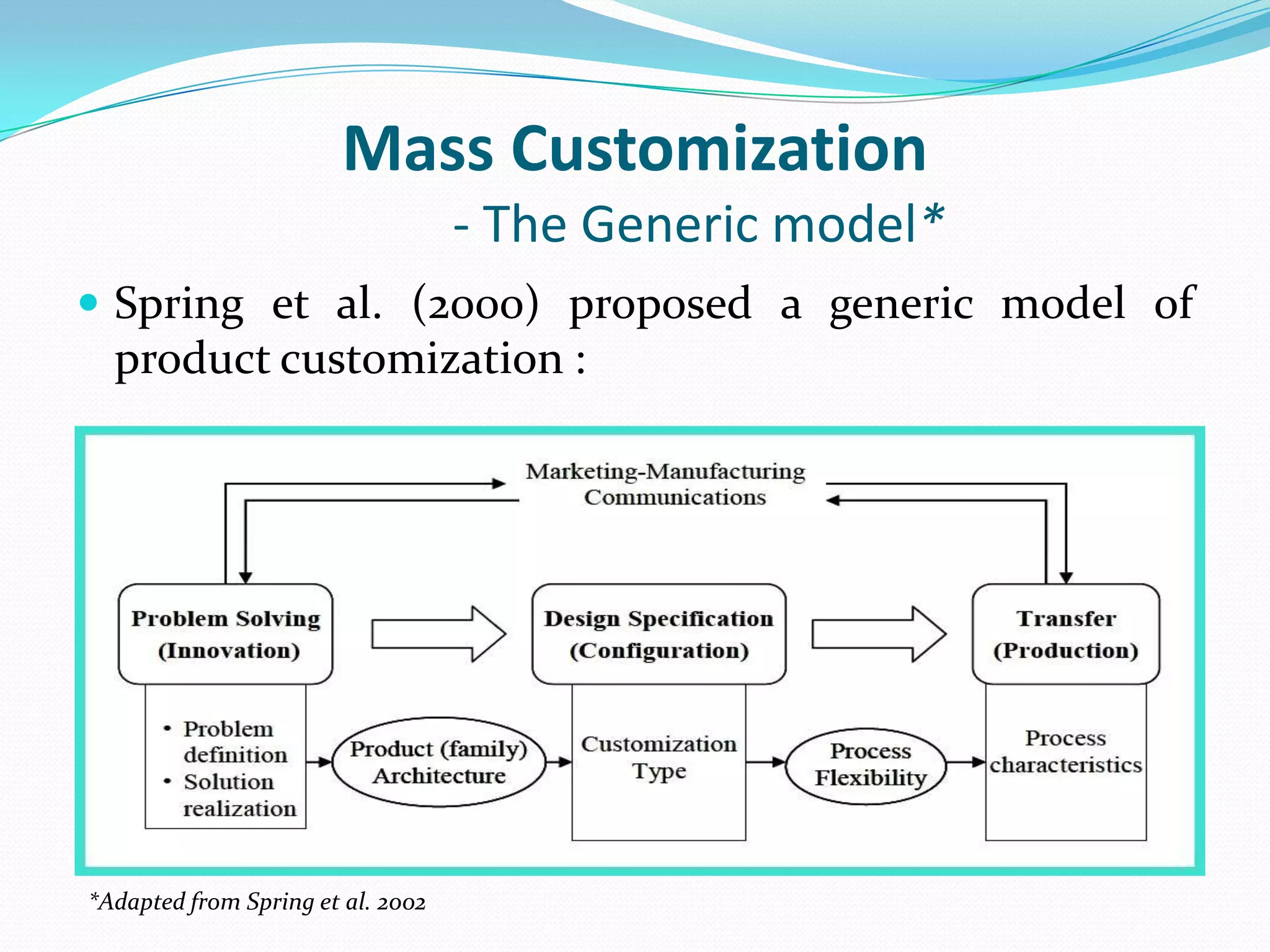

Mass customization aims to deliver customized products and services to customers at near mass production efficiency. It represents a collaborative effort between customers and manufacturers with different priorities. While research has focused on mass customization's strategic viability and operational feasibility, engineering collaboration promises to address challenges limiting many mass customization programs. Collaborative engineering views mass customization as customers and manufacturers engaging in joint conflict resolution to co-create customized products.