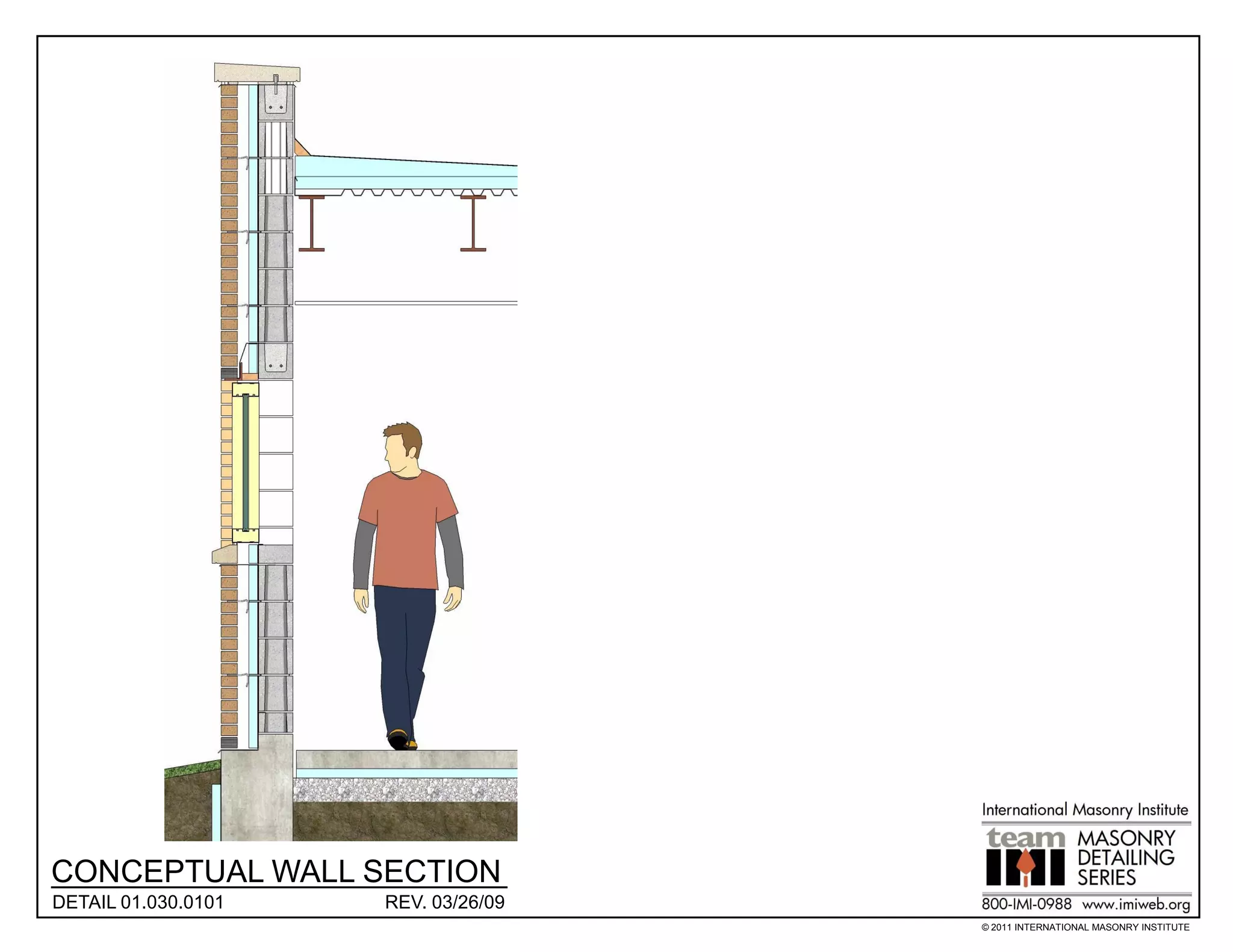

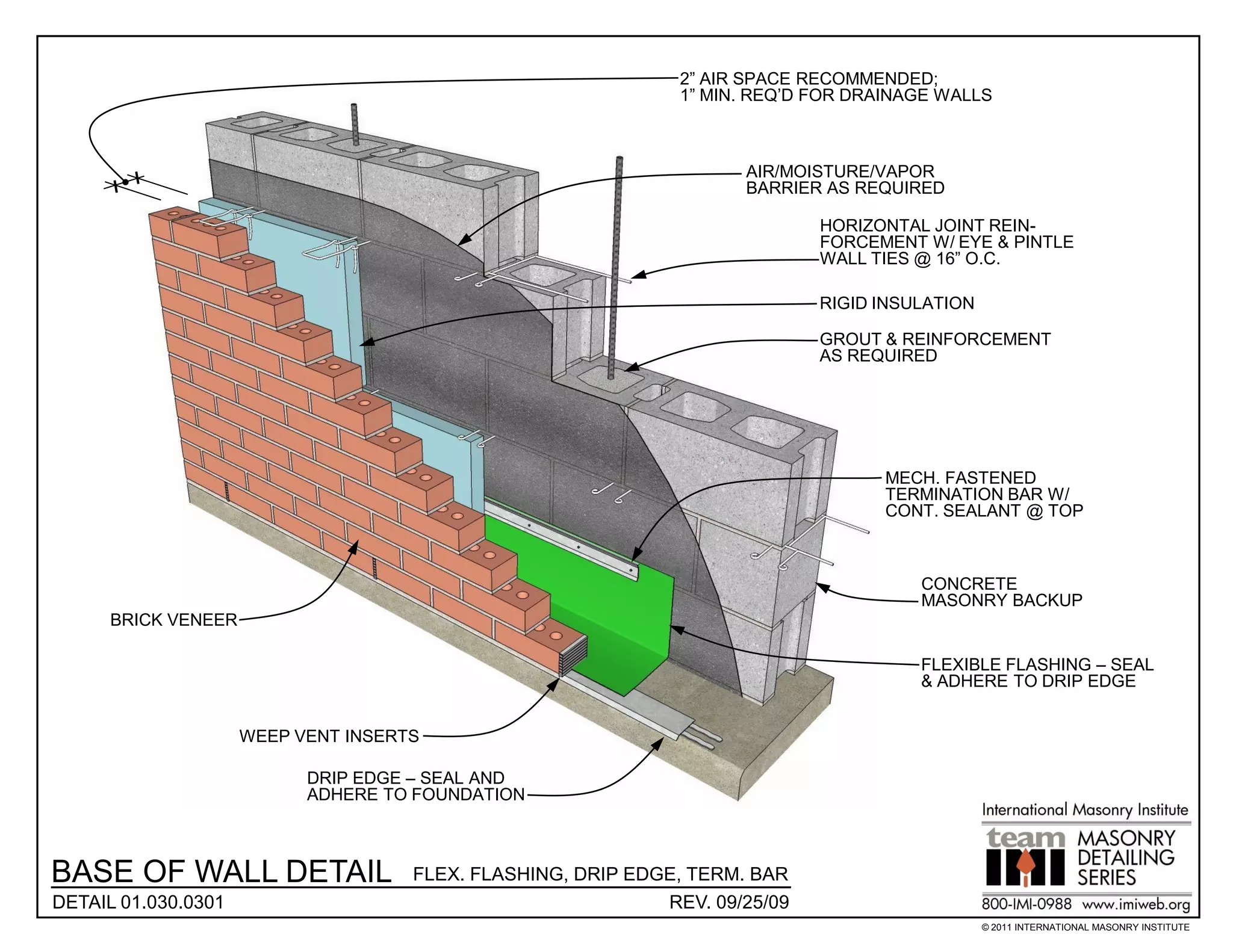

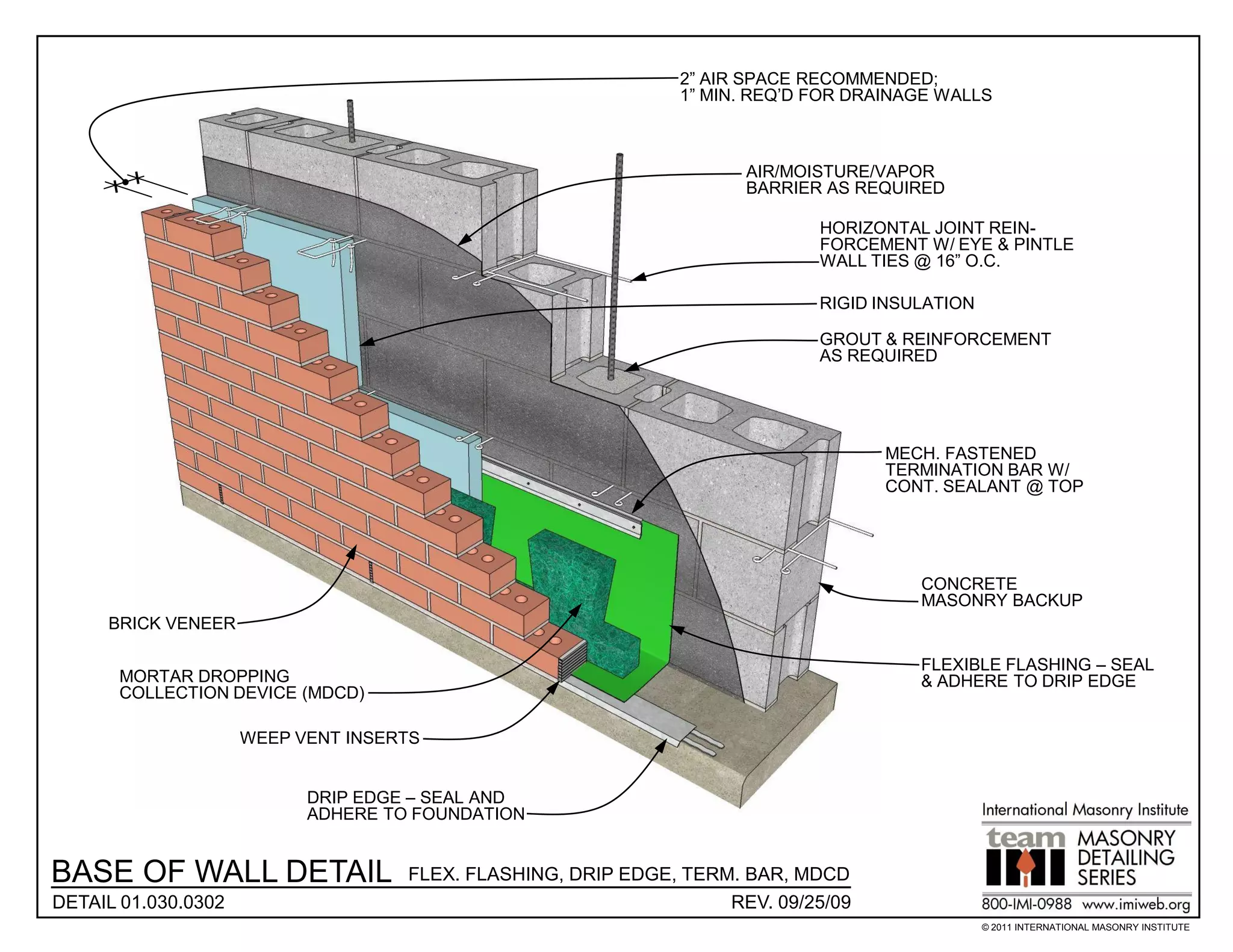

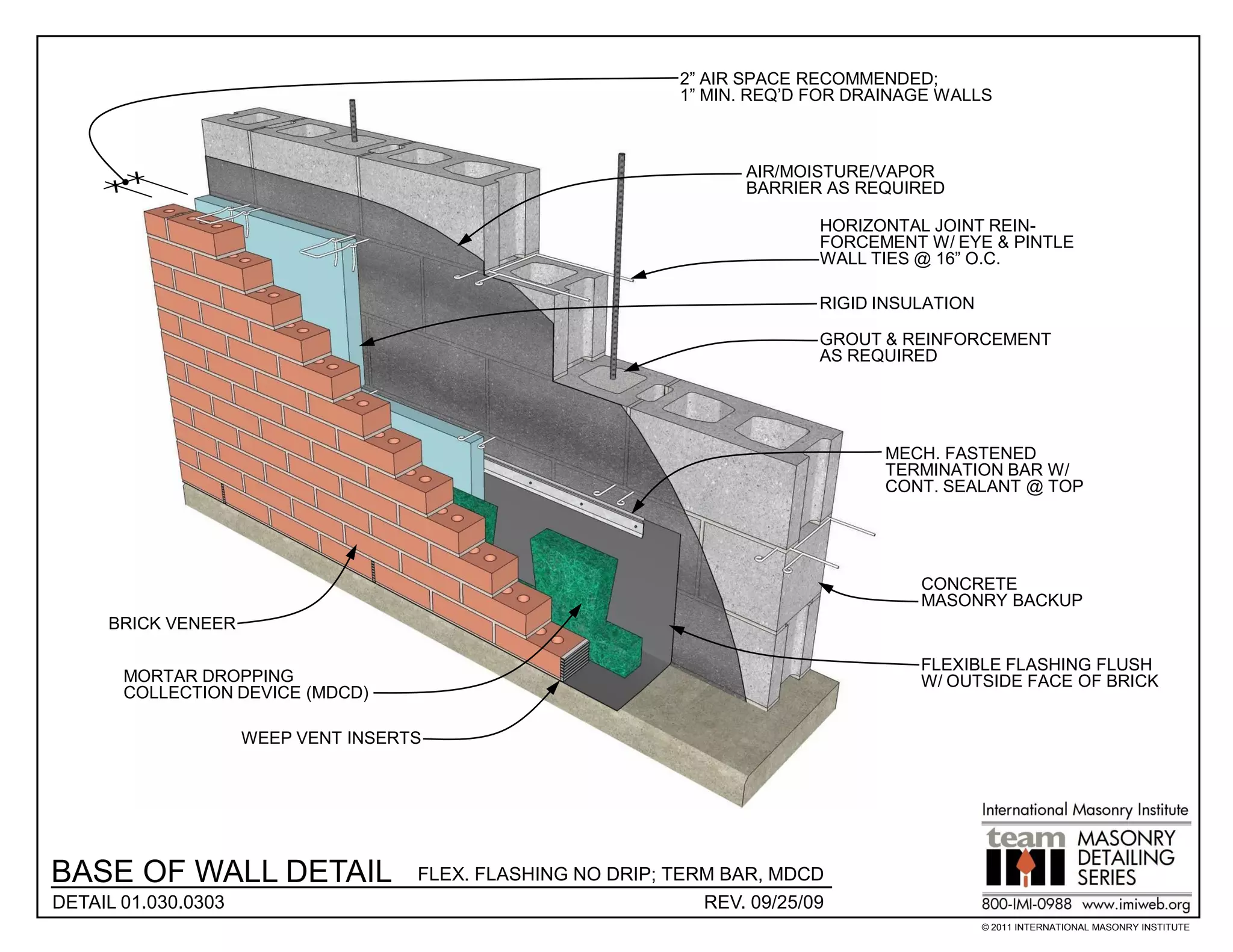

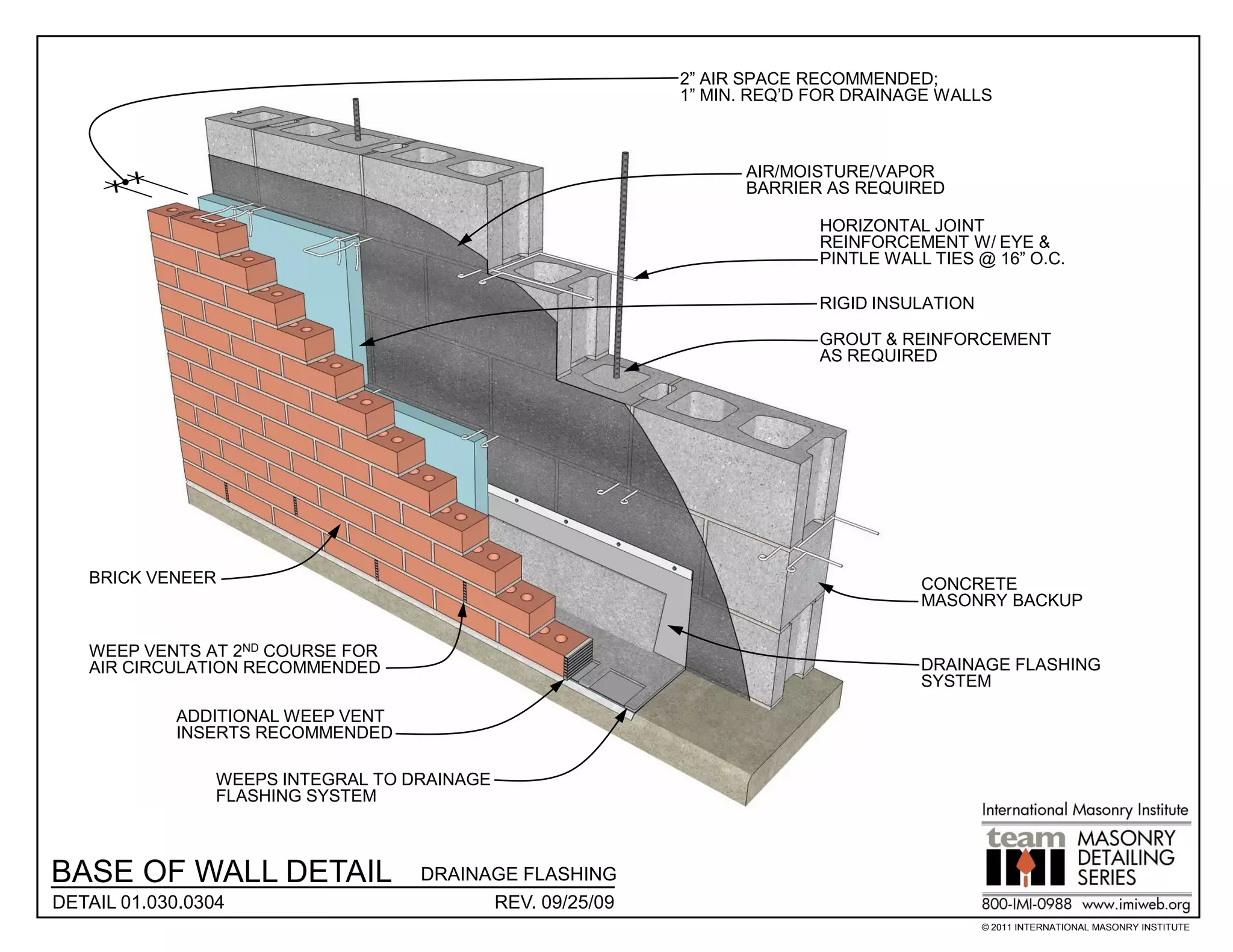

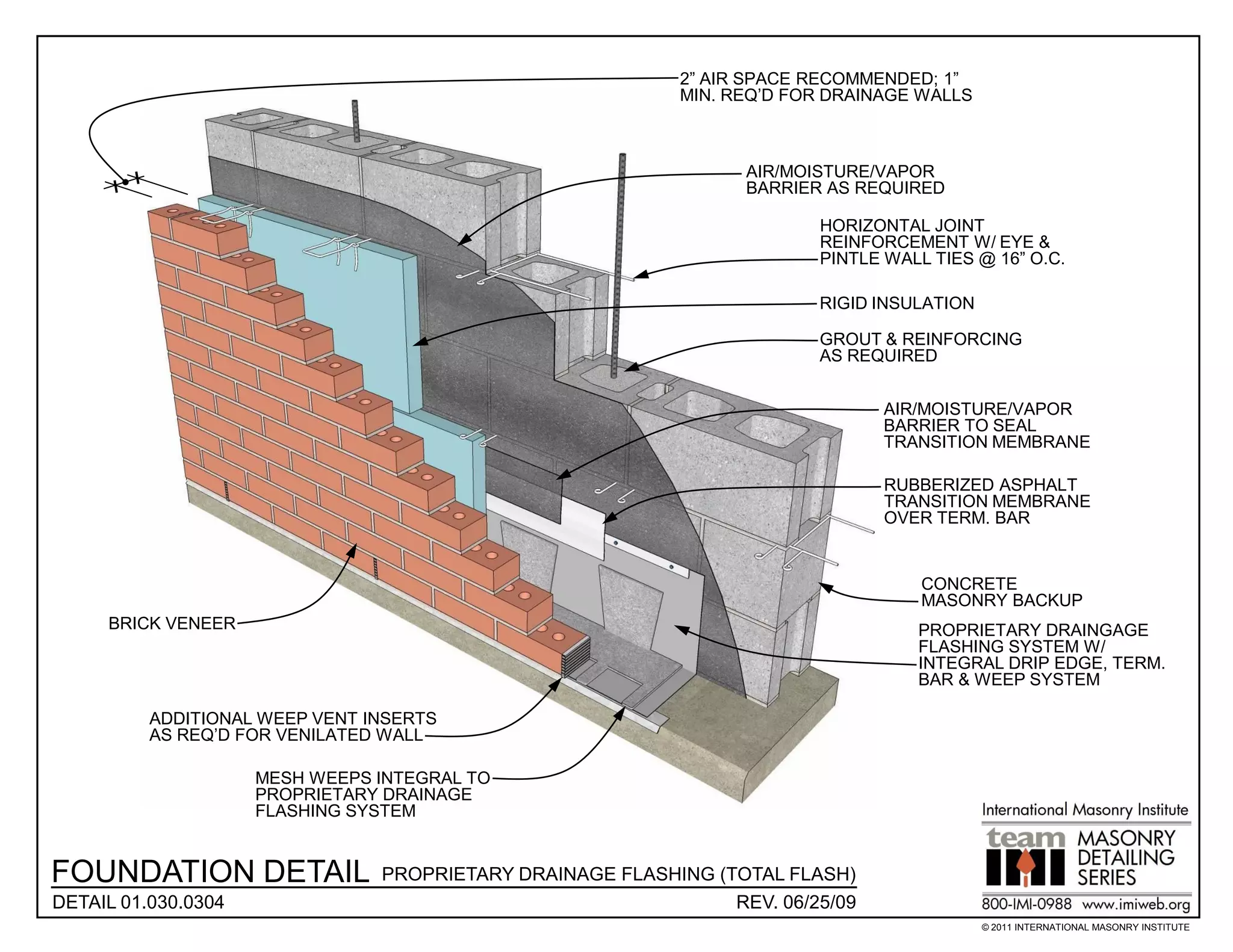

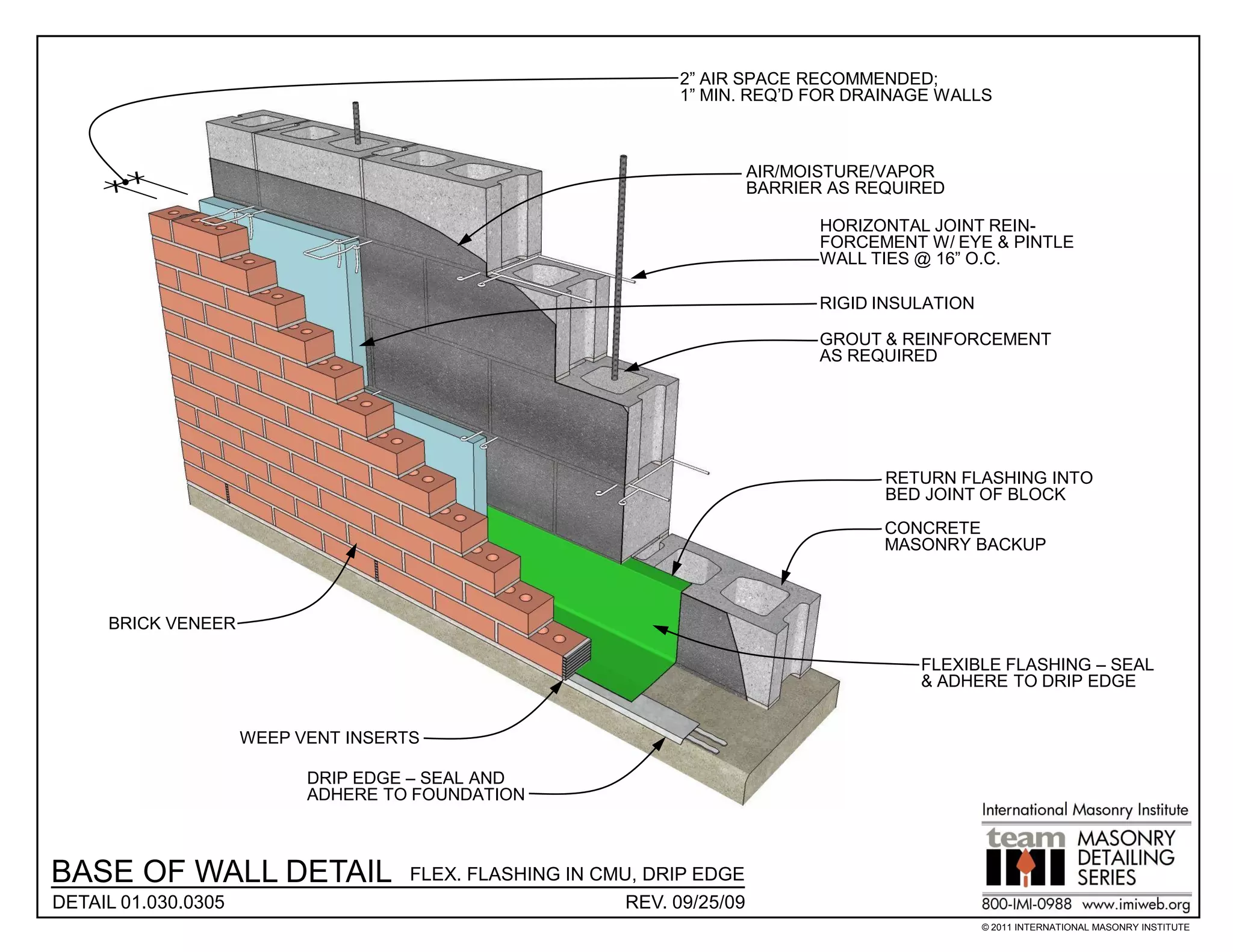

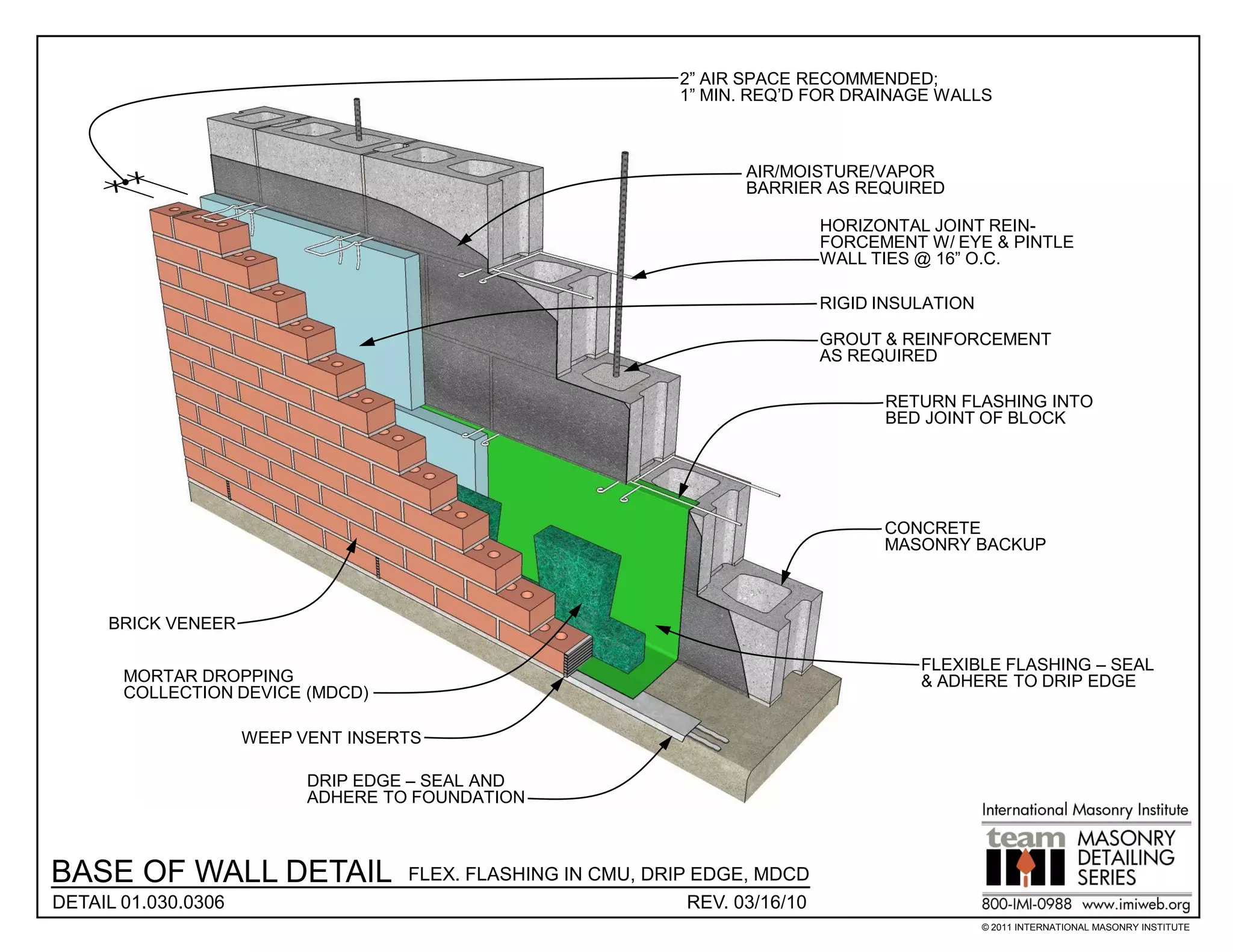

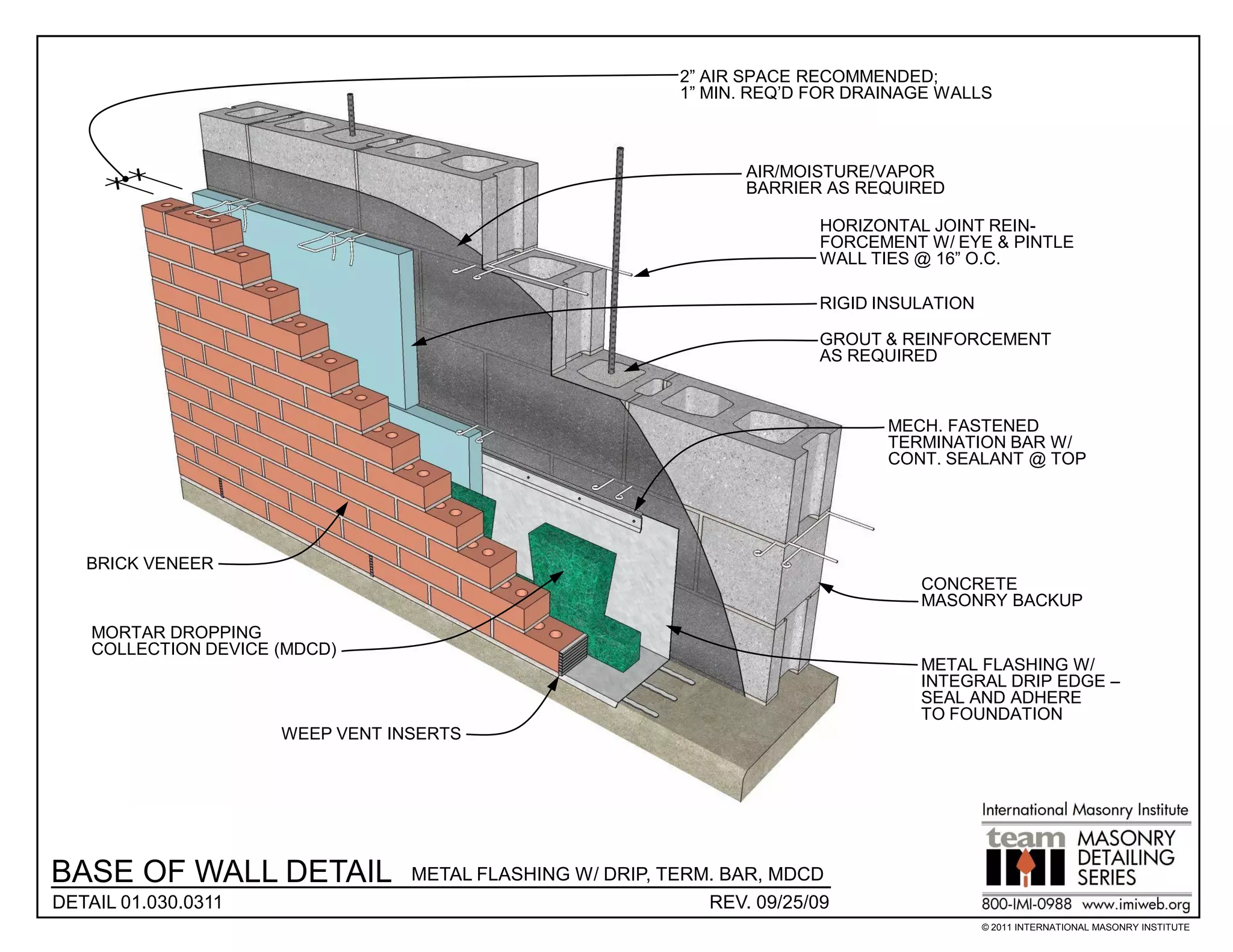

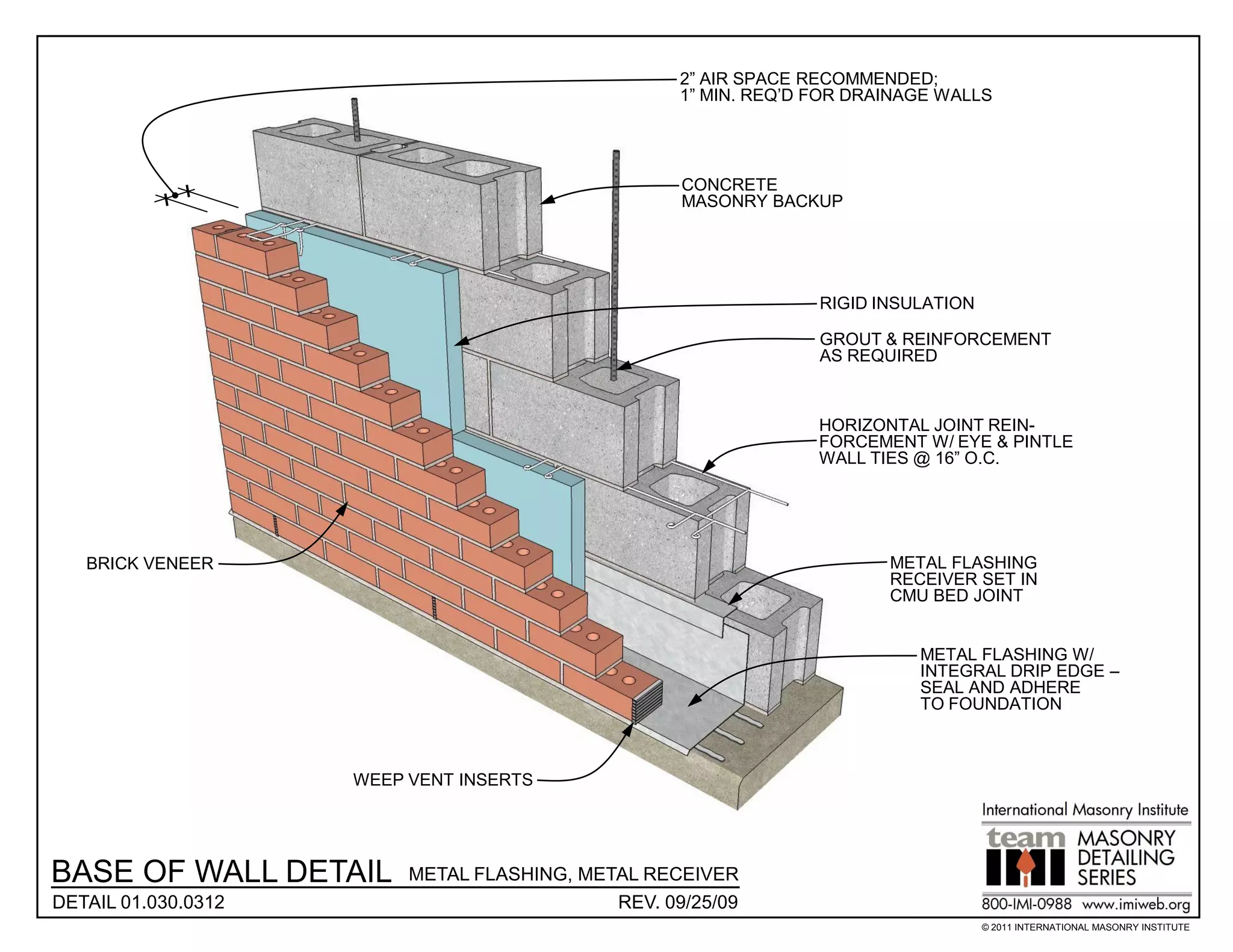

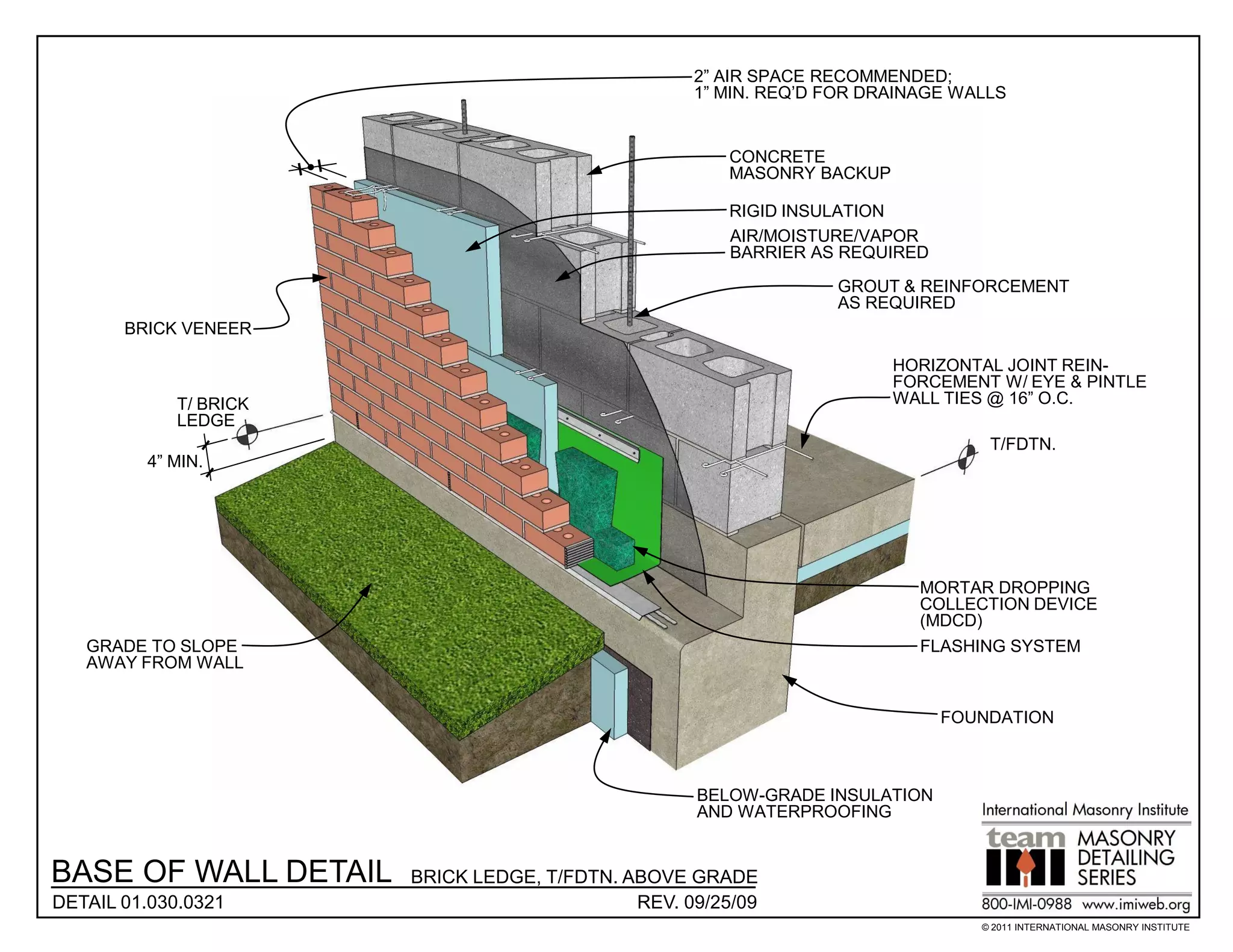

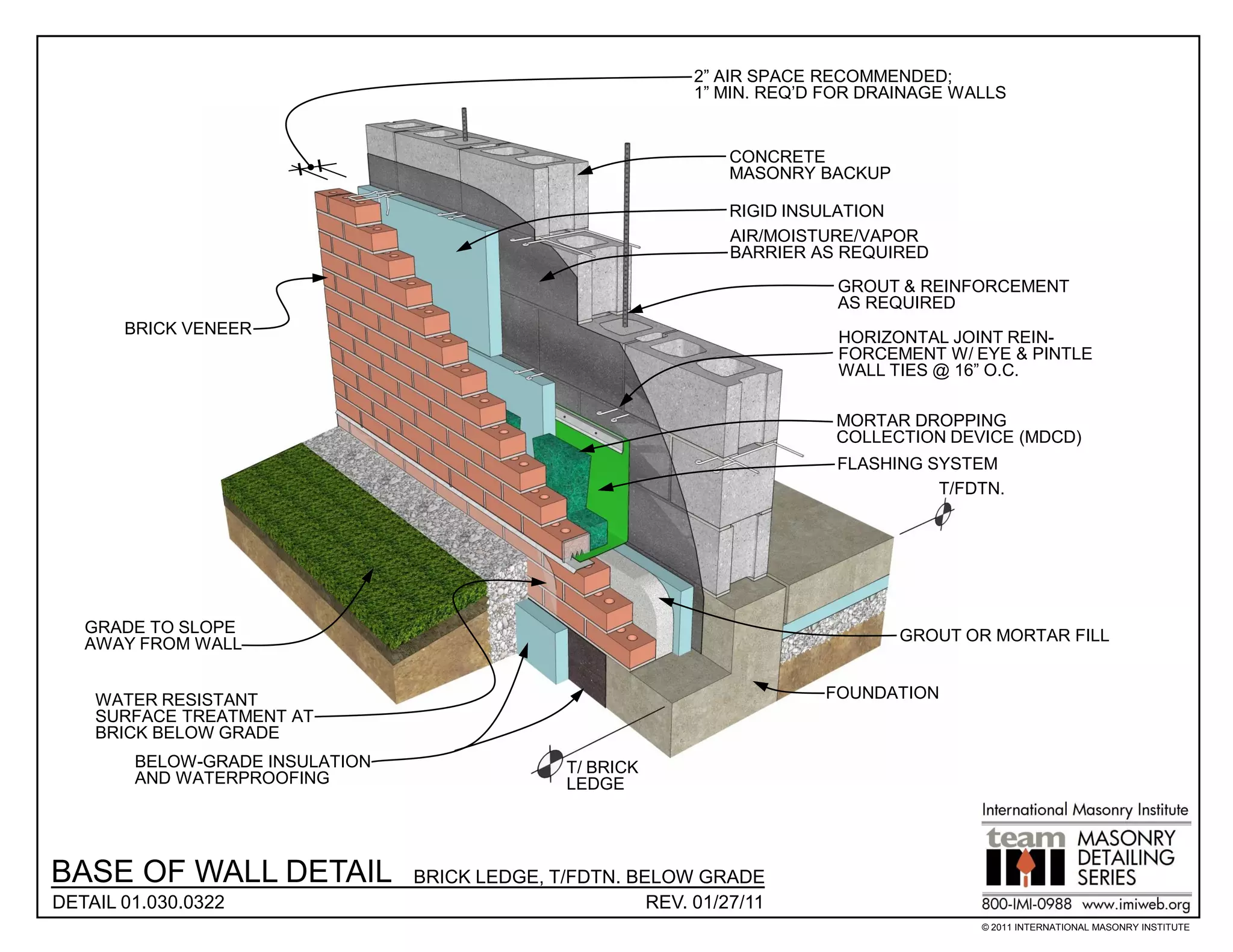

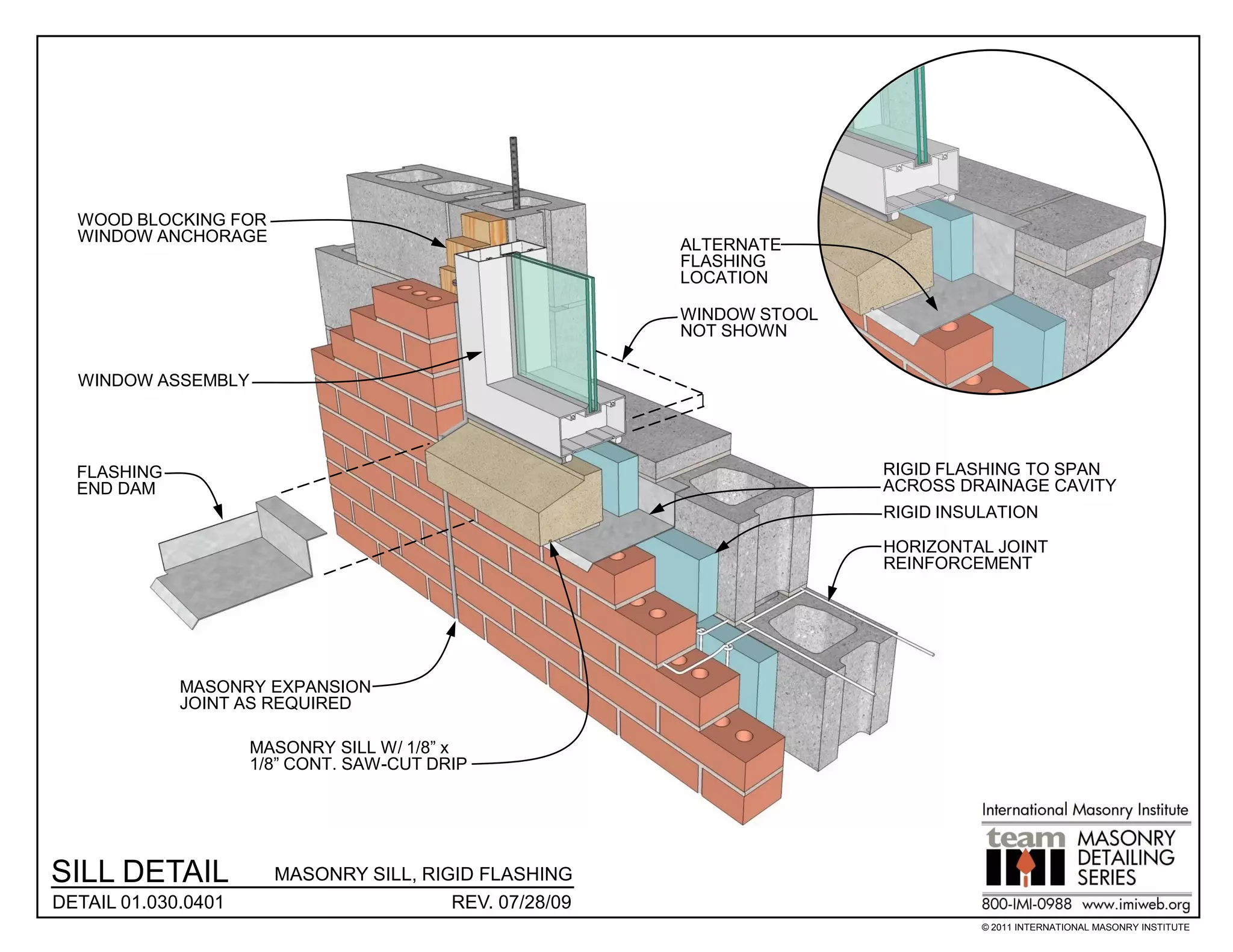

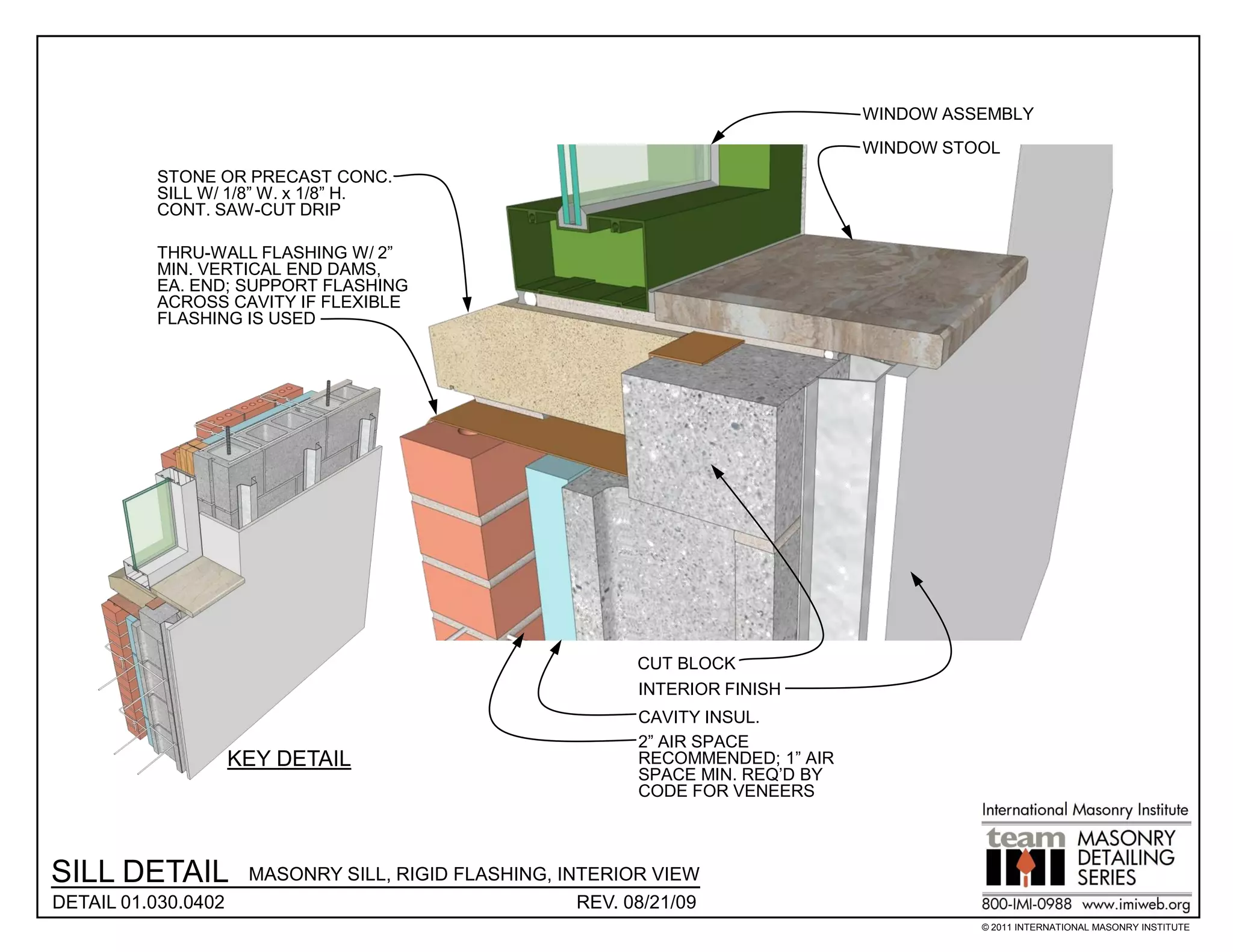

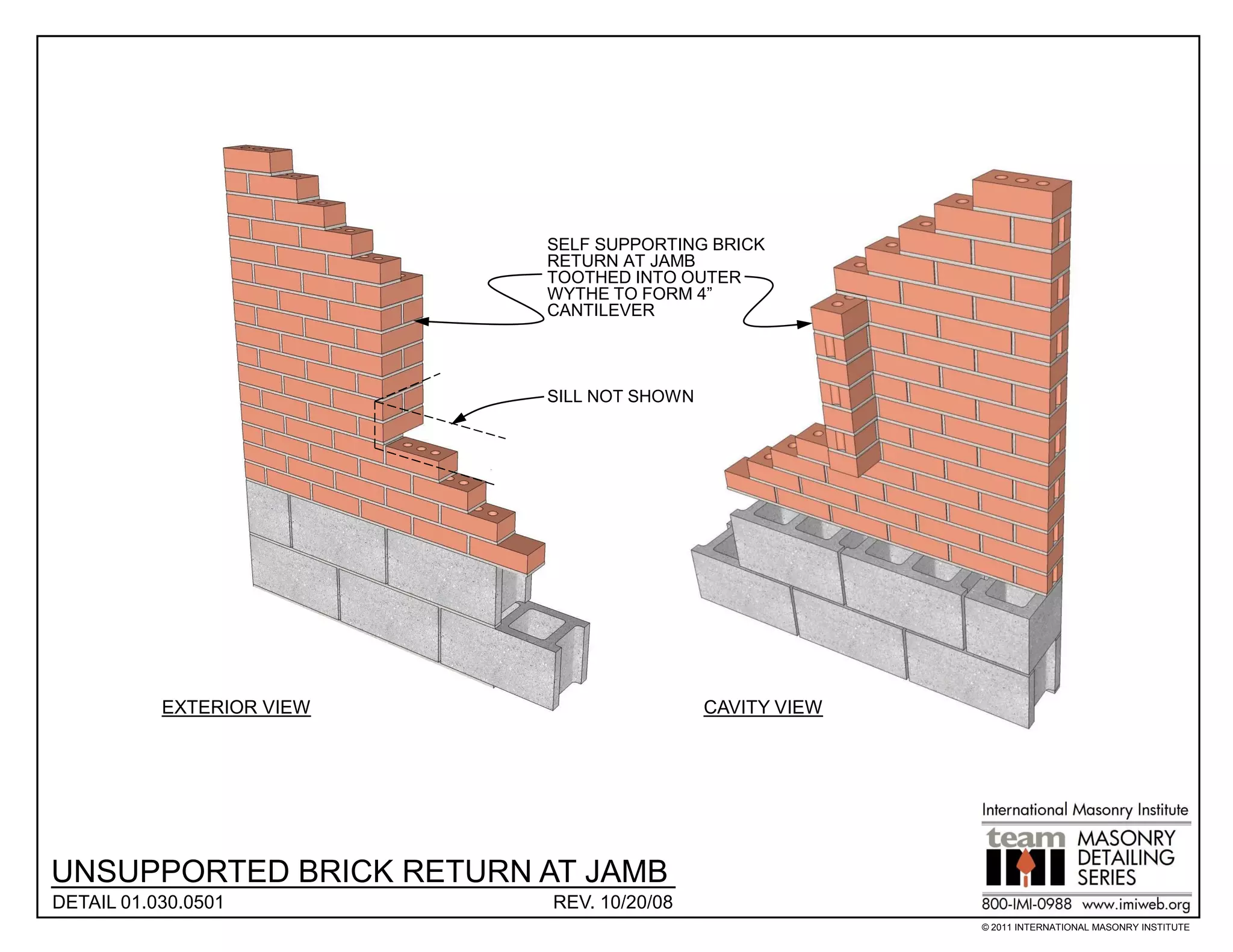

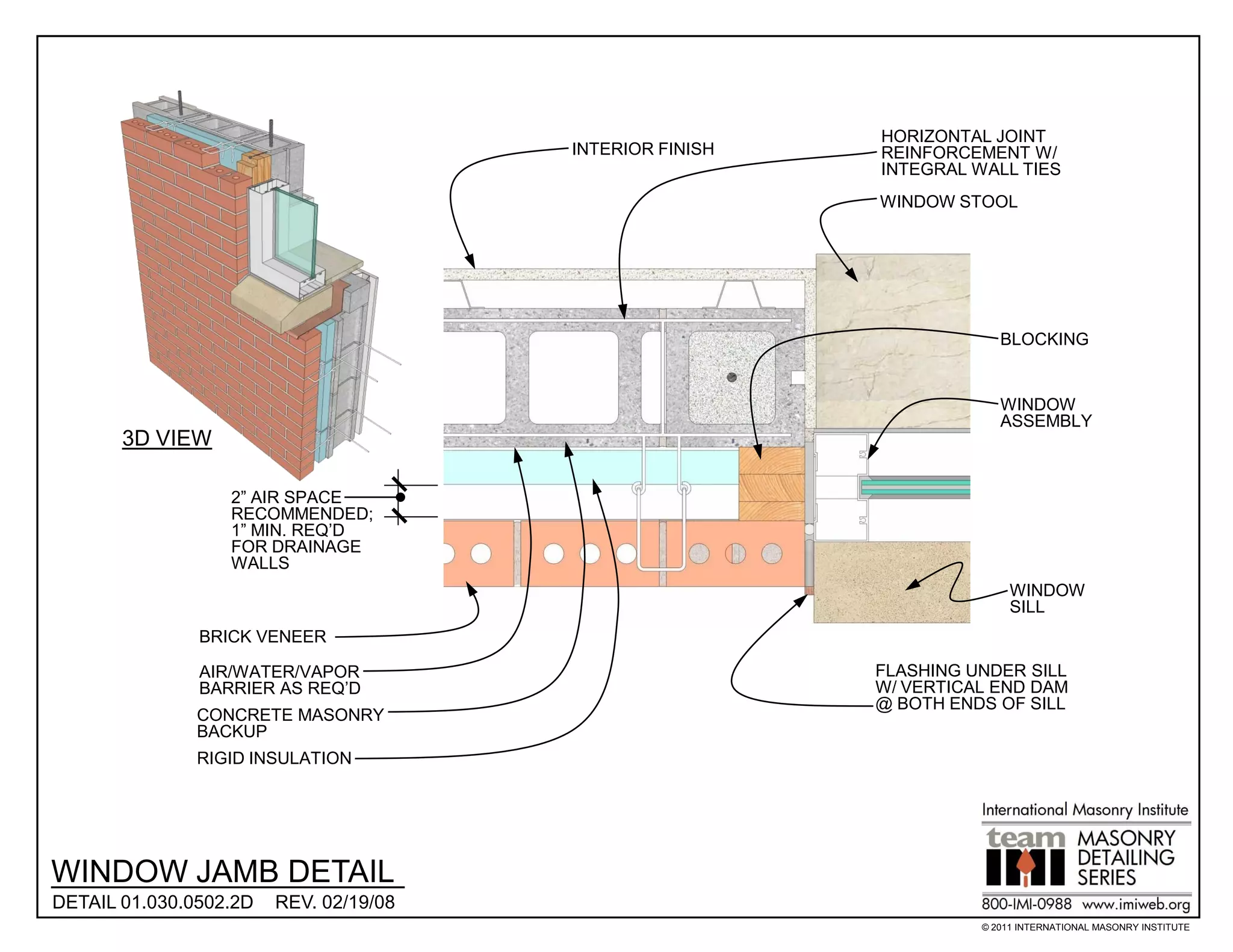

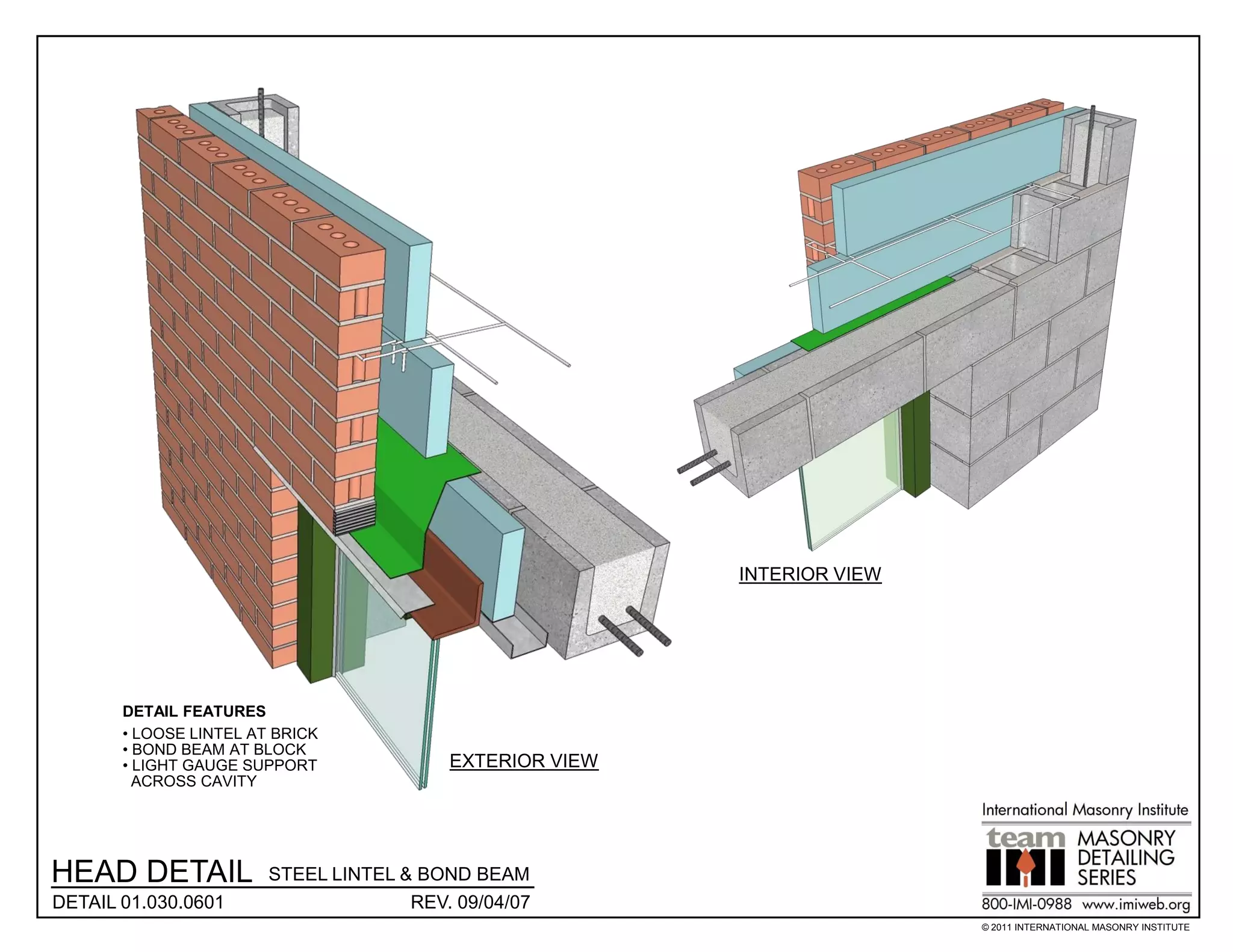

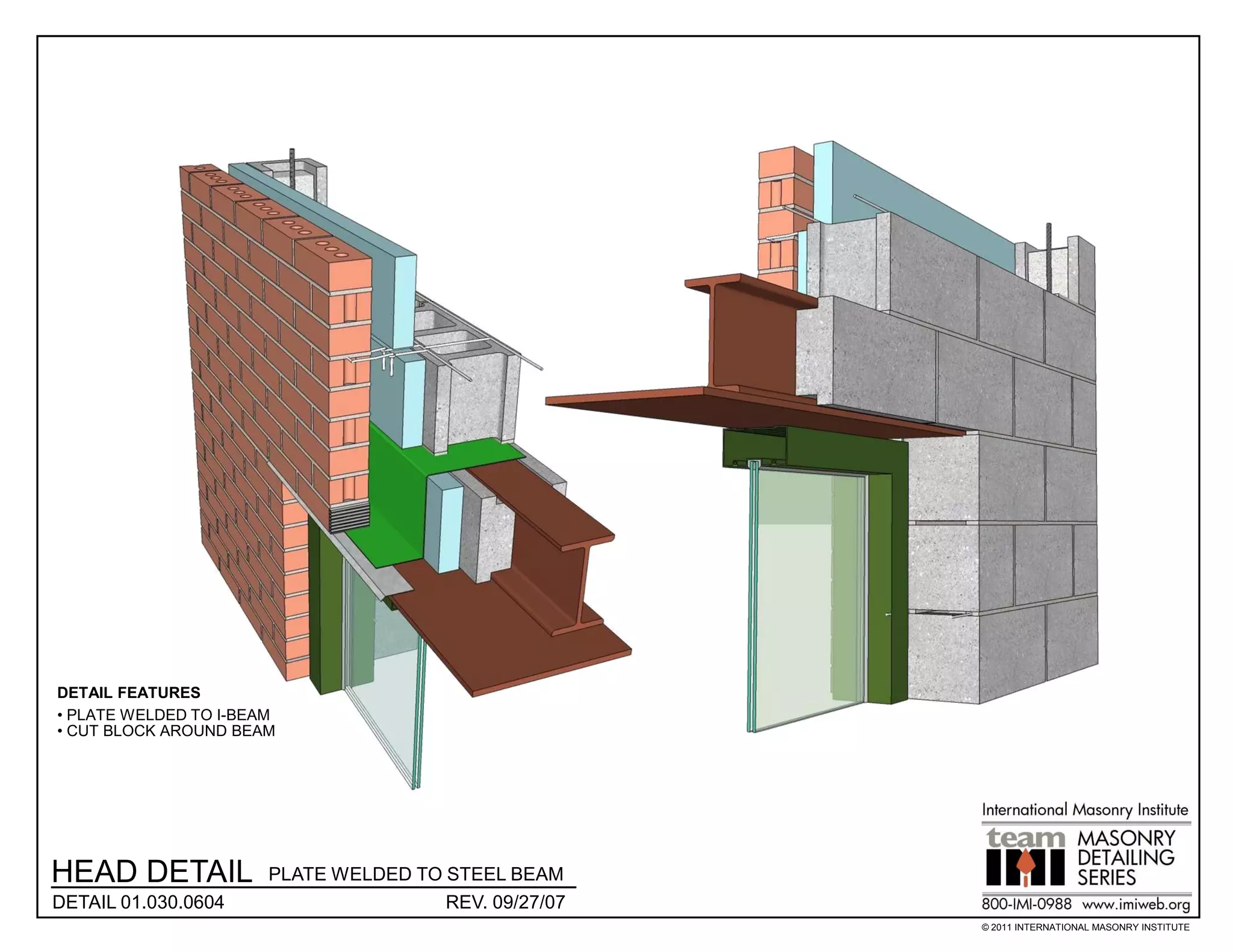

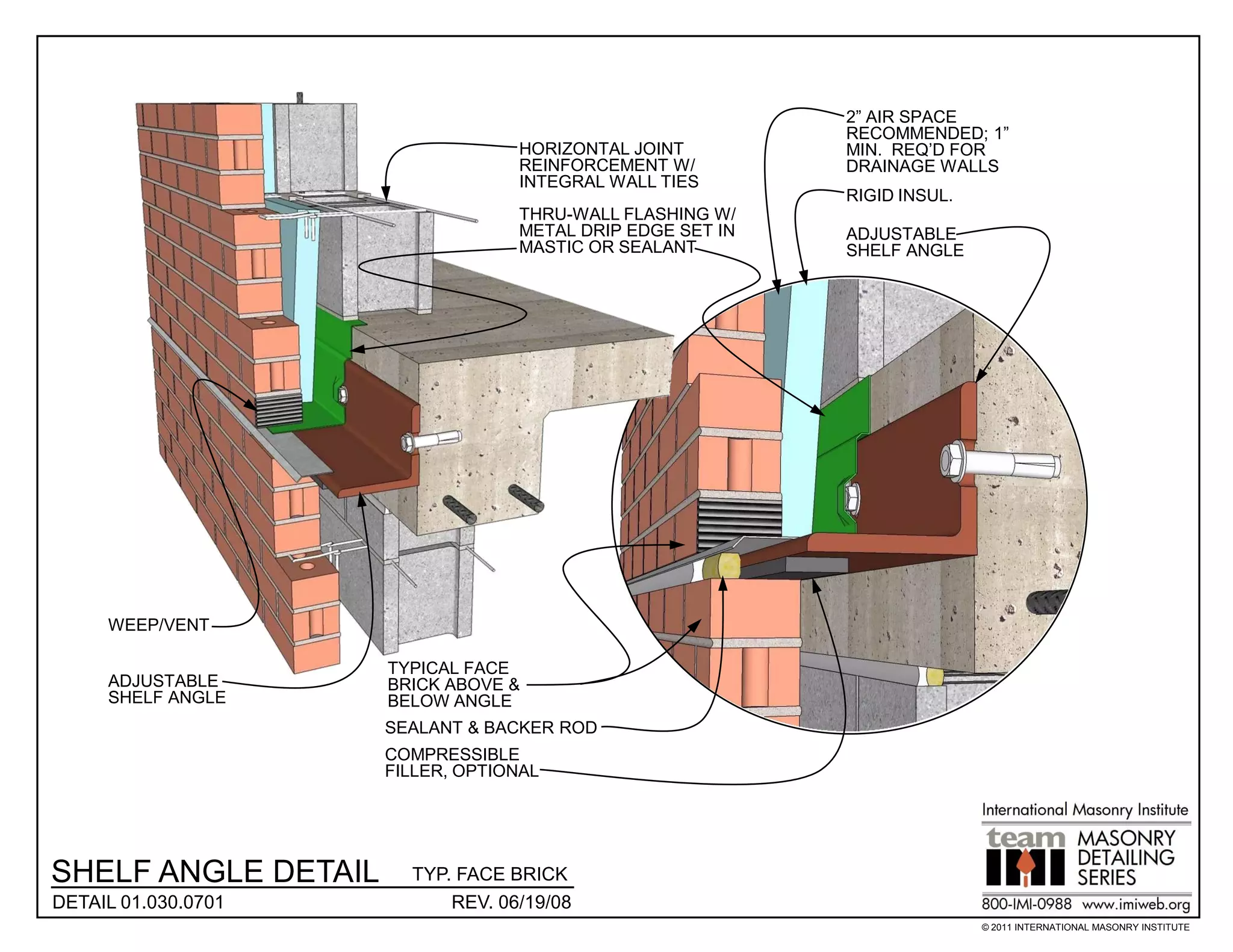

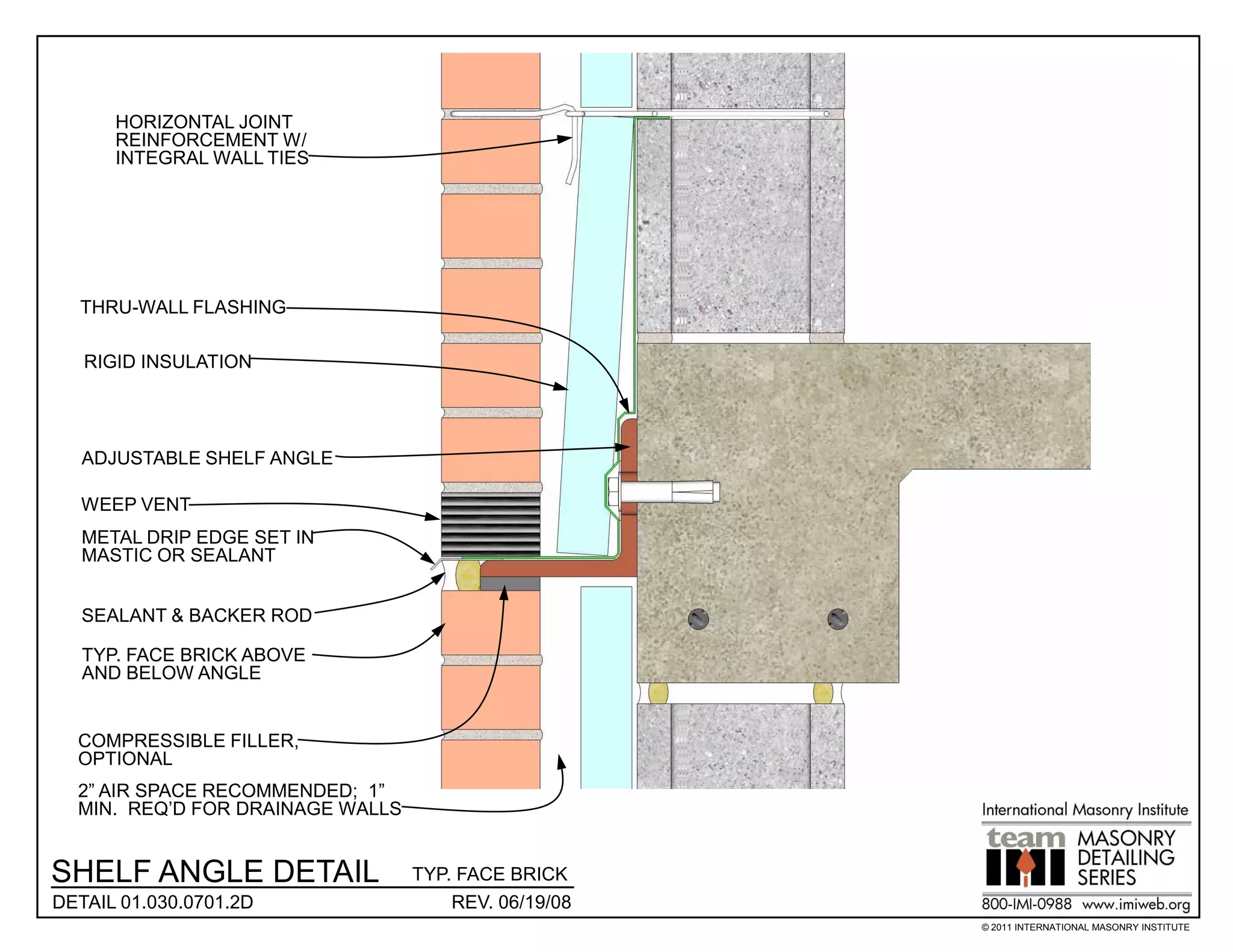

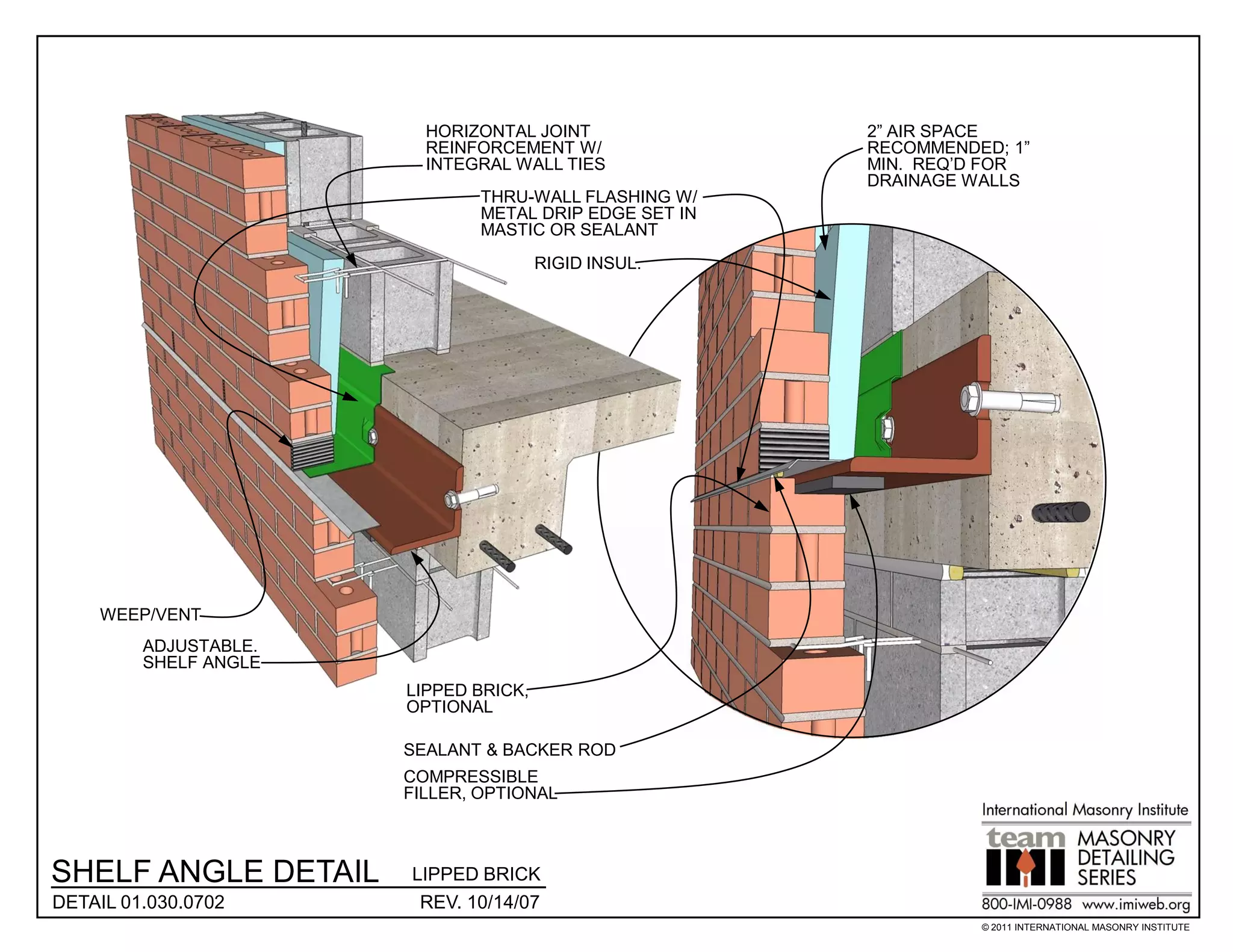

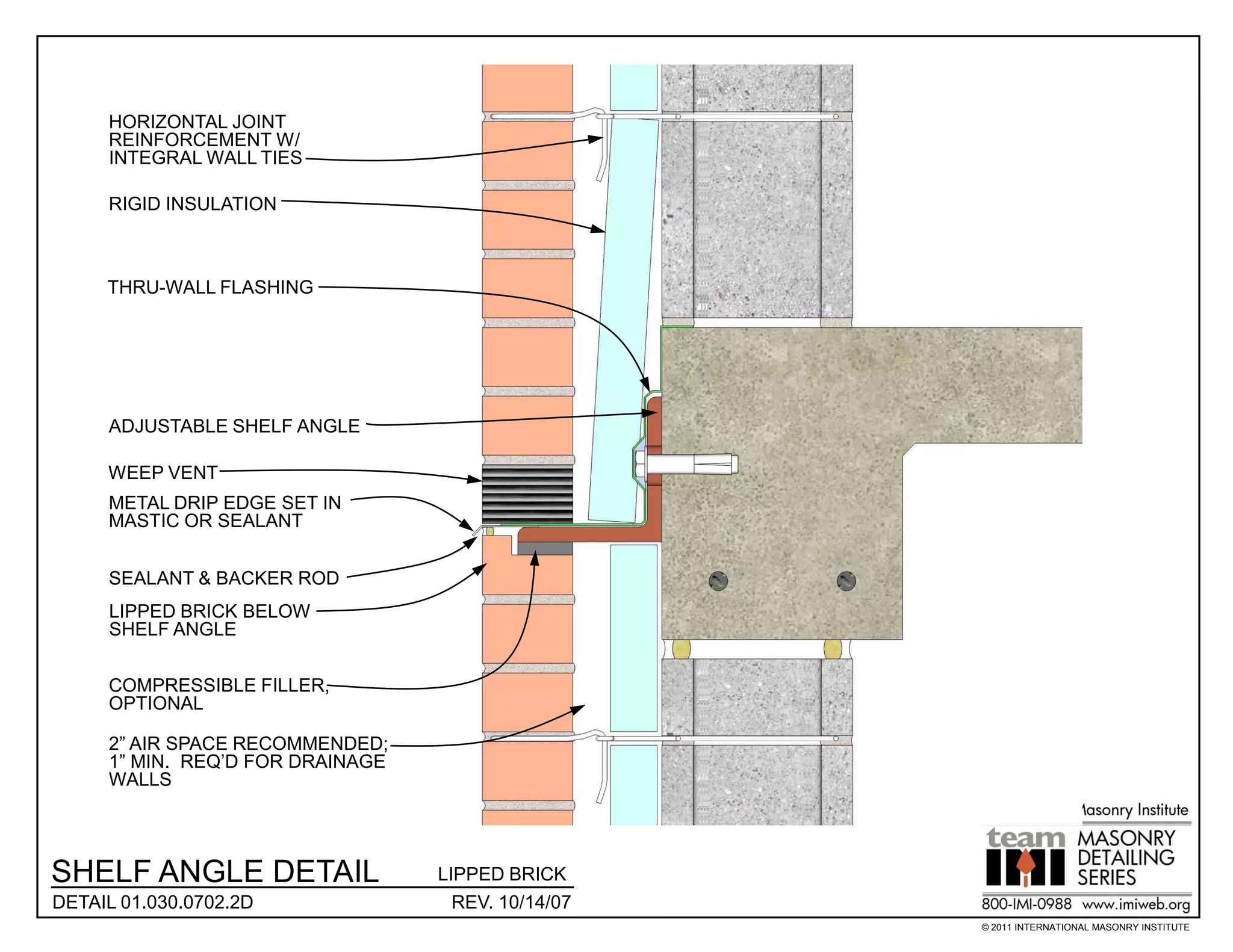

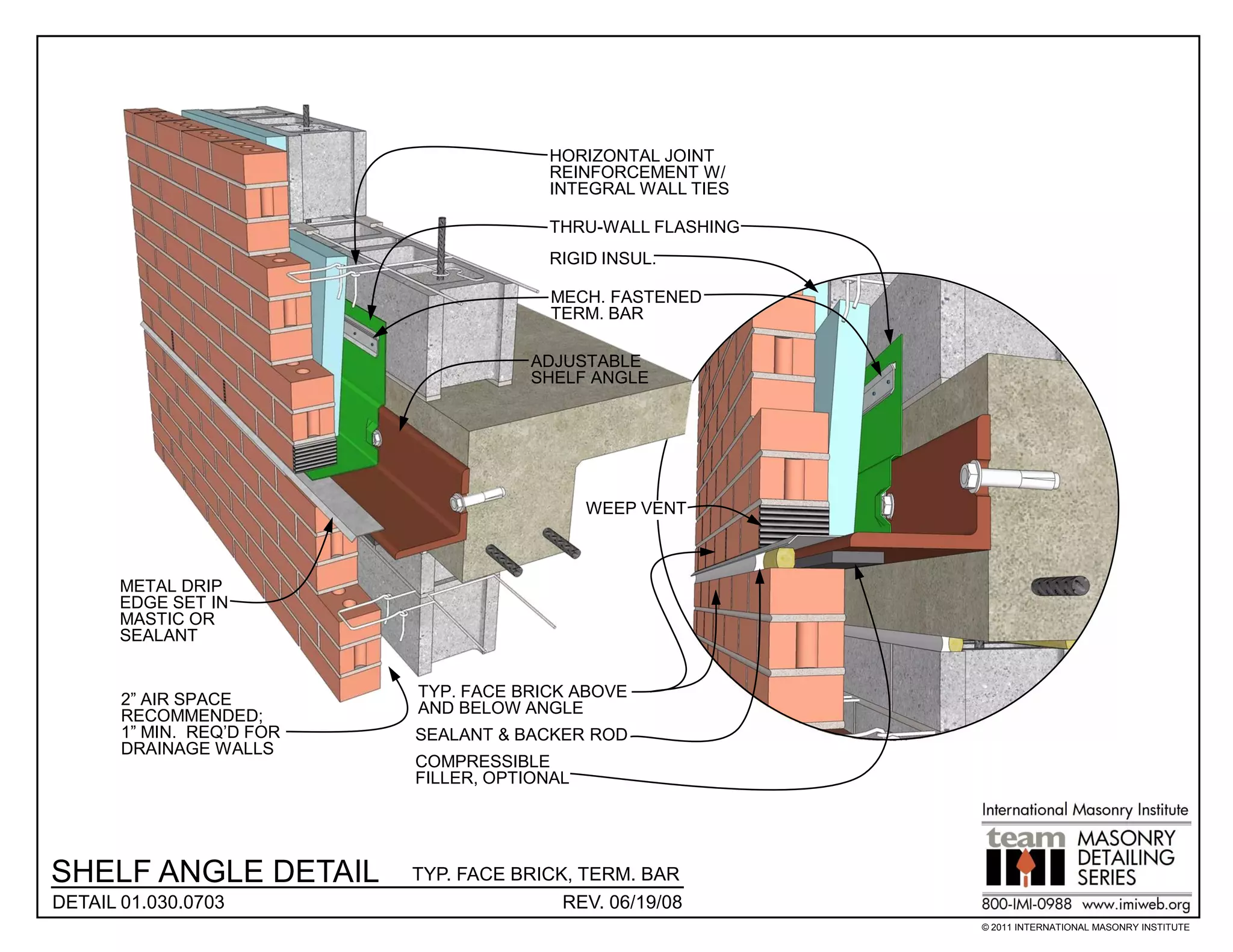

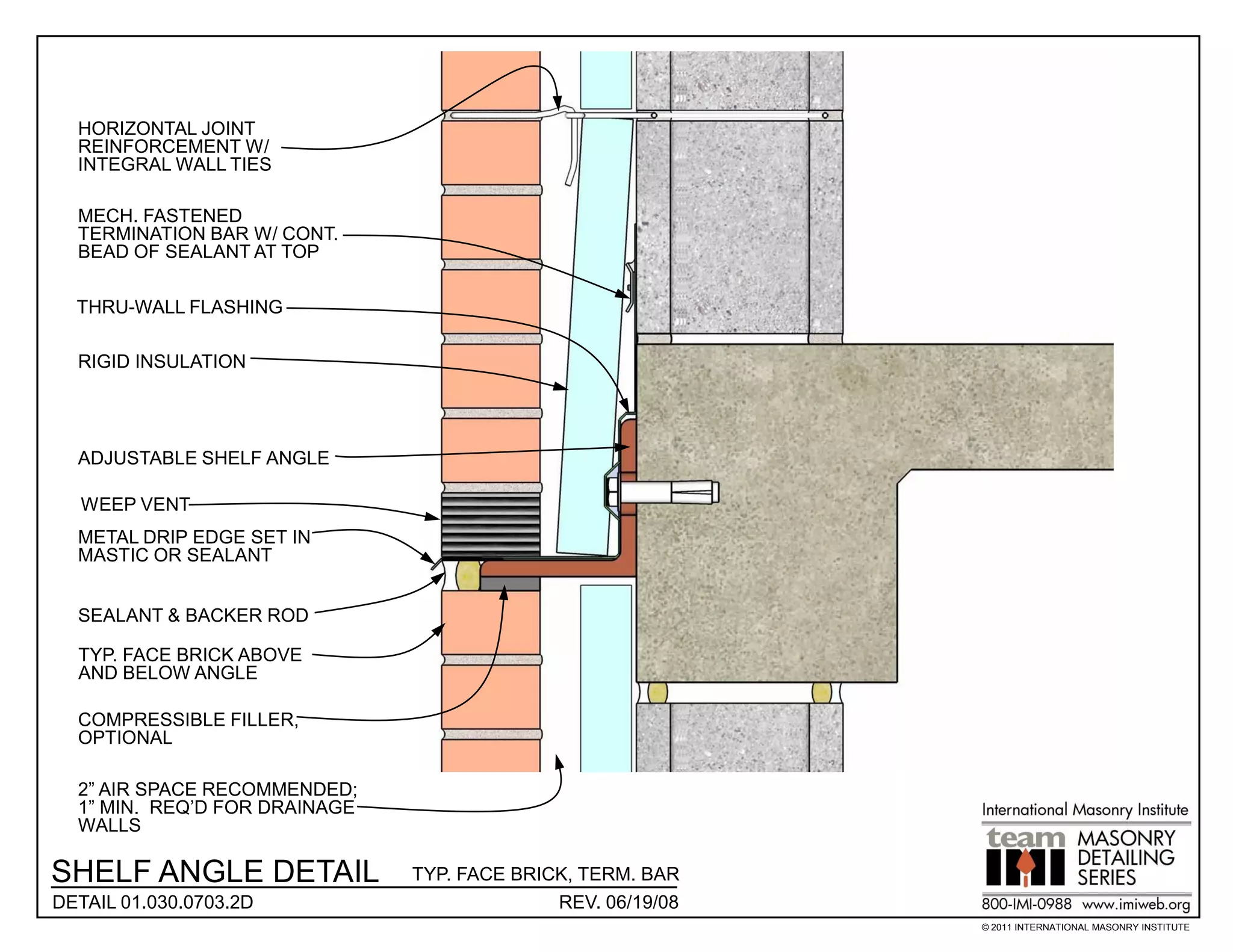

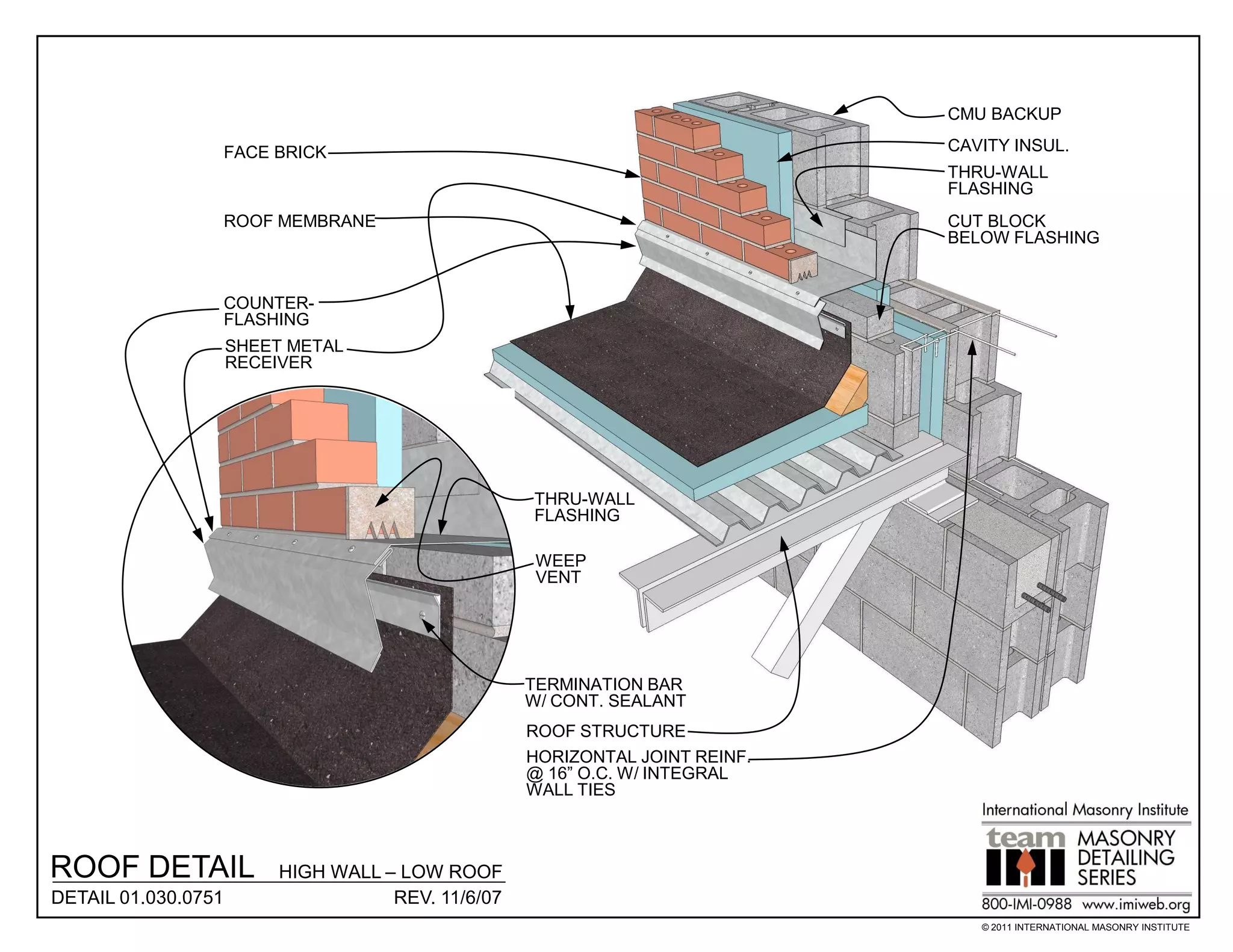

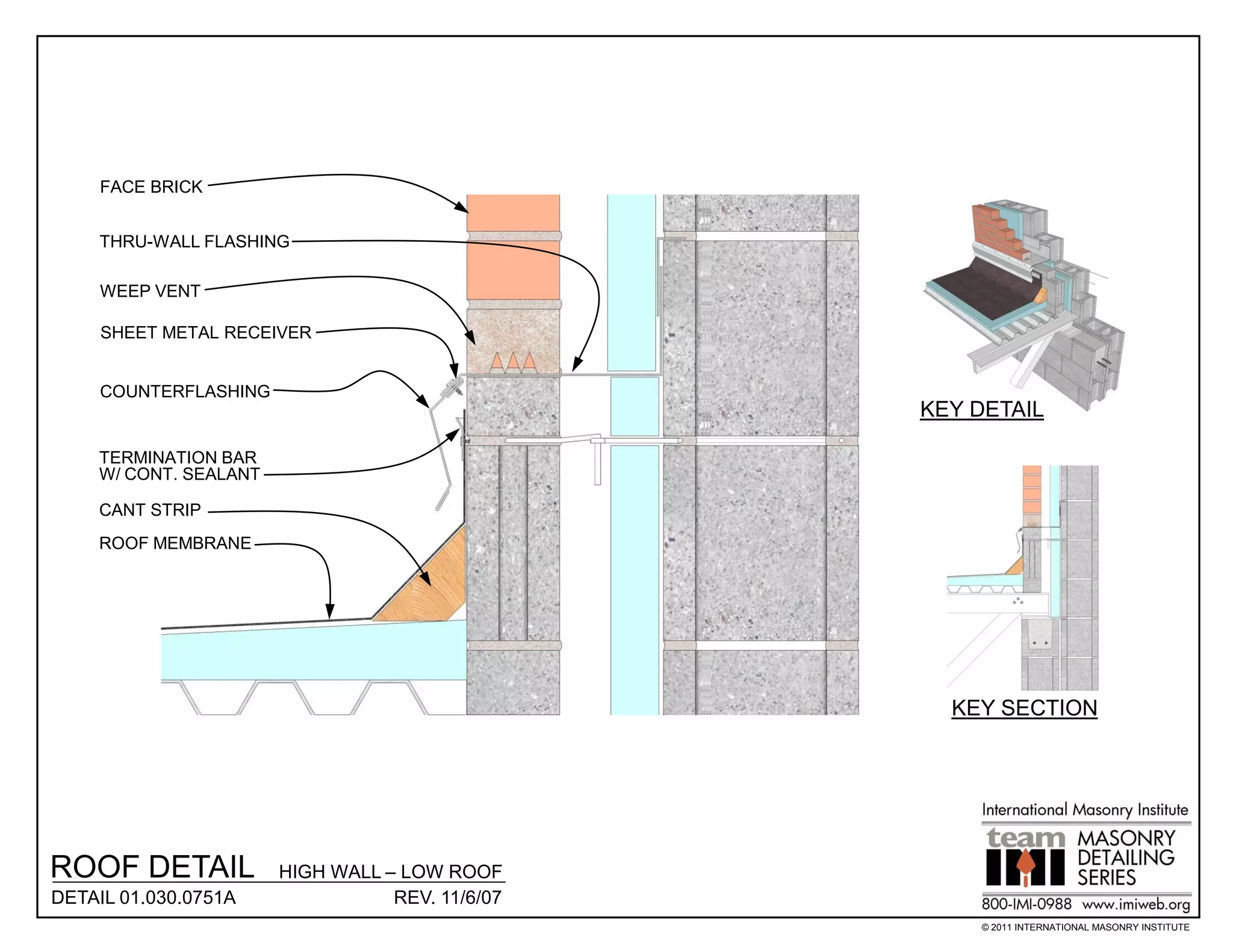

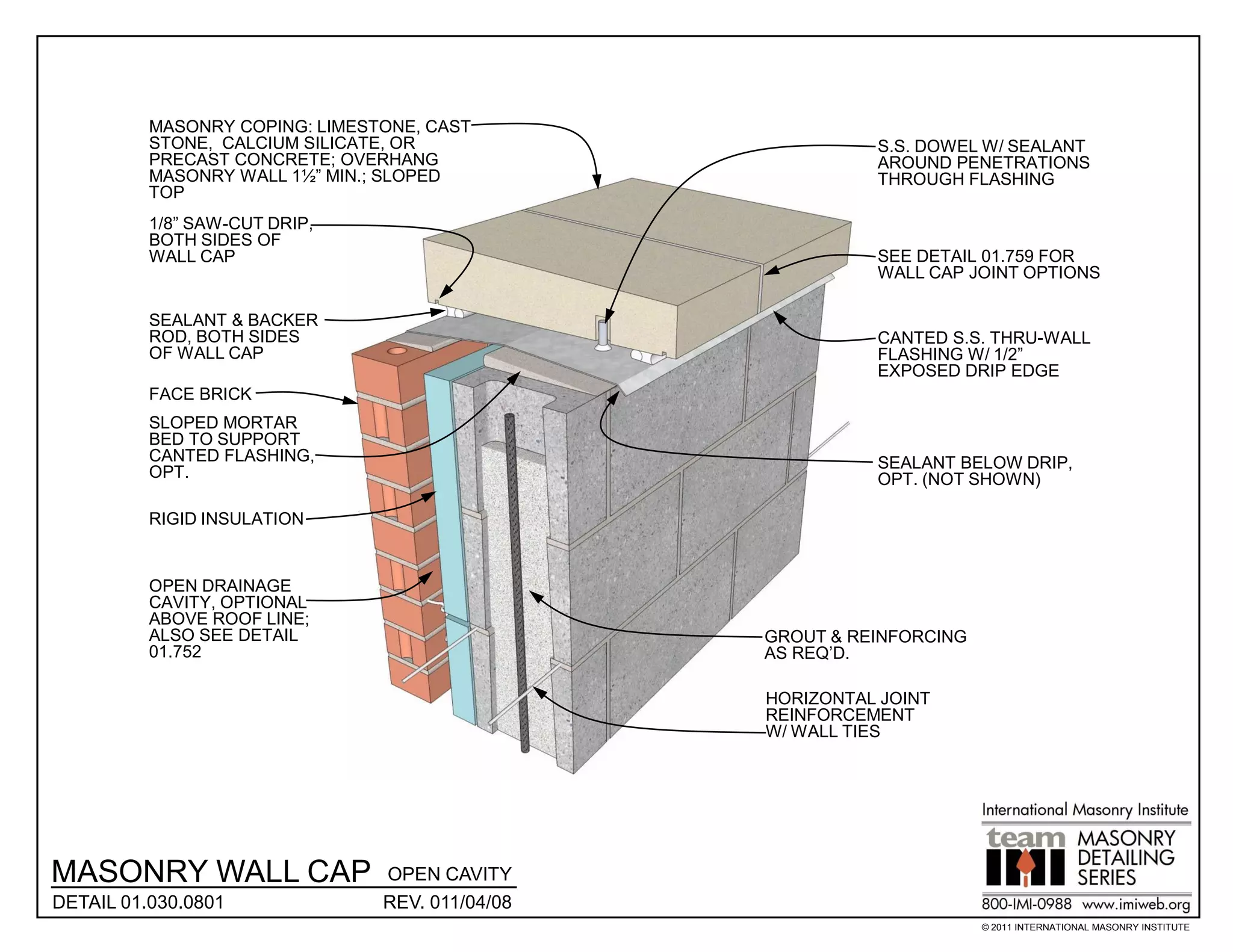

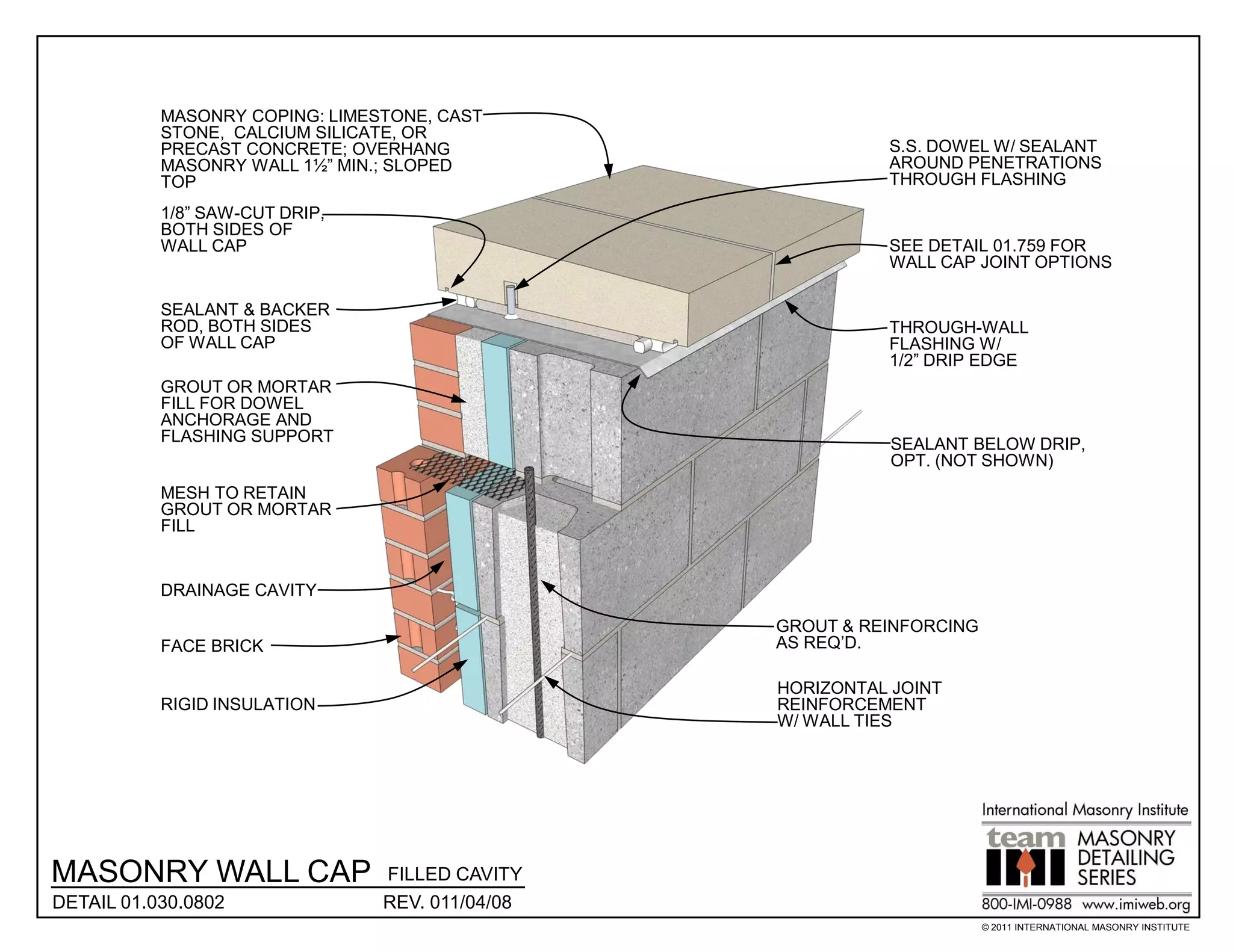

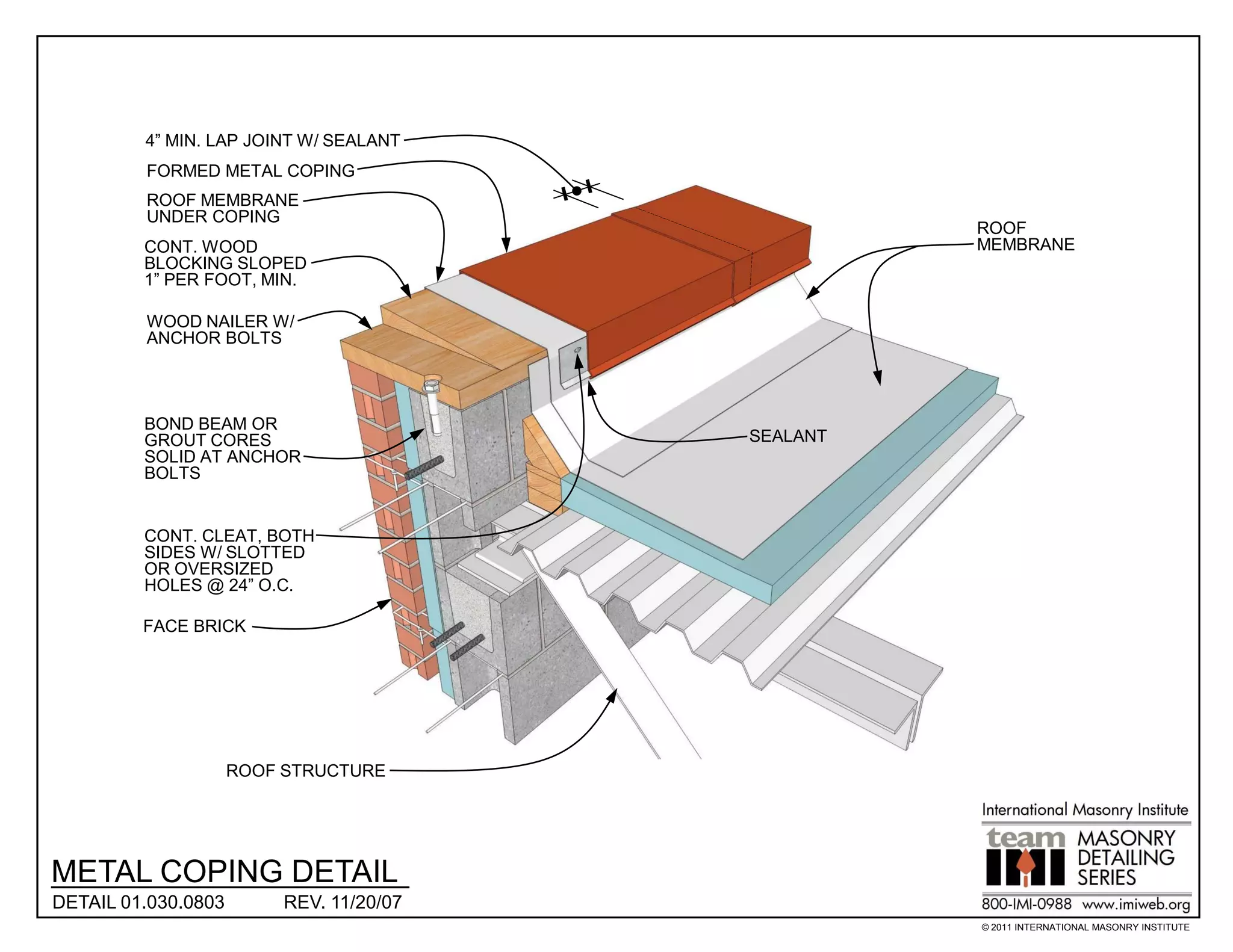

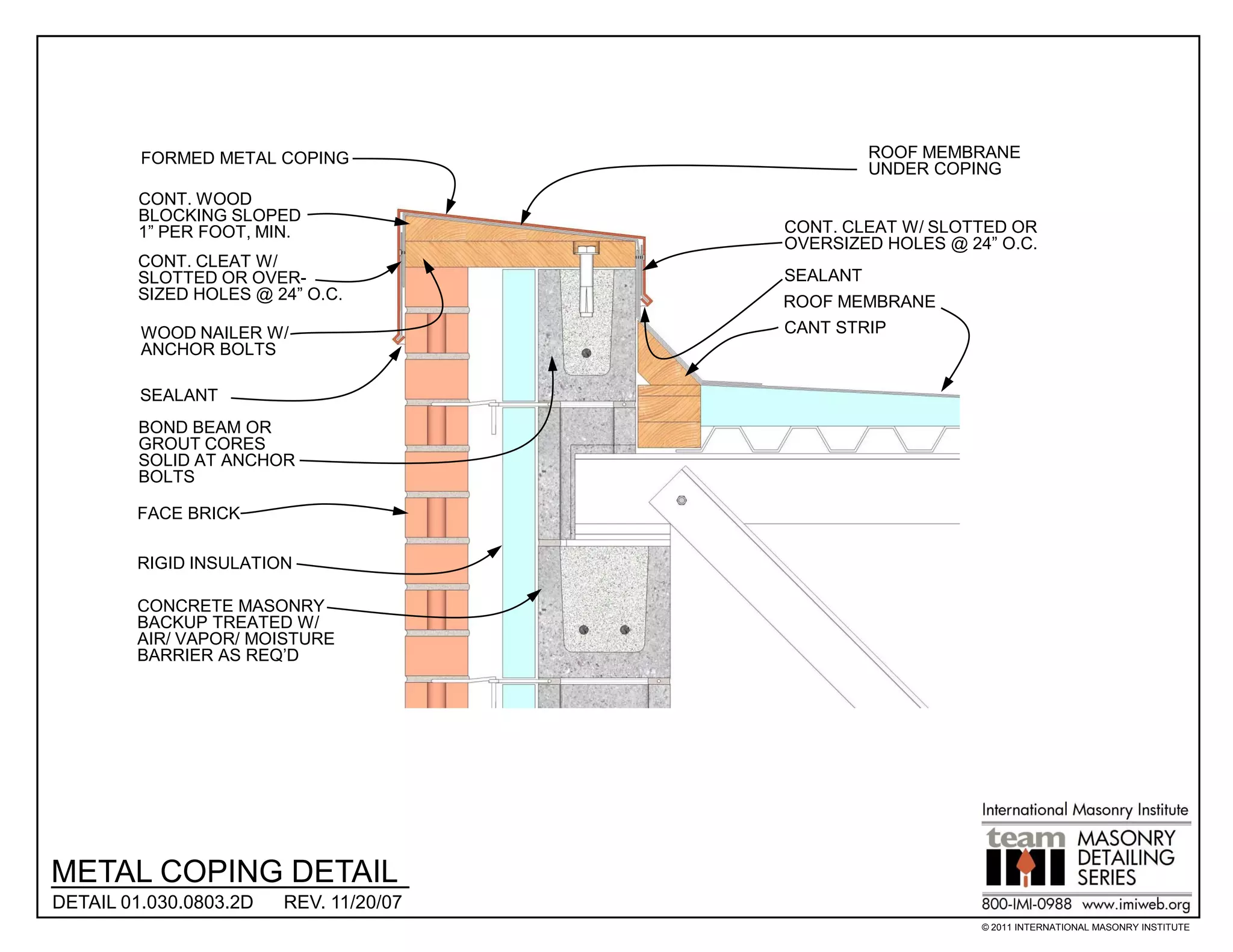

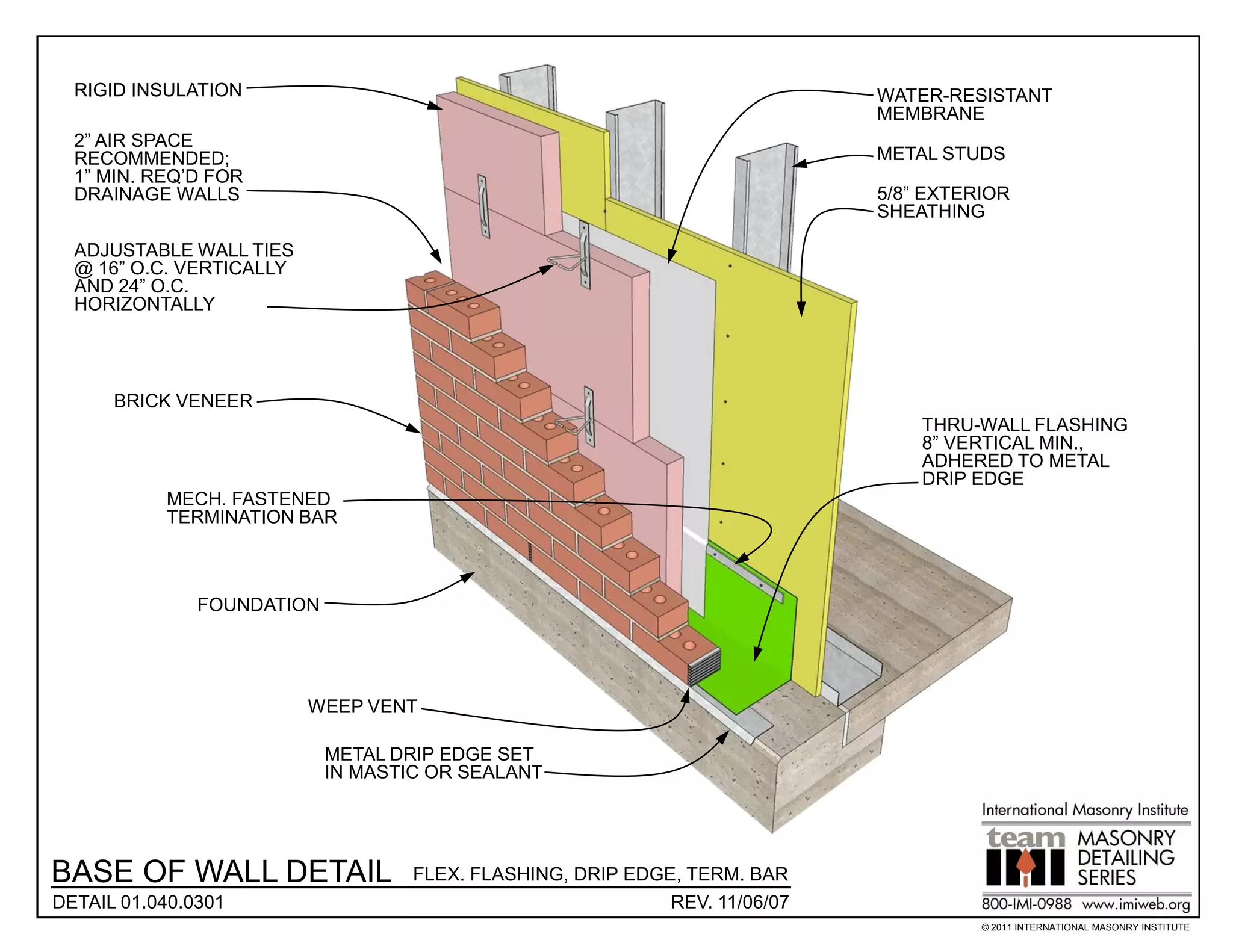

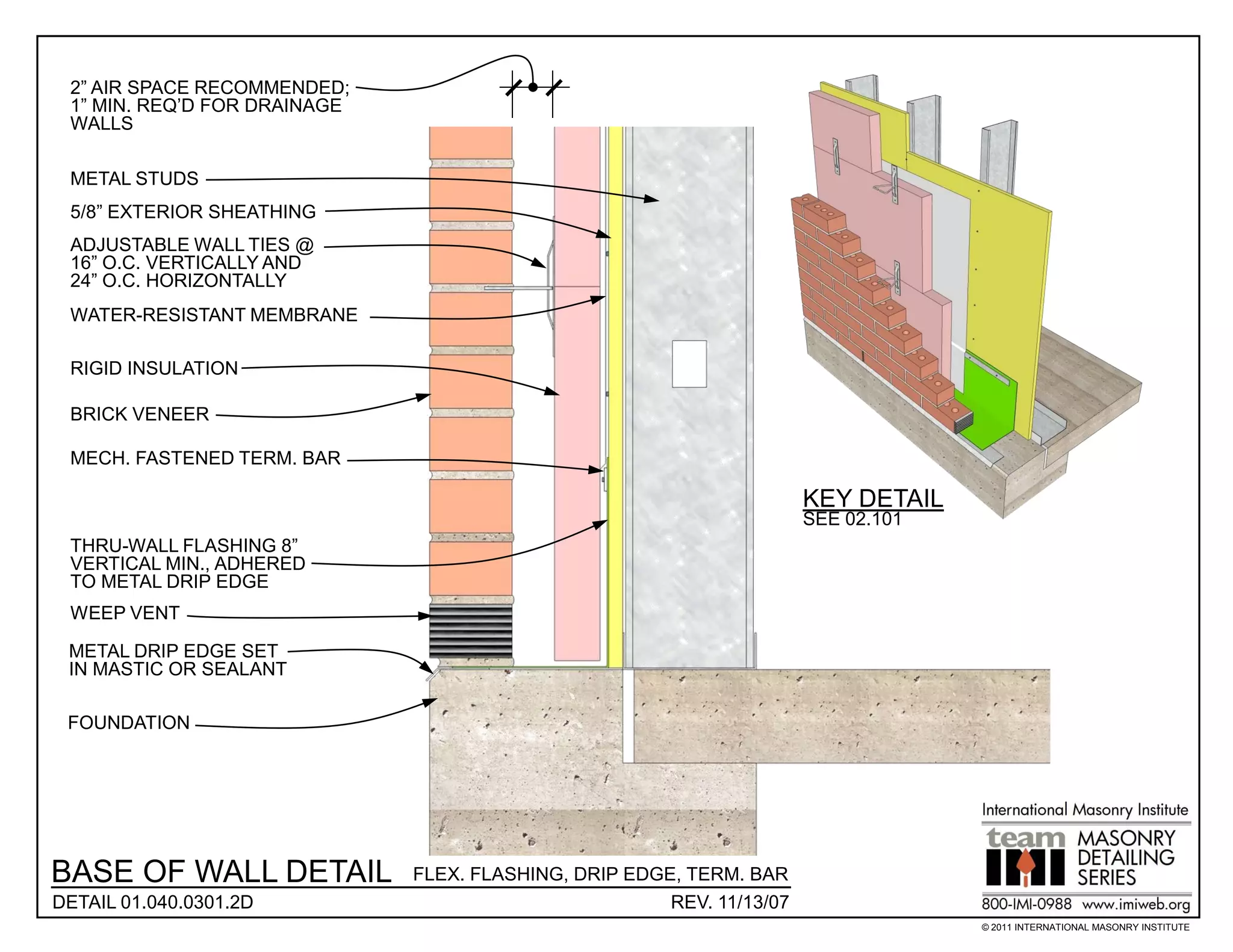

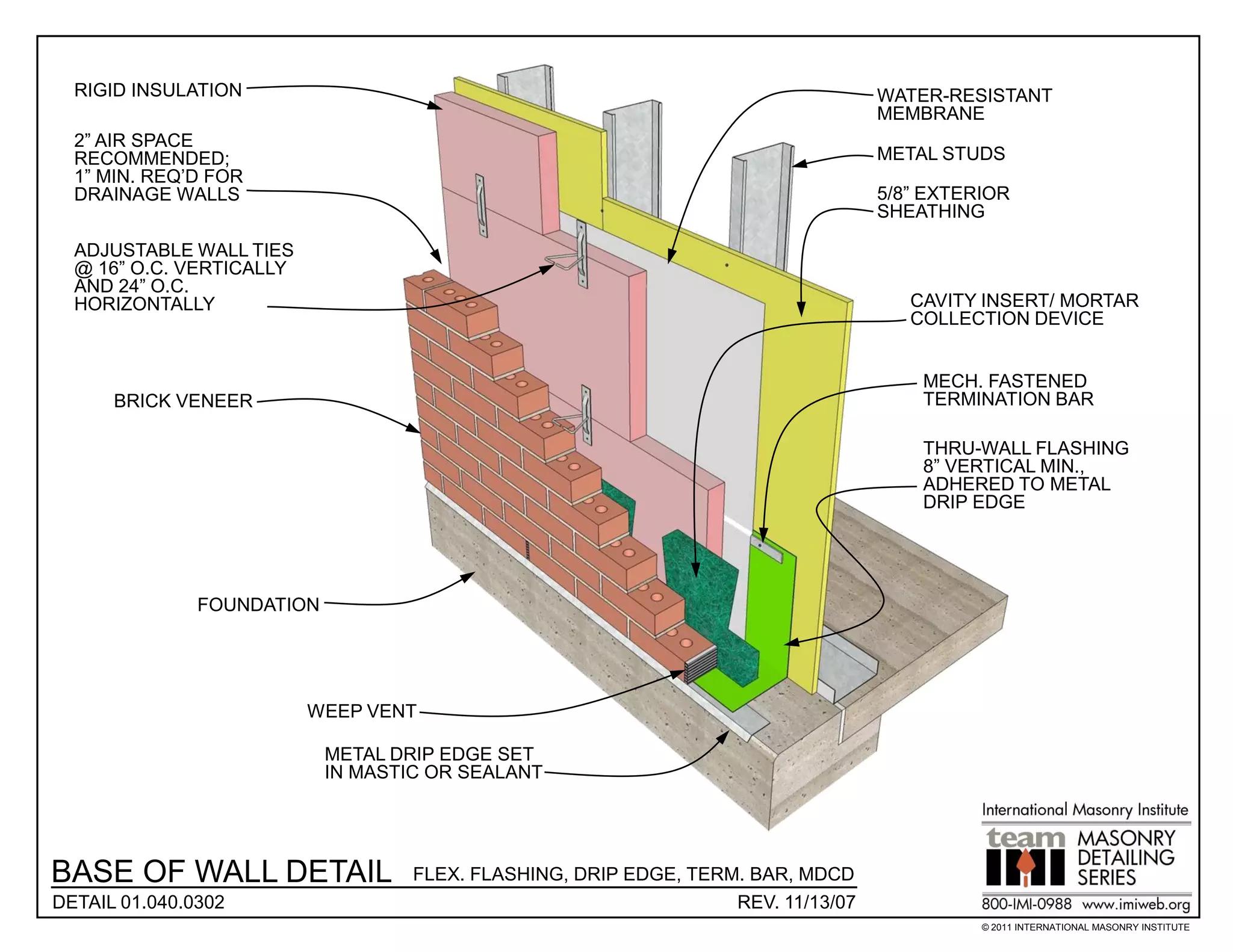

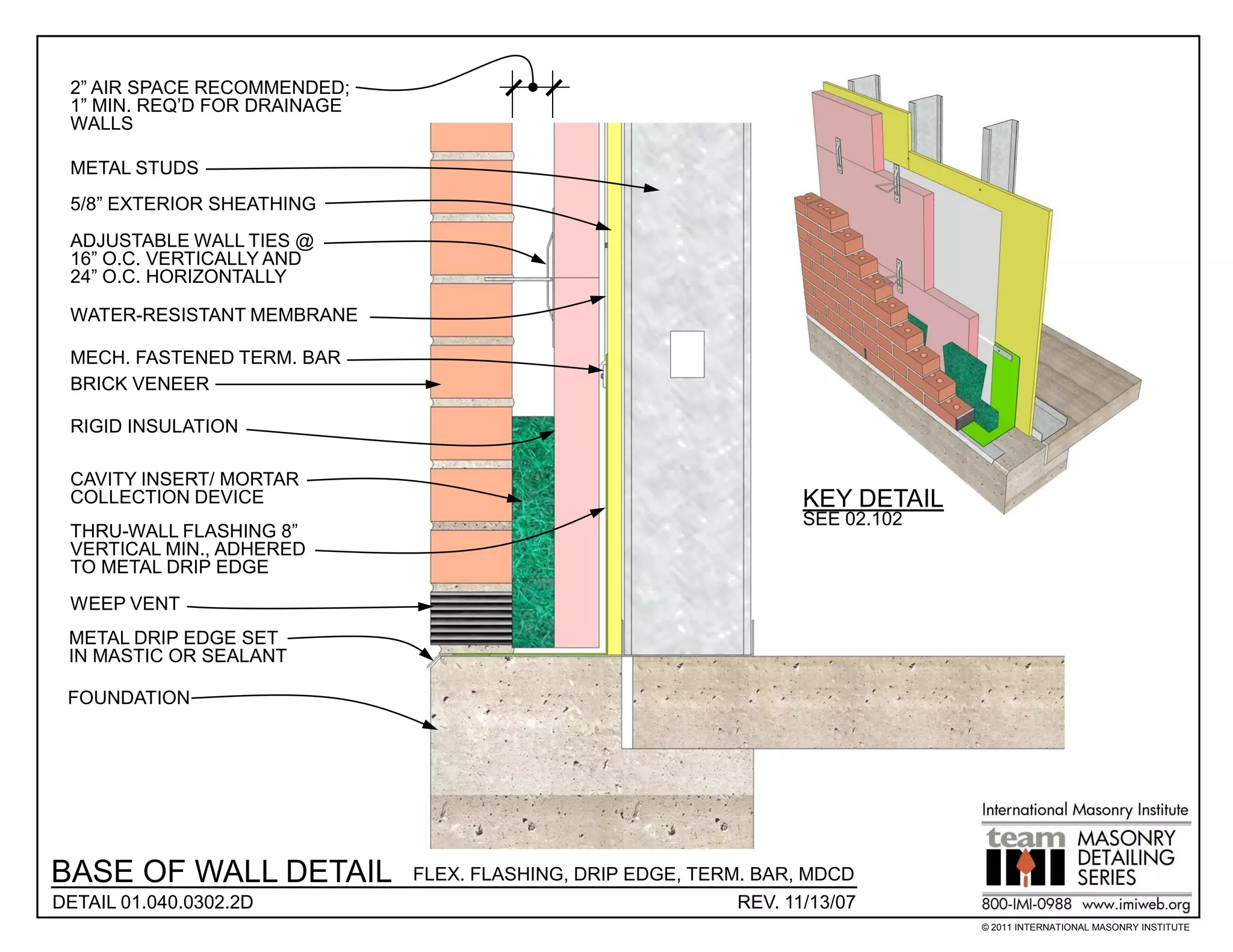

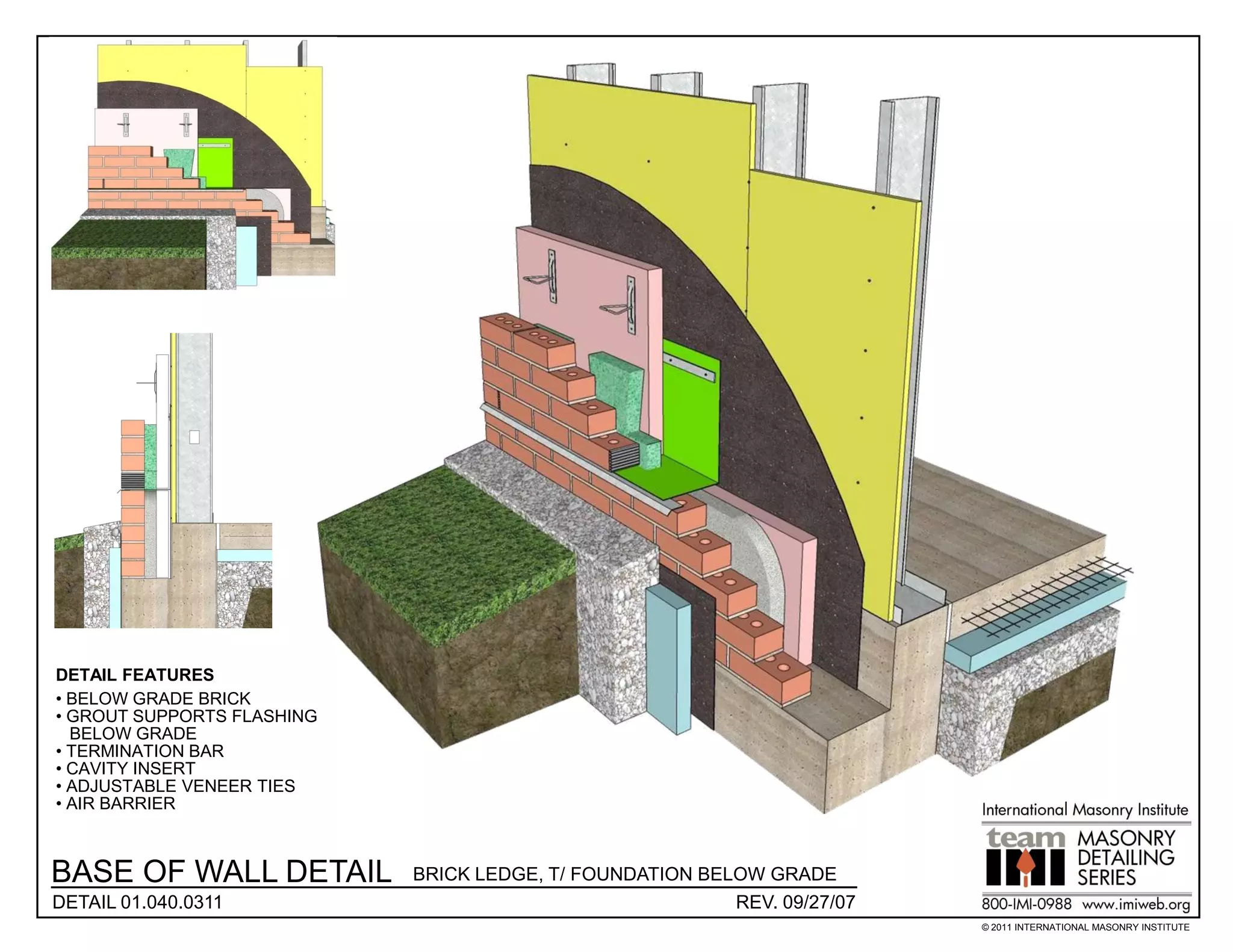

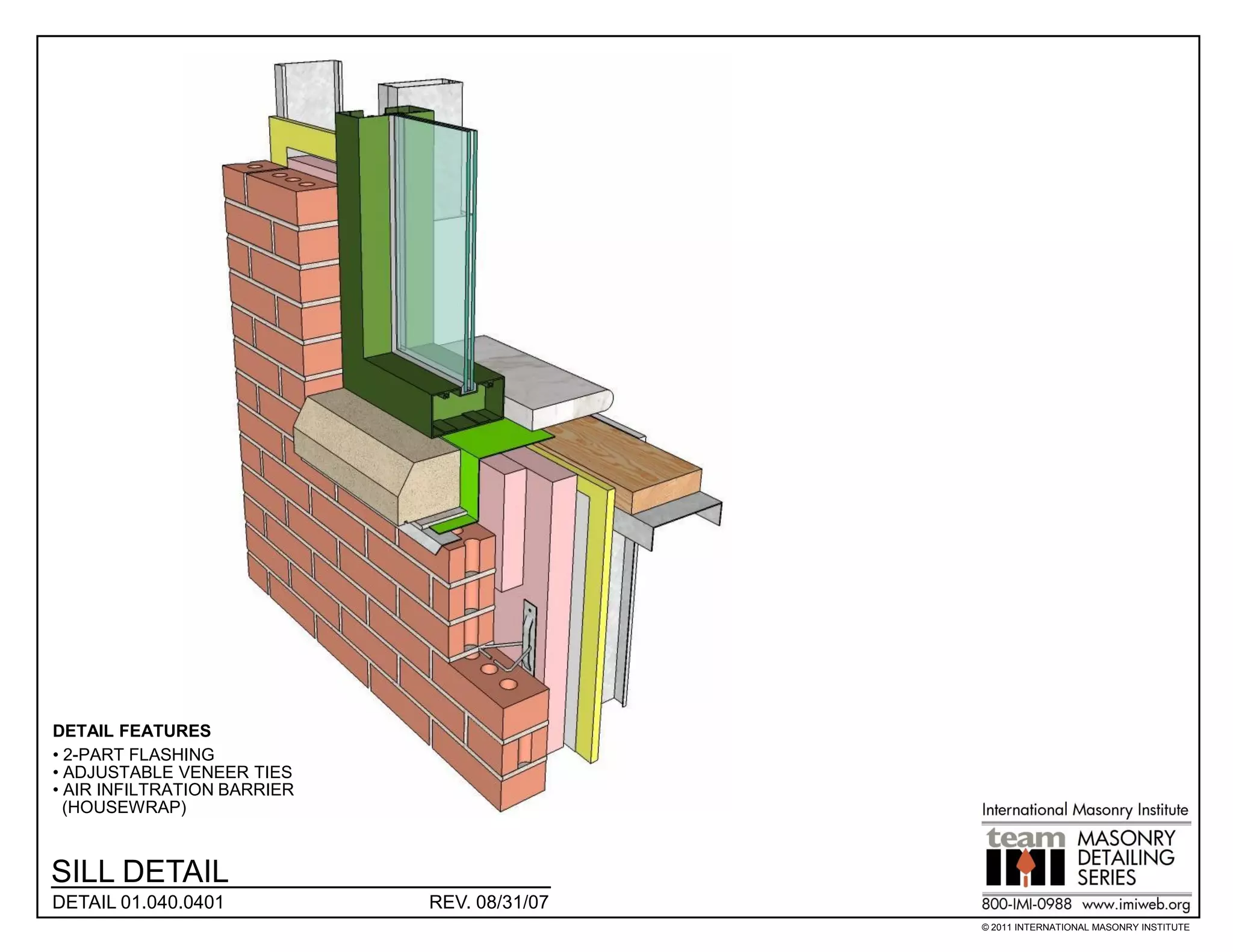

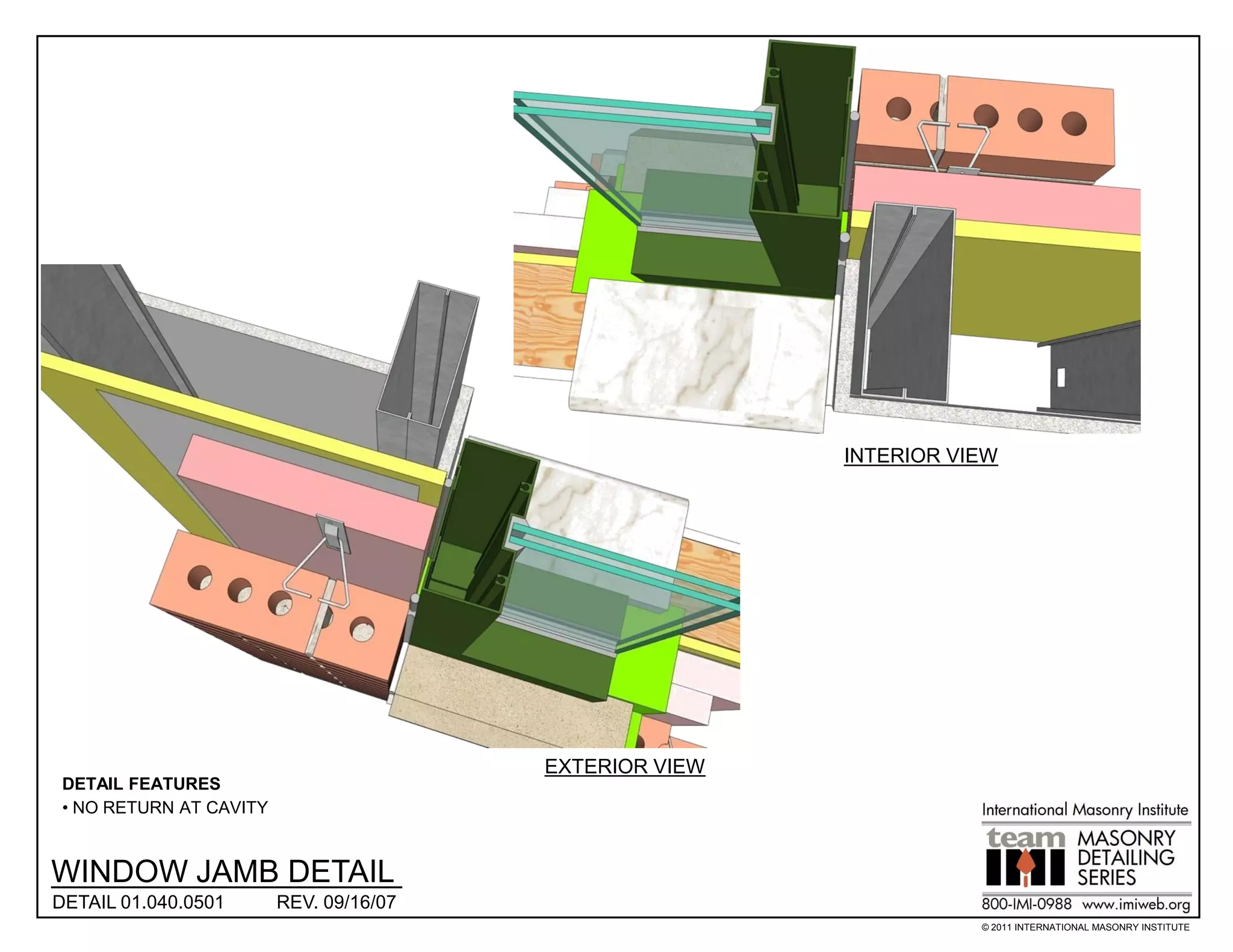

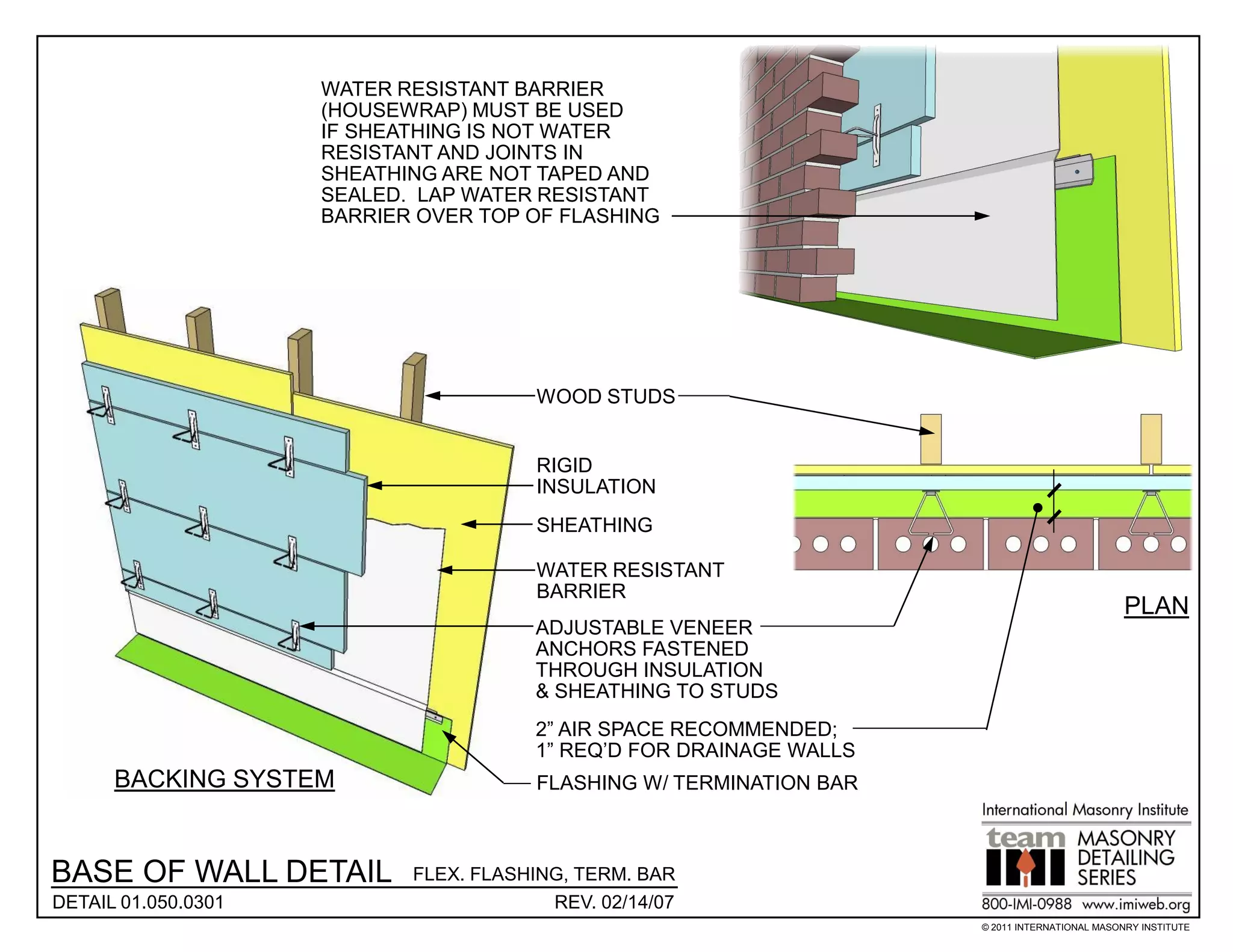

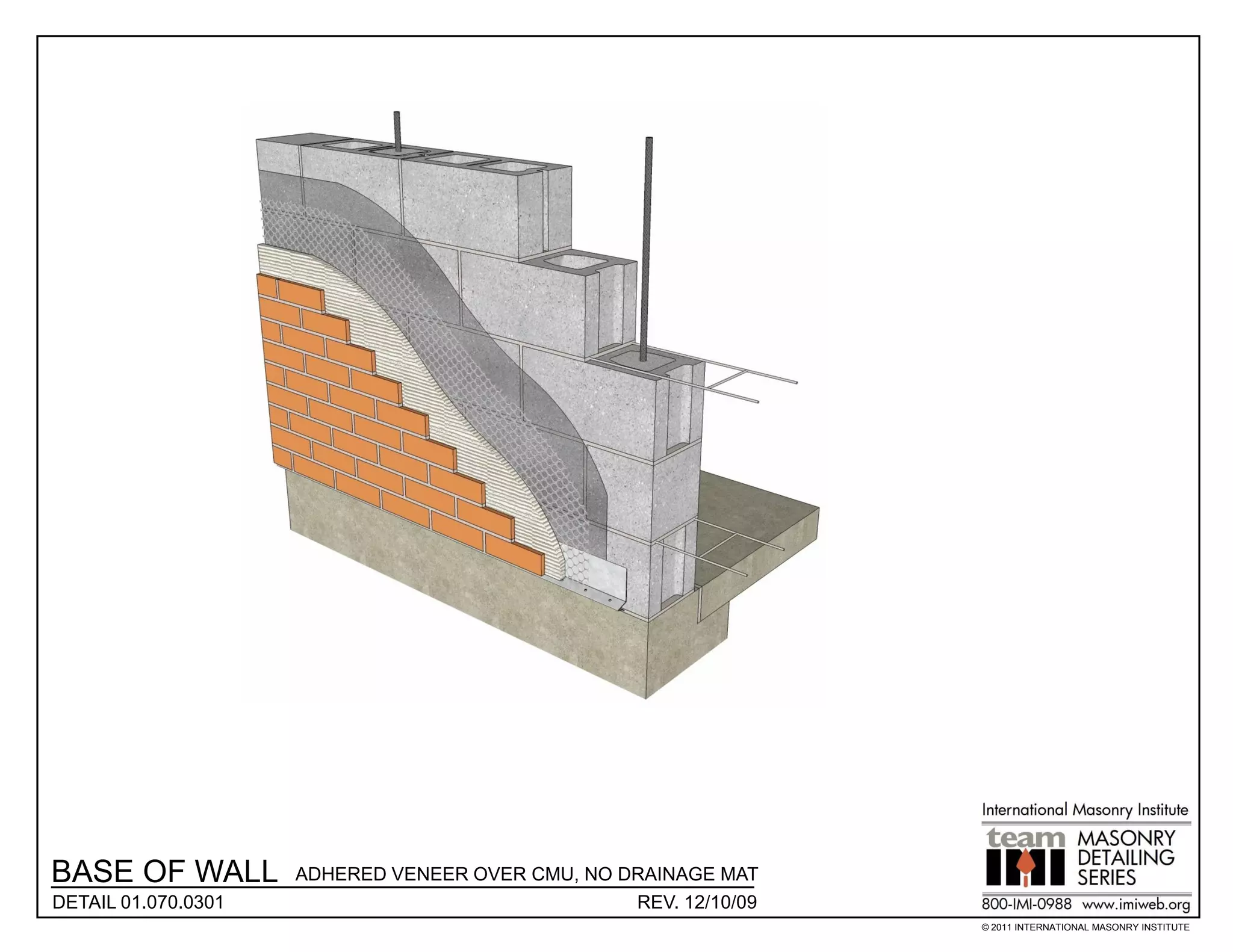

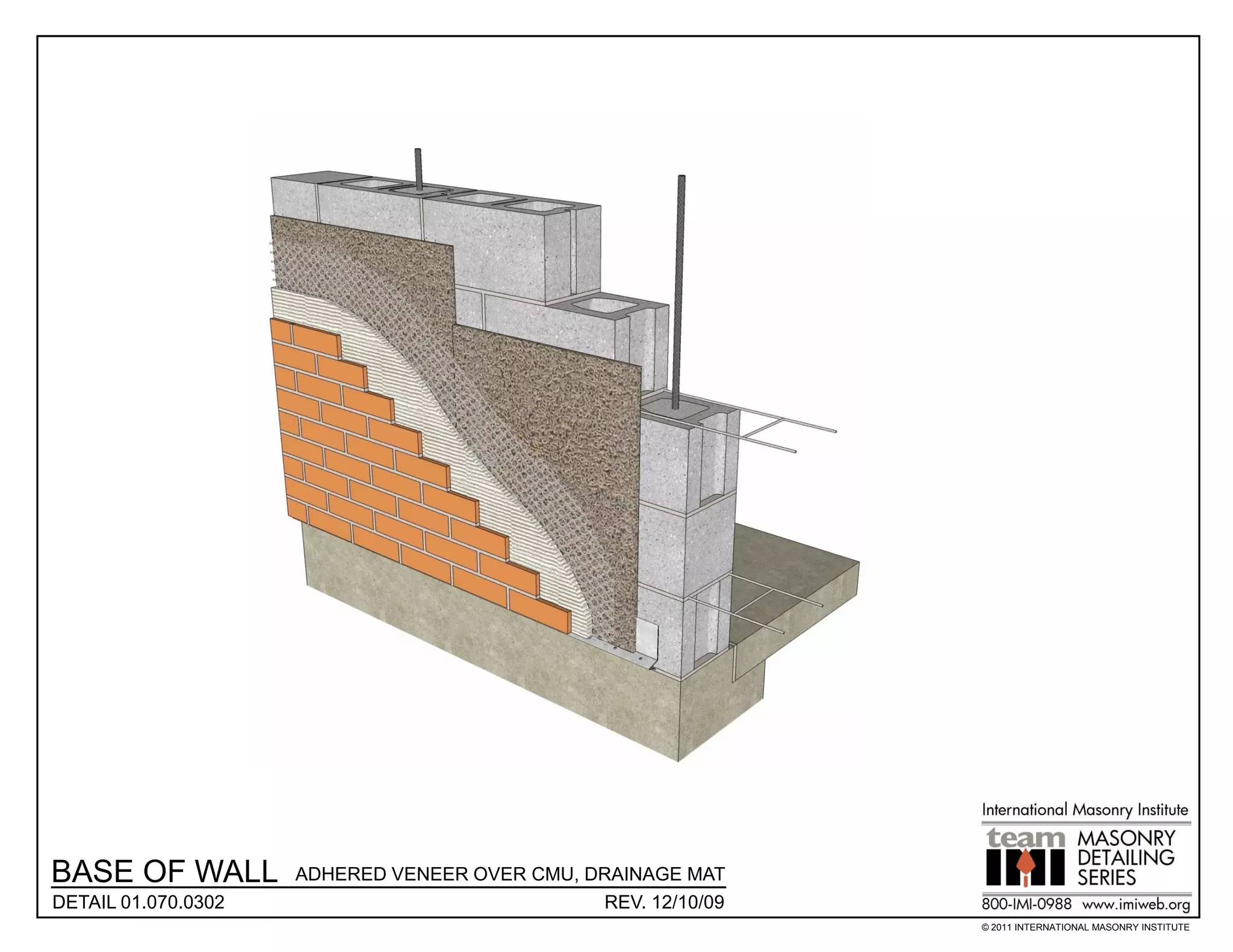

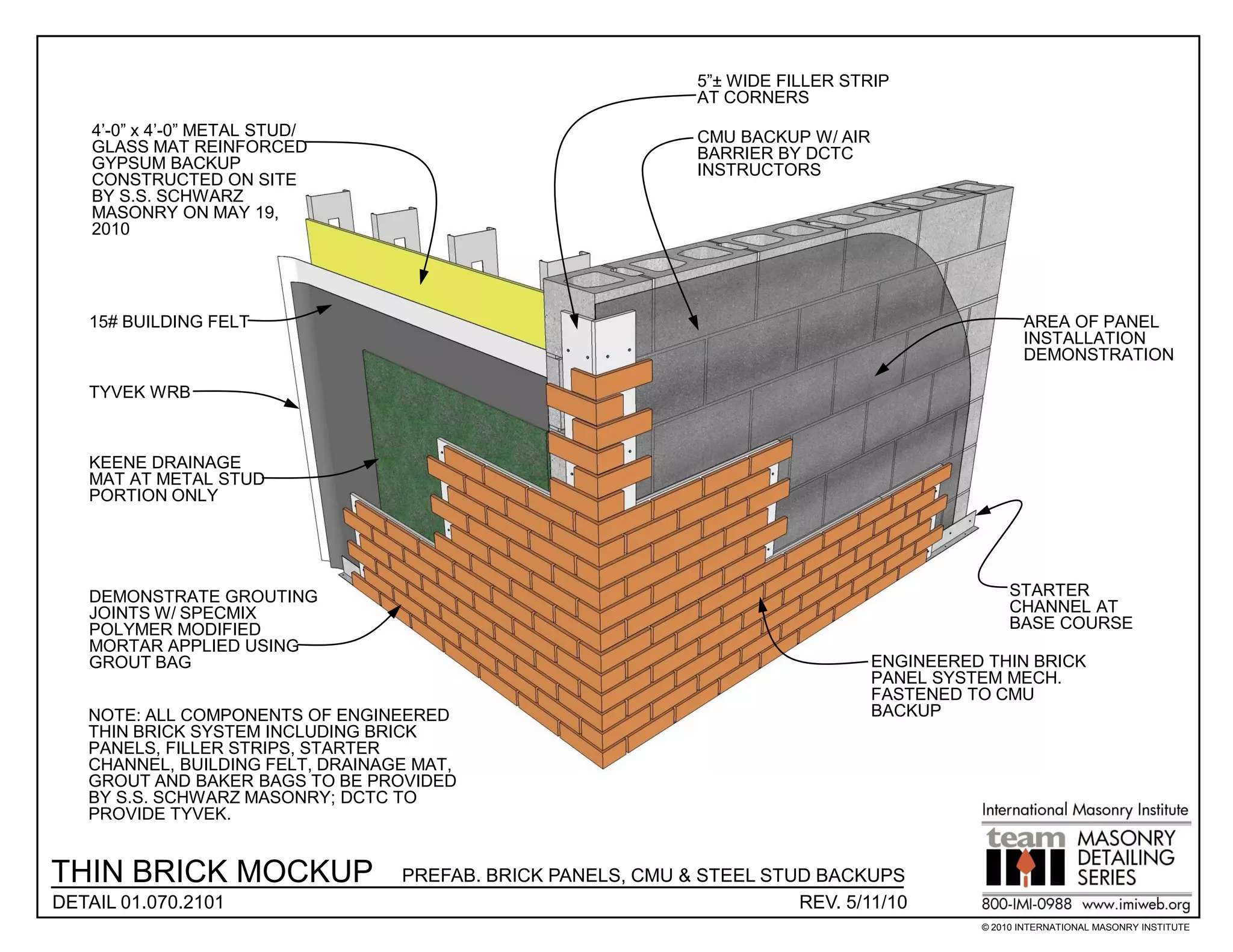

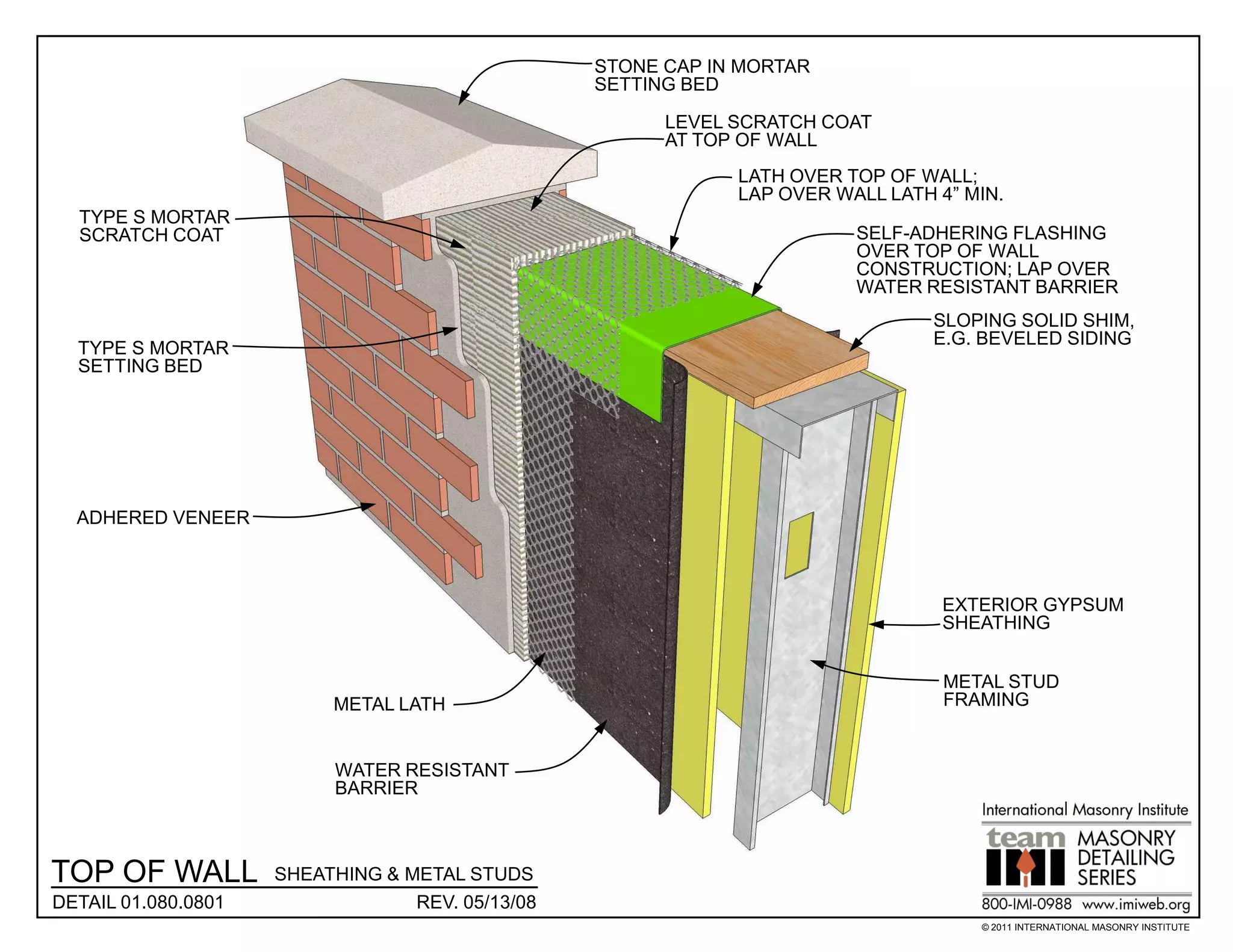

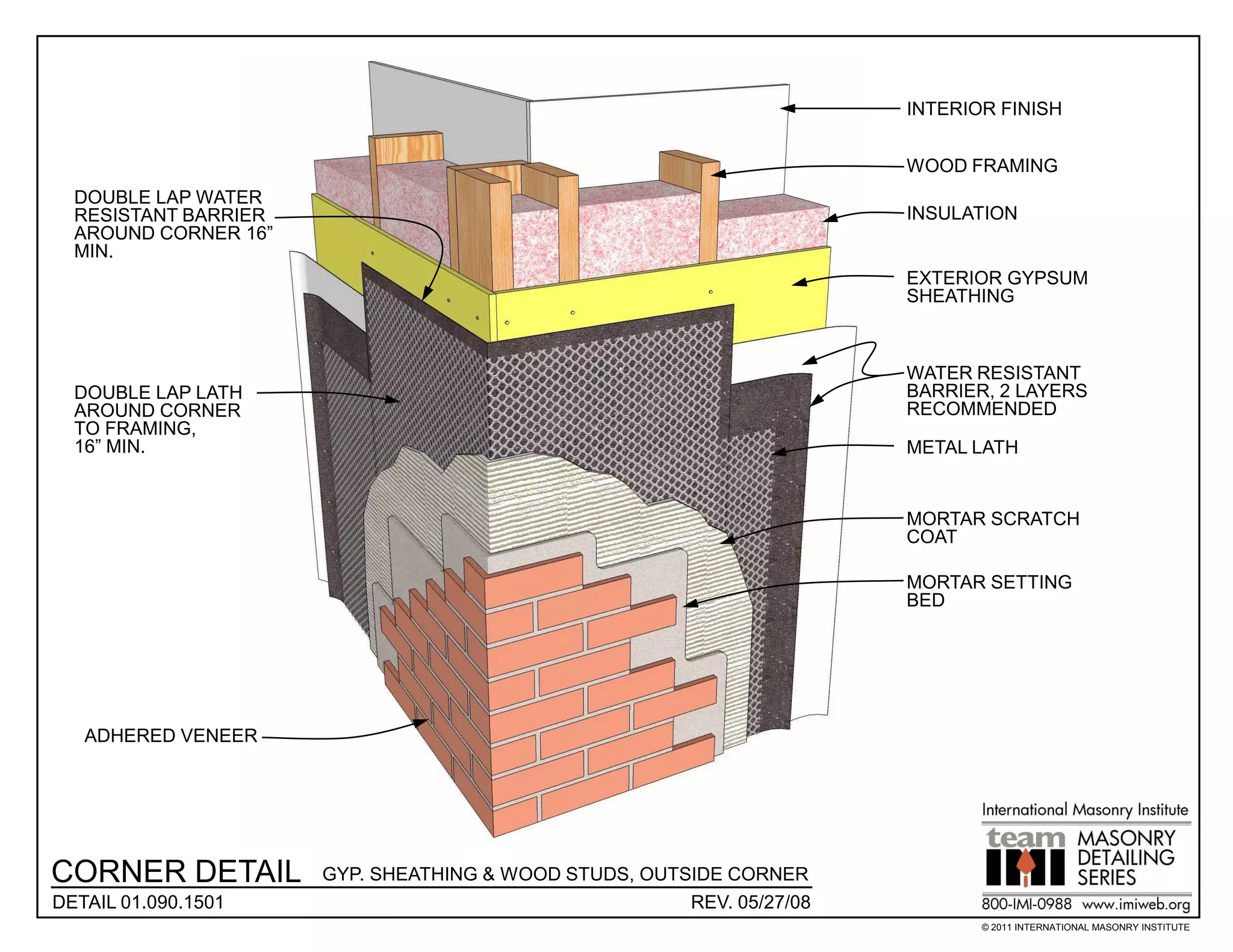

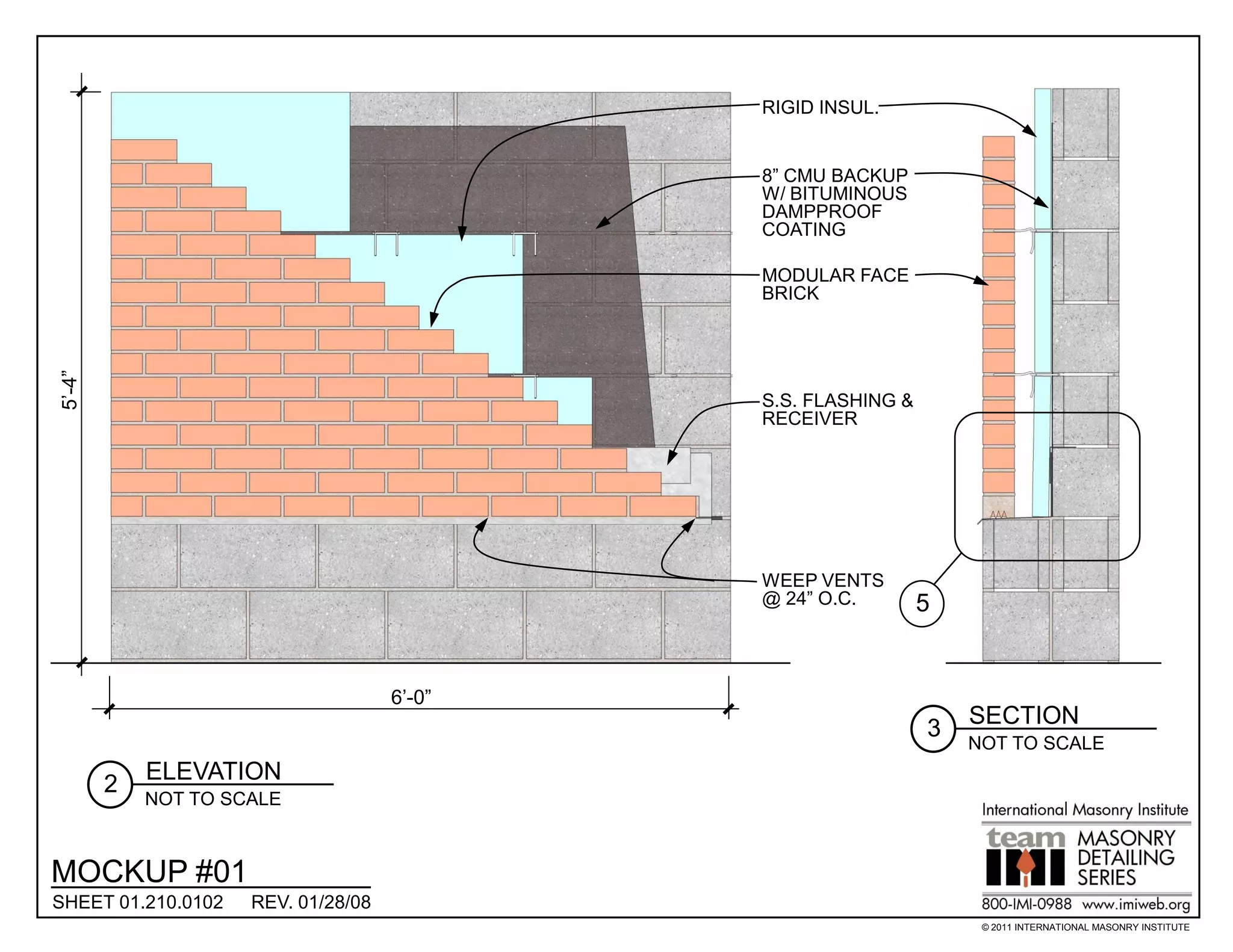

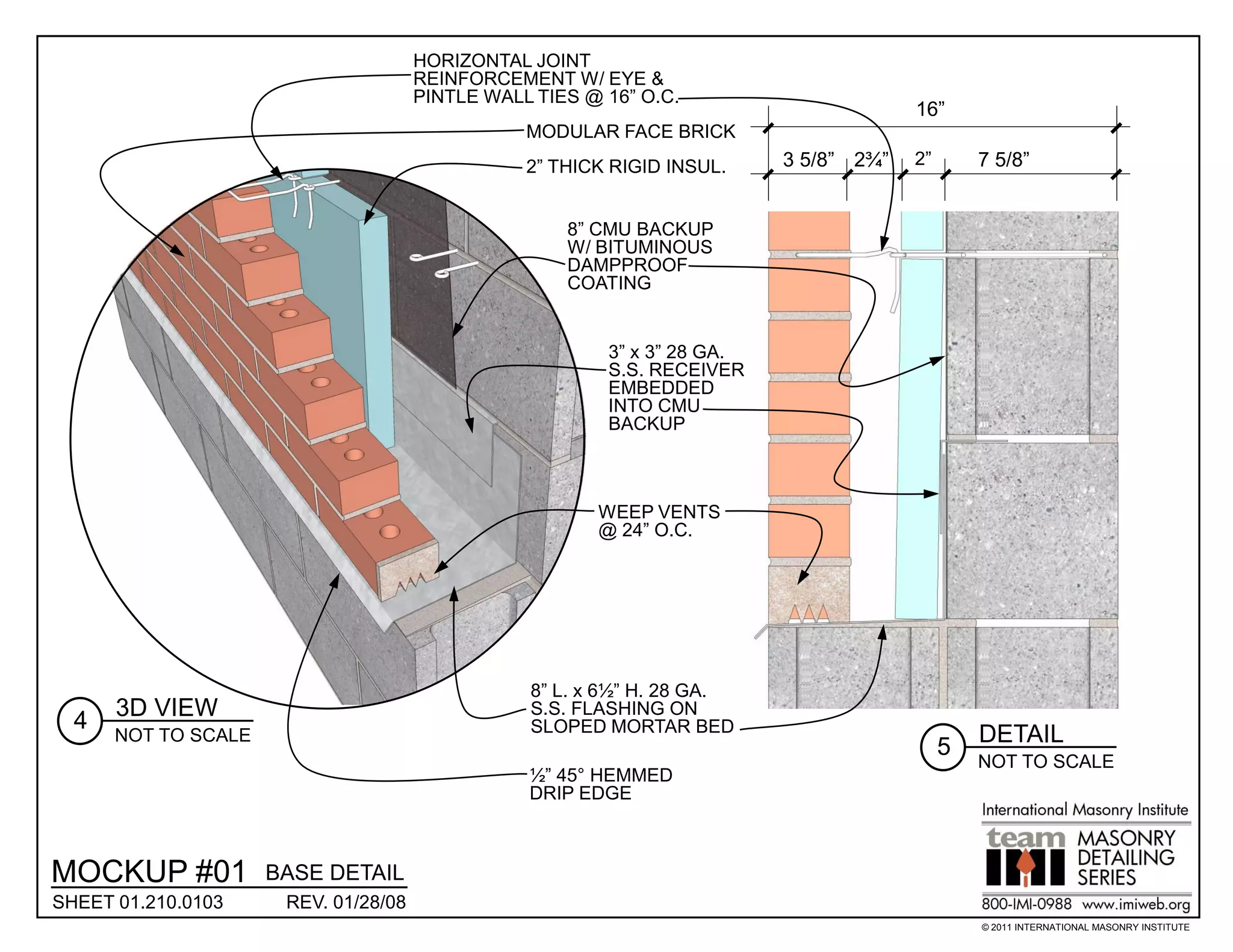

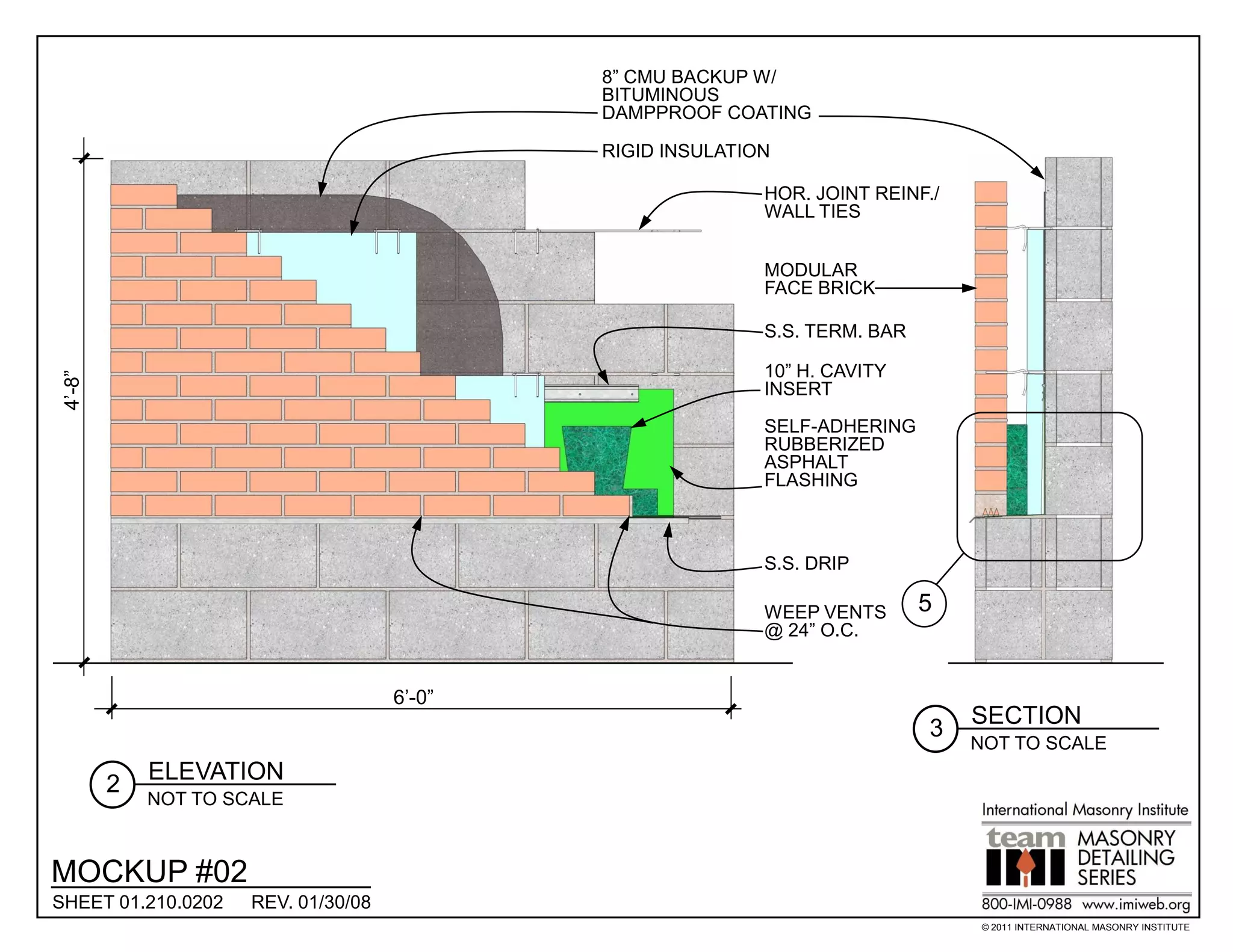

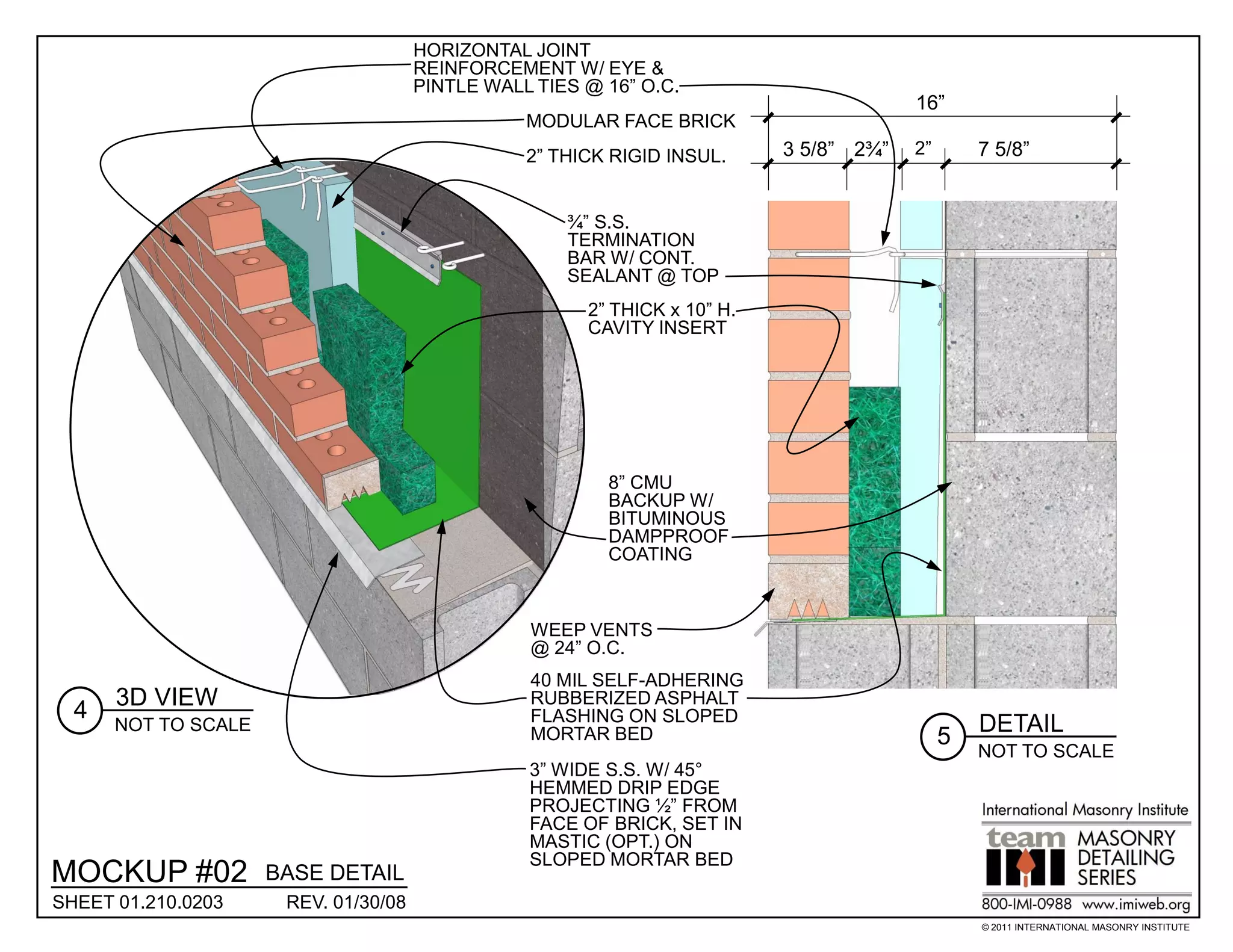

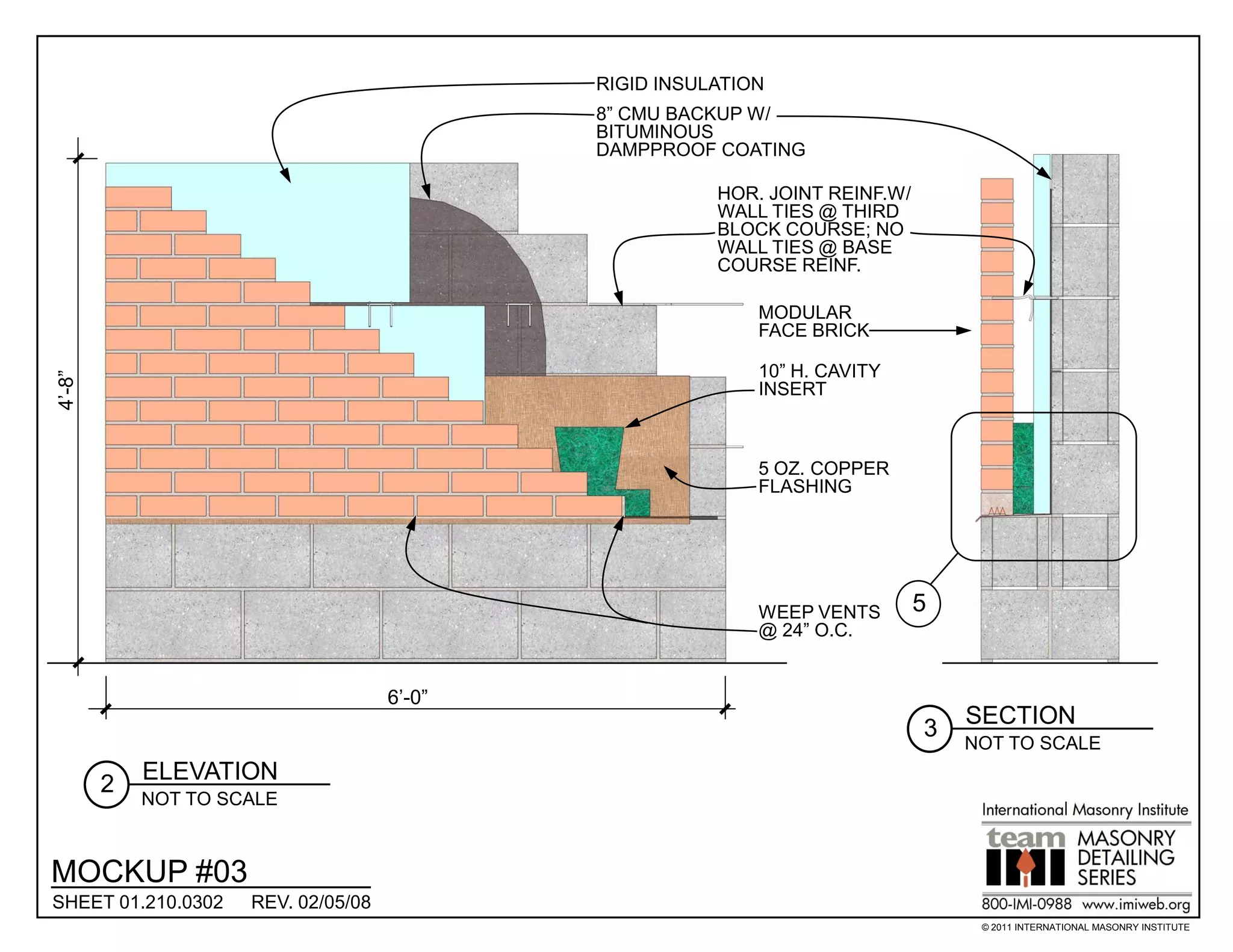

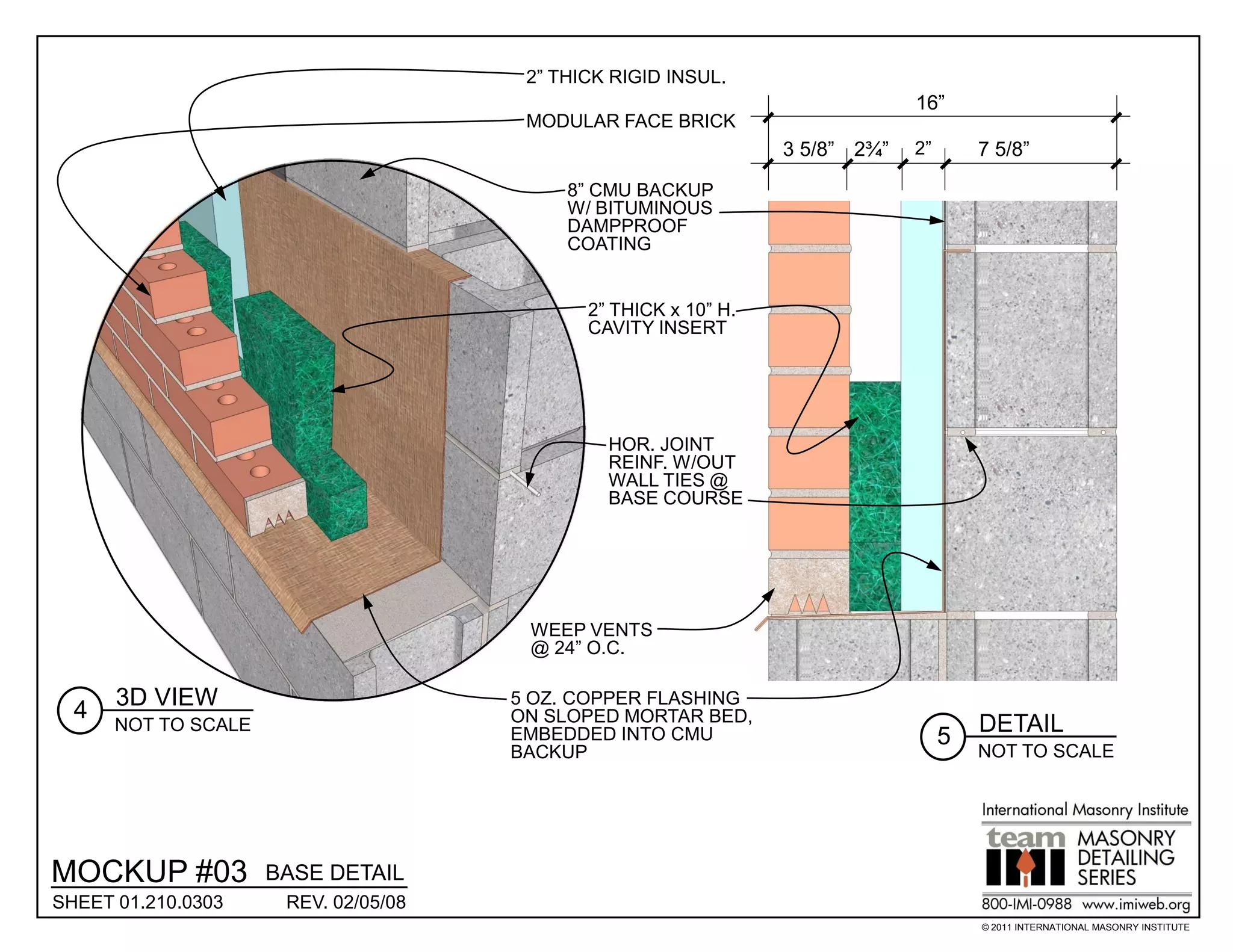

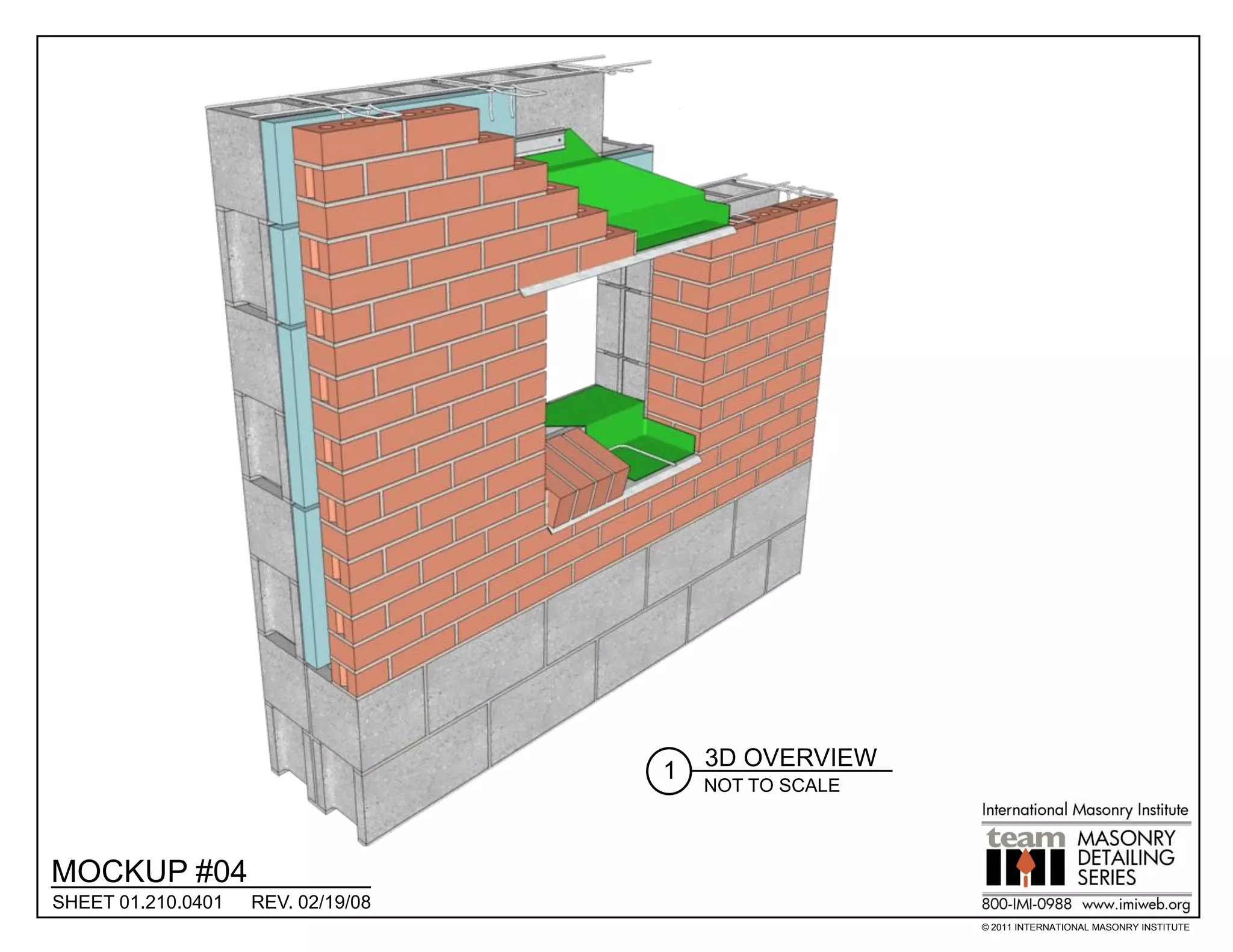

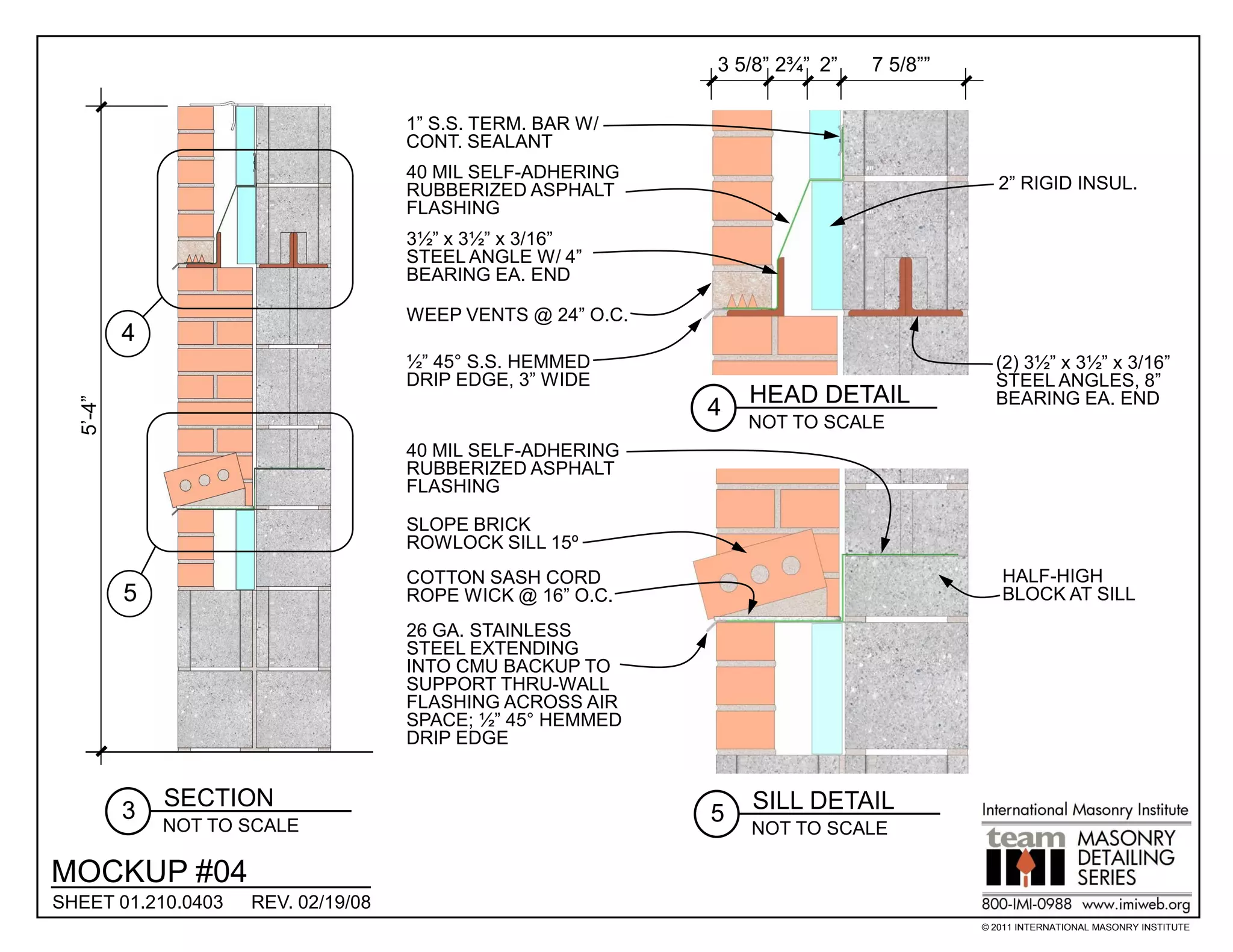

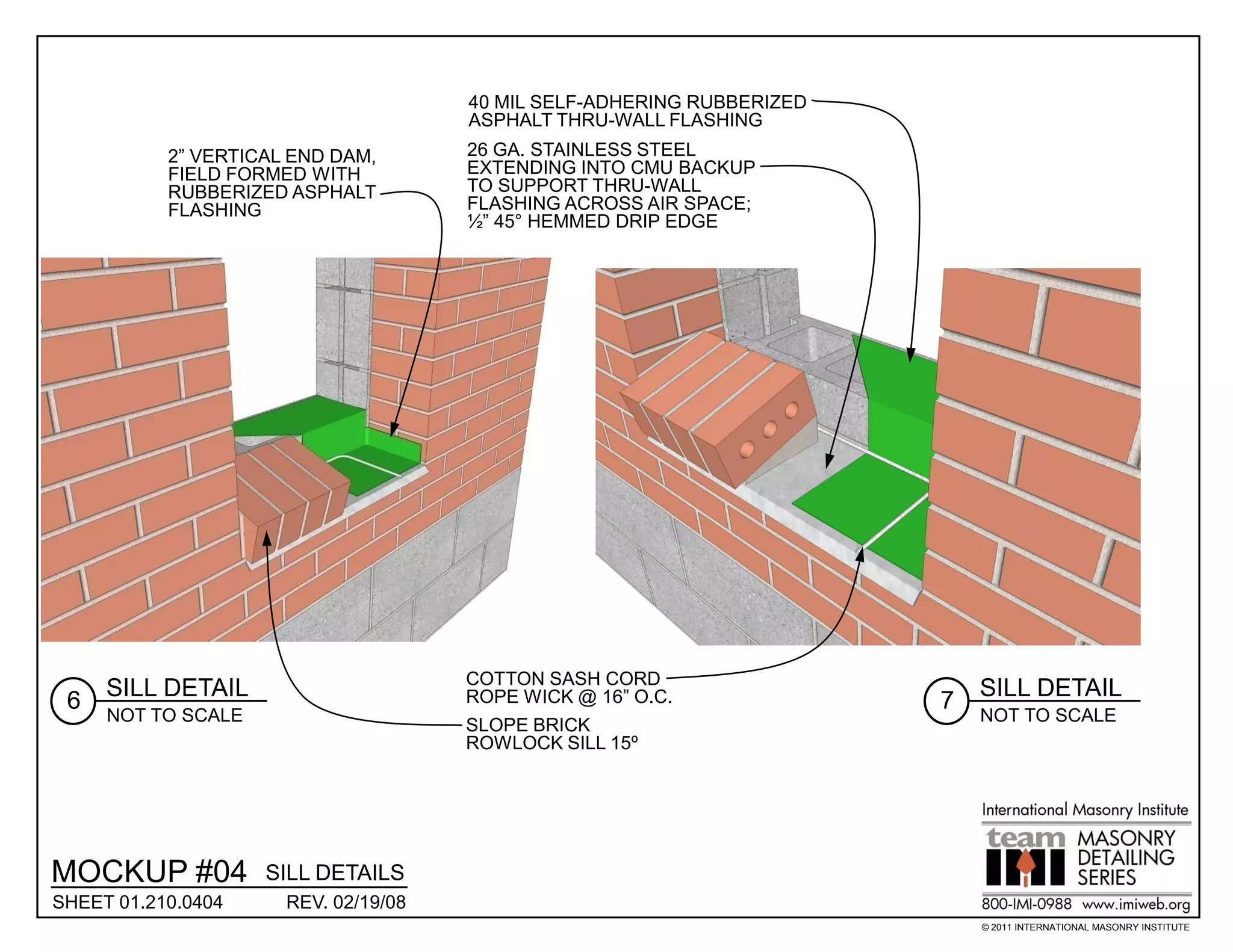

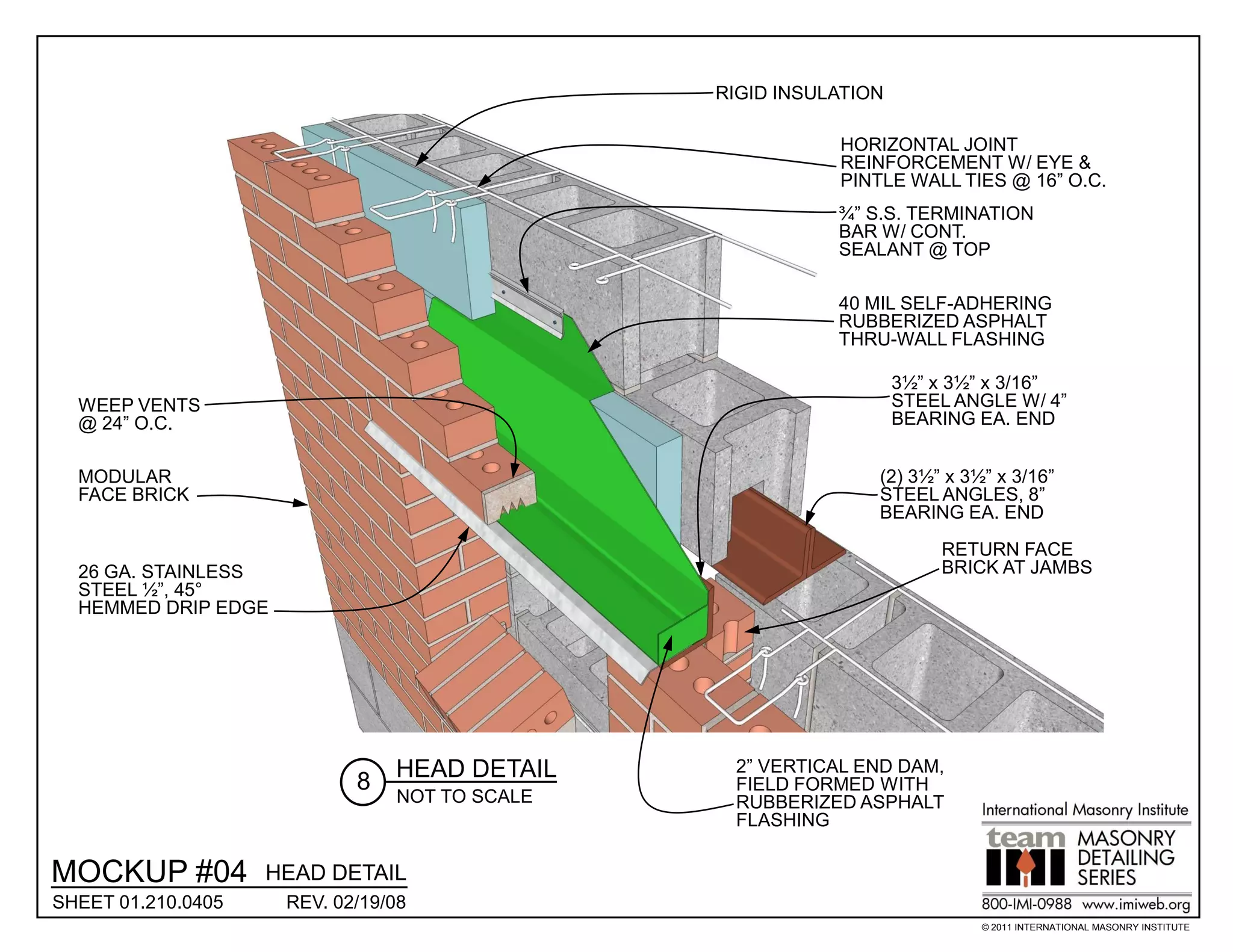

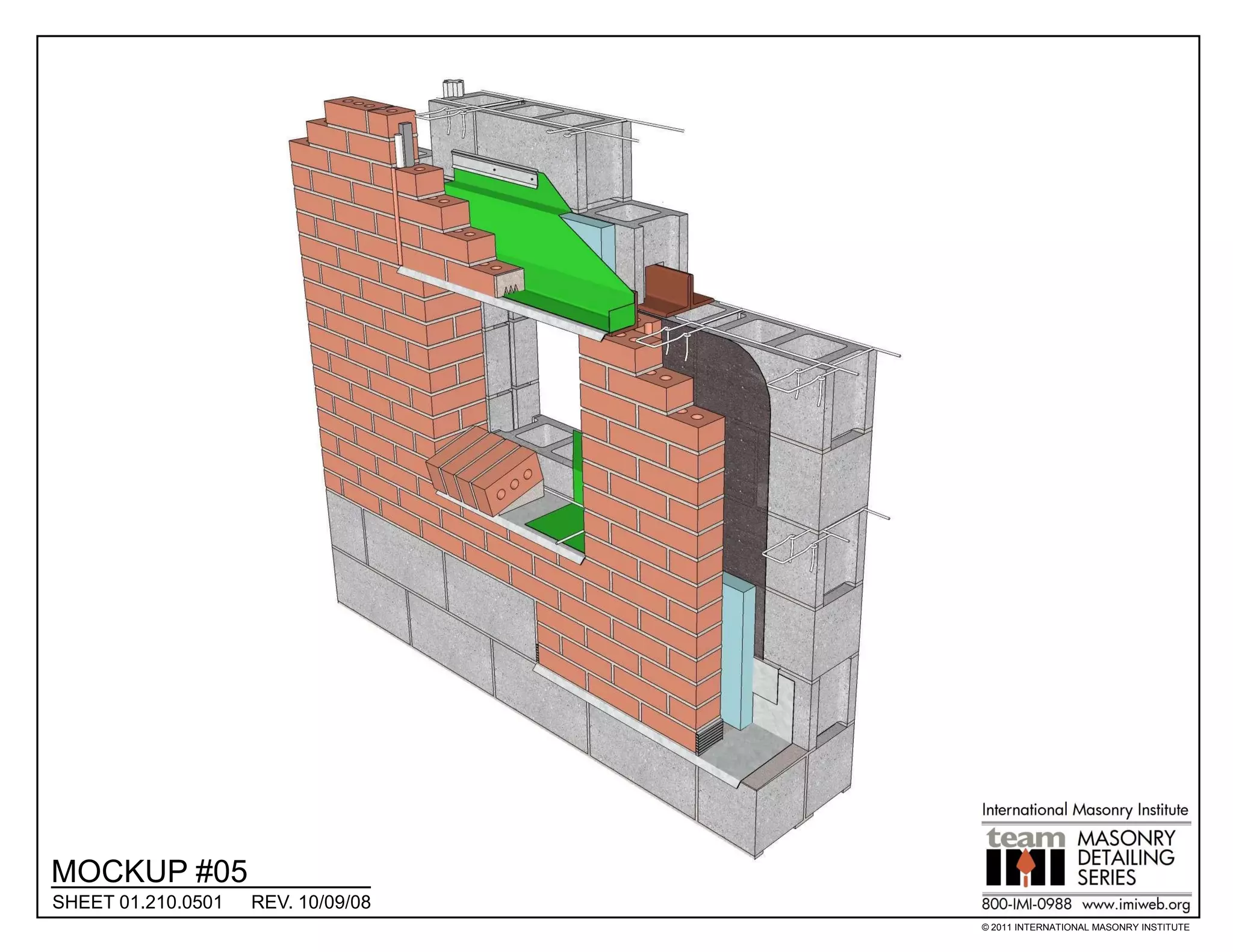

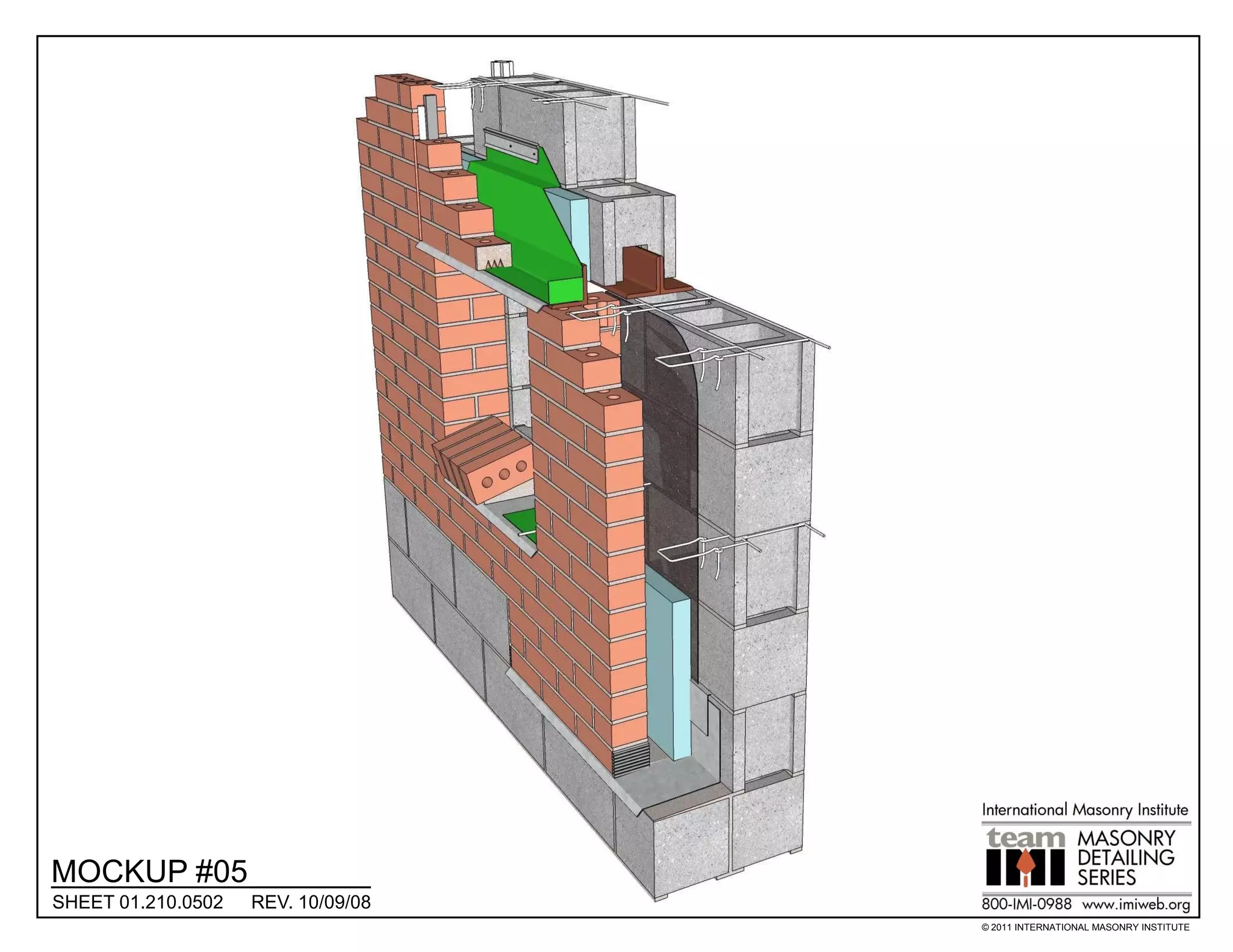

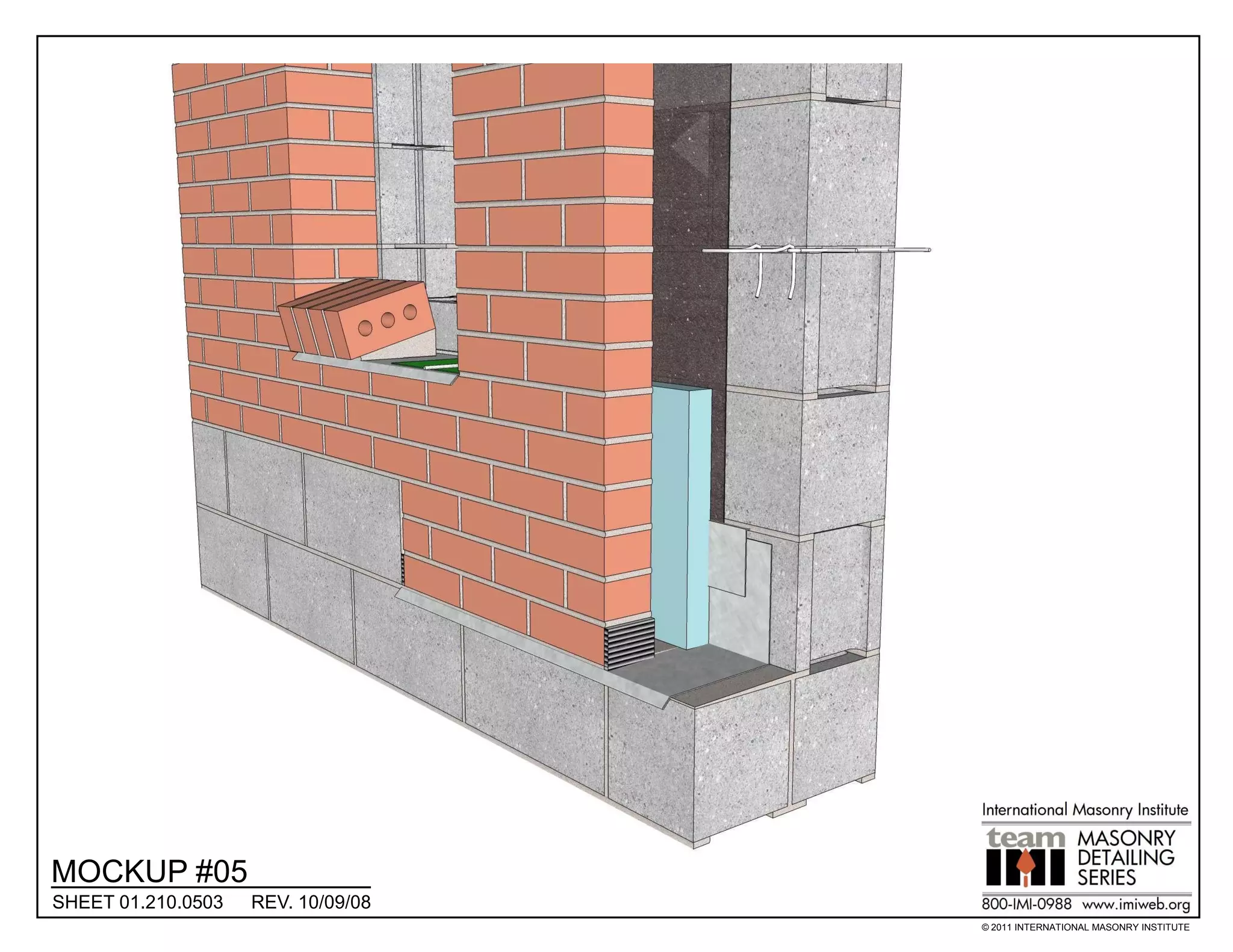

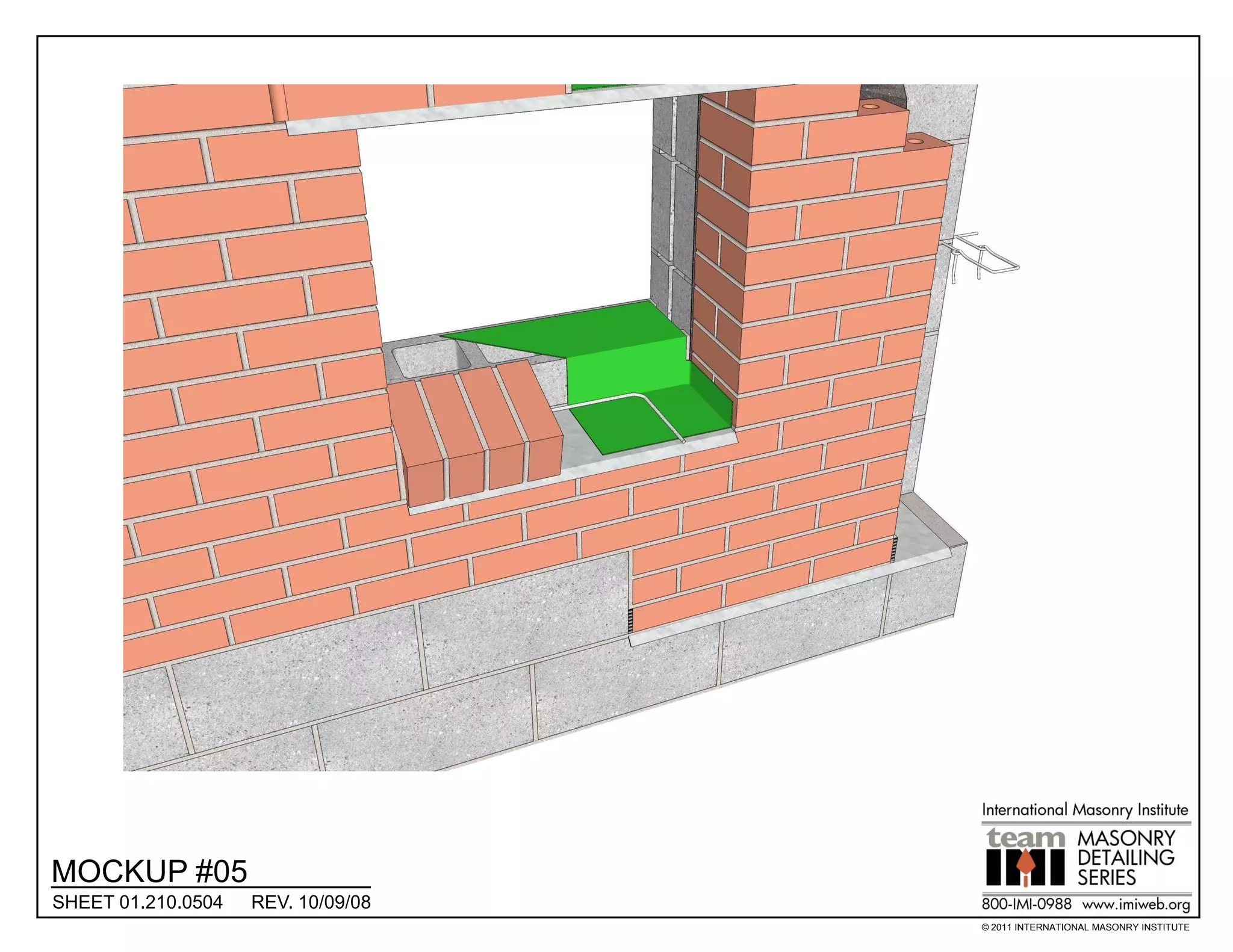

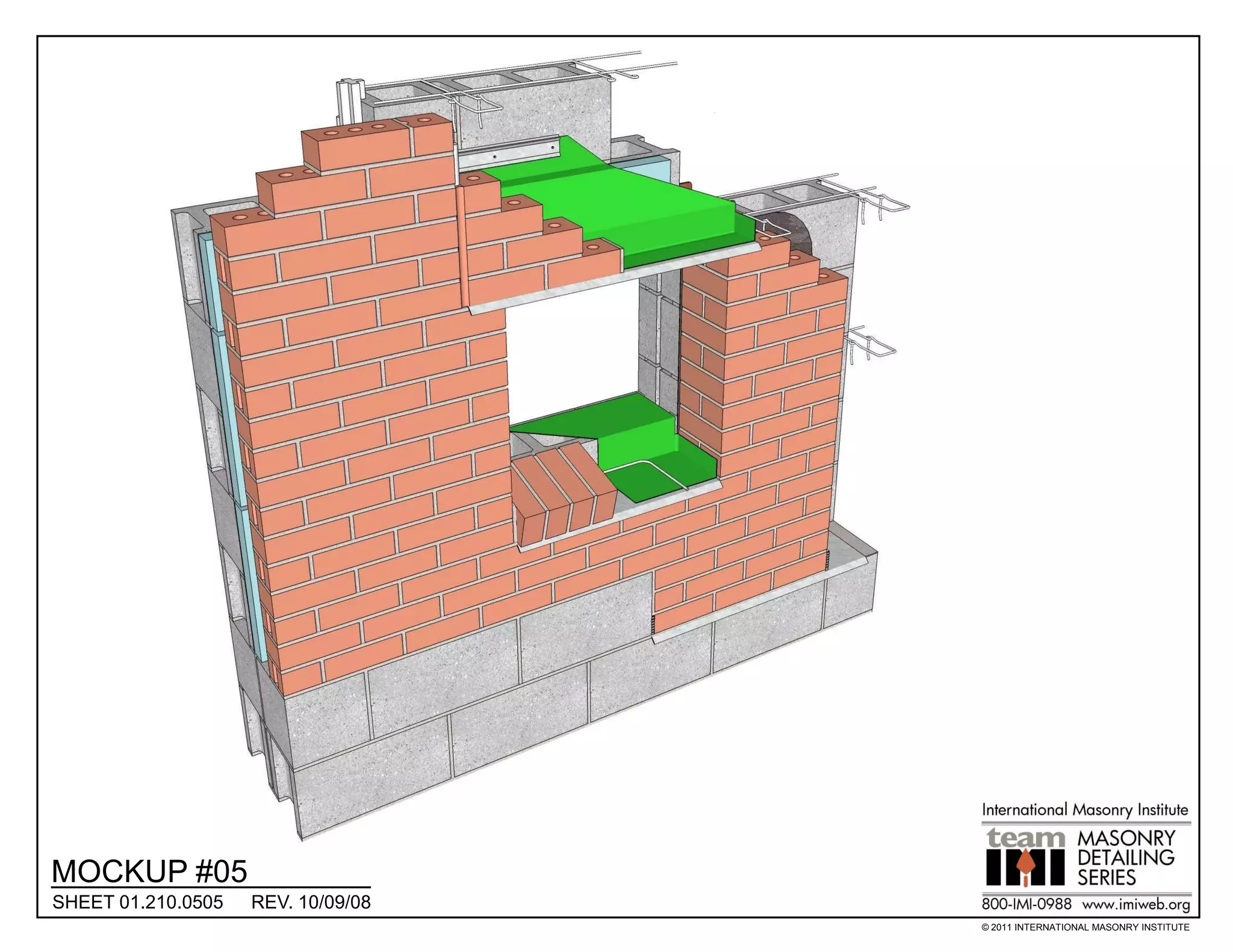

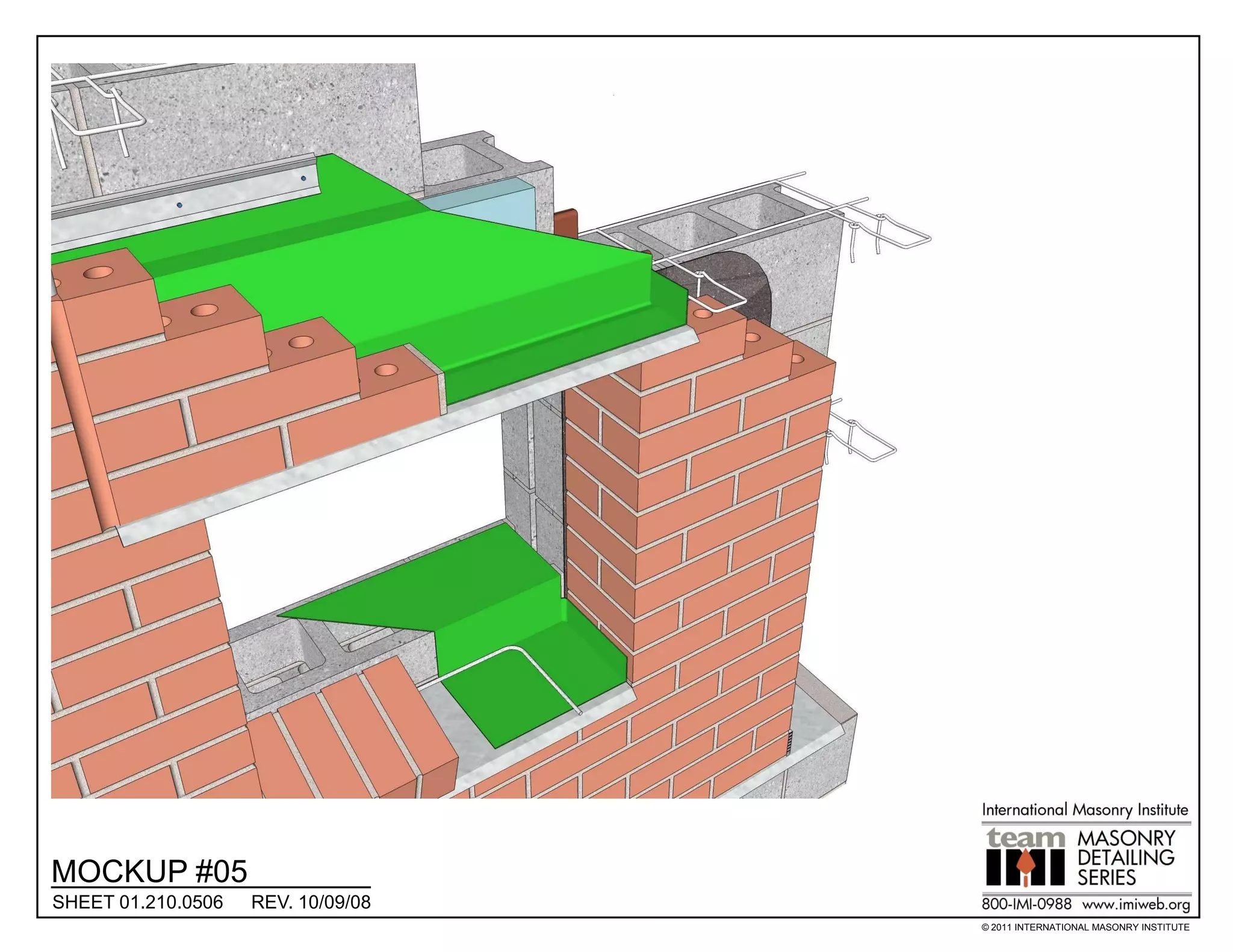

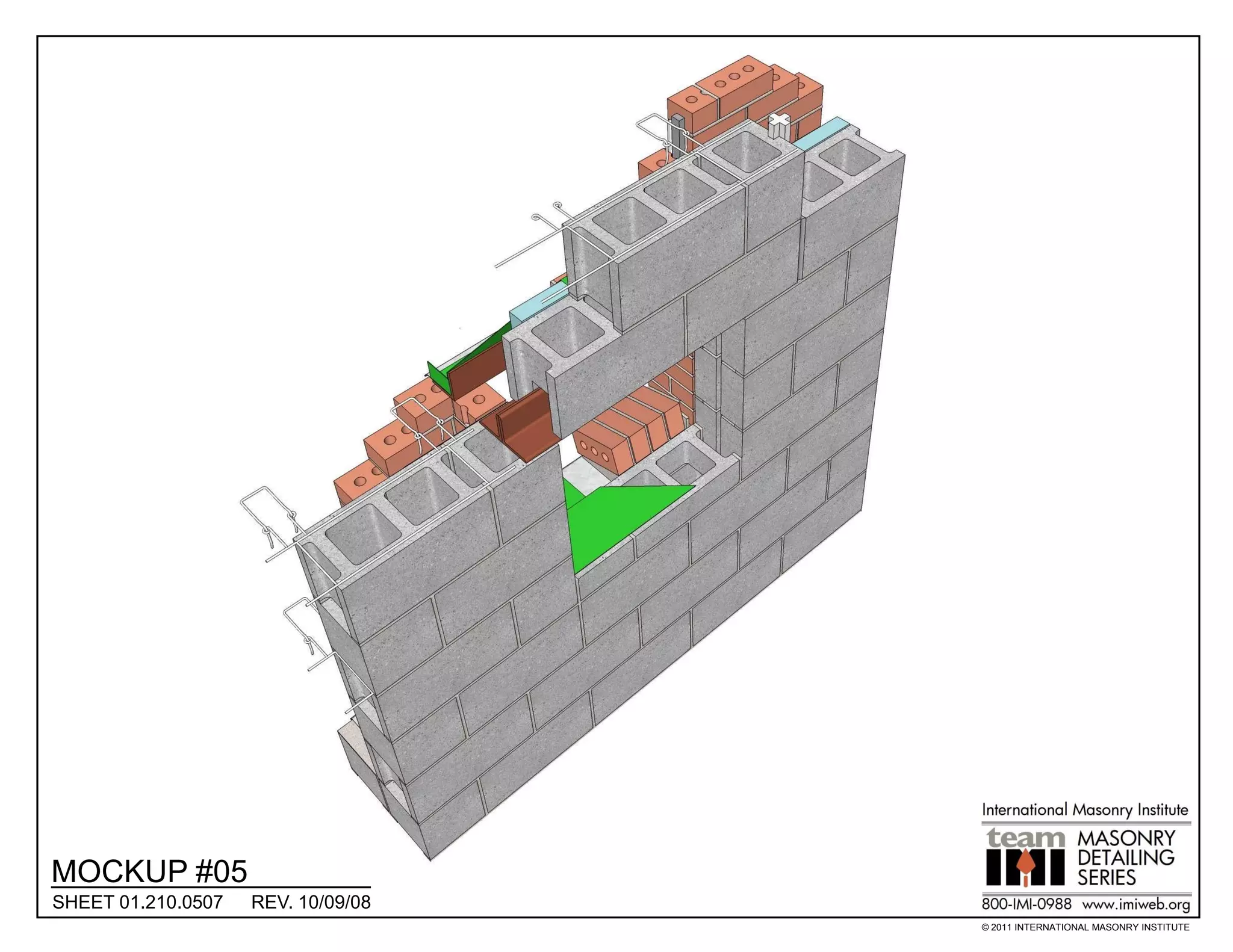

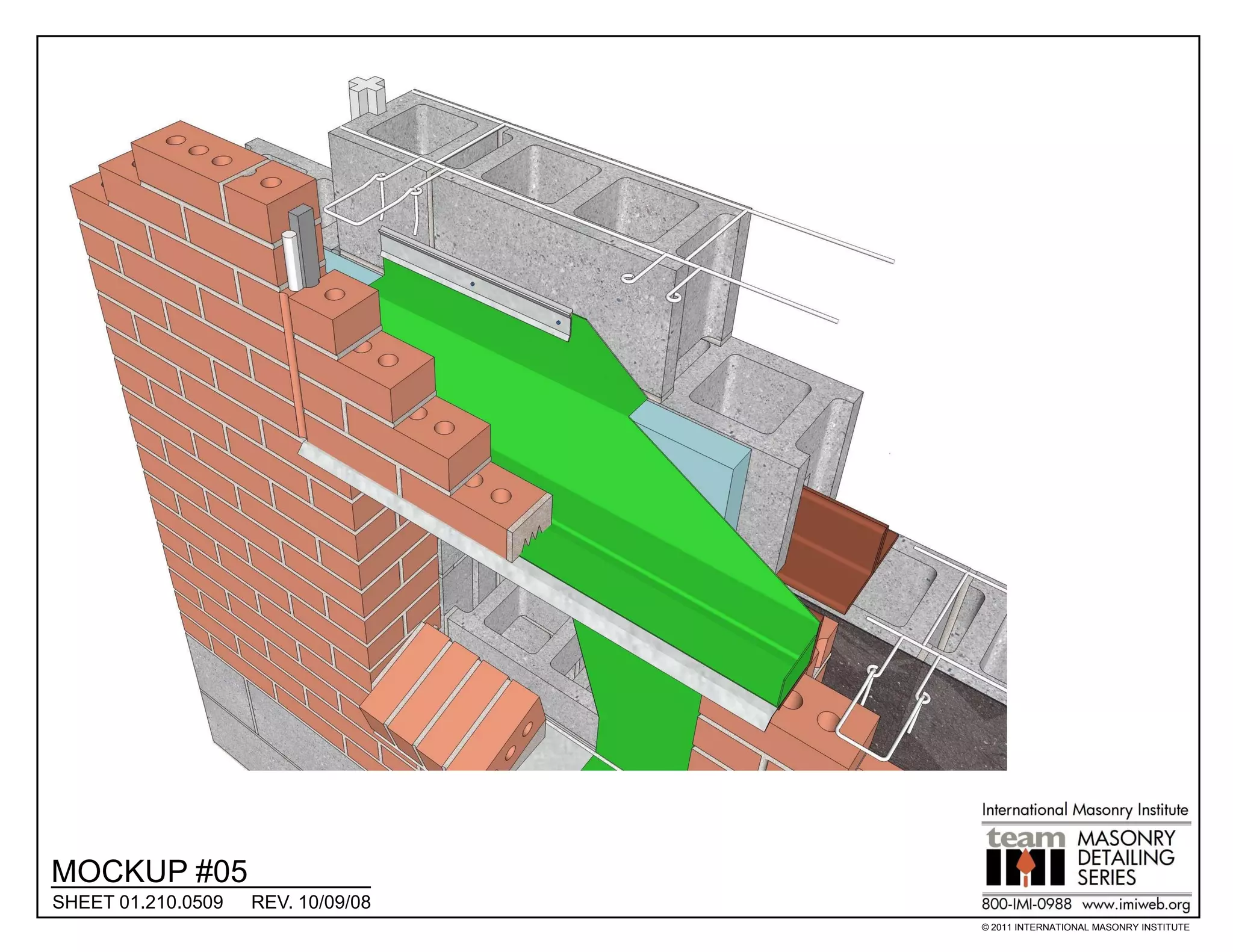

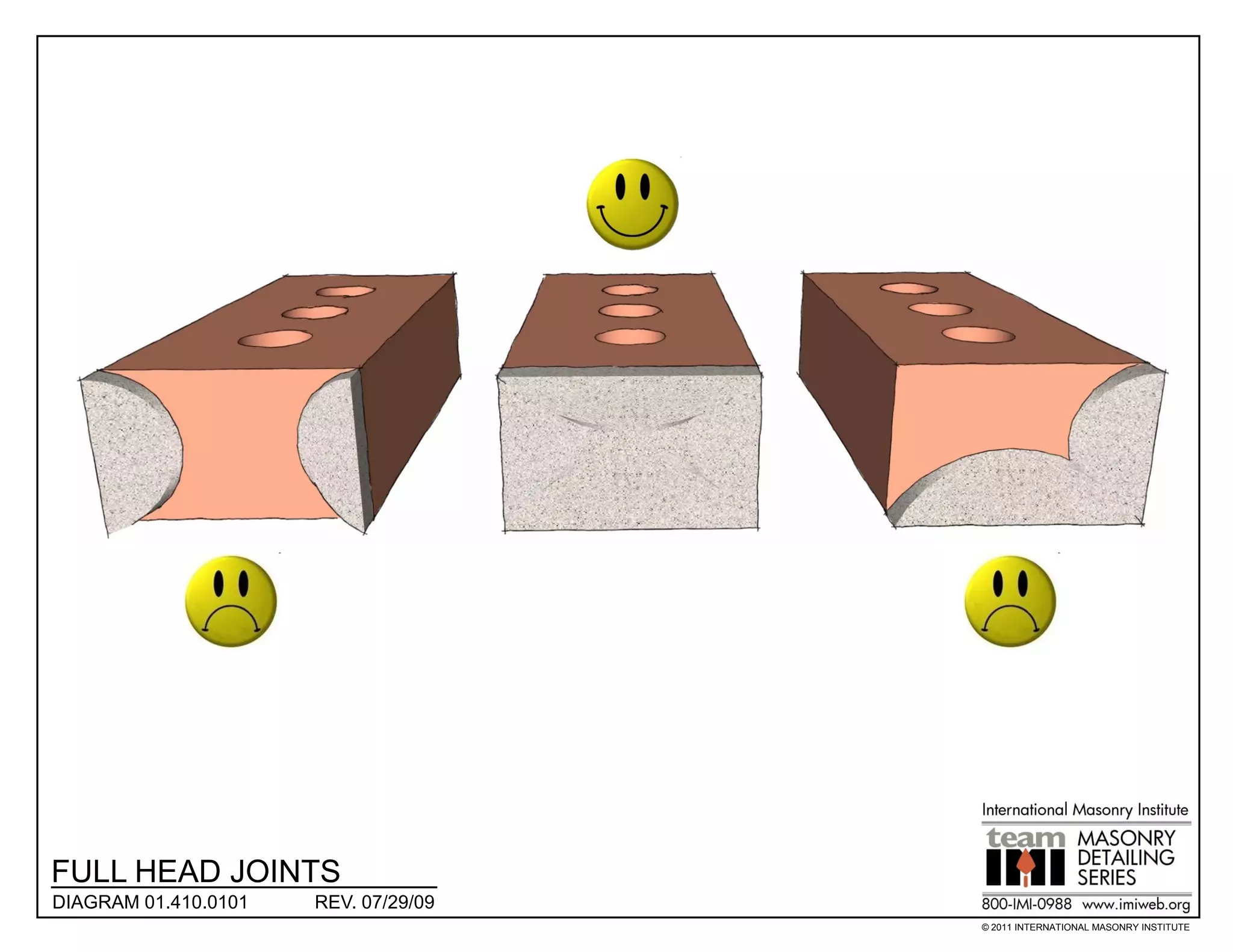

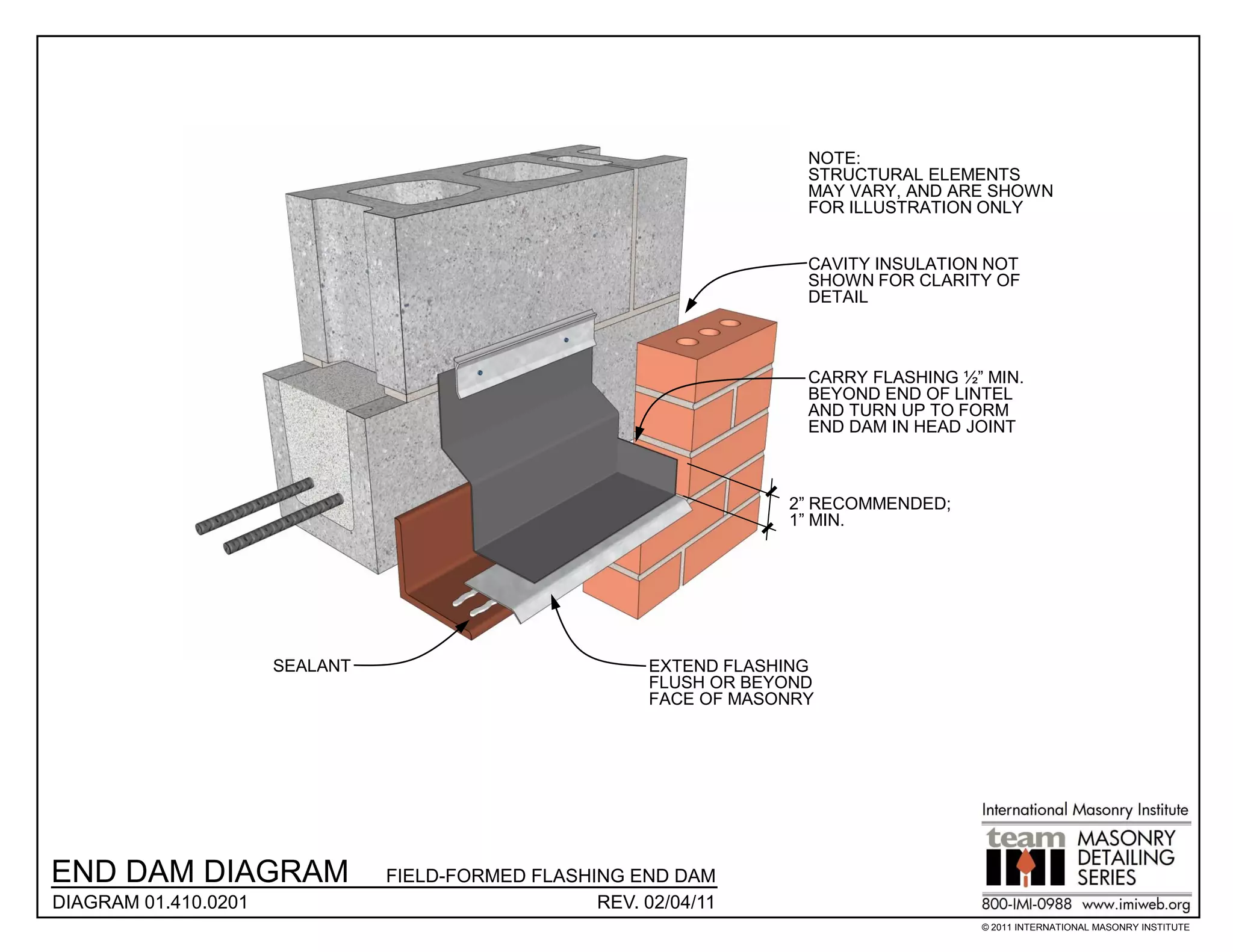

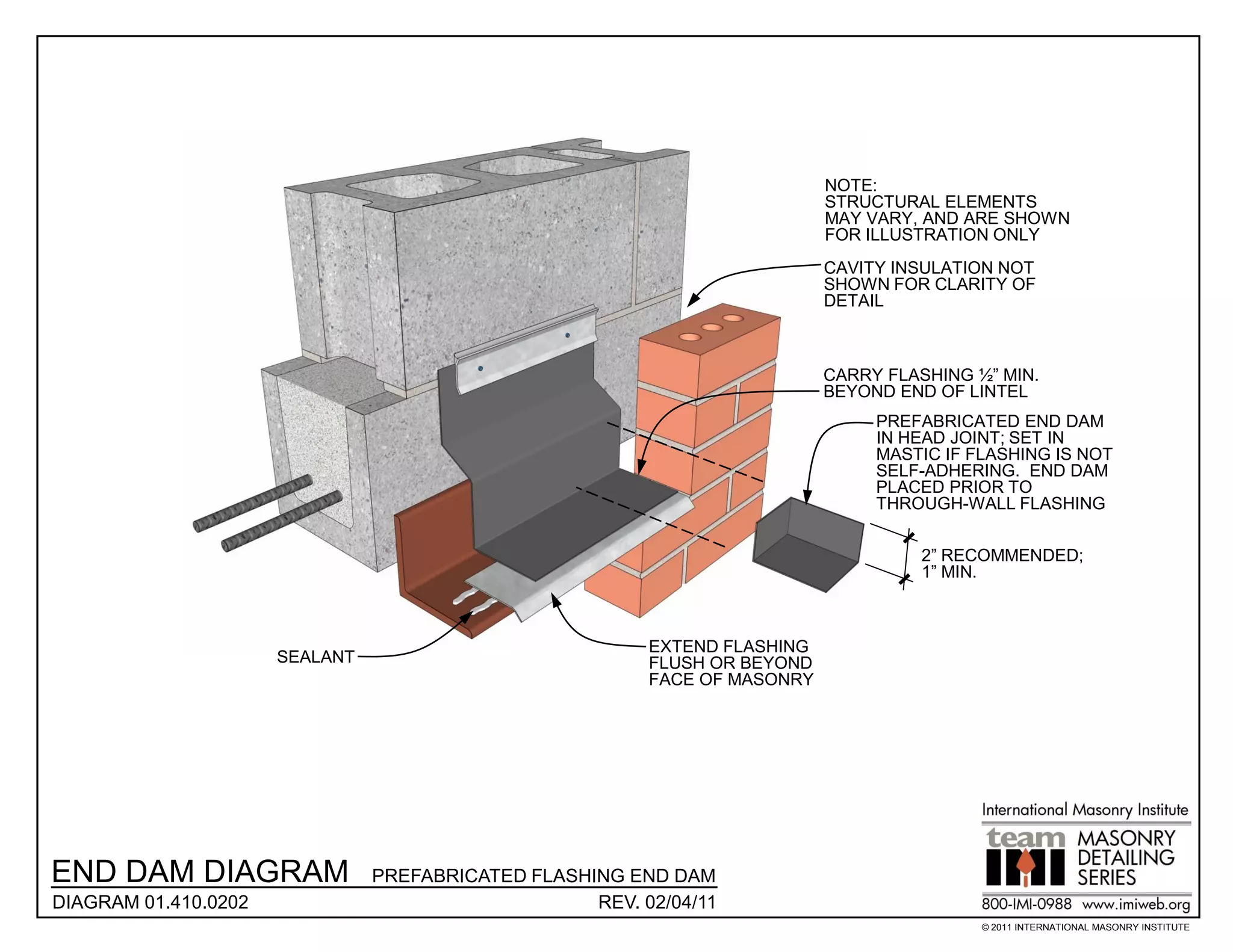

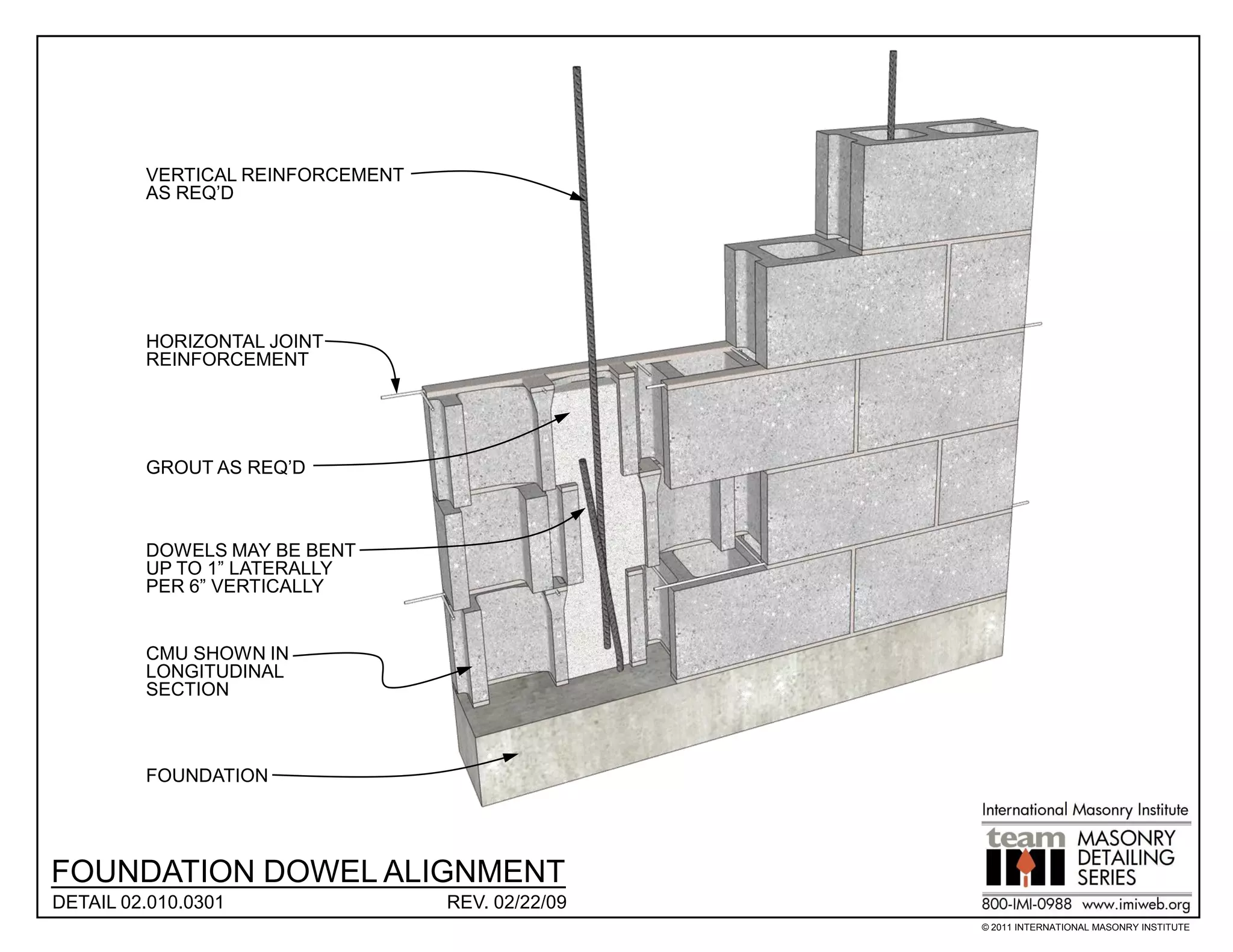

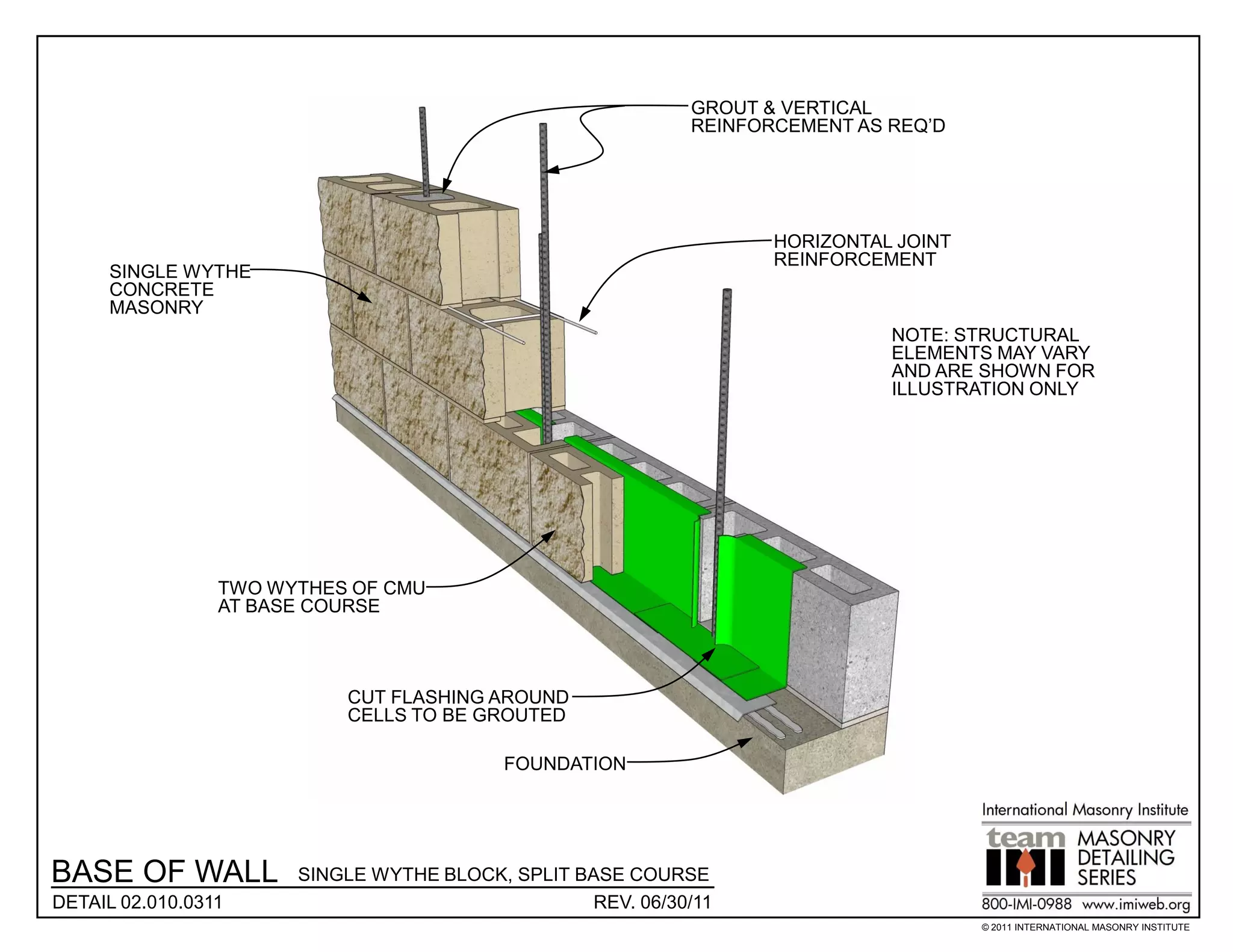

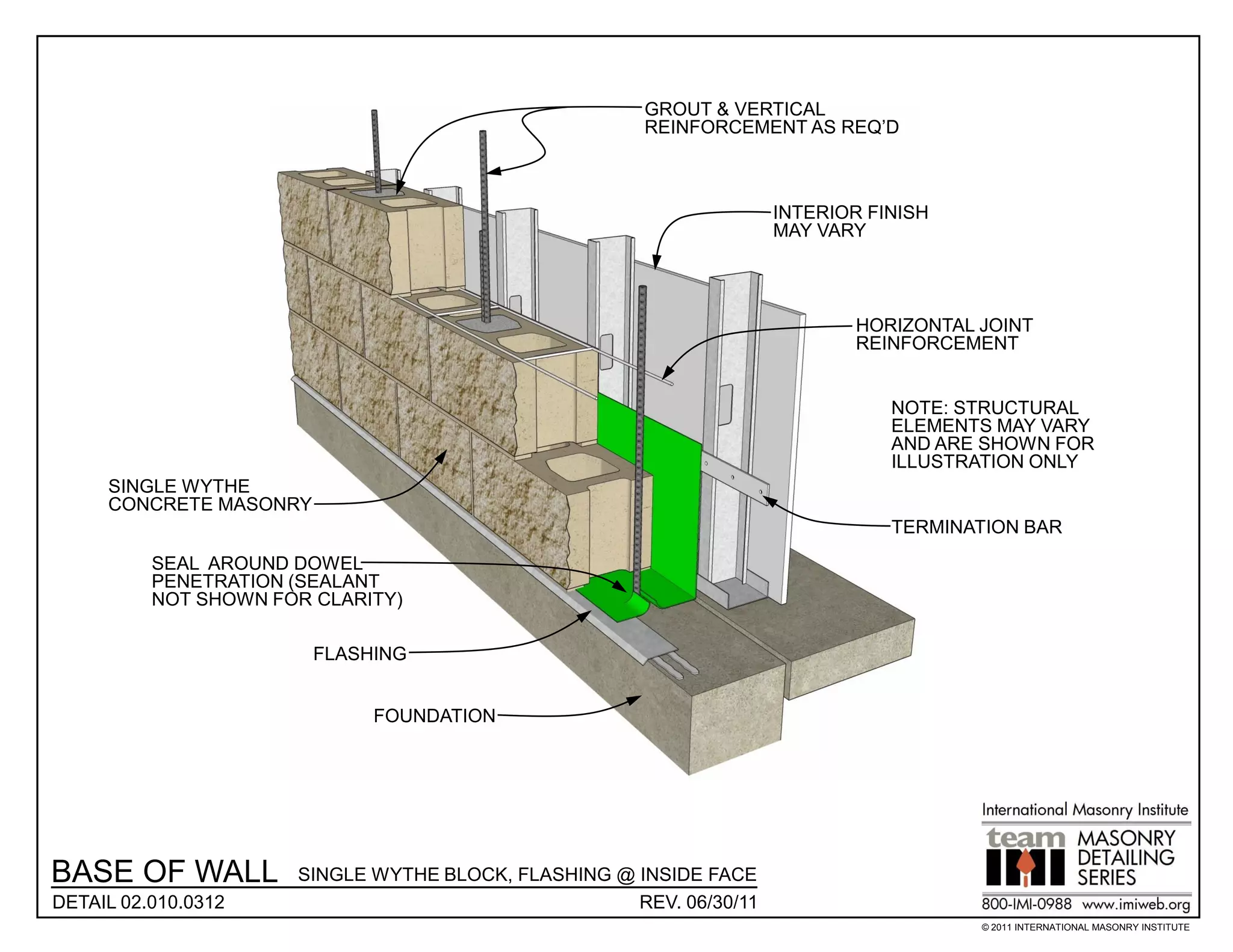

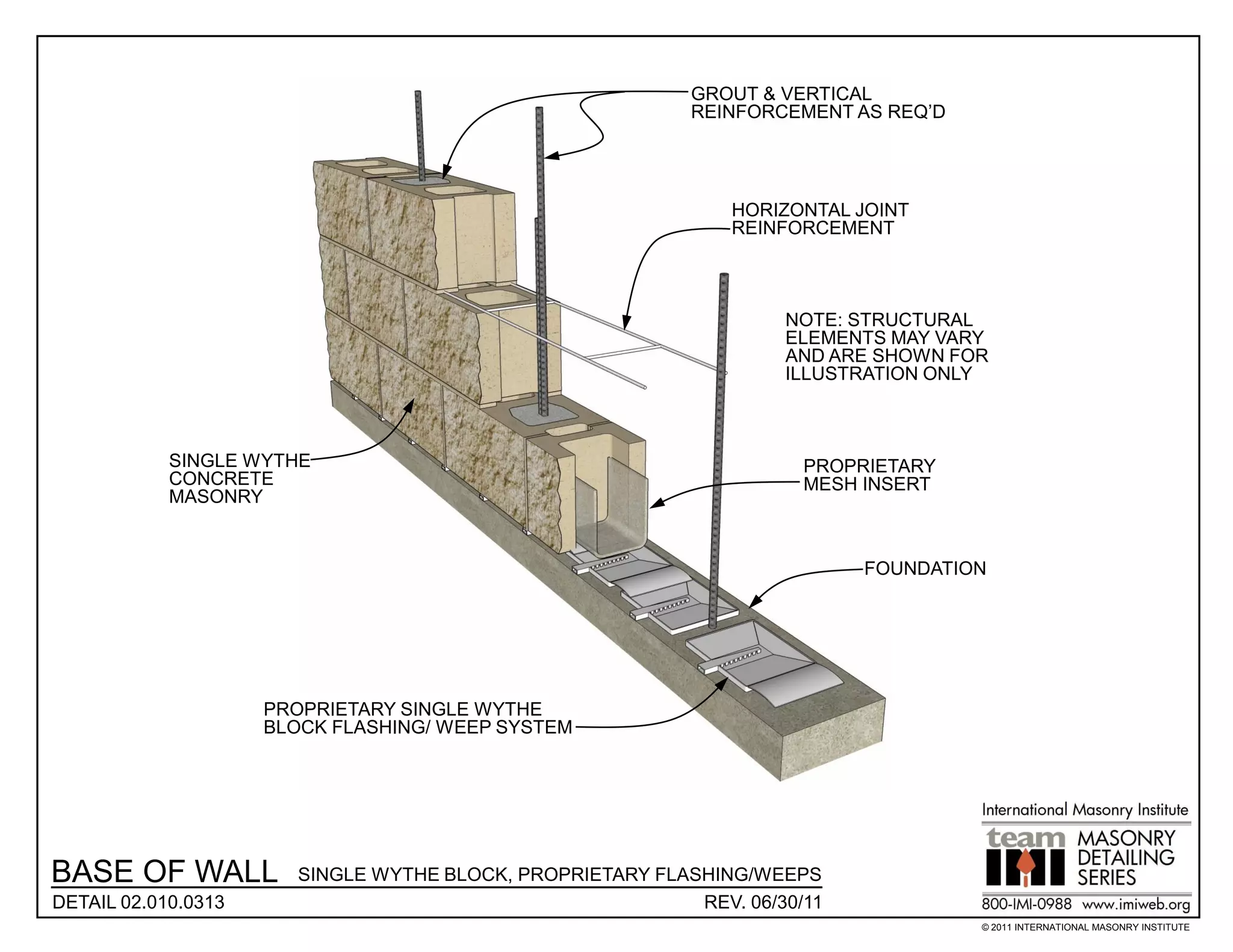

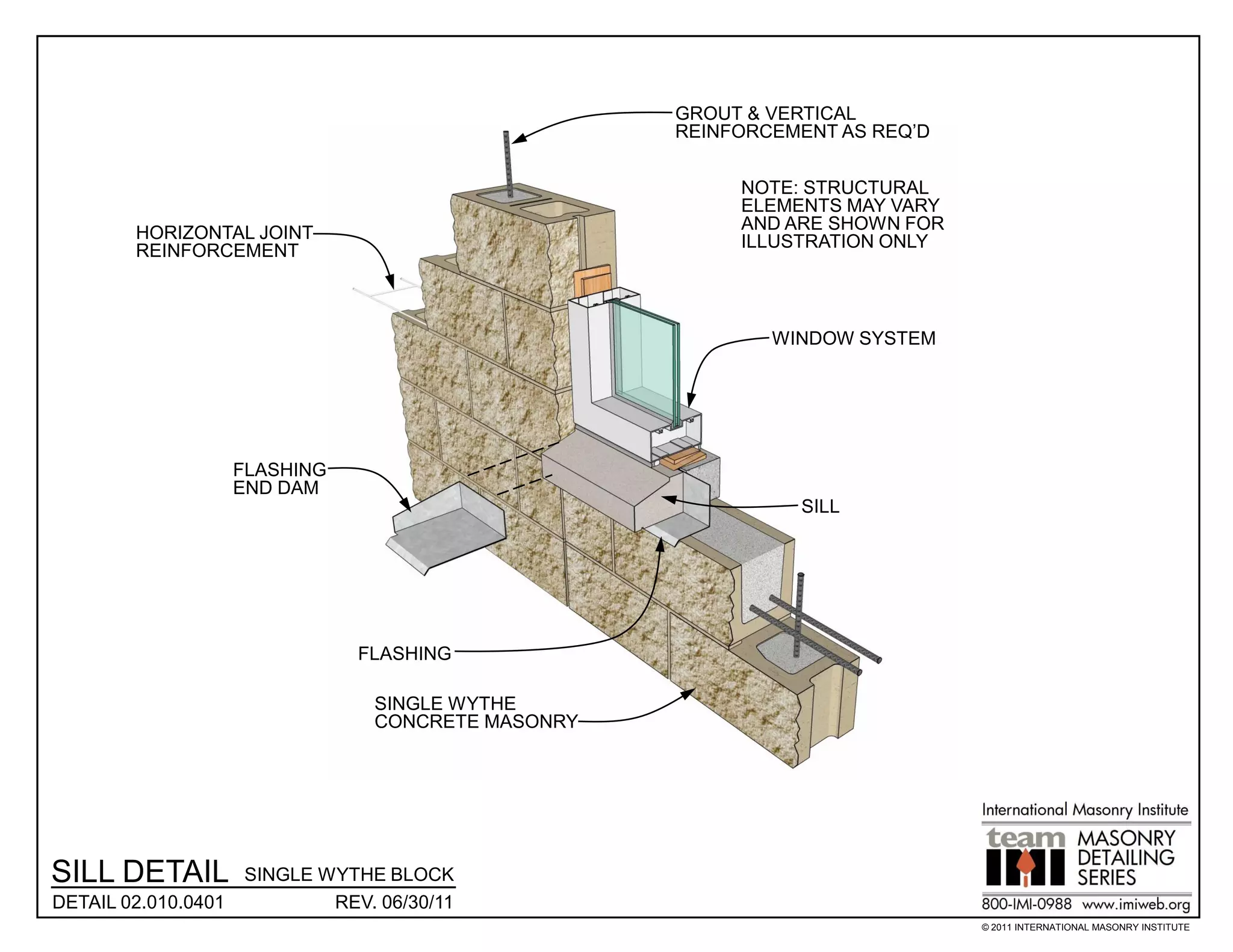

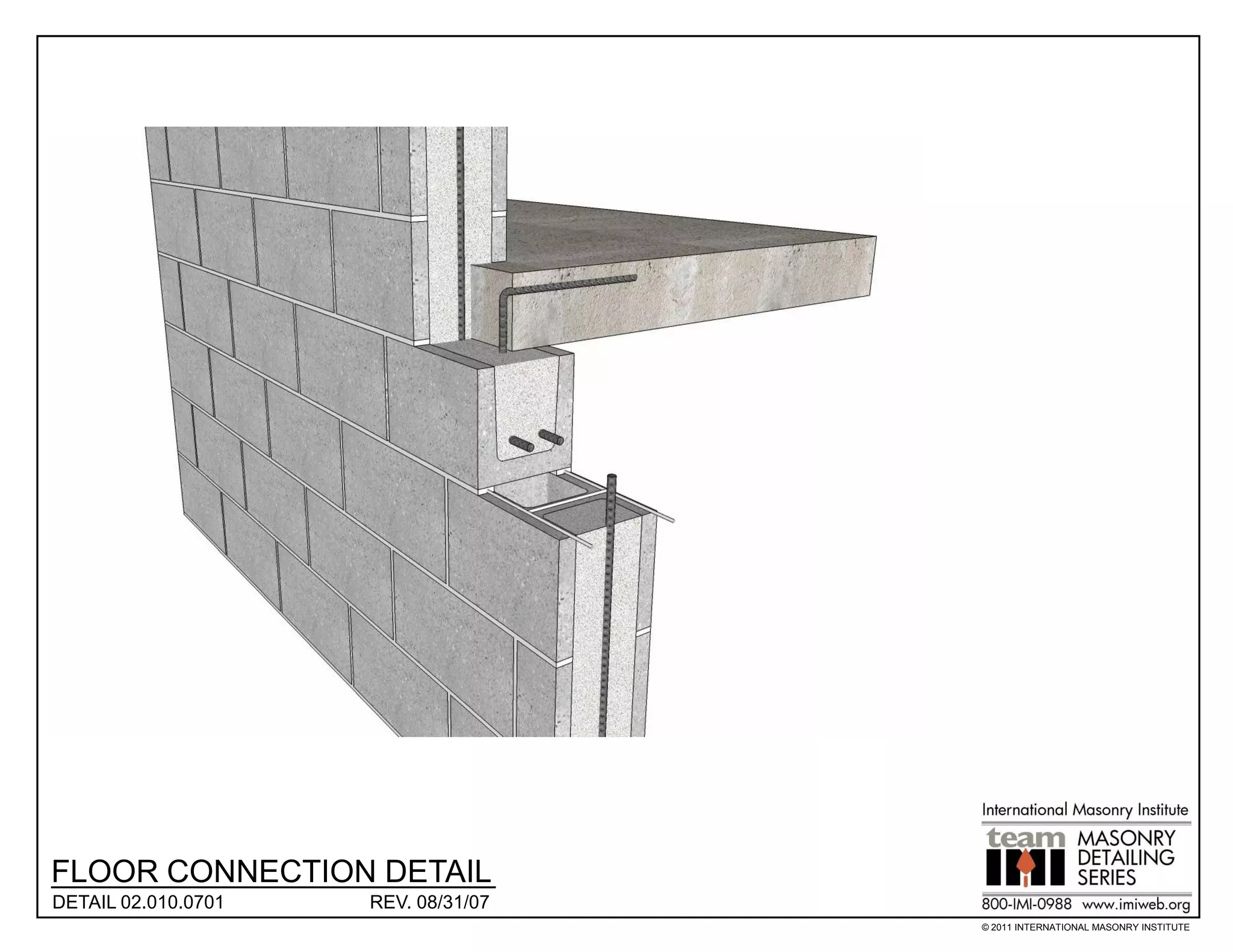

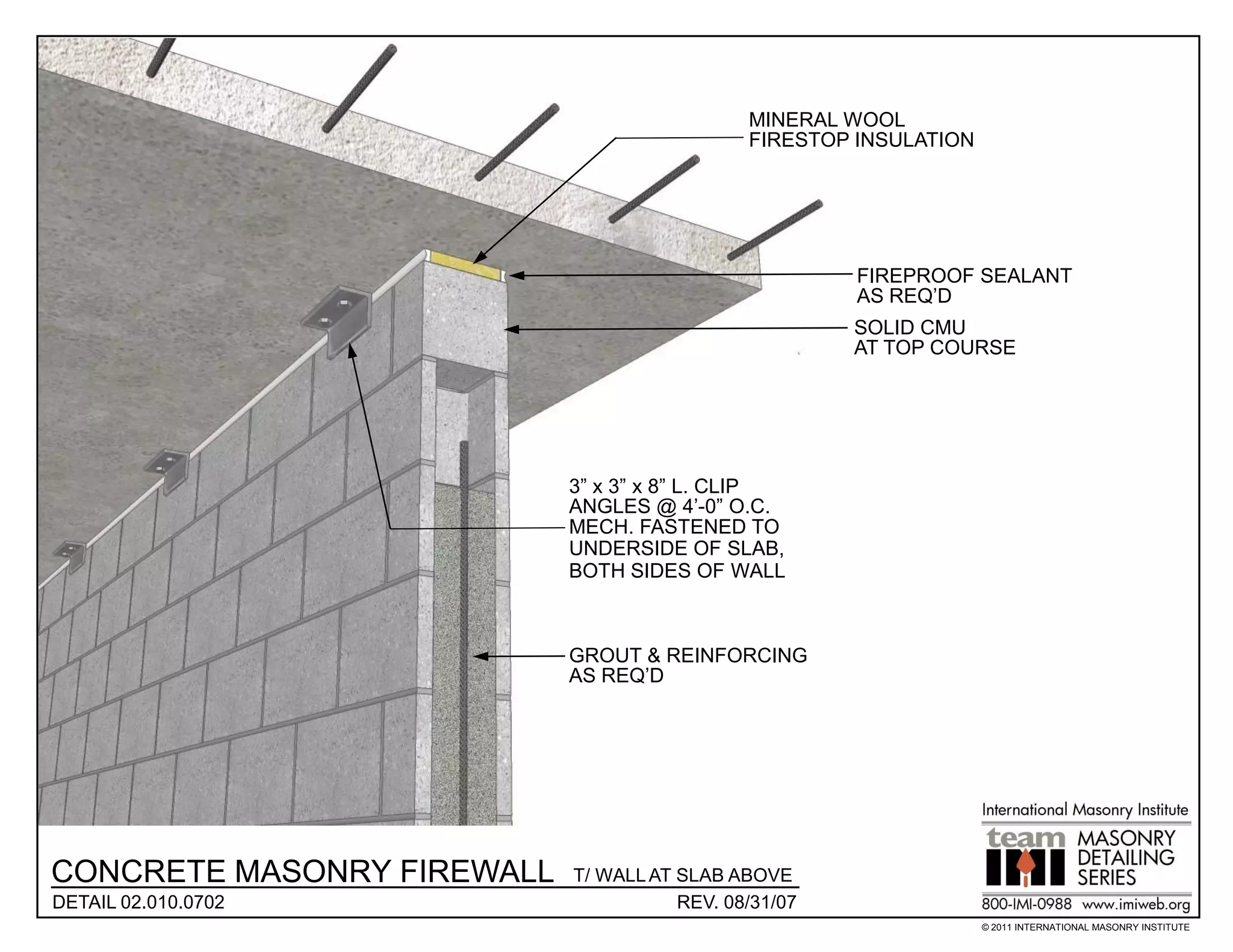

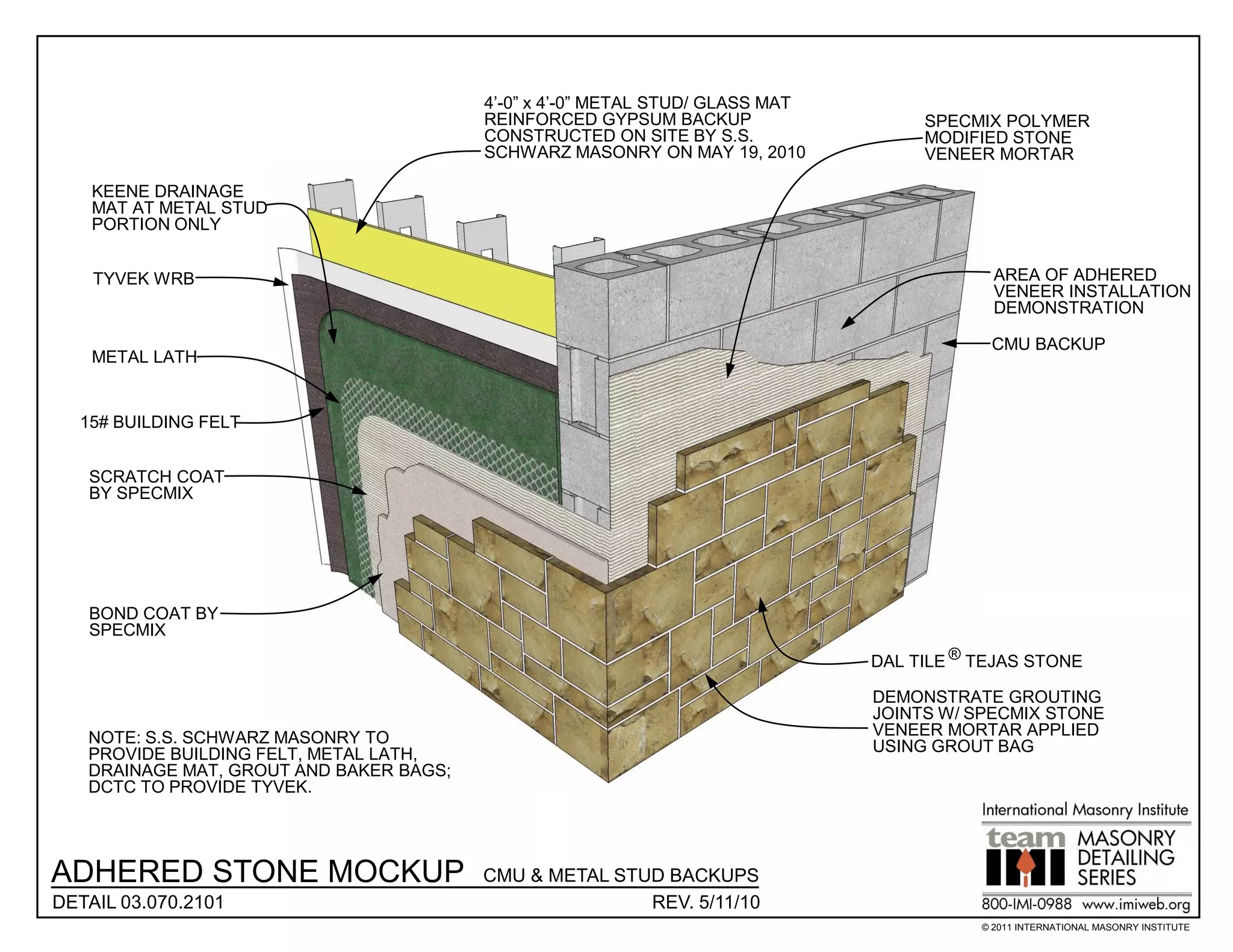

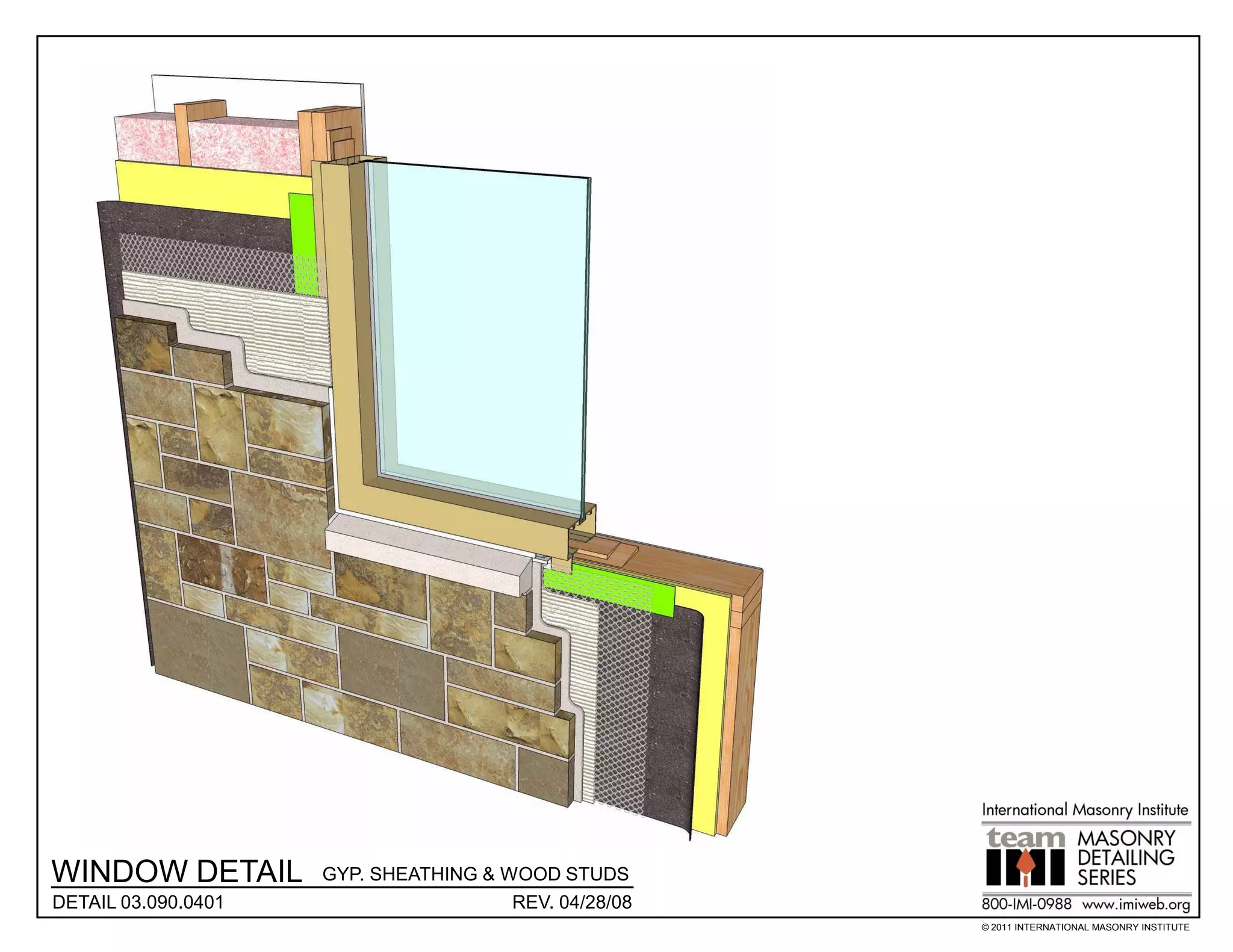

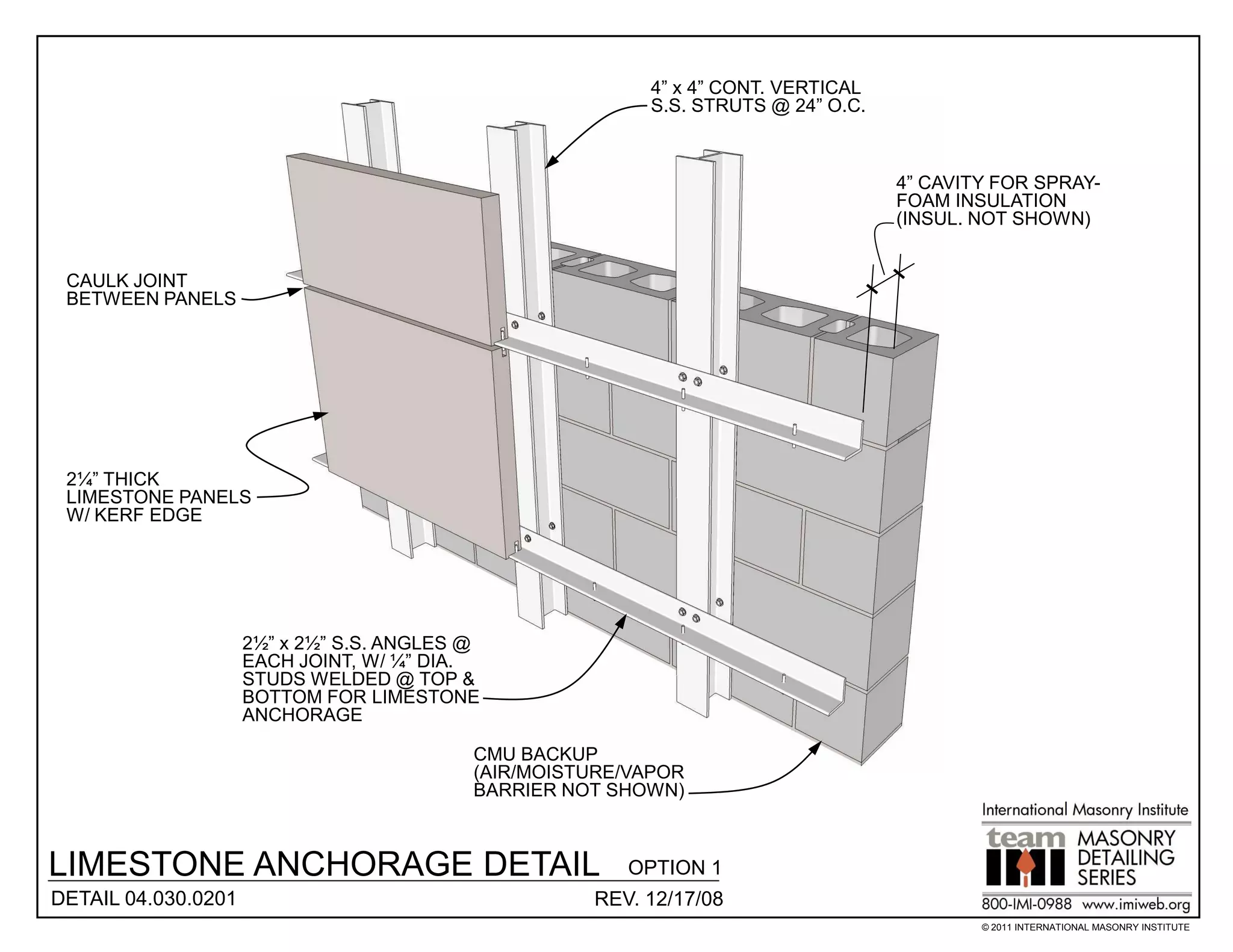

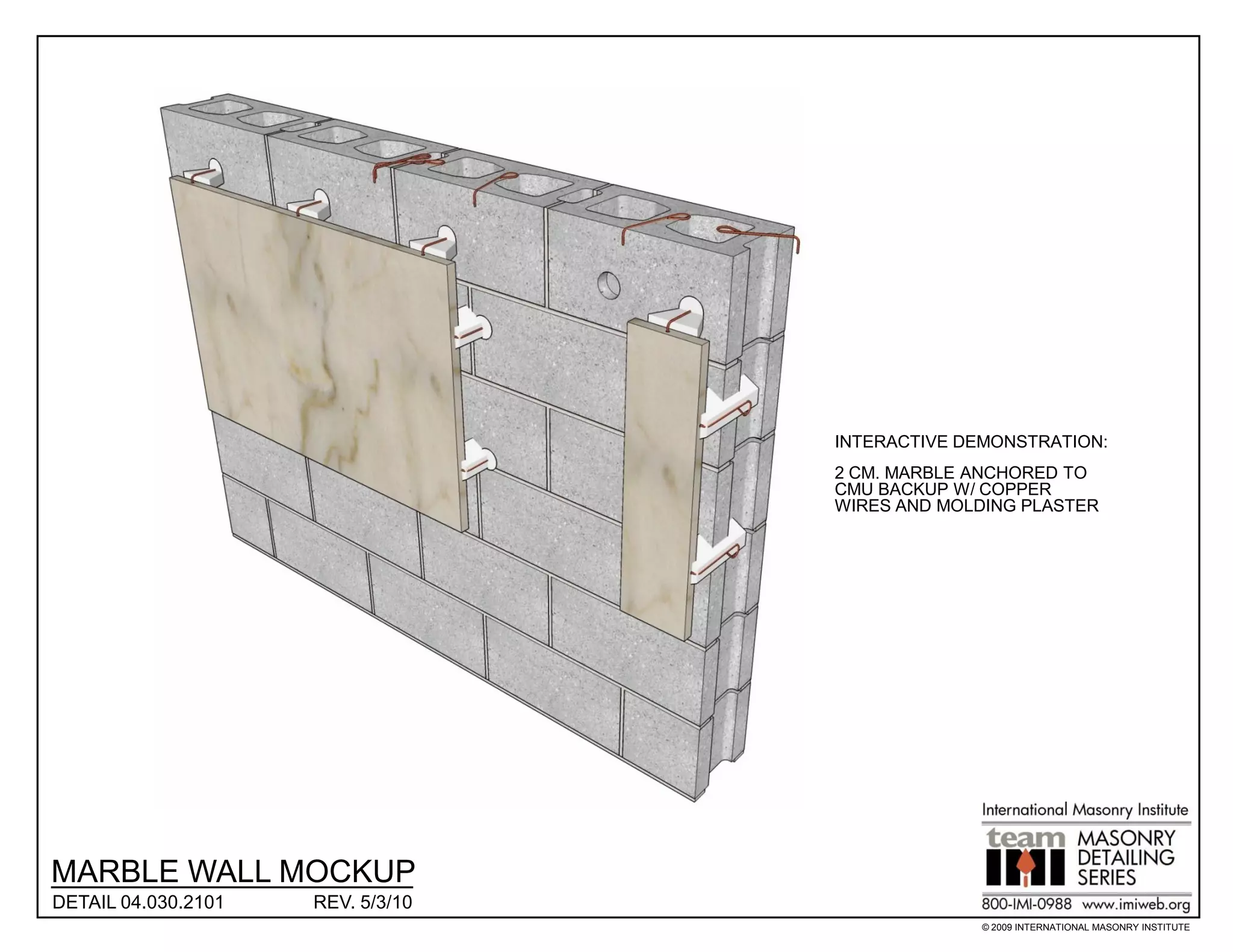

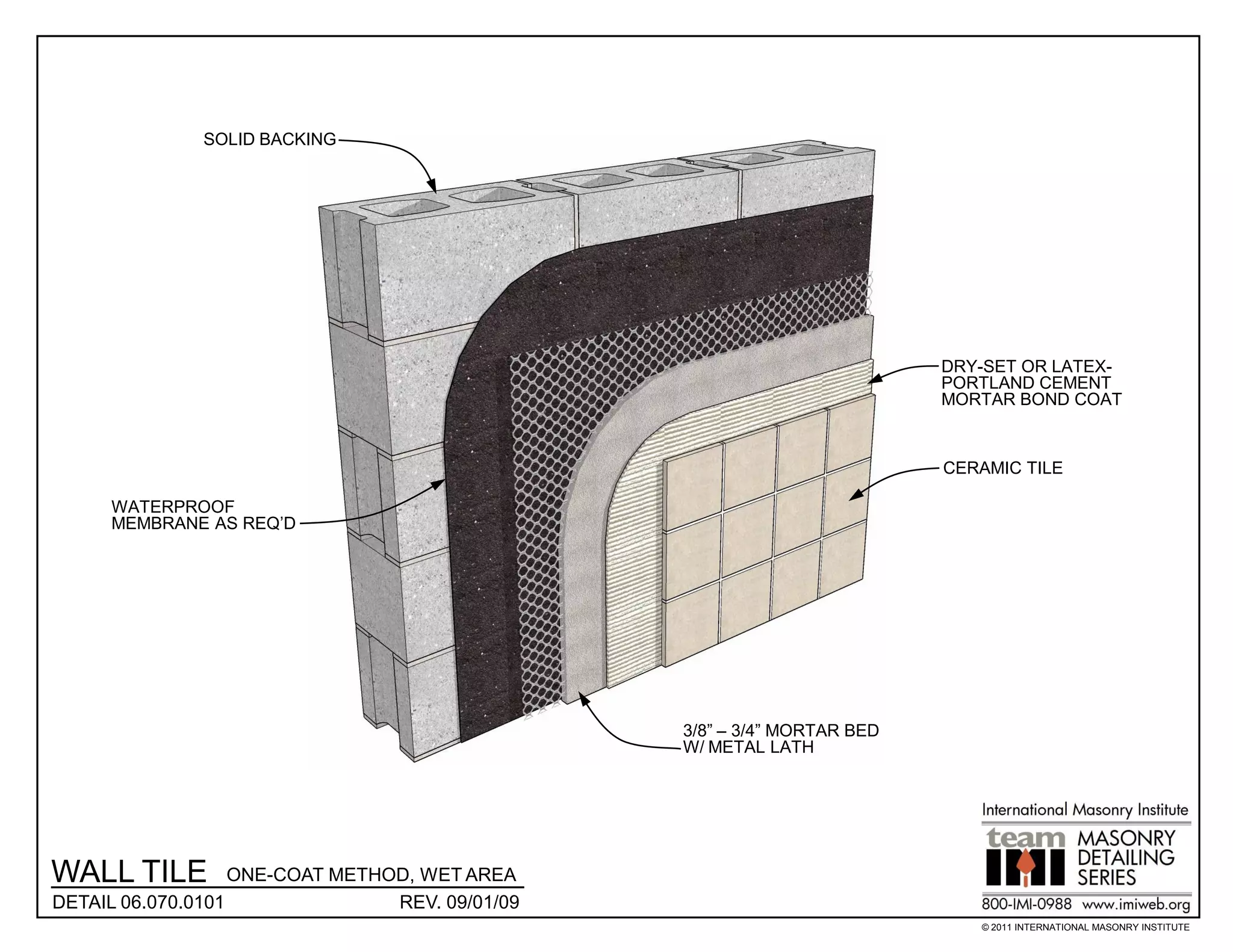

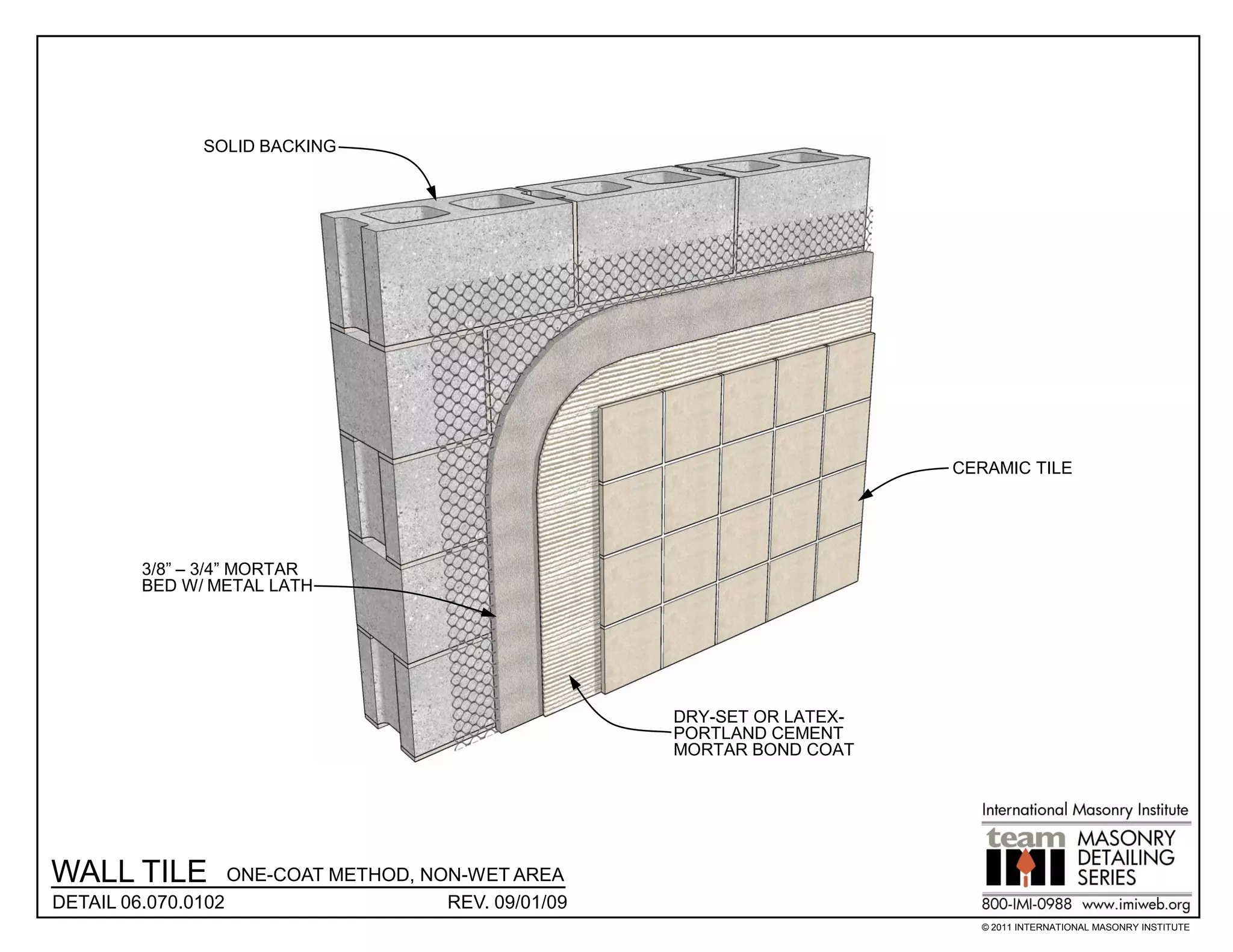

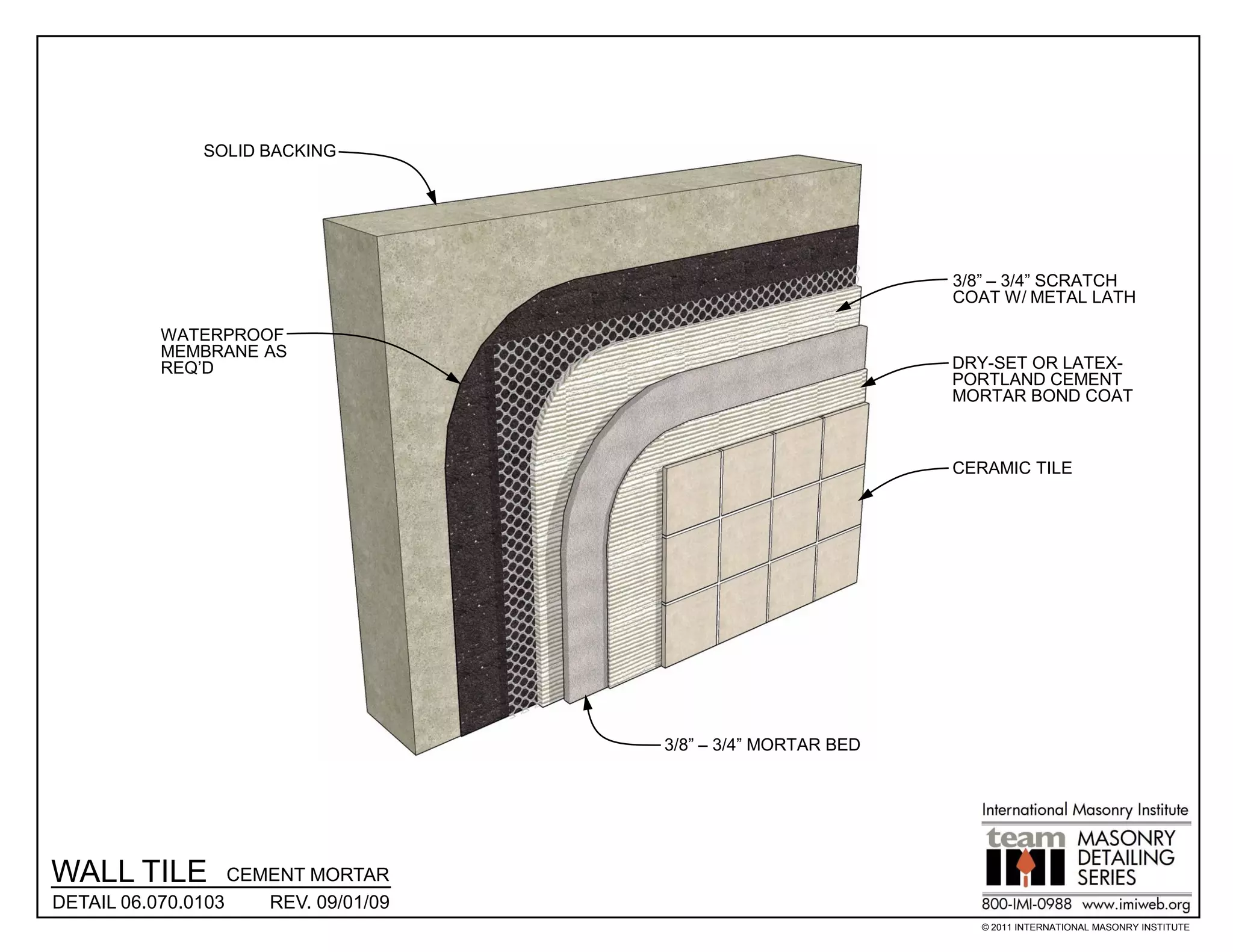

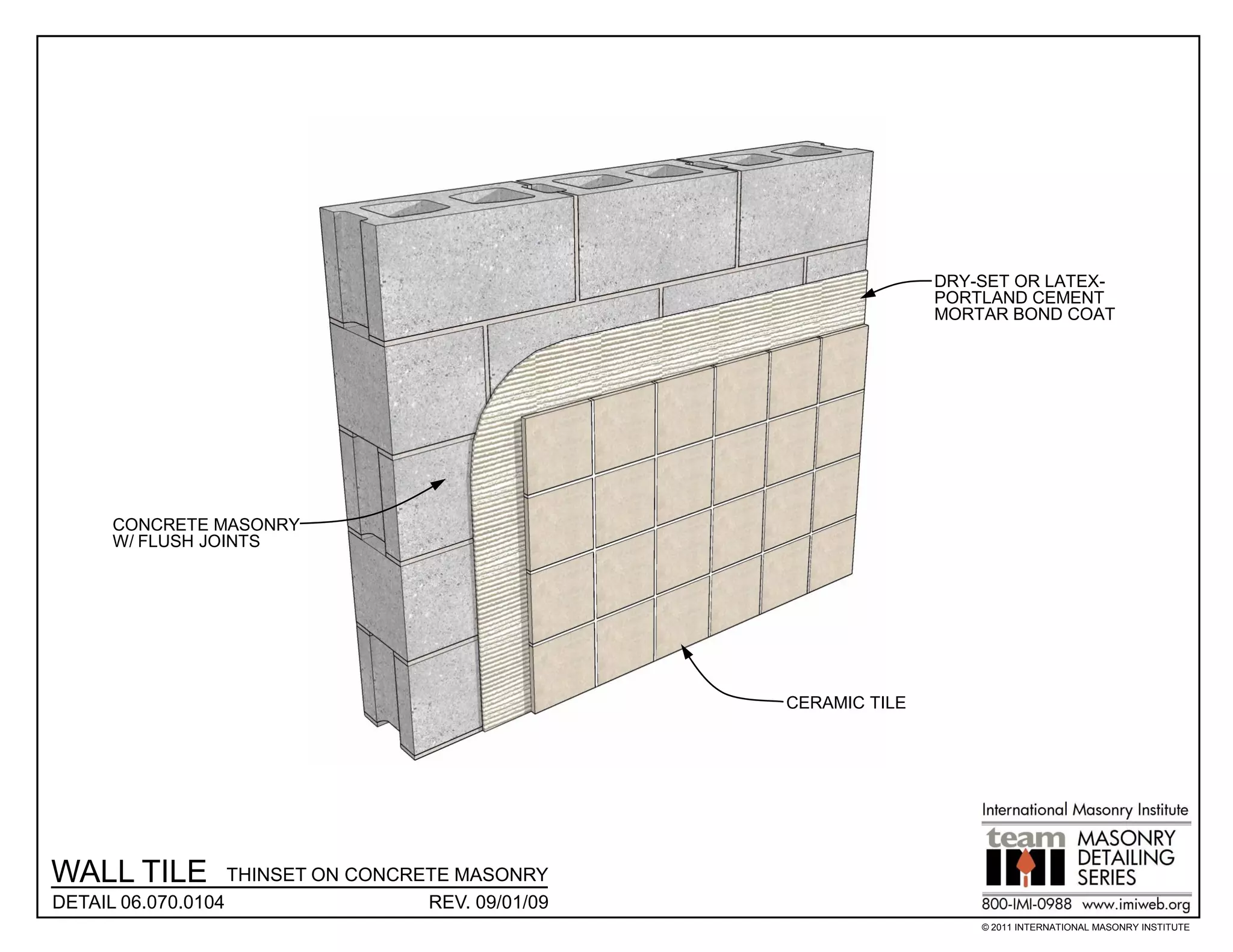

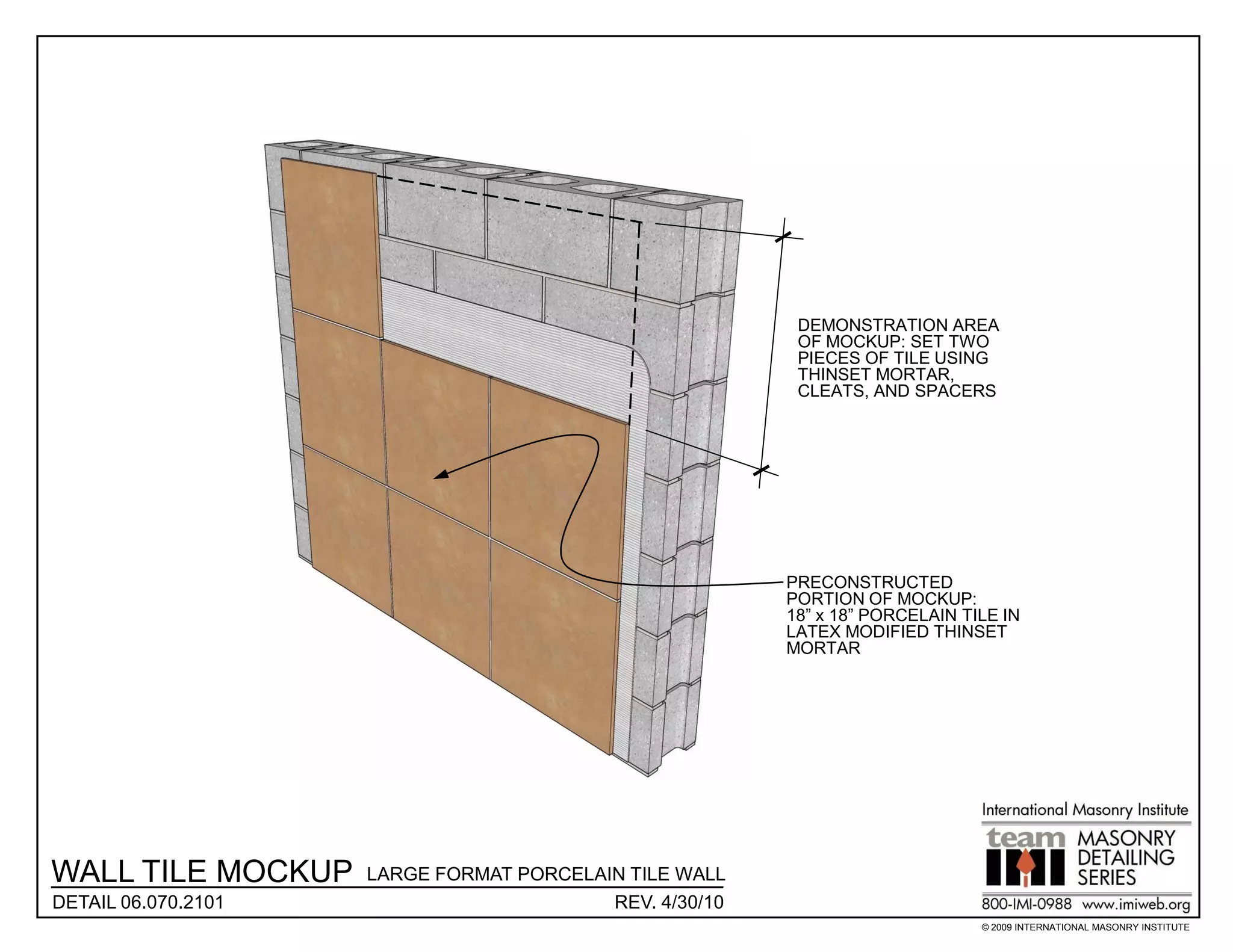

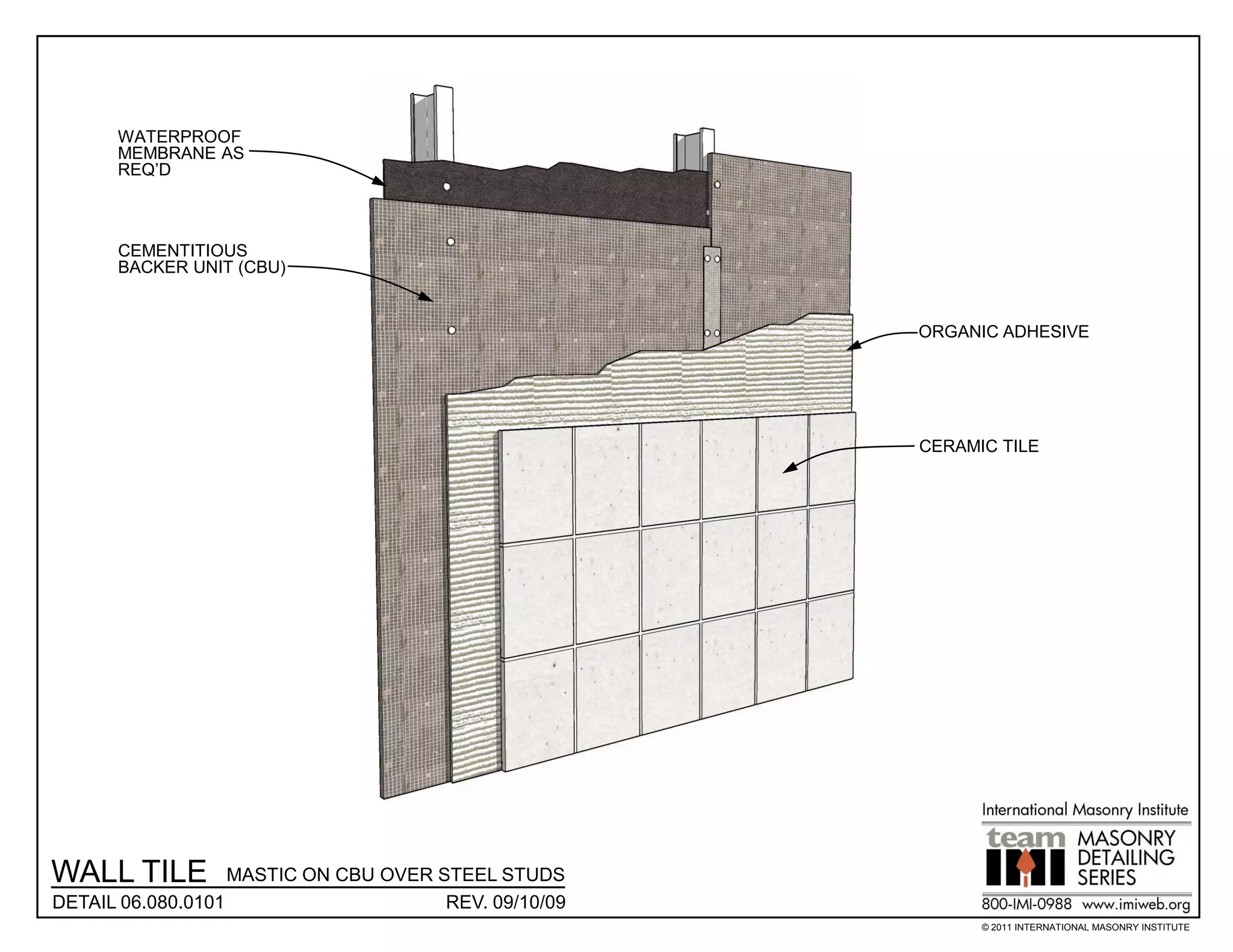

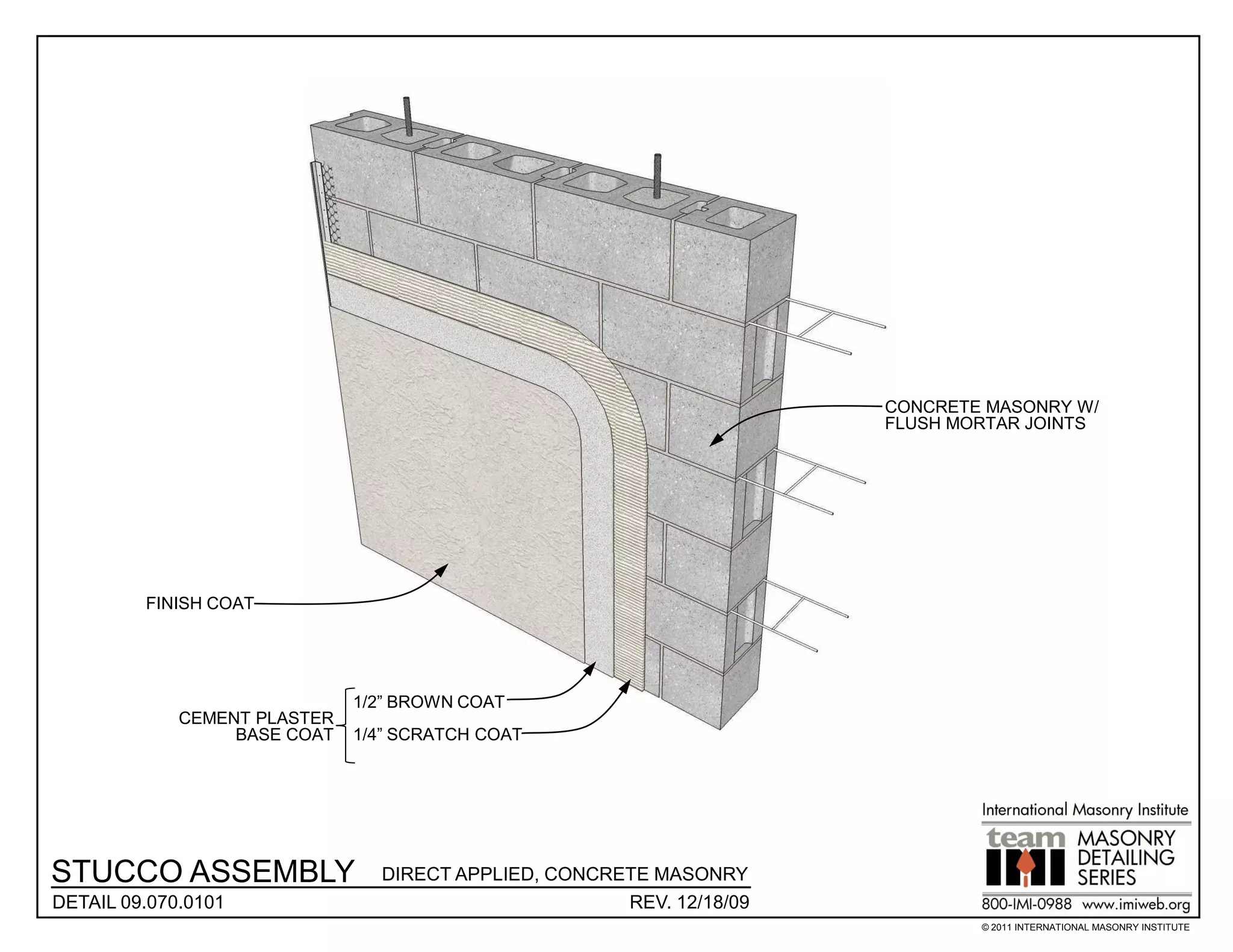

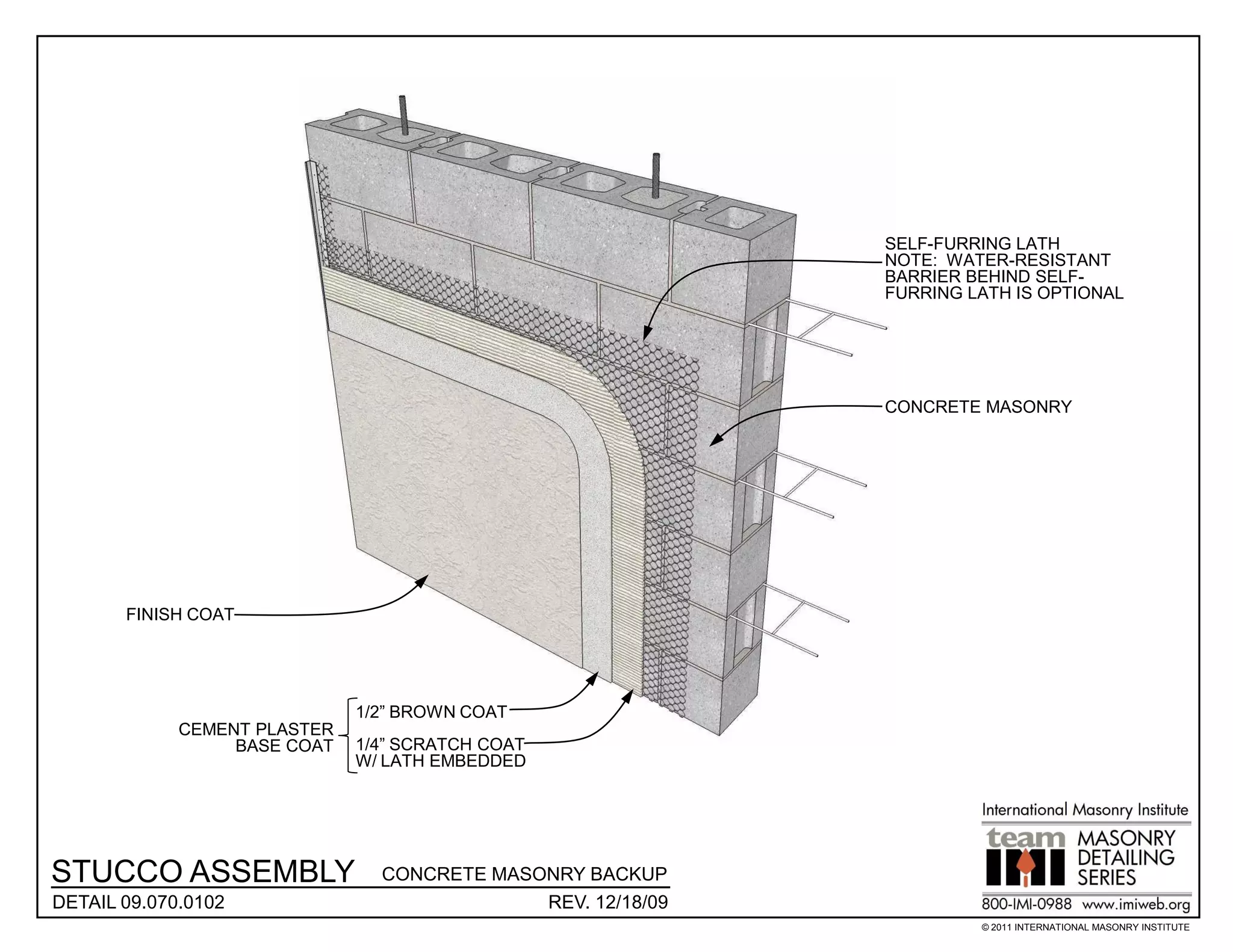

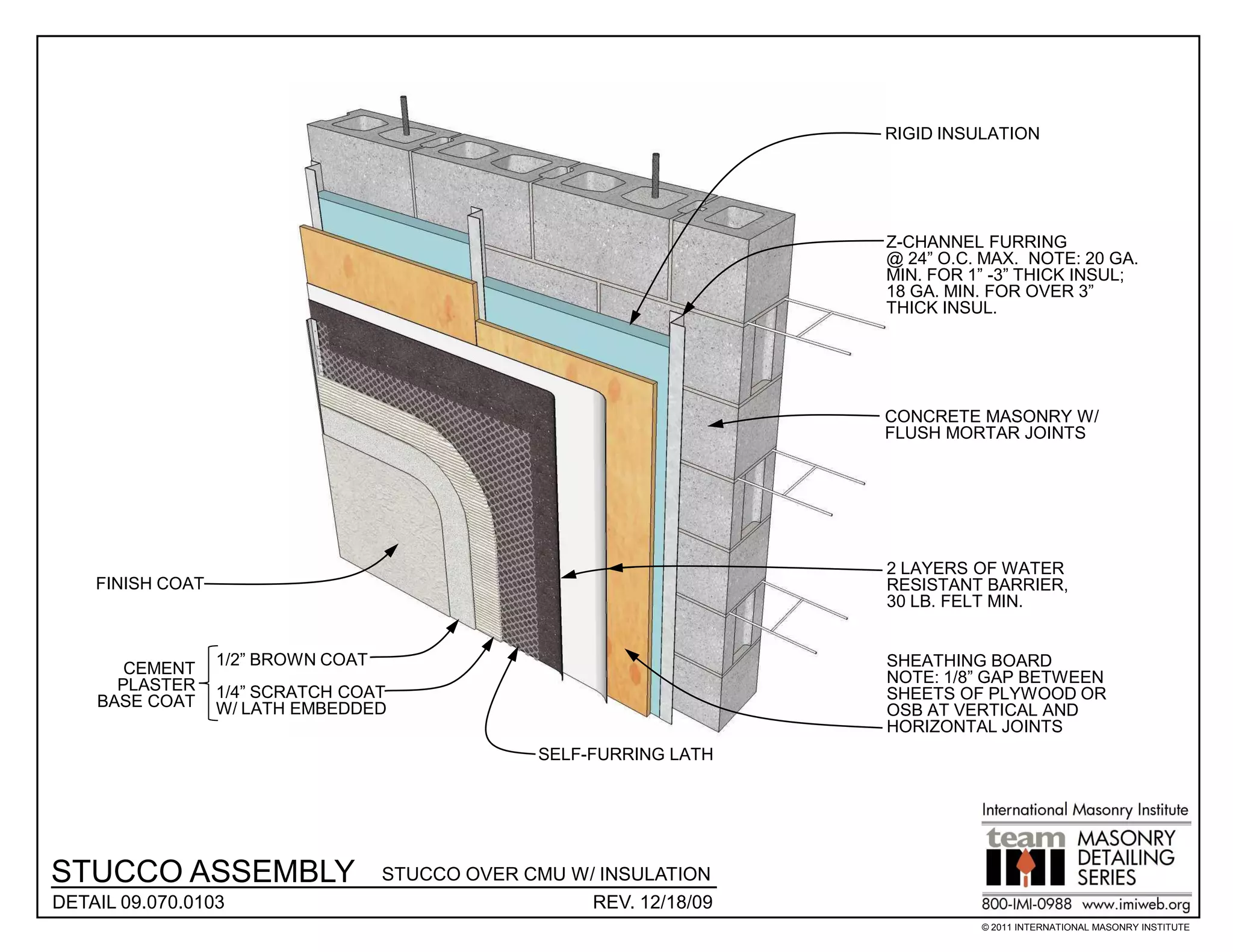

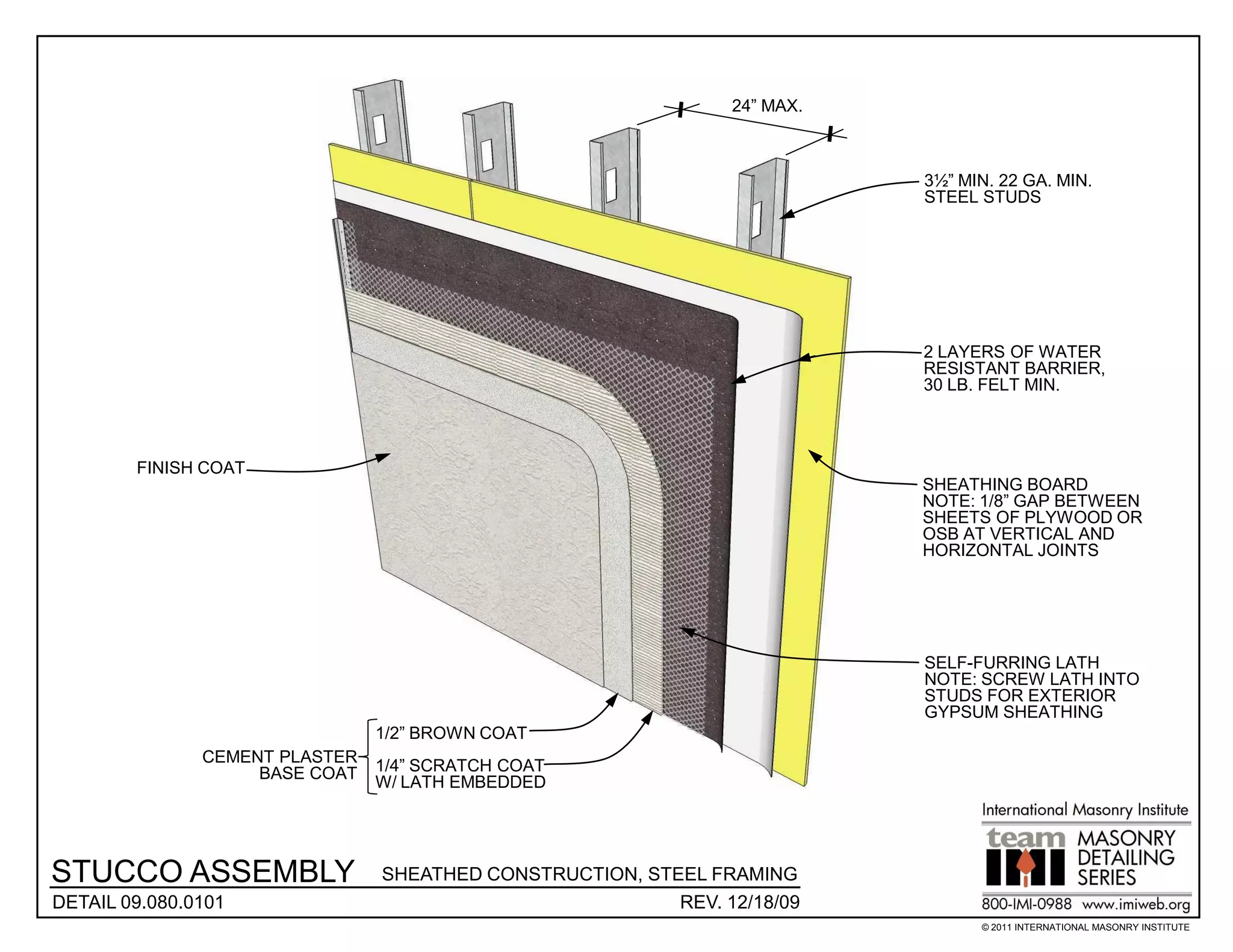

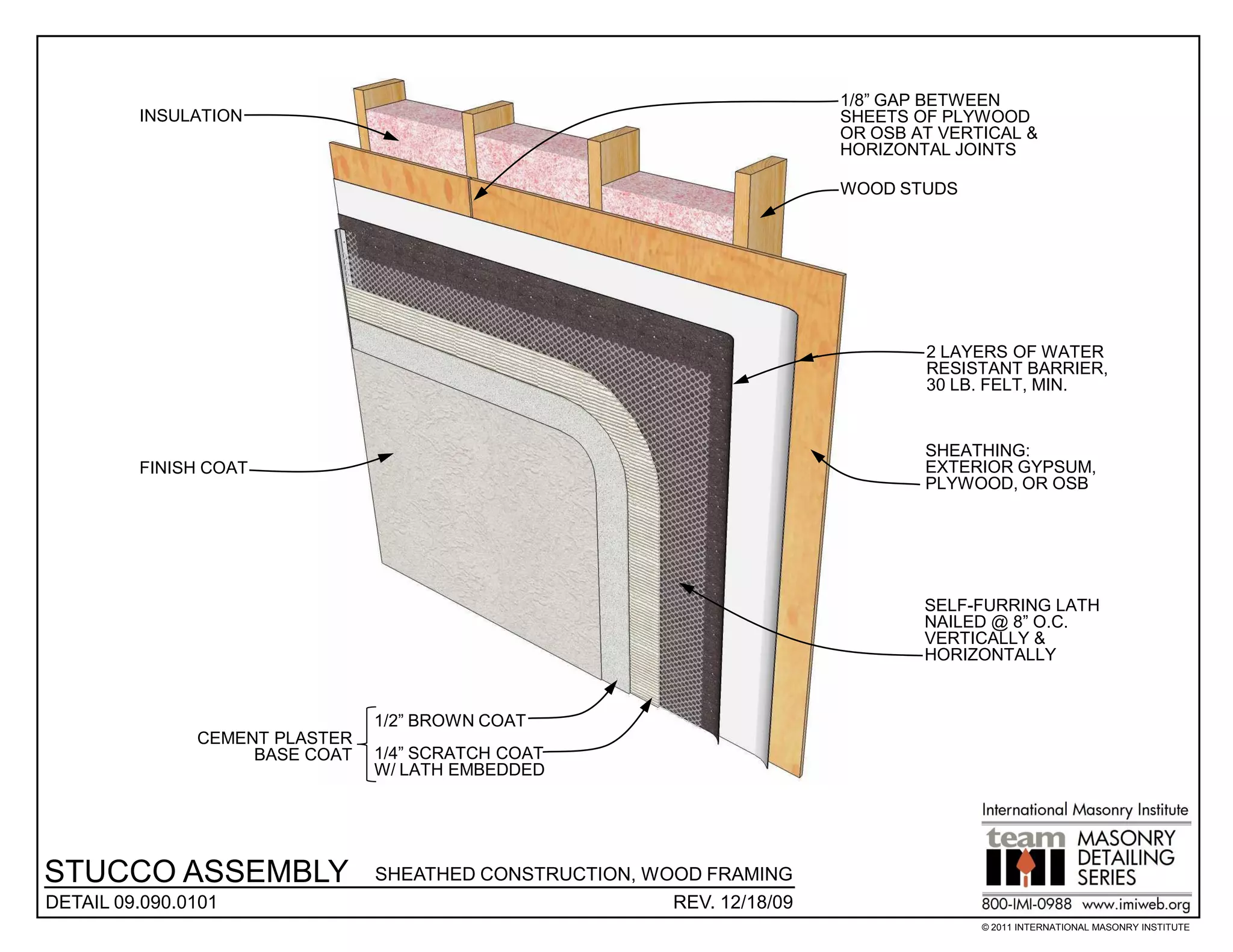

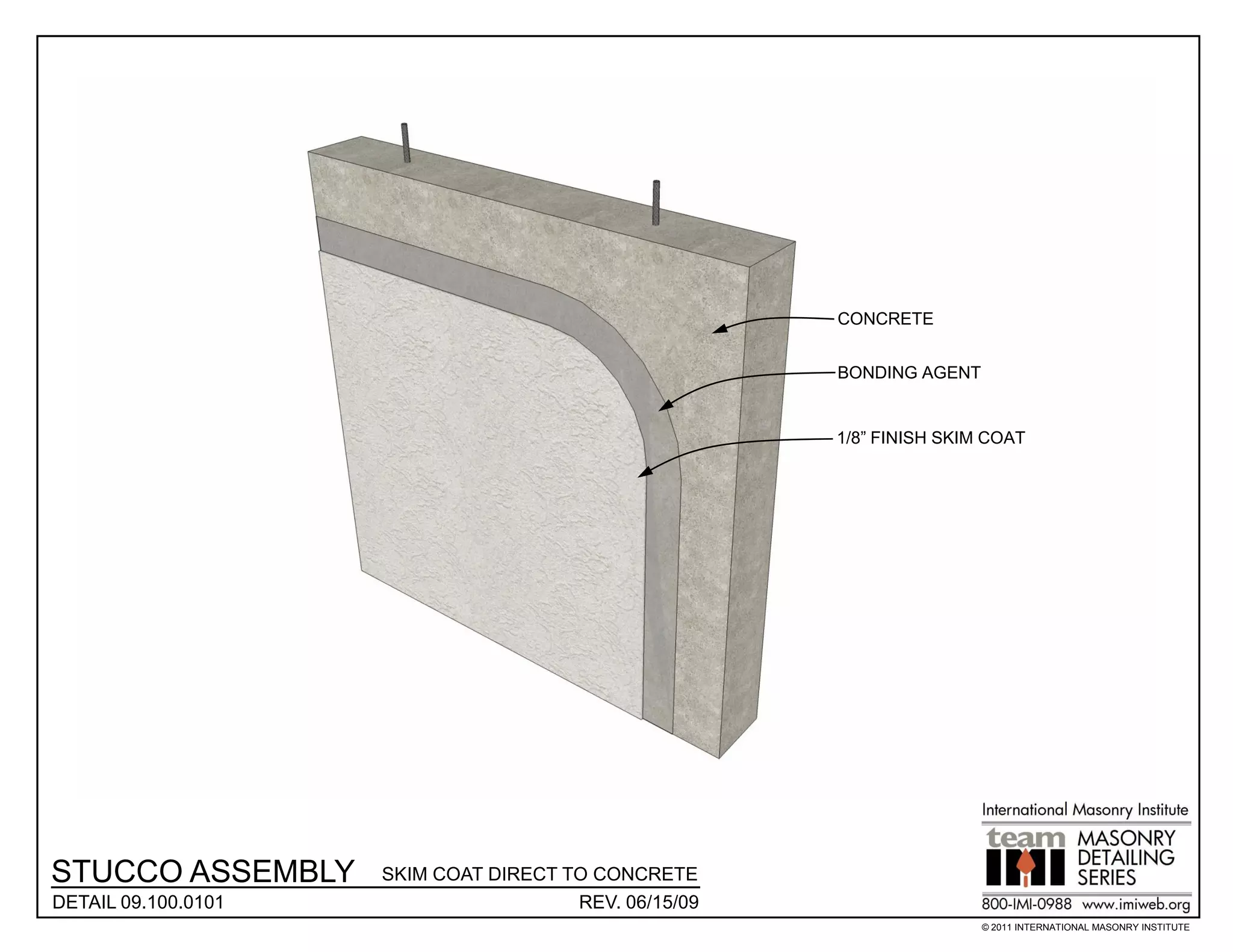

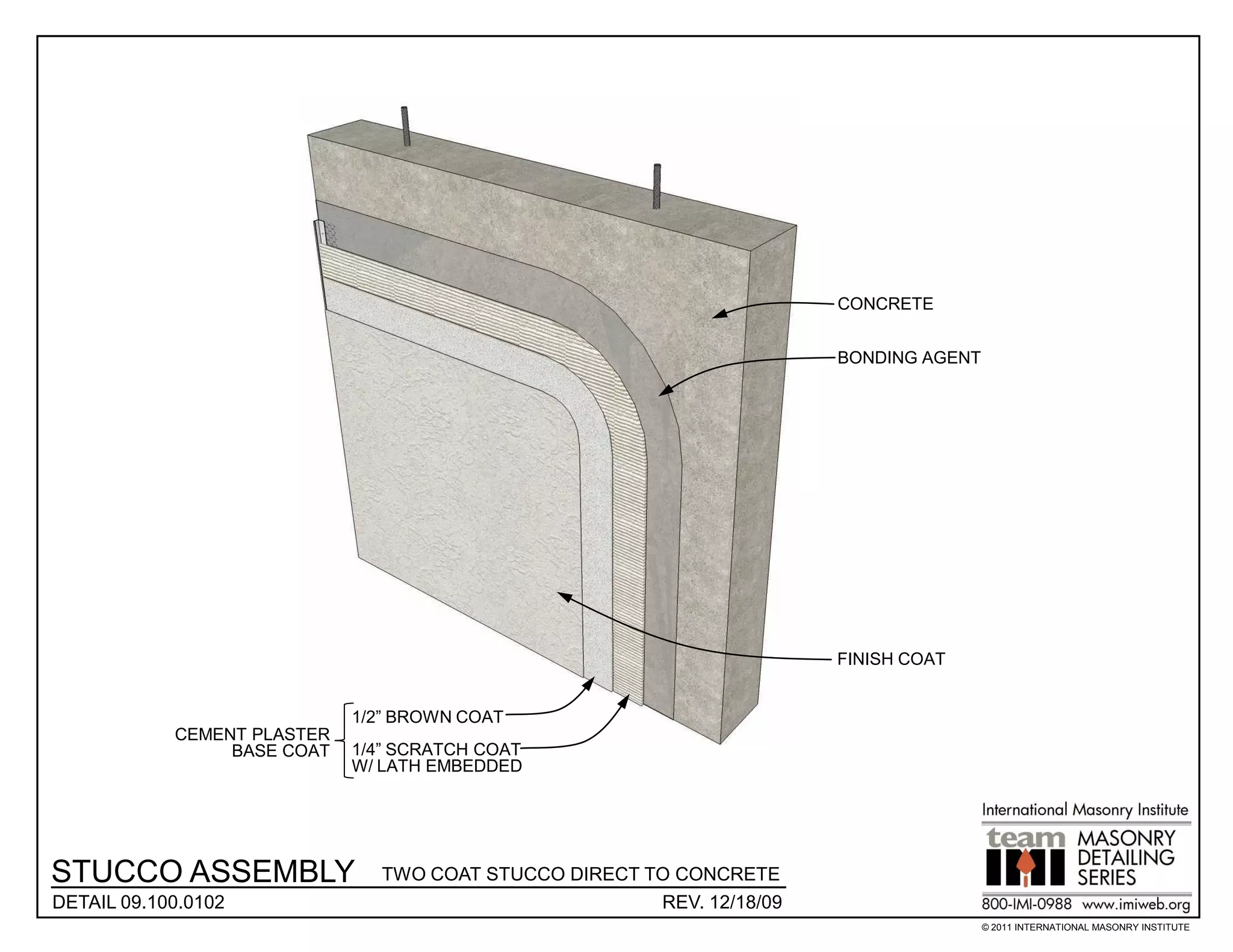

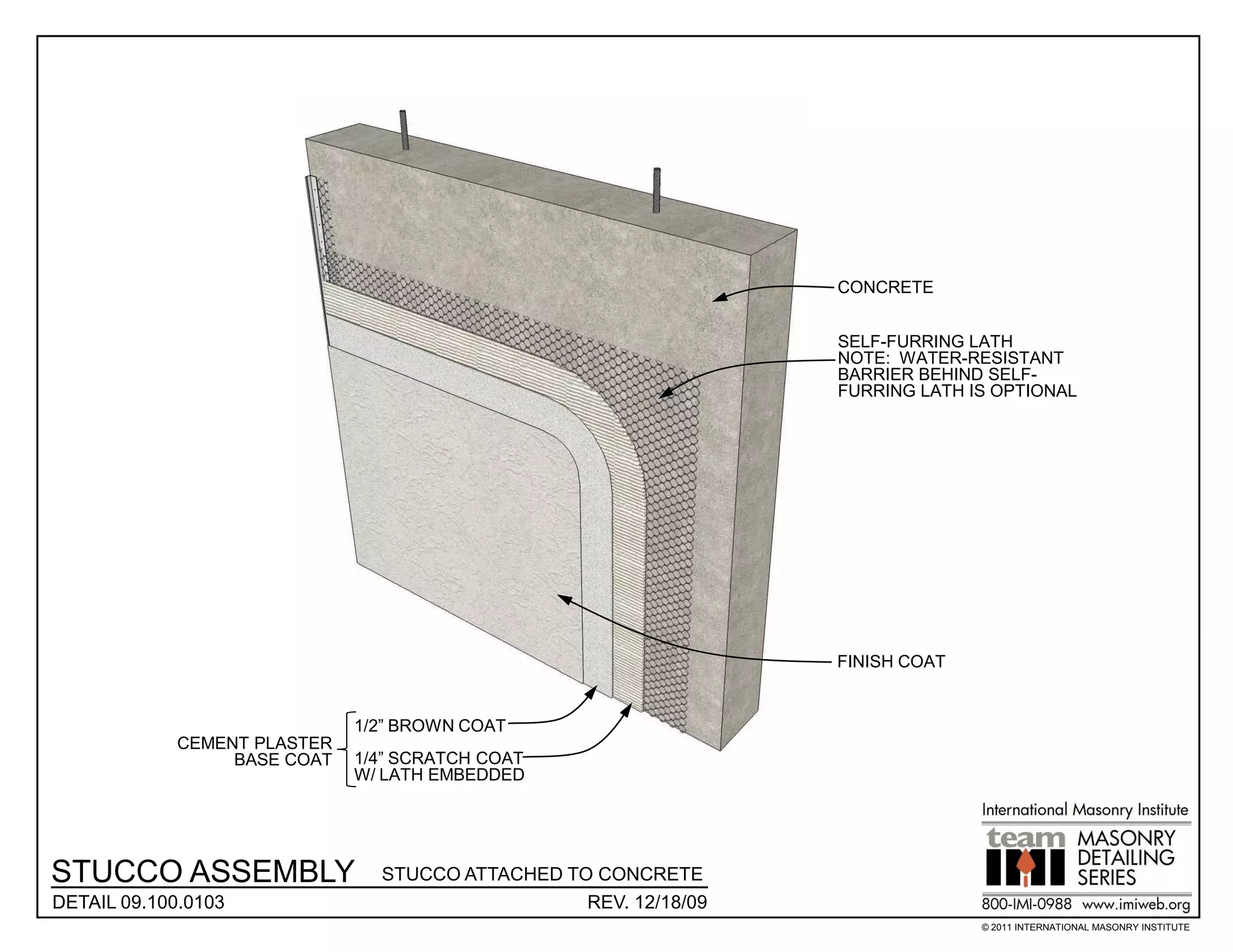

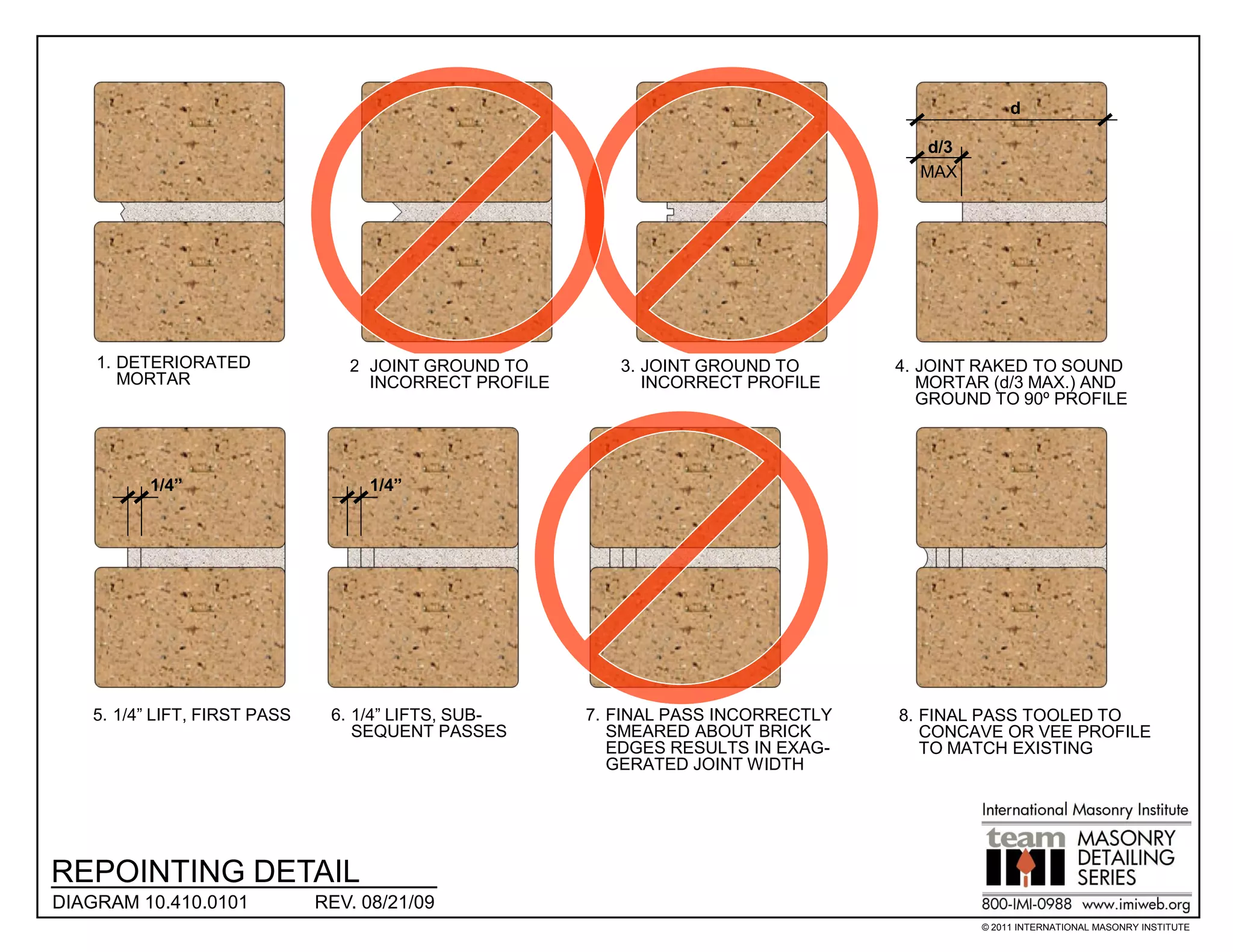

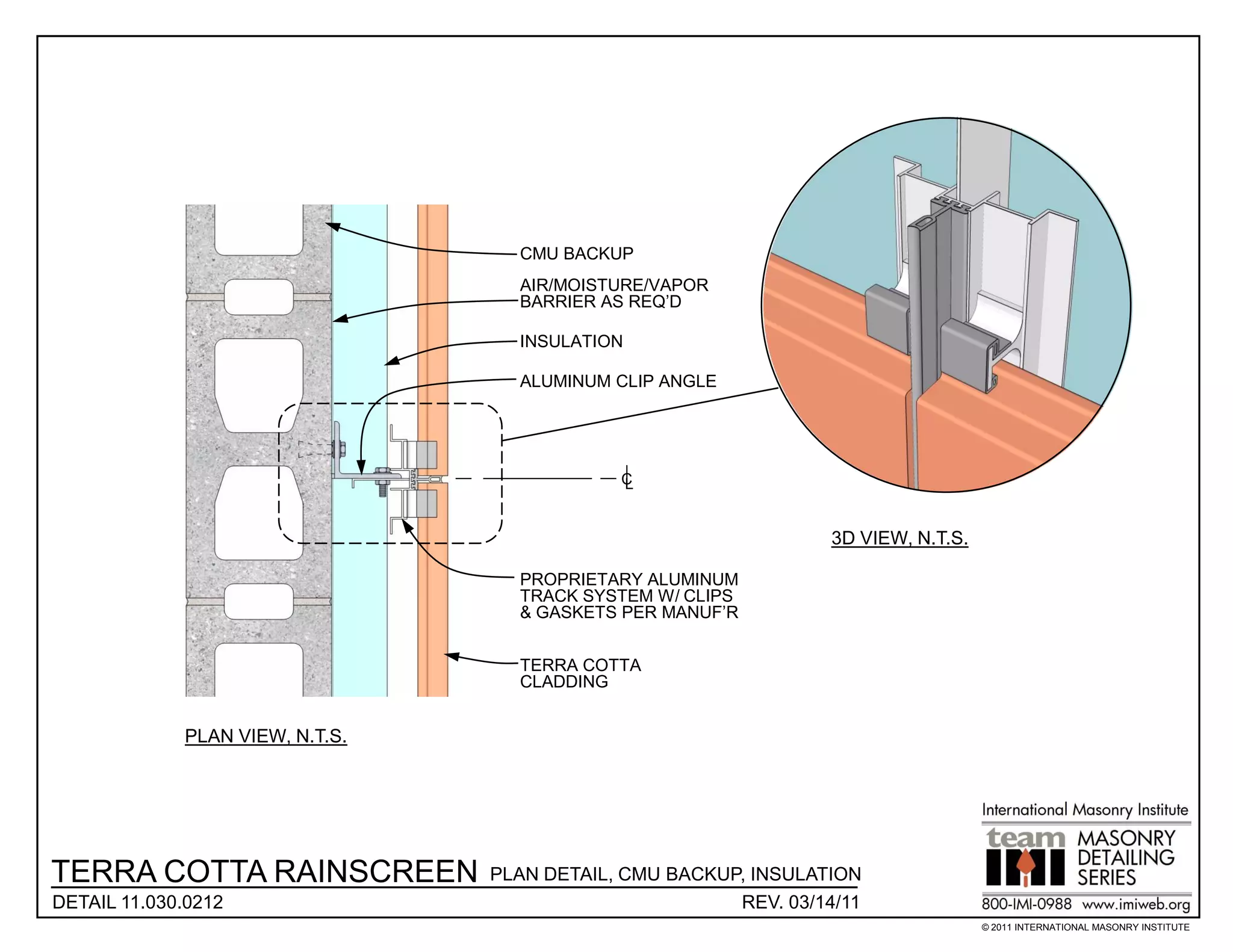

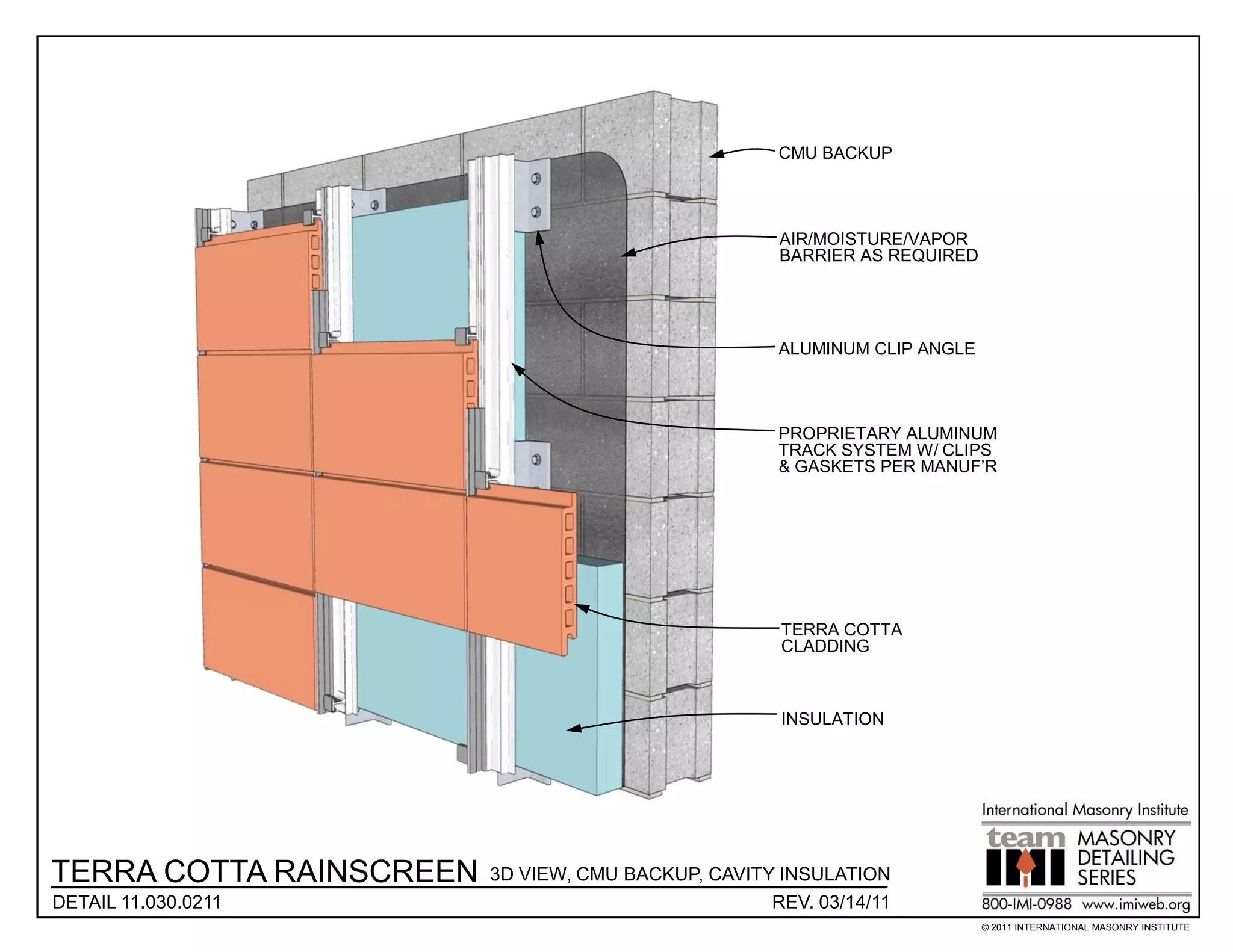

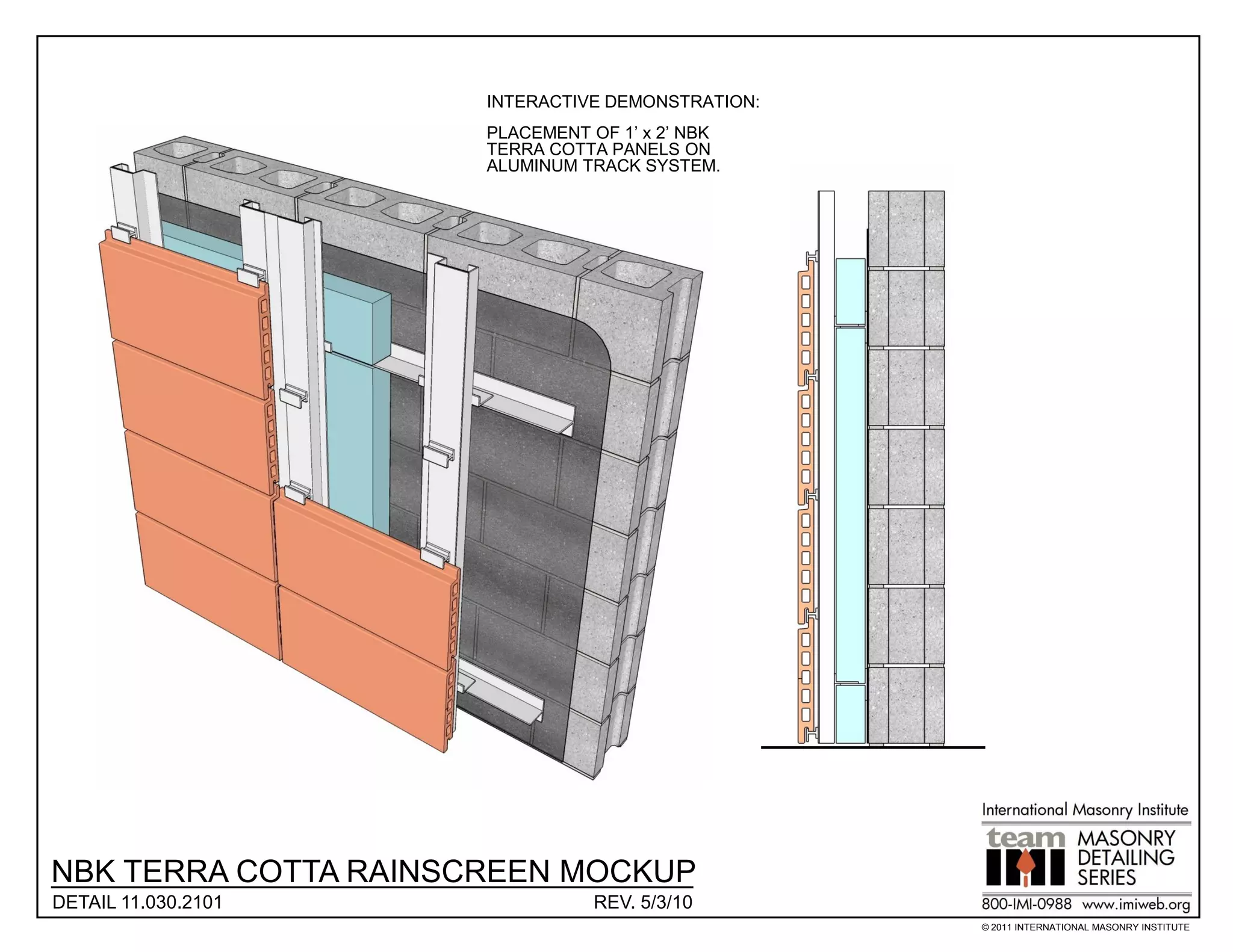

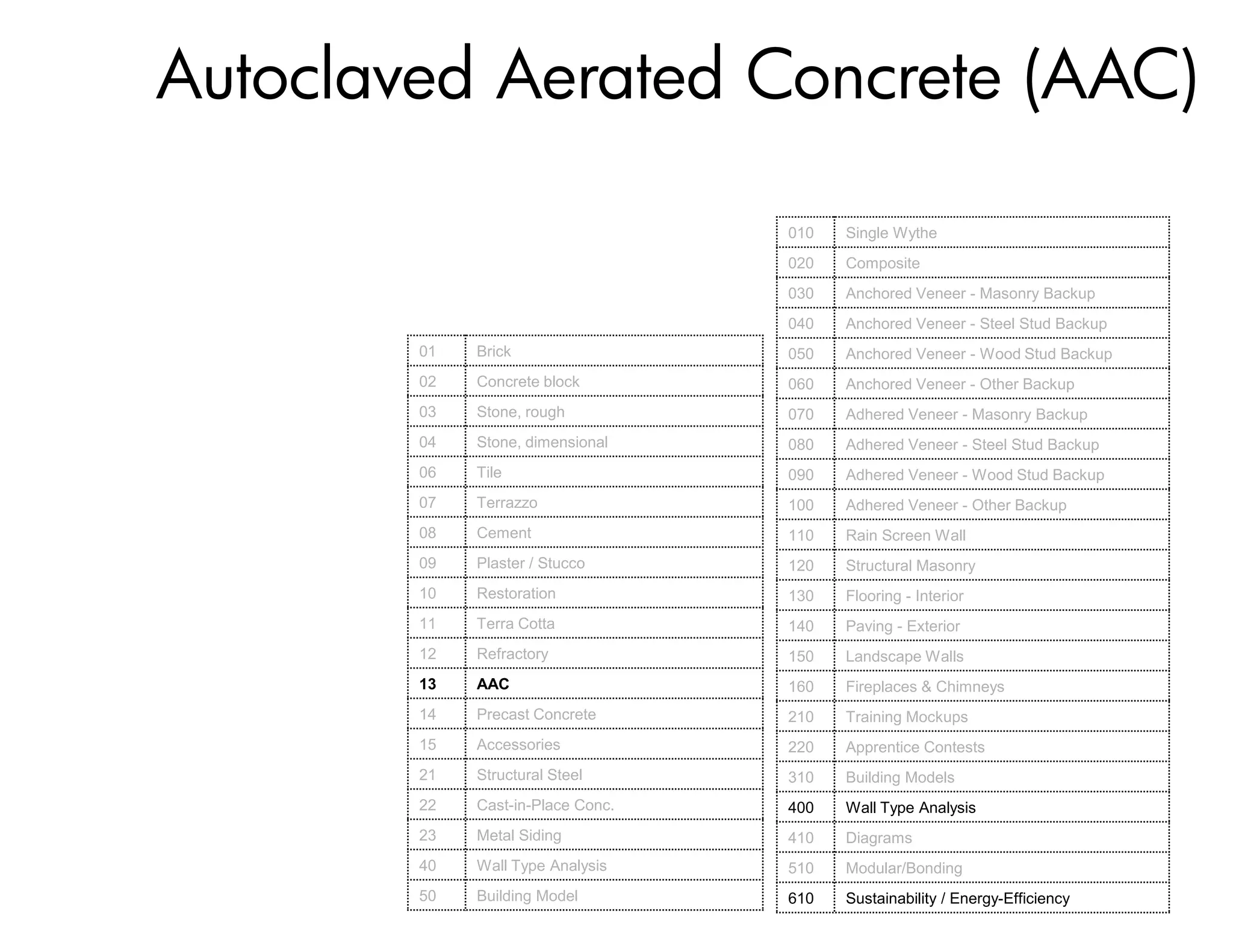

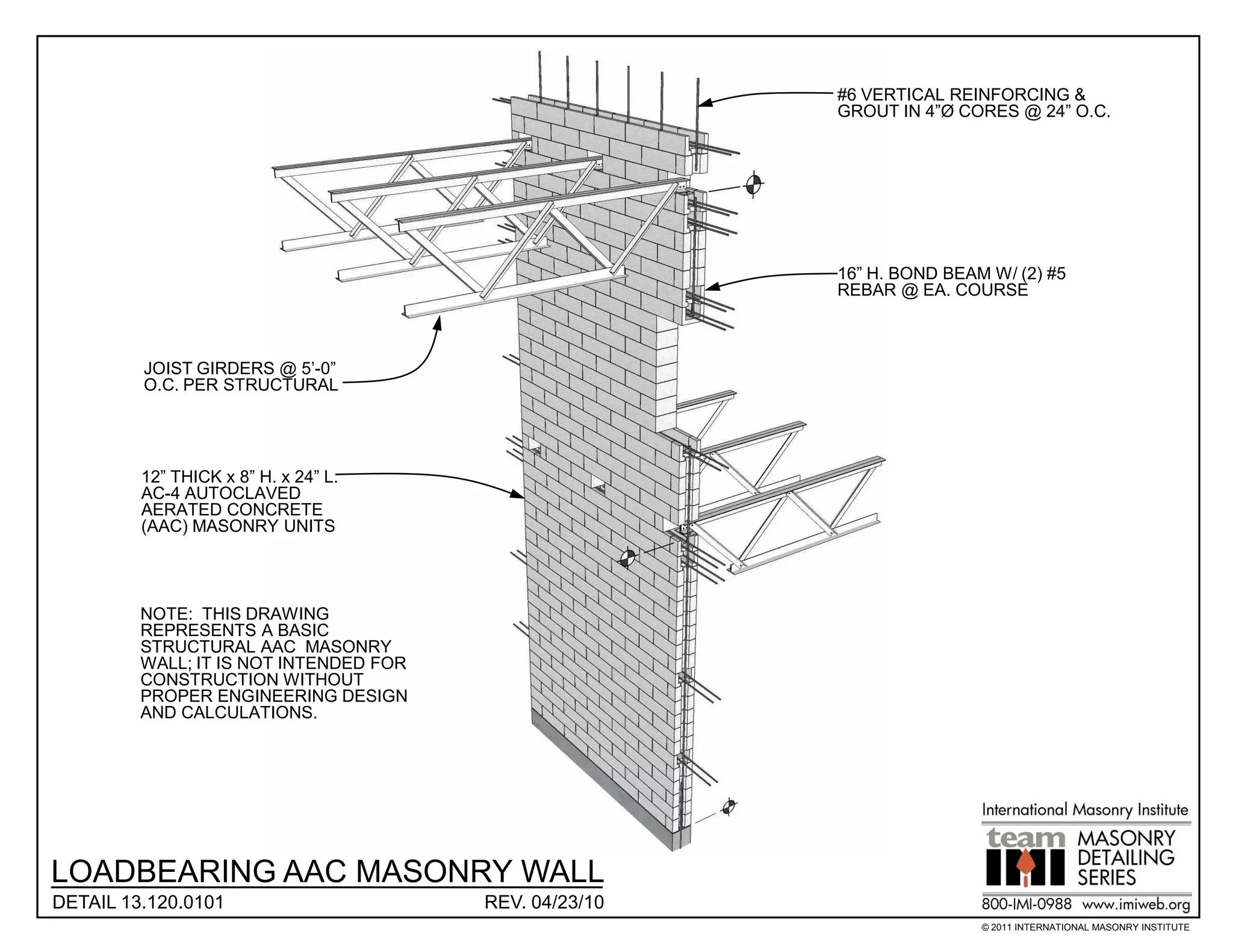

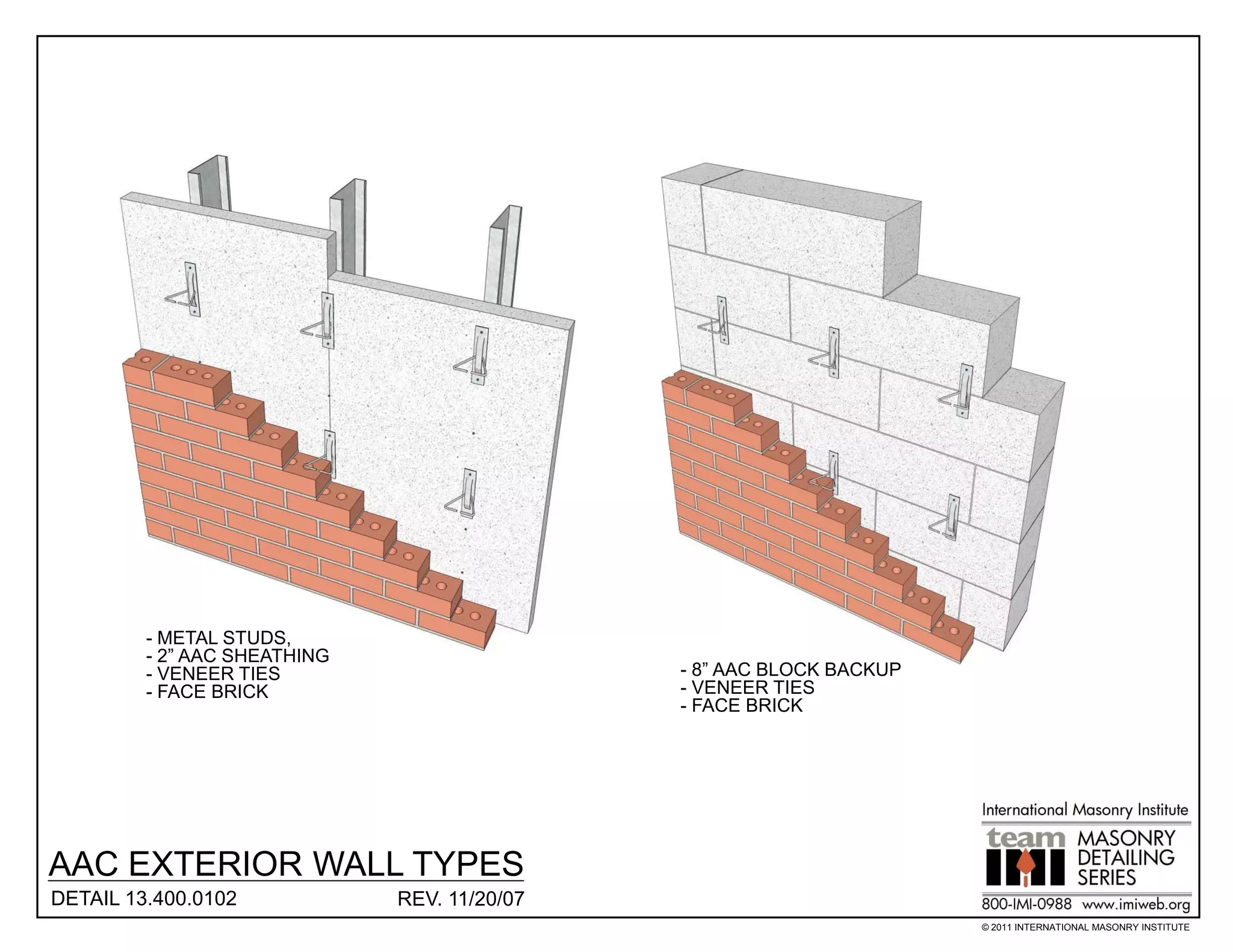

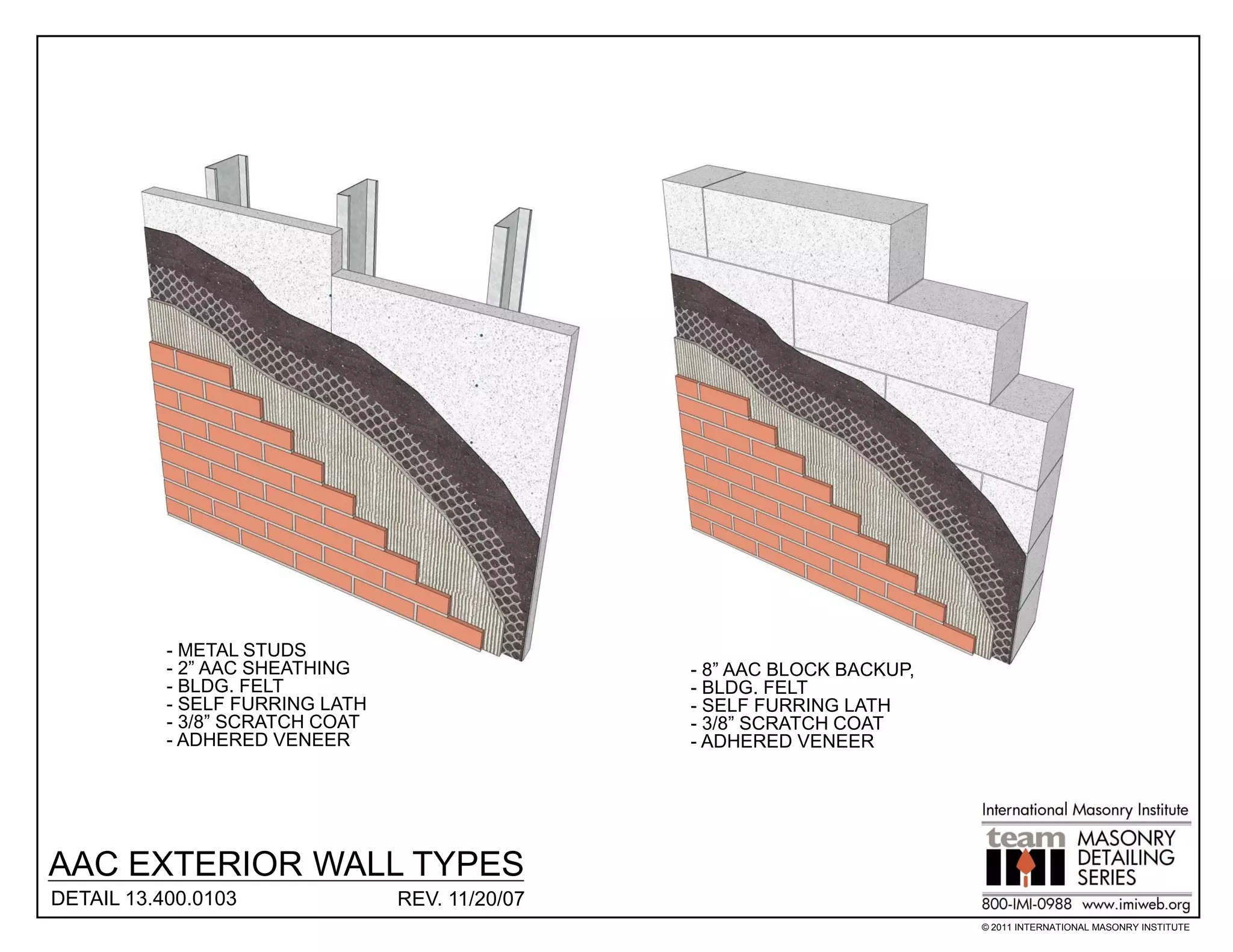

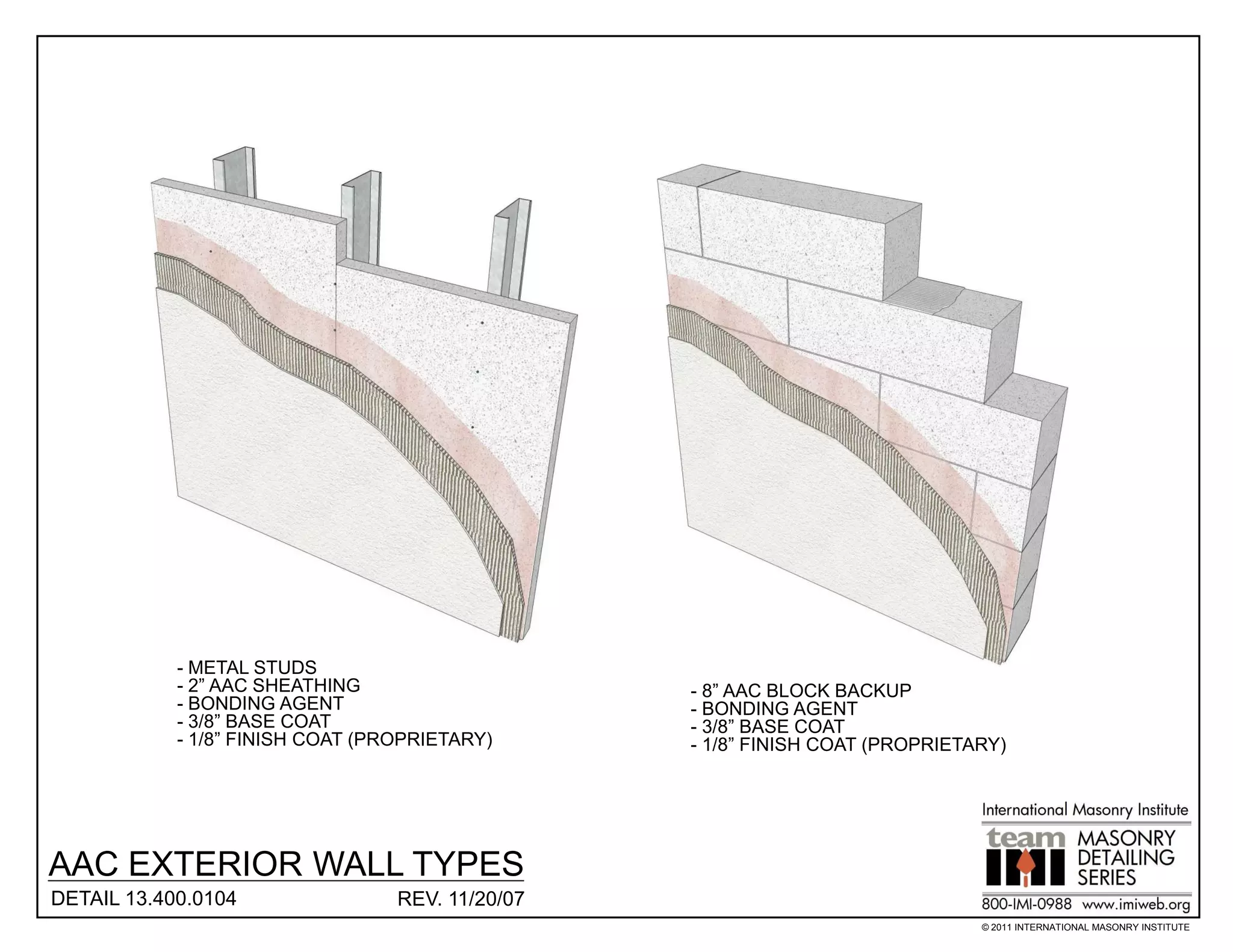

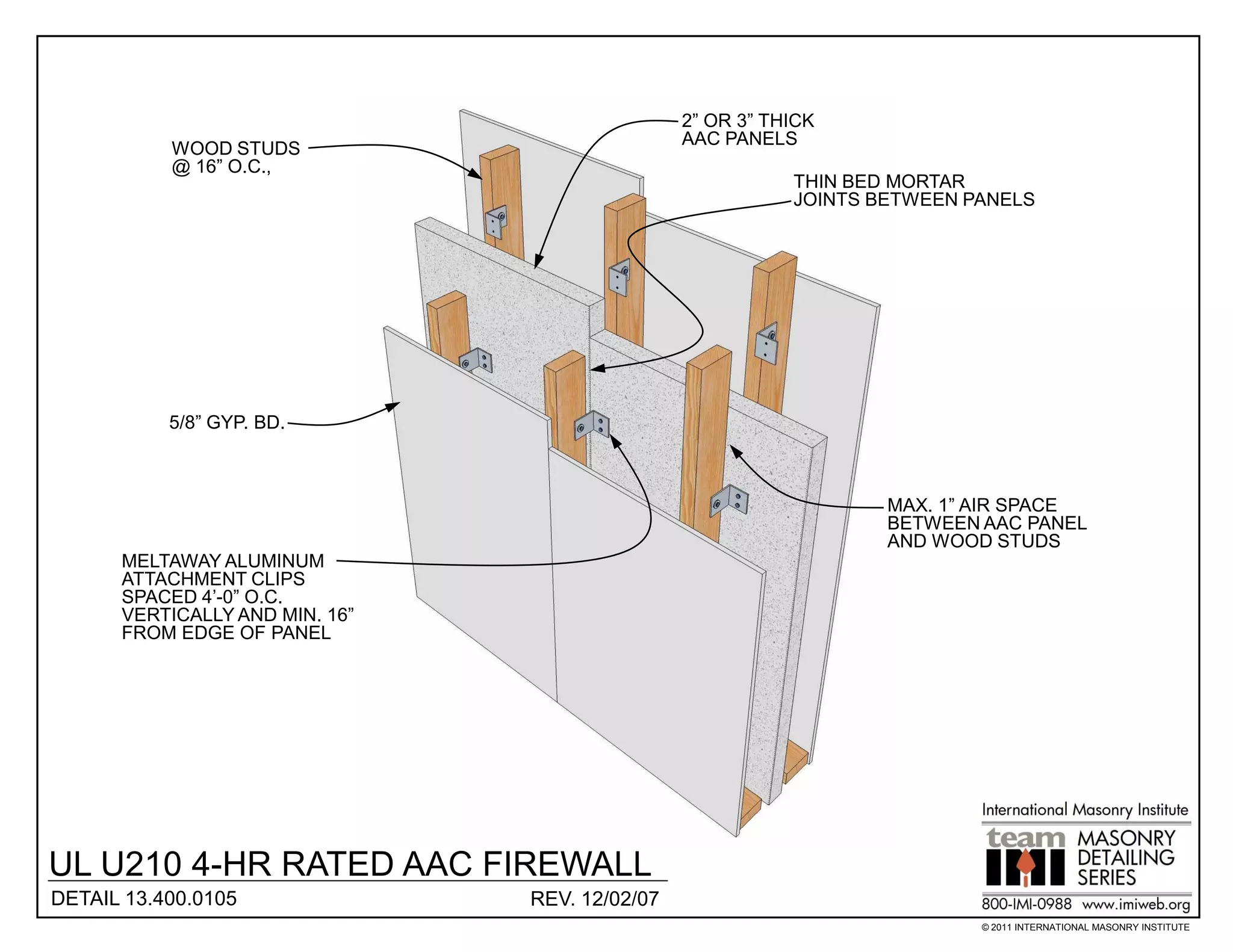

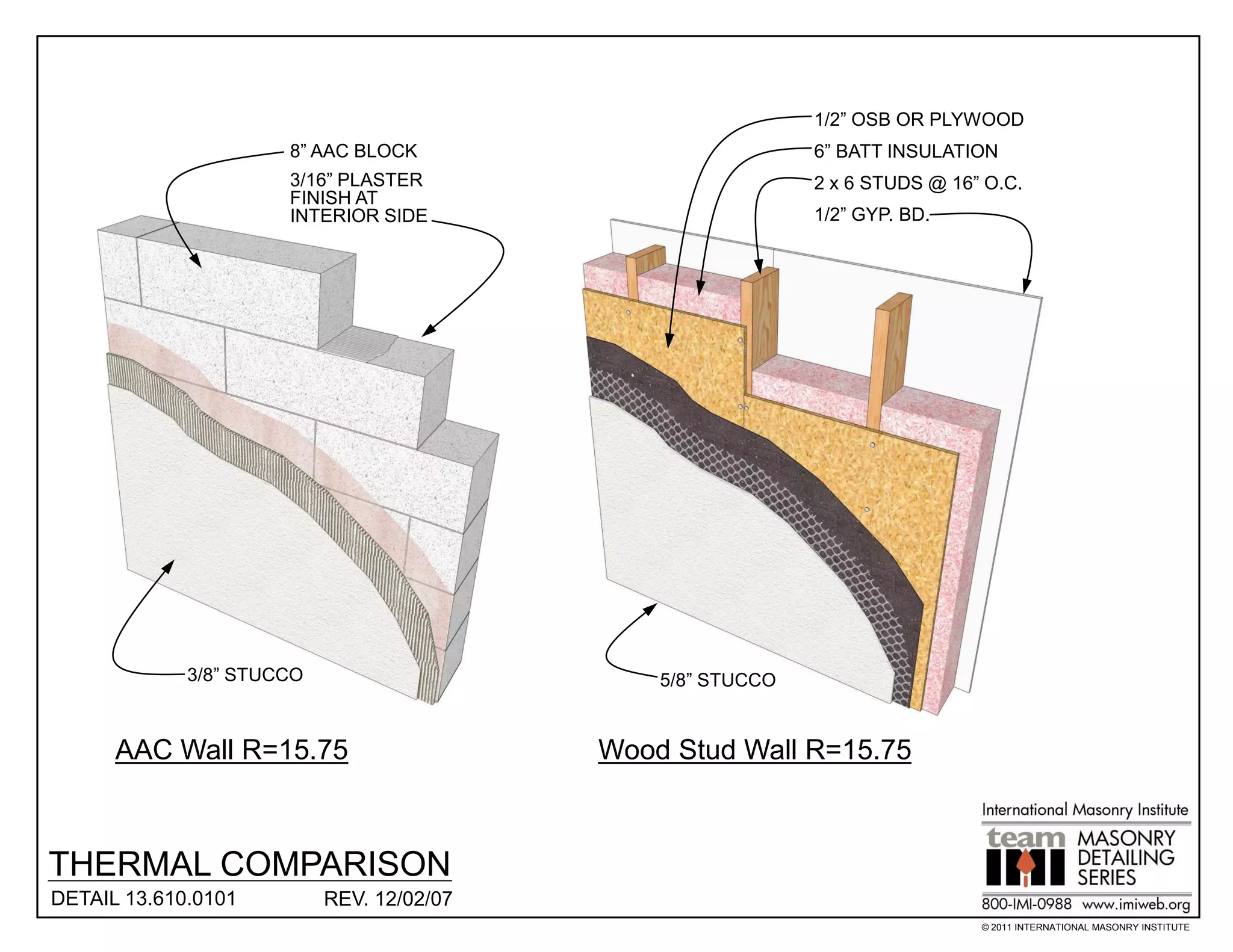

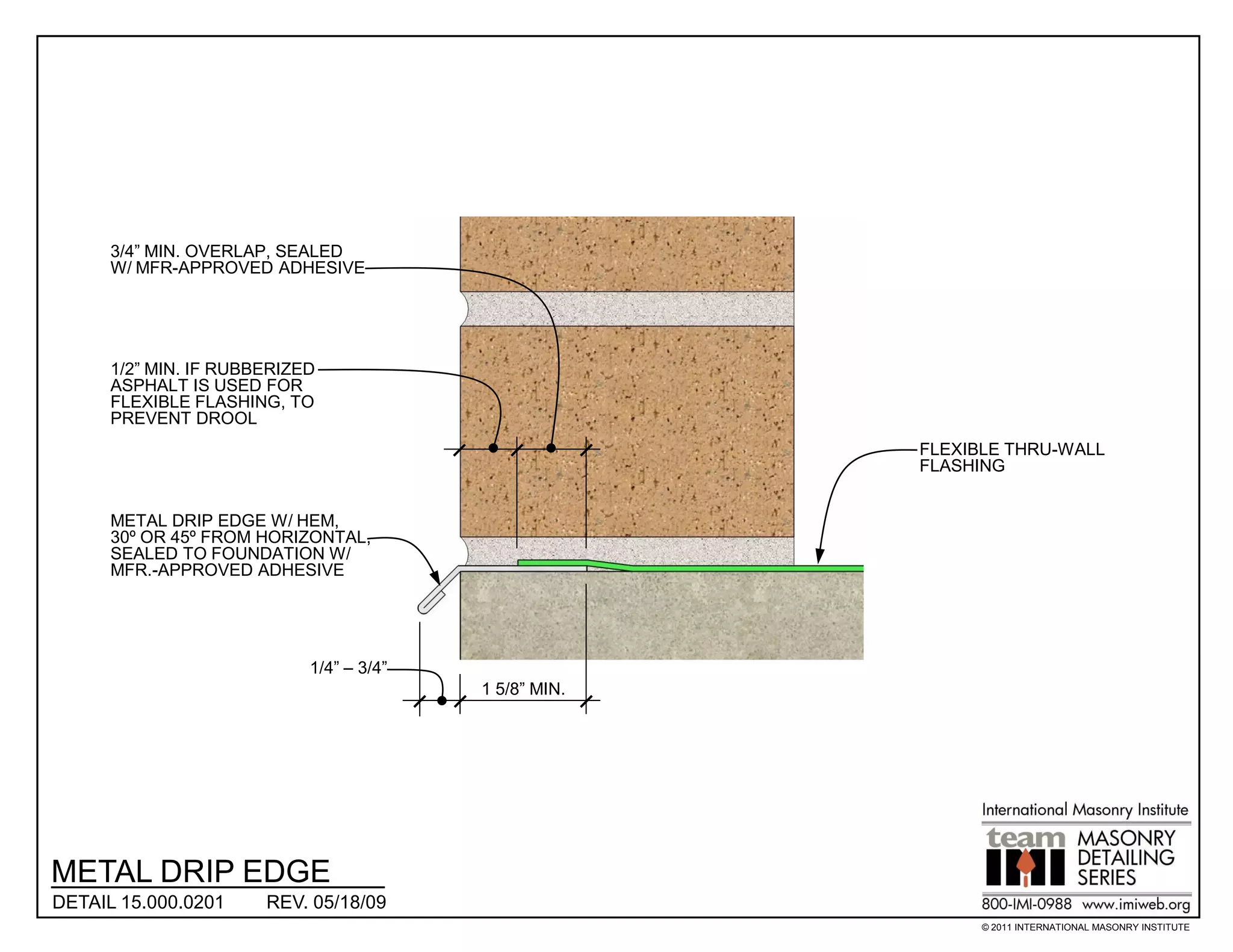

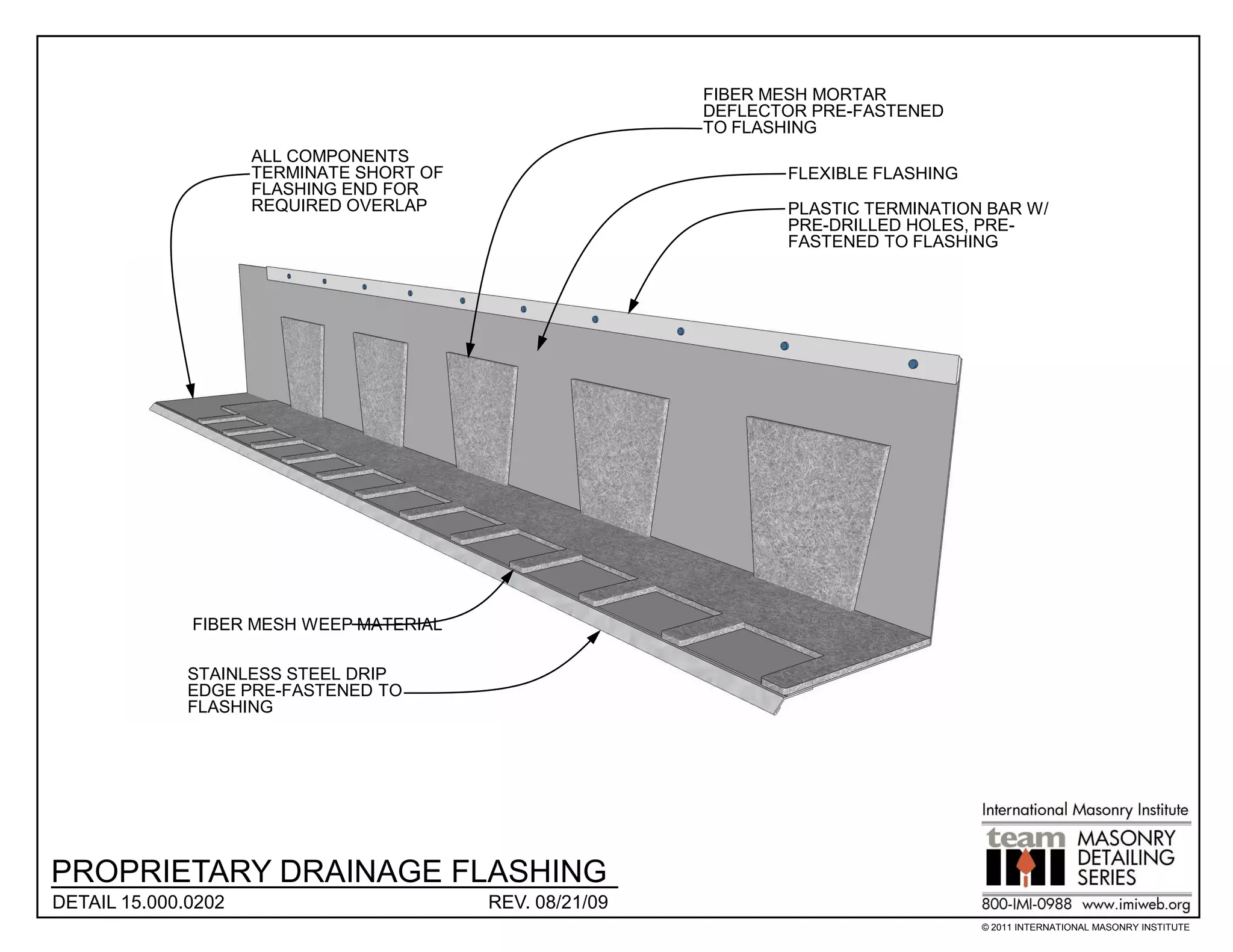

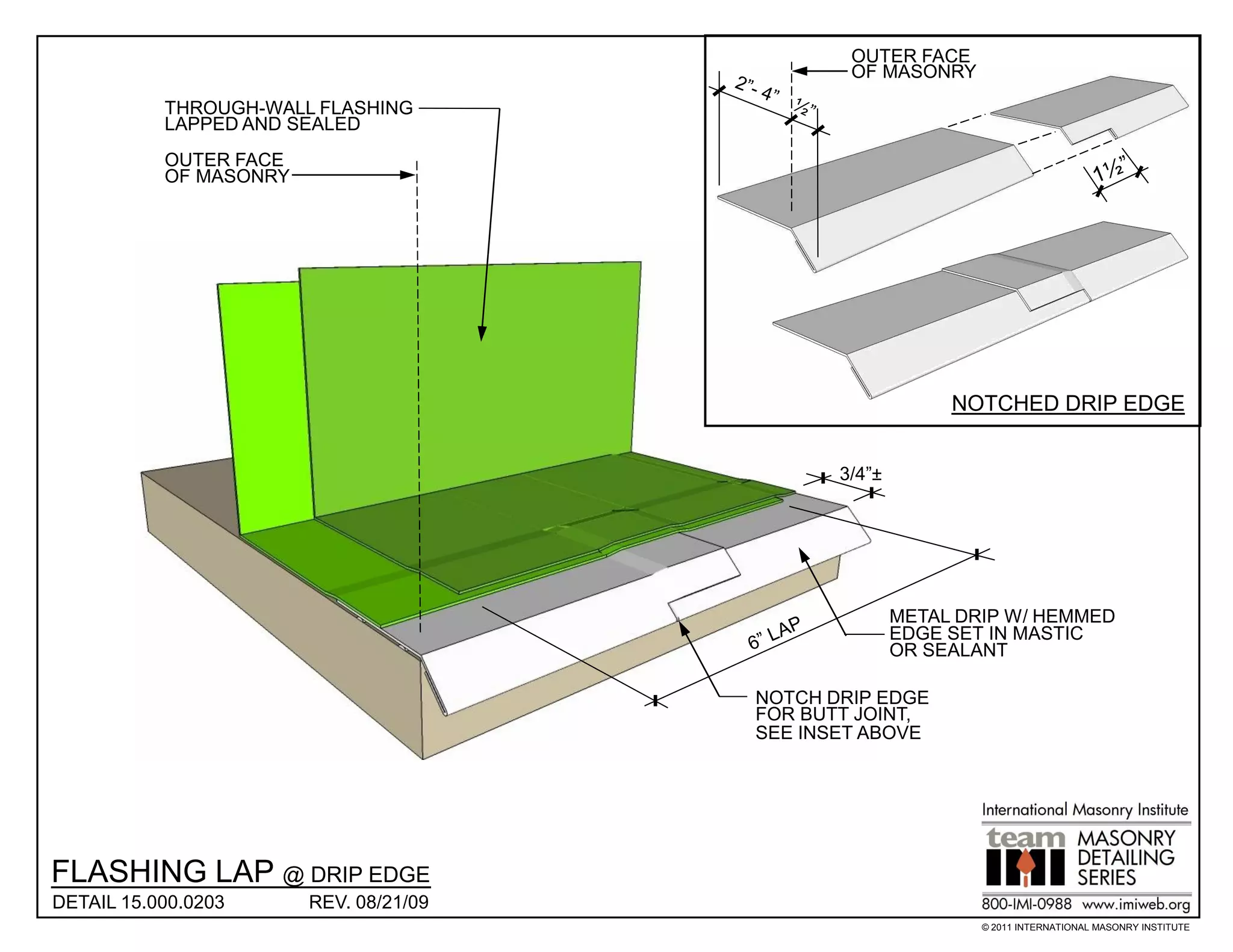

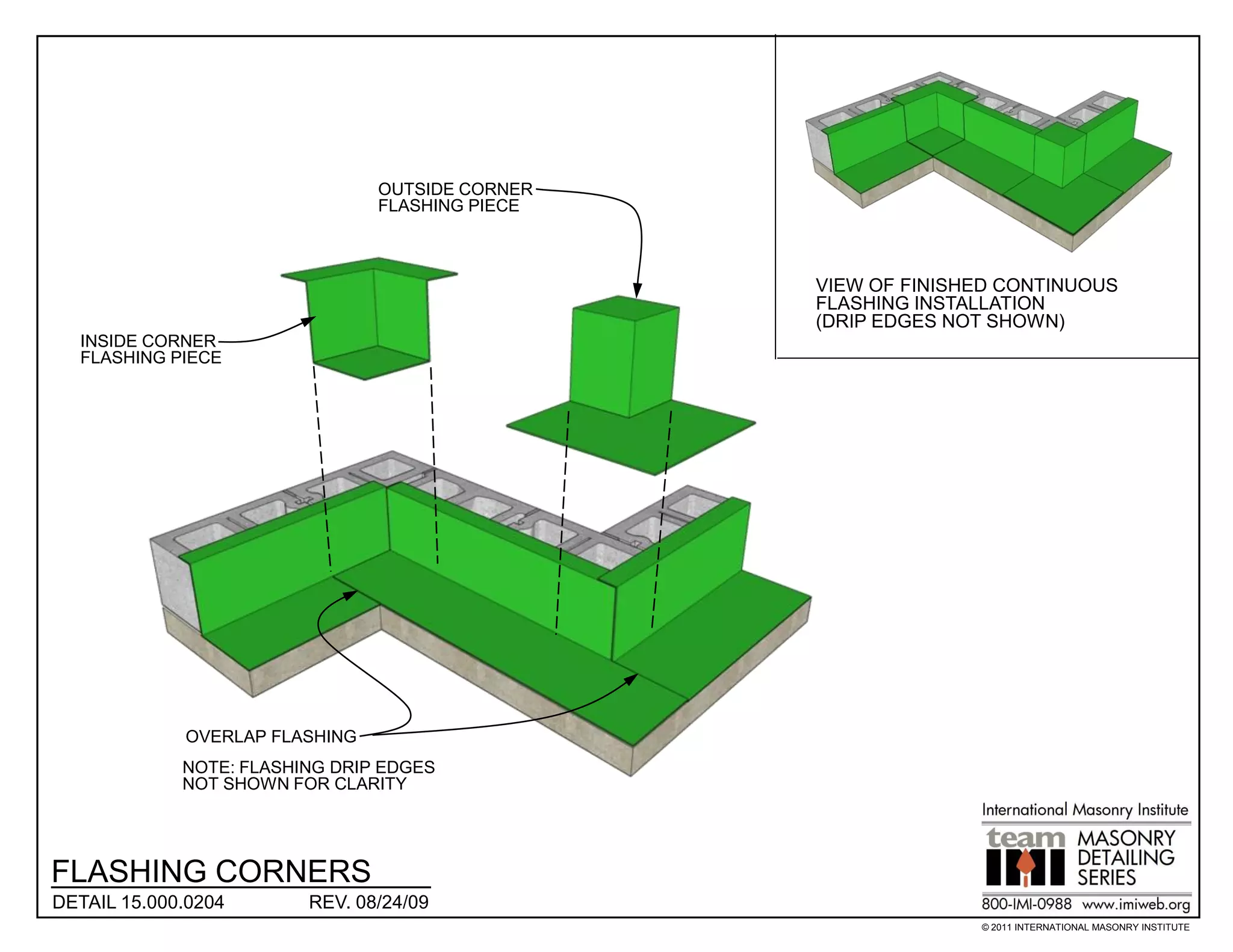

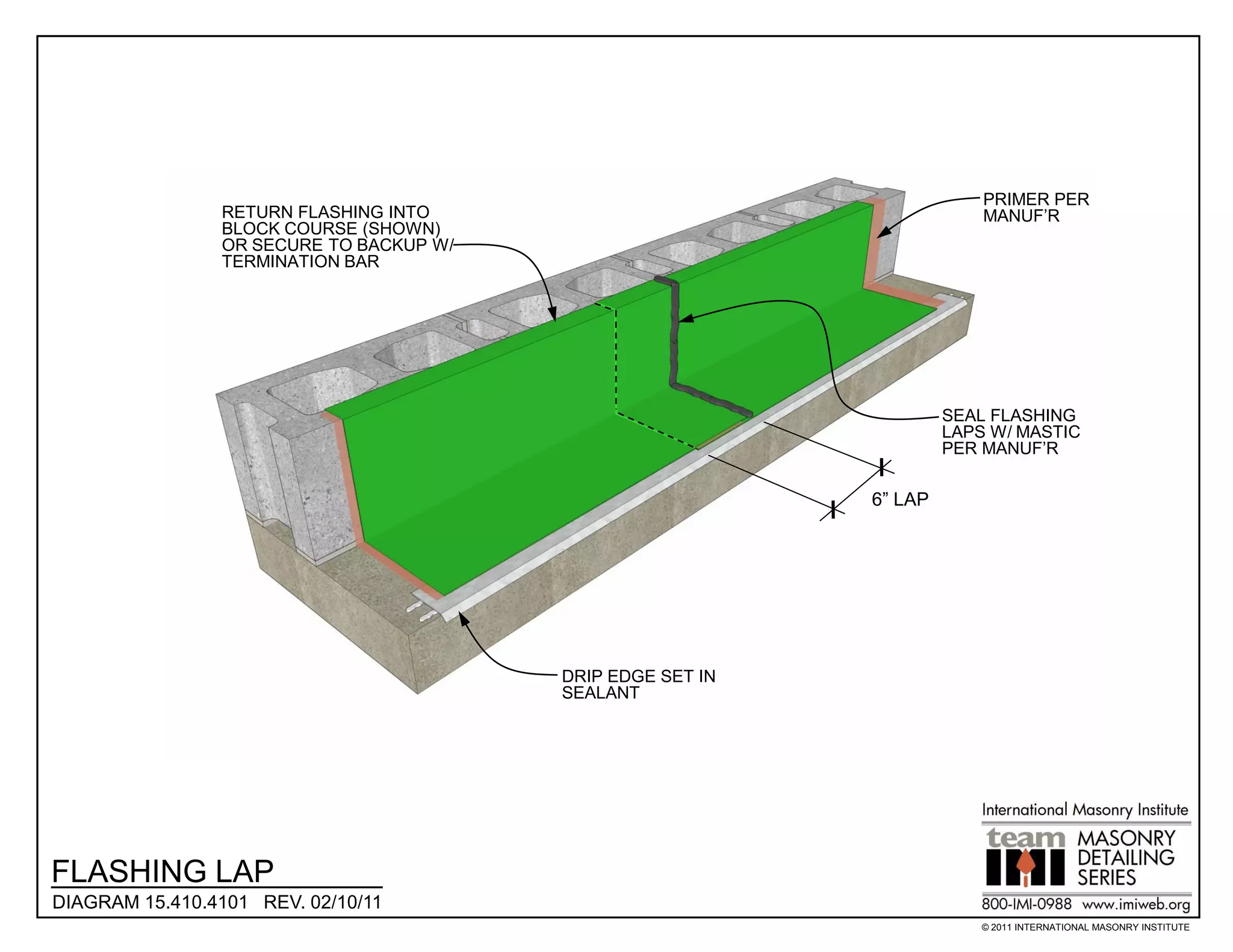

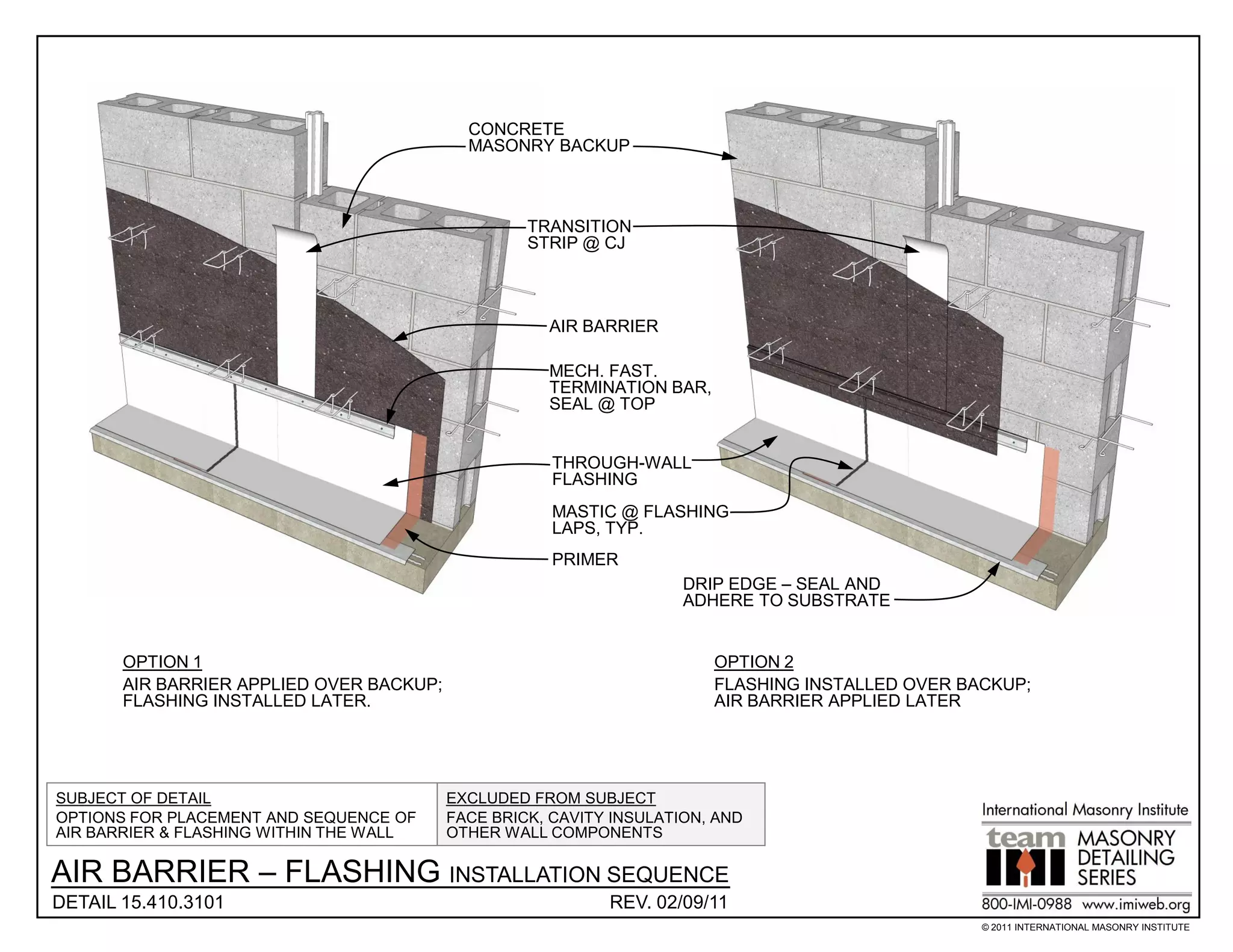

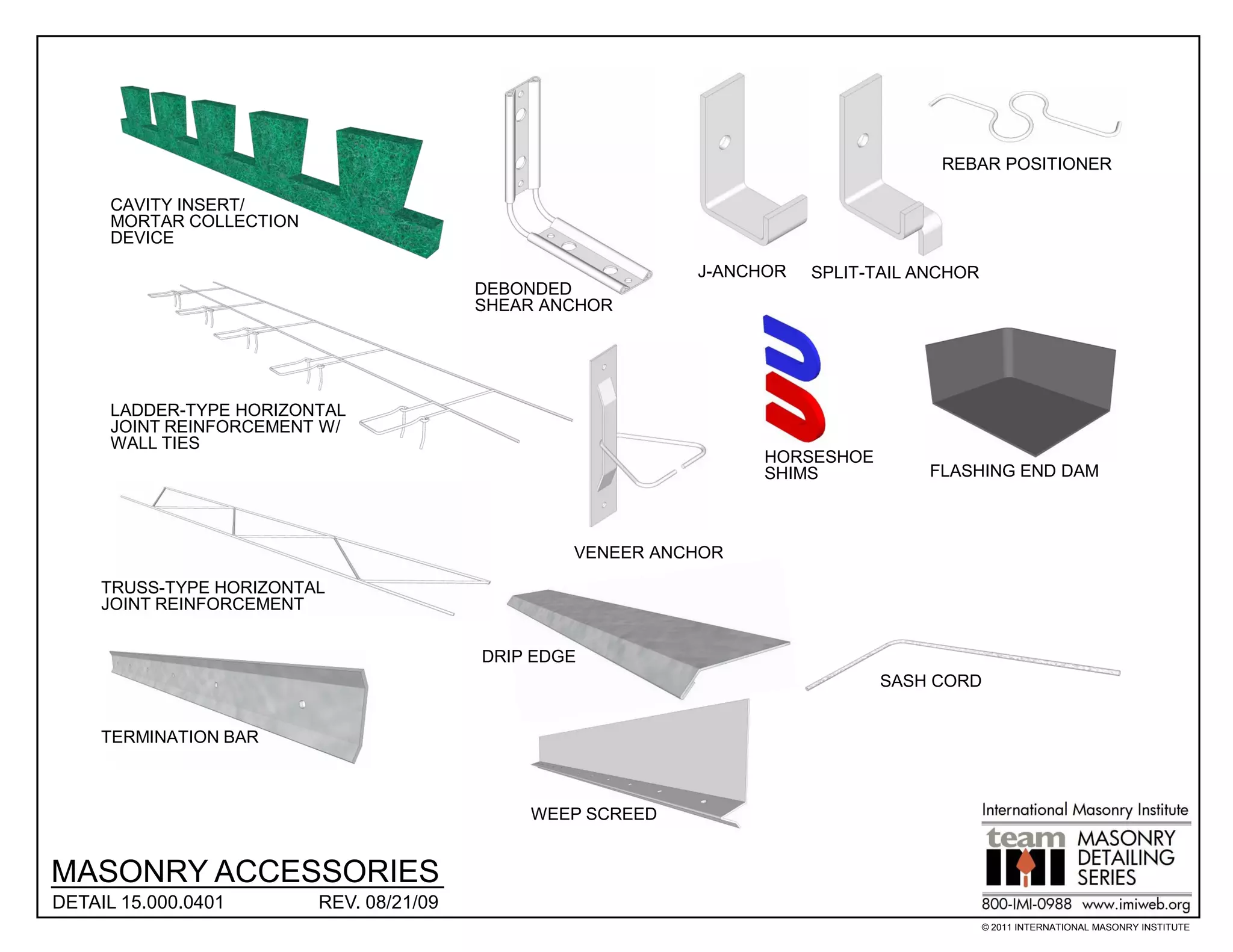

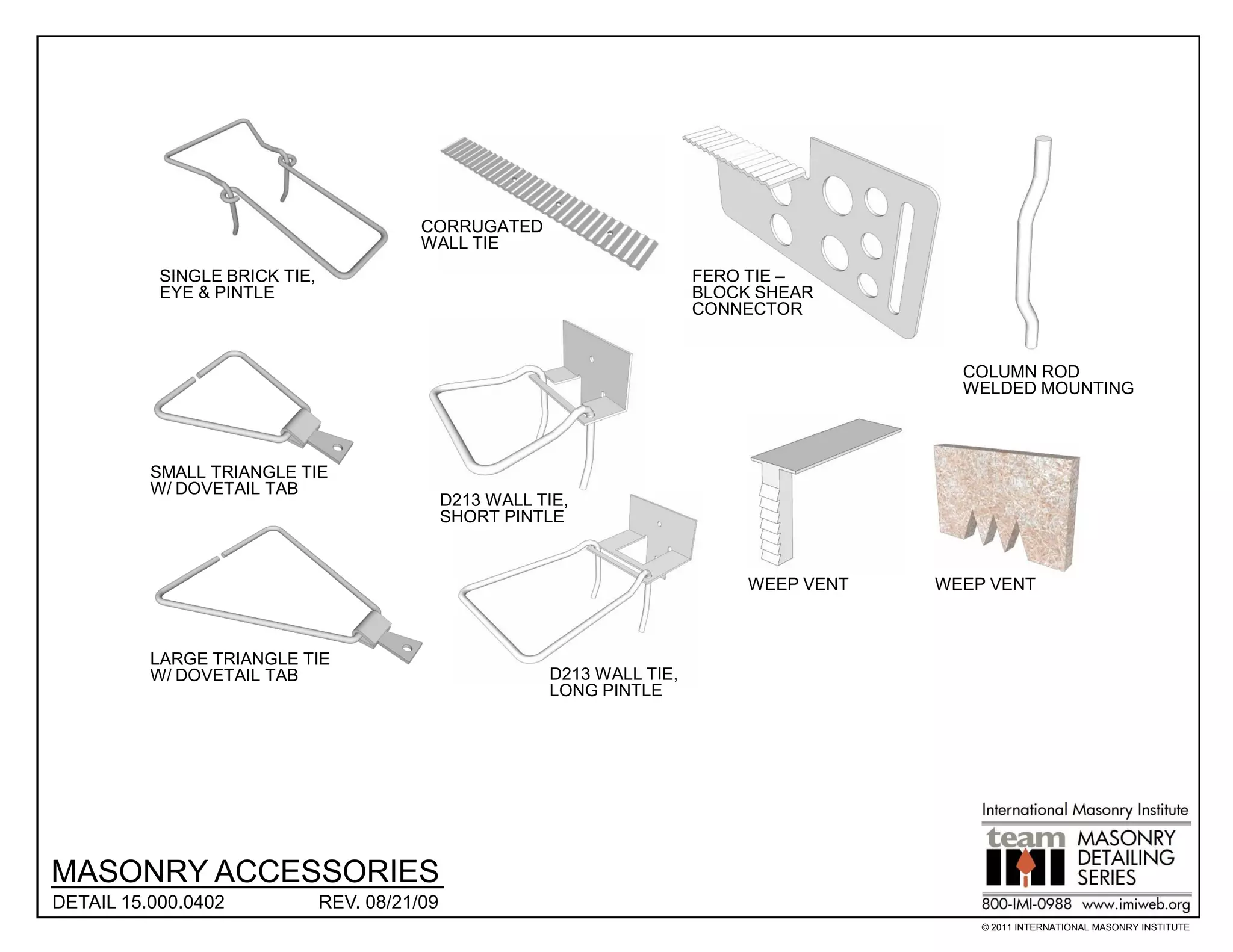

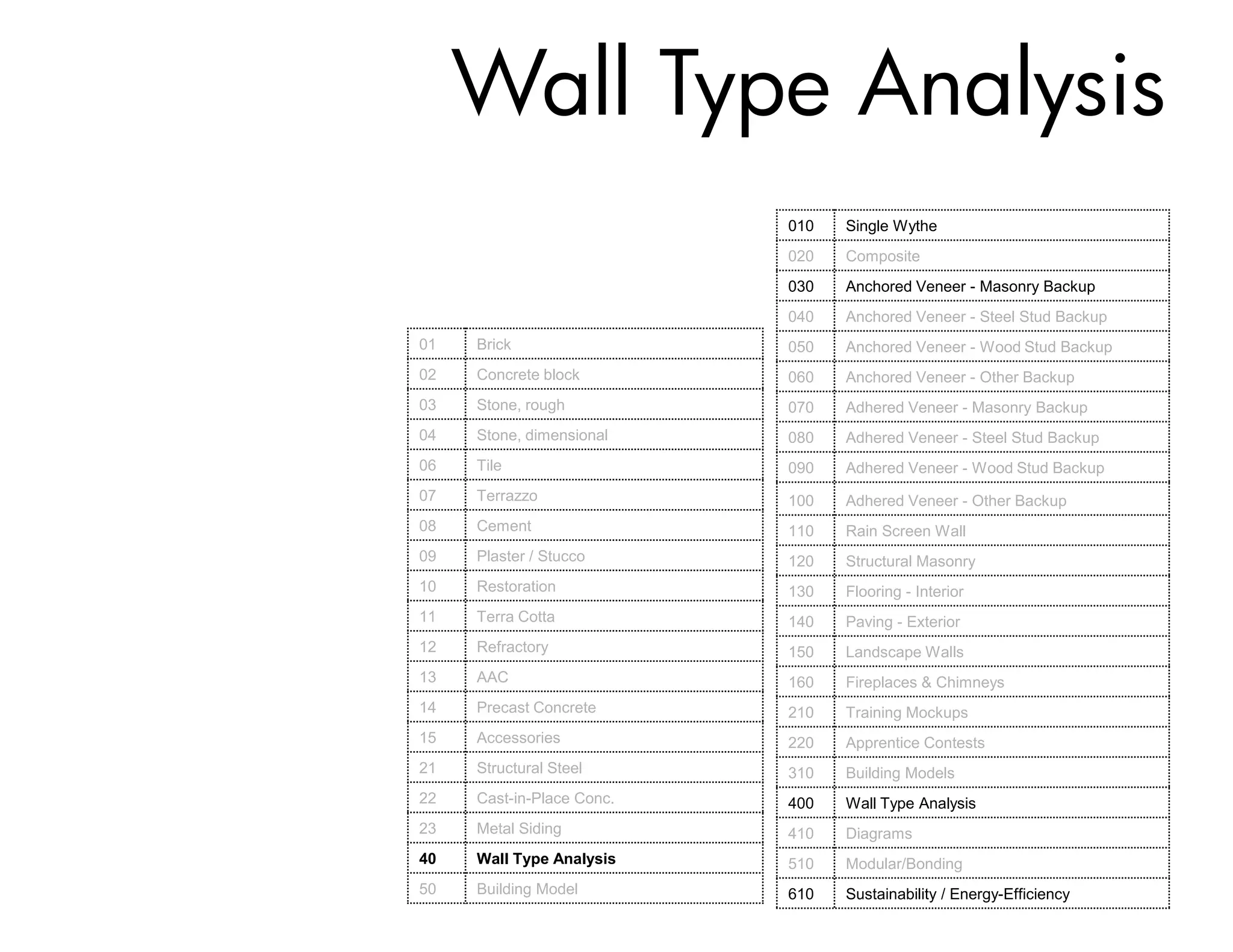

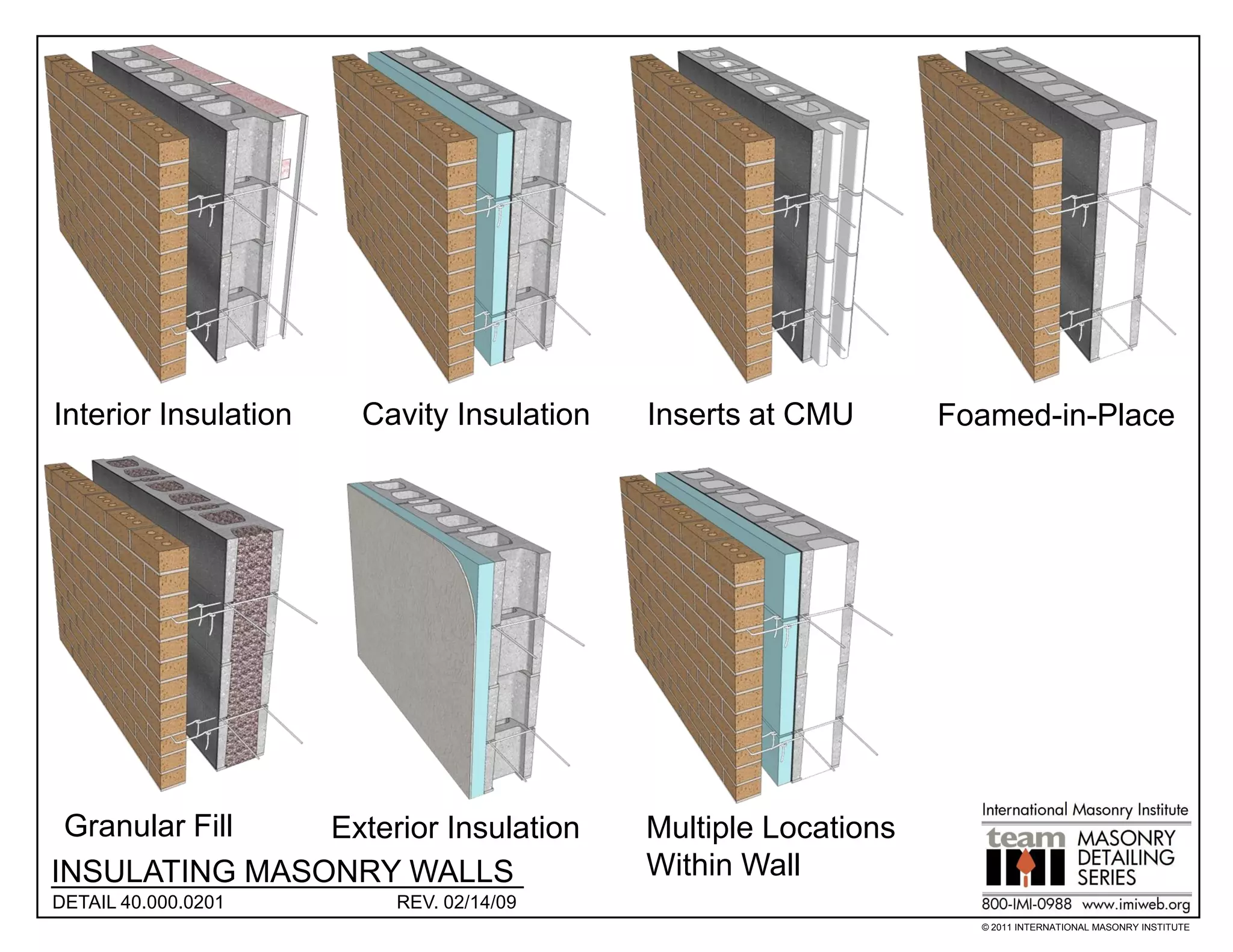

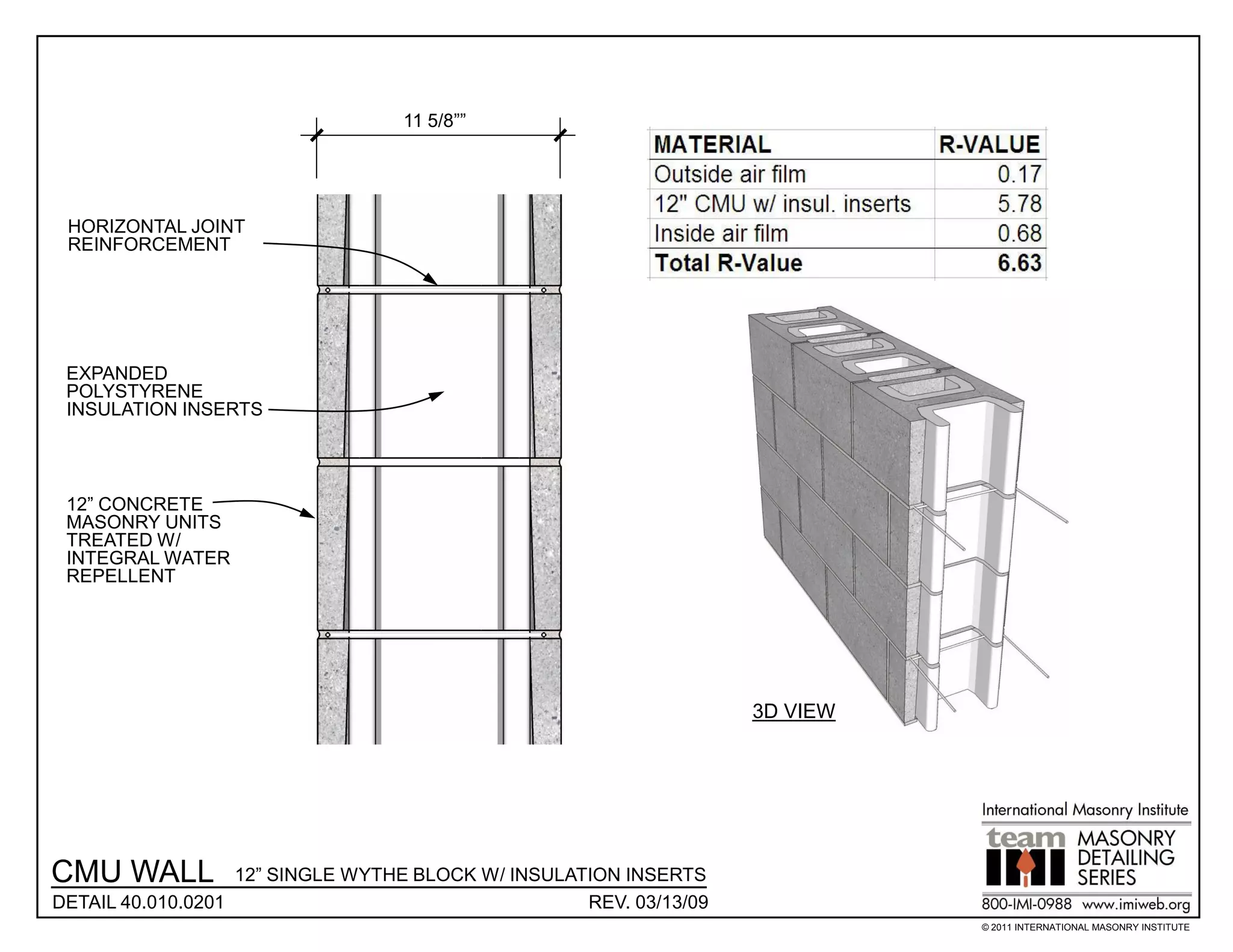

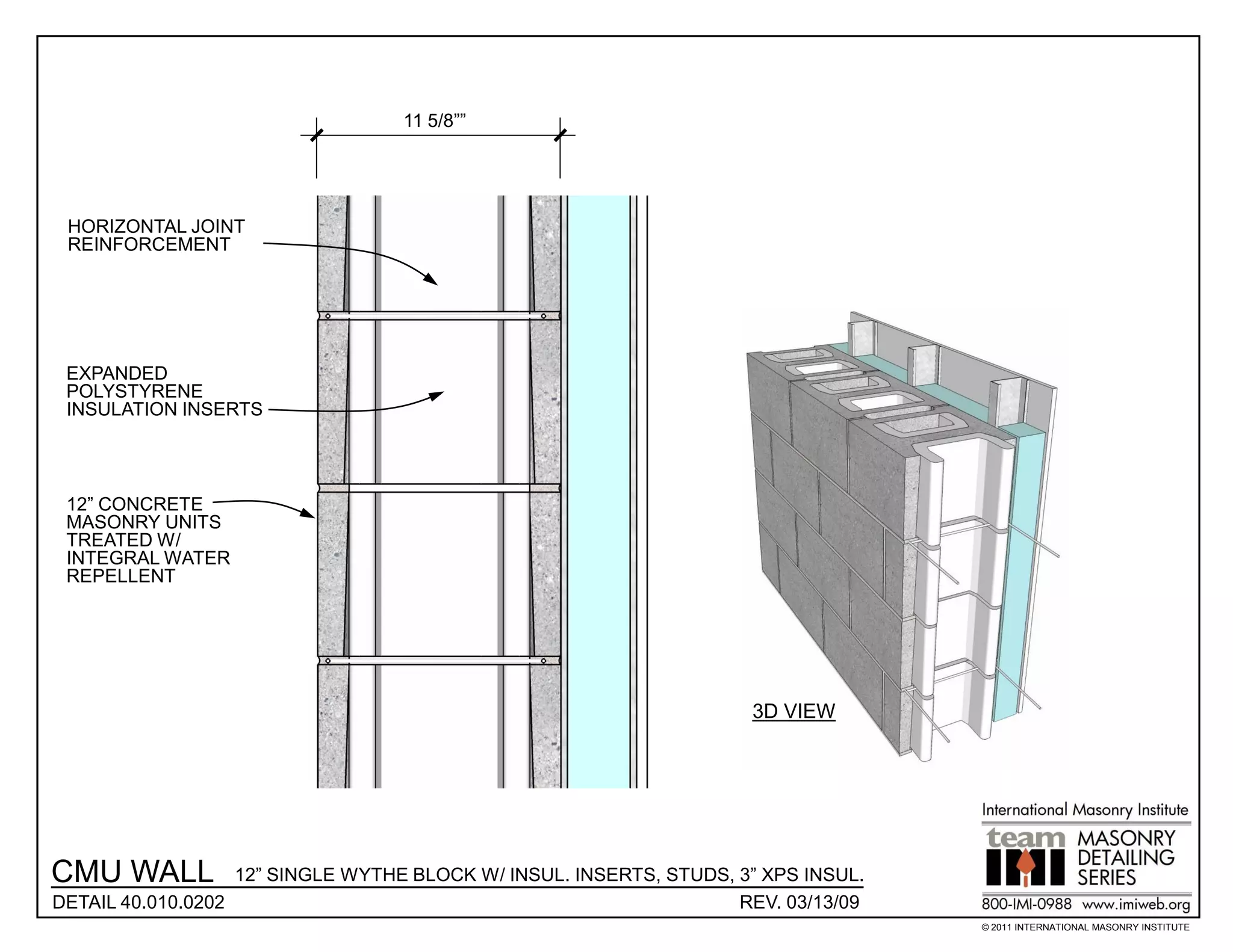

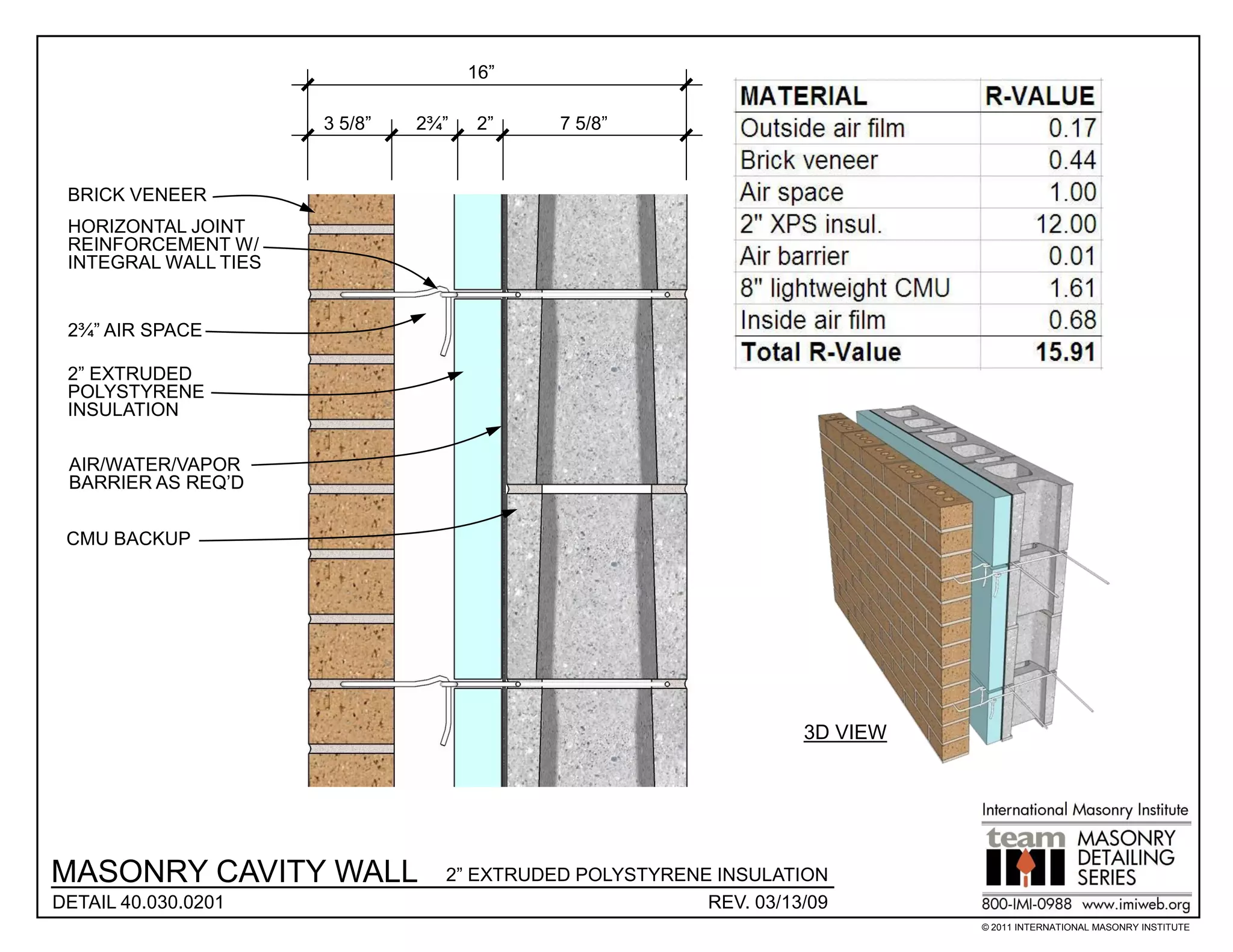

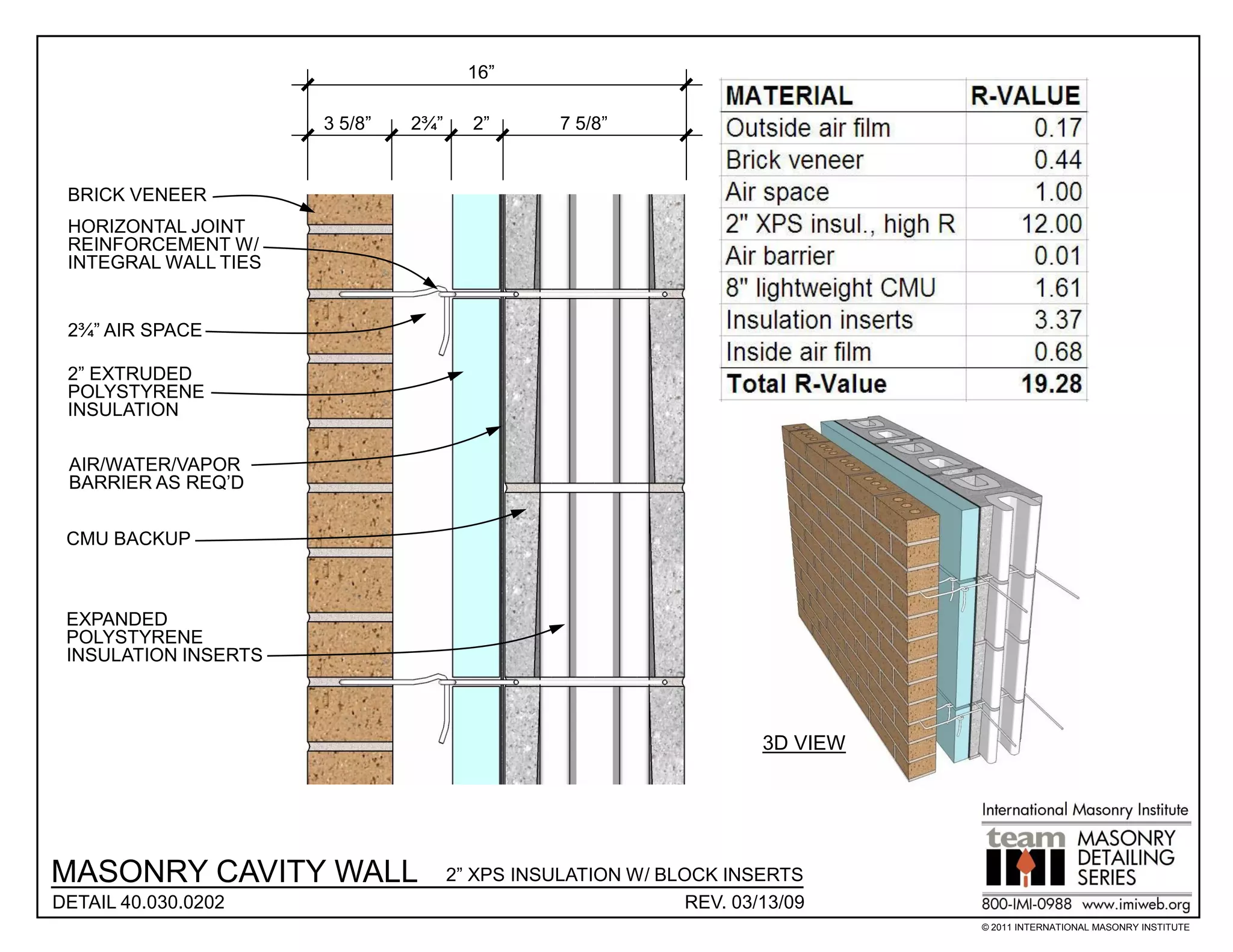

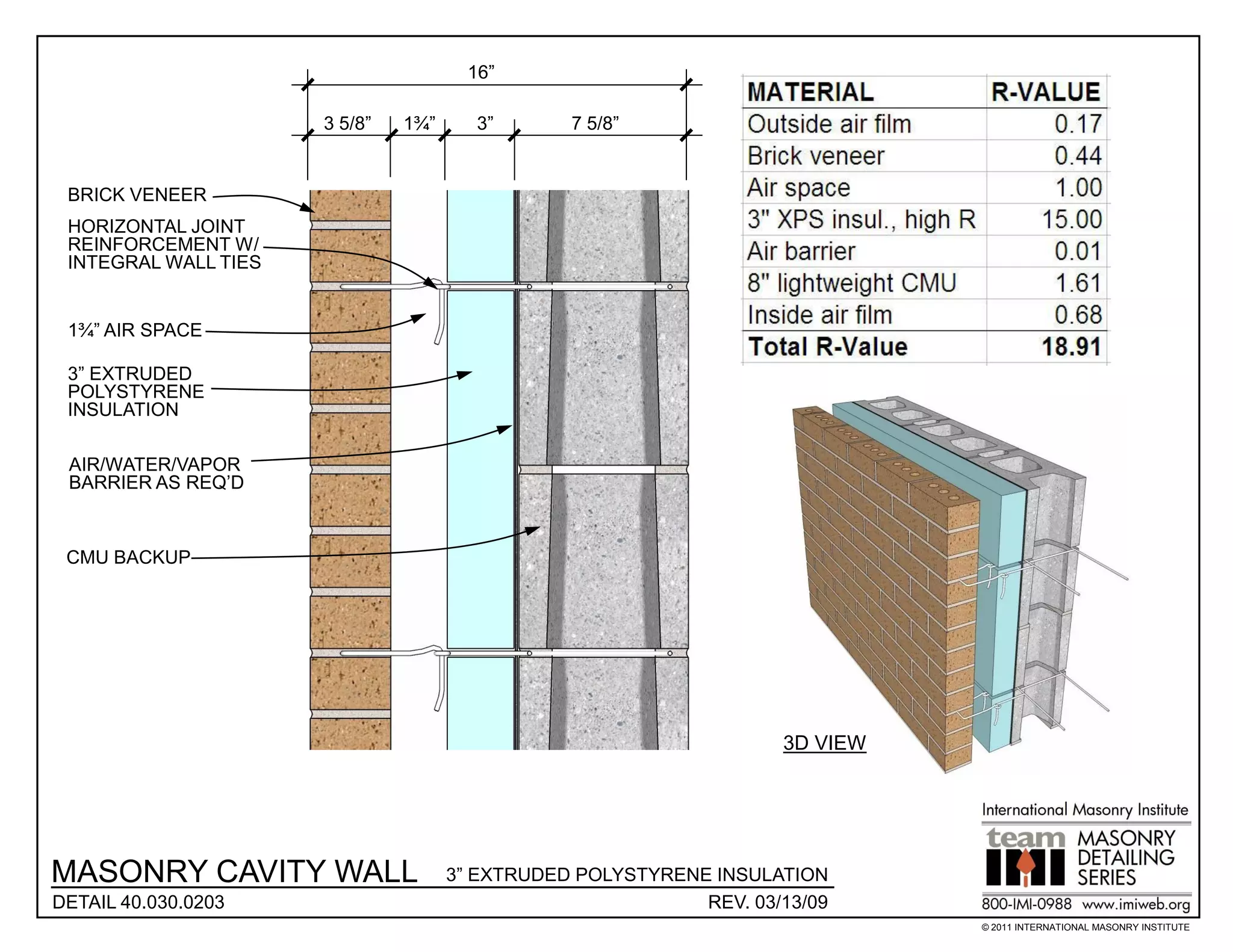

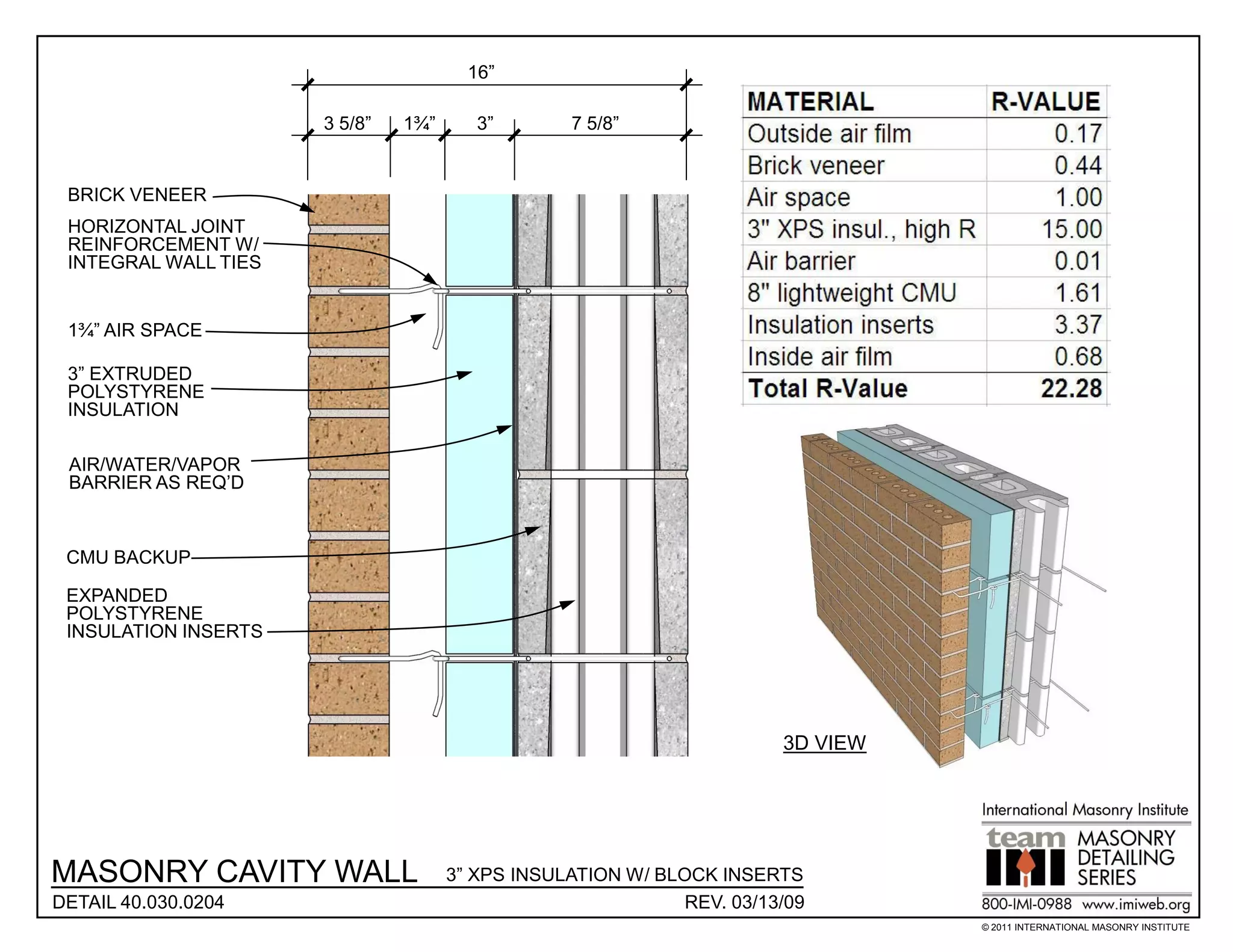

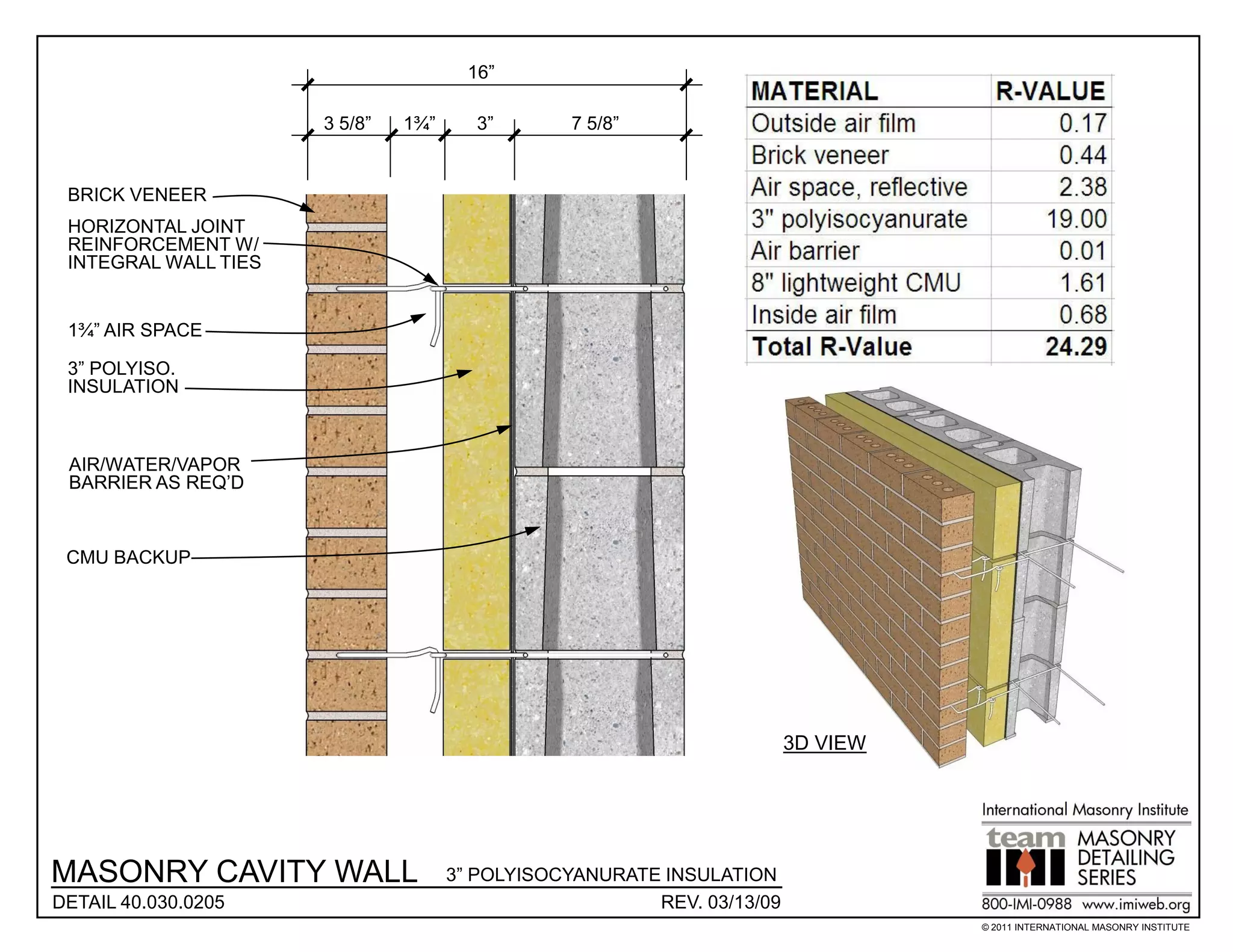

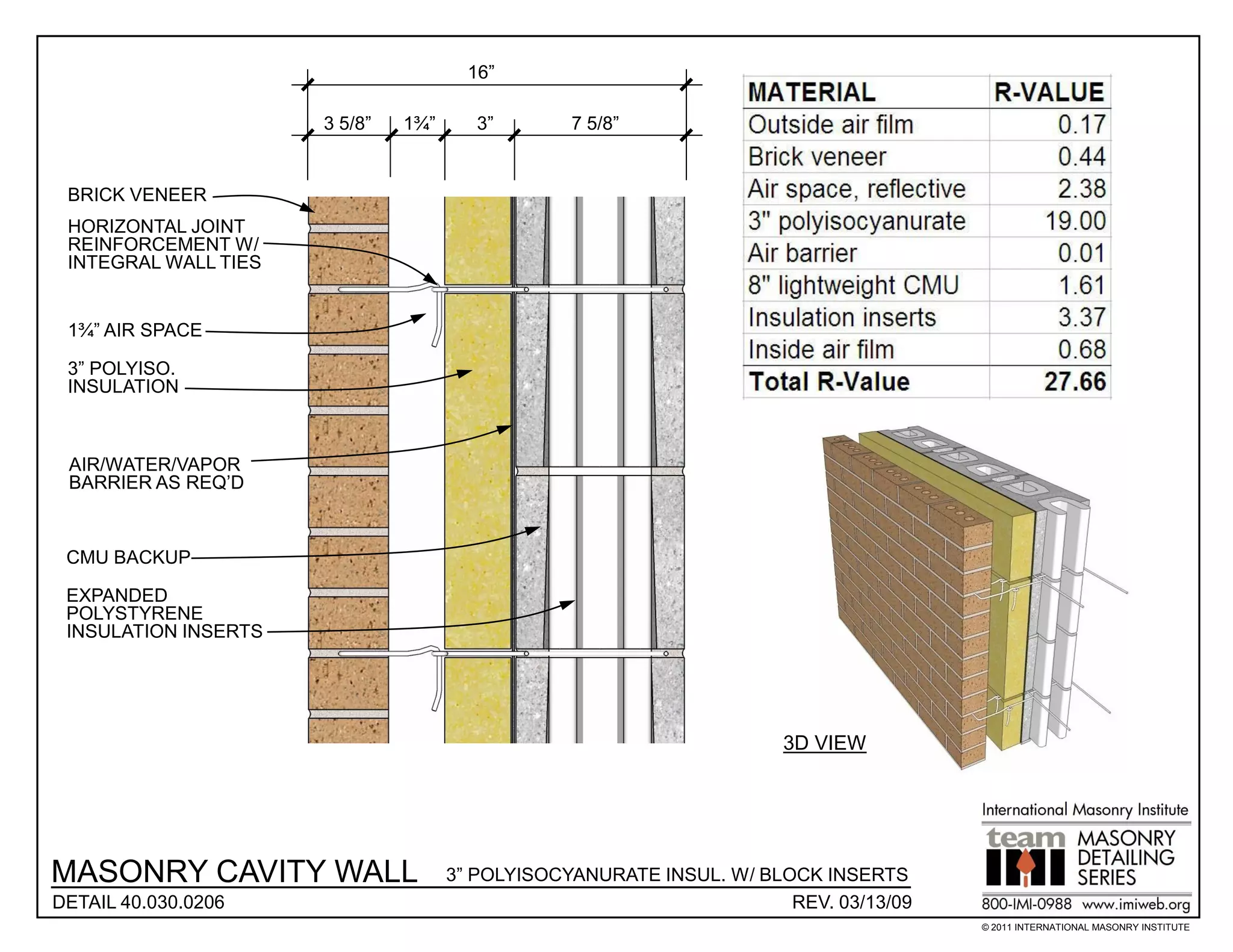

This document provides detailed specifications and guidelines for various masonry wall types, including anchored and adhered veneers, and comprehensive installation requirements. It covers essential components such as air/moisture/vapor barriers, insulation, flashing systems, and weep vent placement to ensure proper drainage and structural integrity. Each detail includes recommendations for materials and construction techniques per industry standards set by the International Masonry Institute.