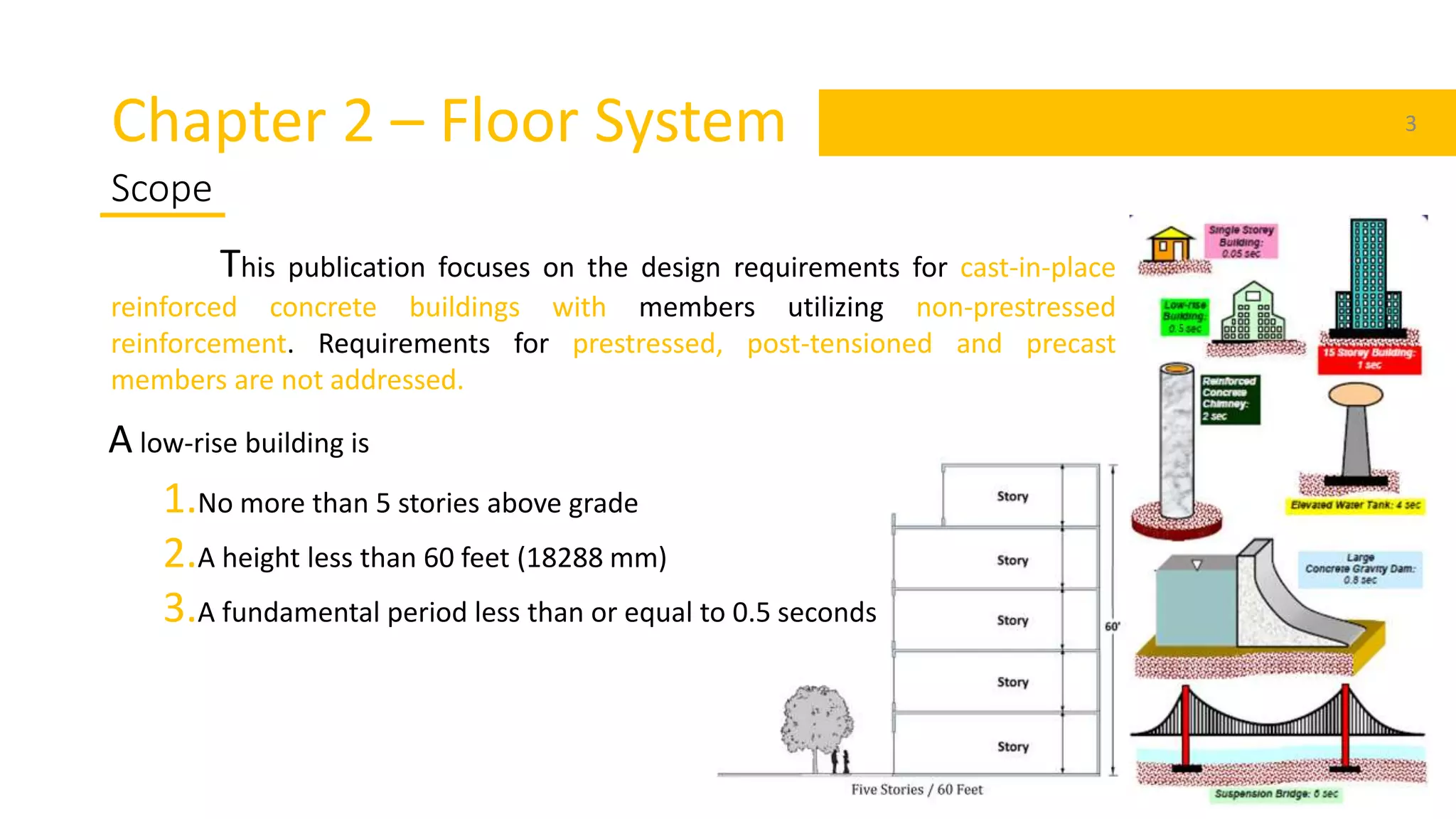

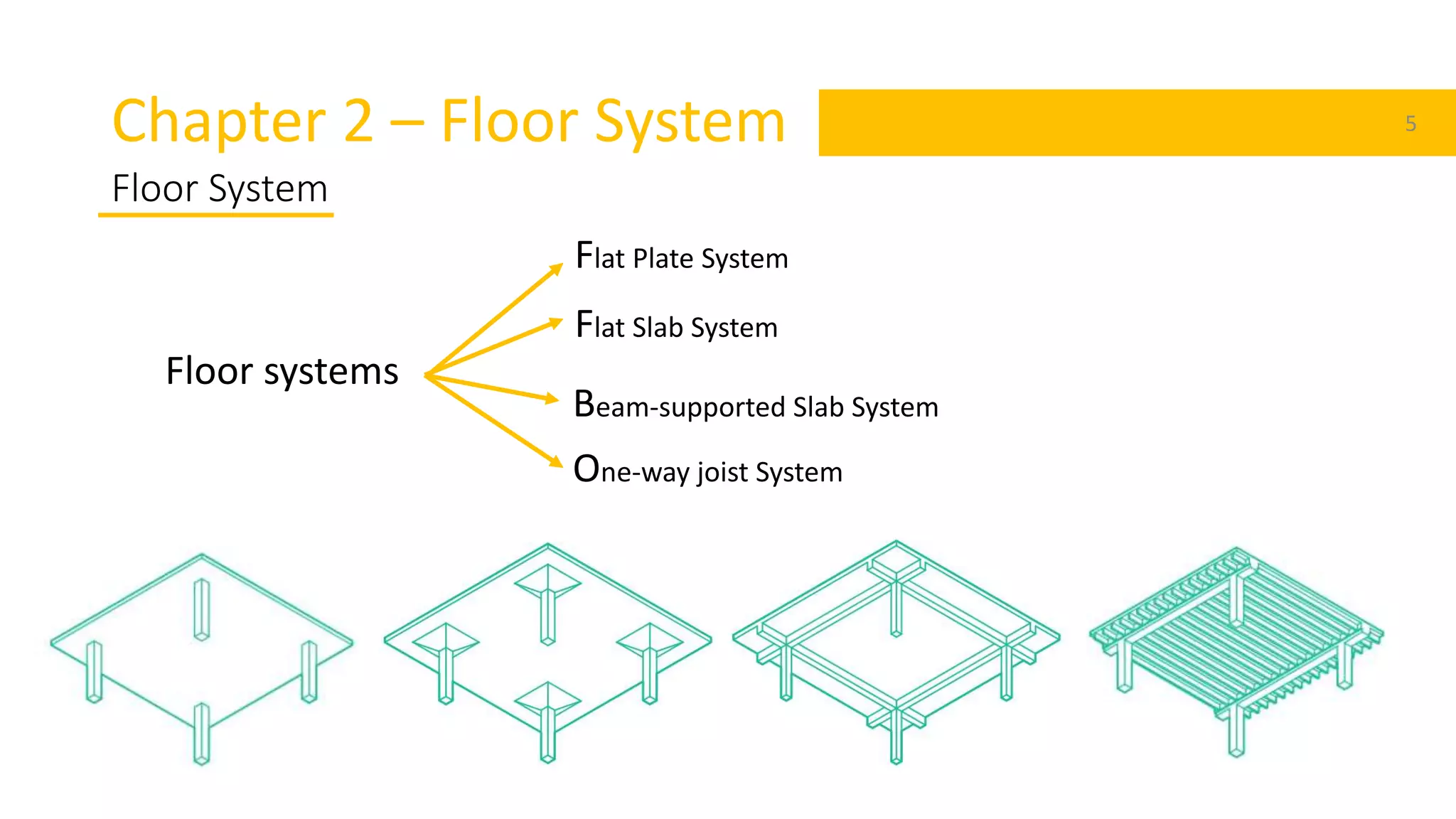

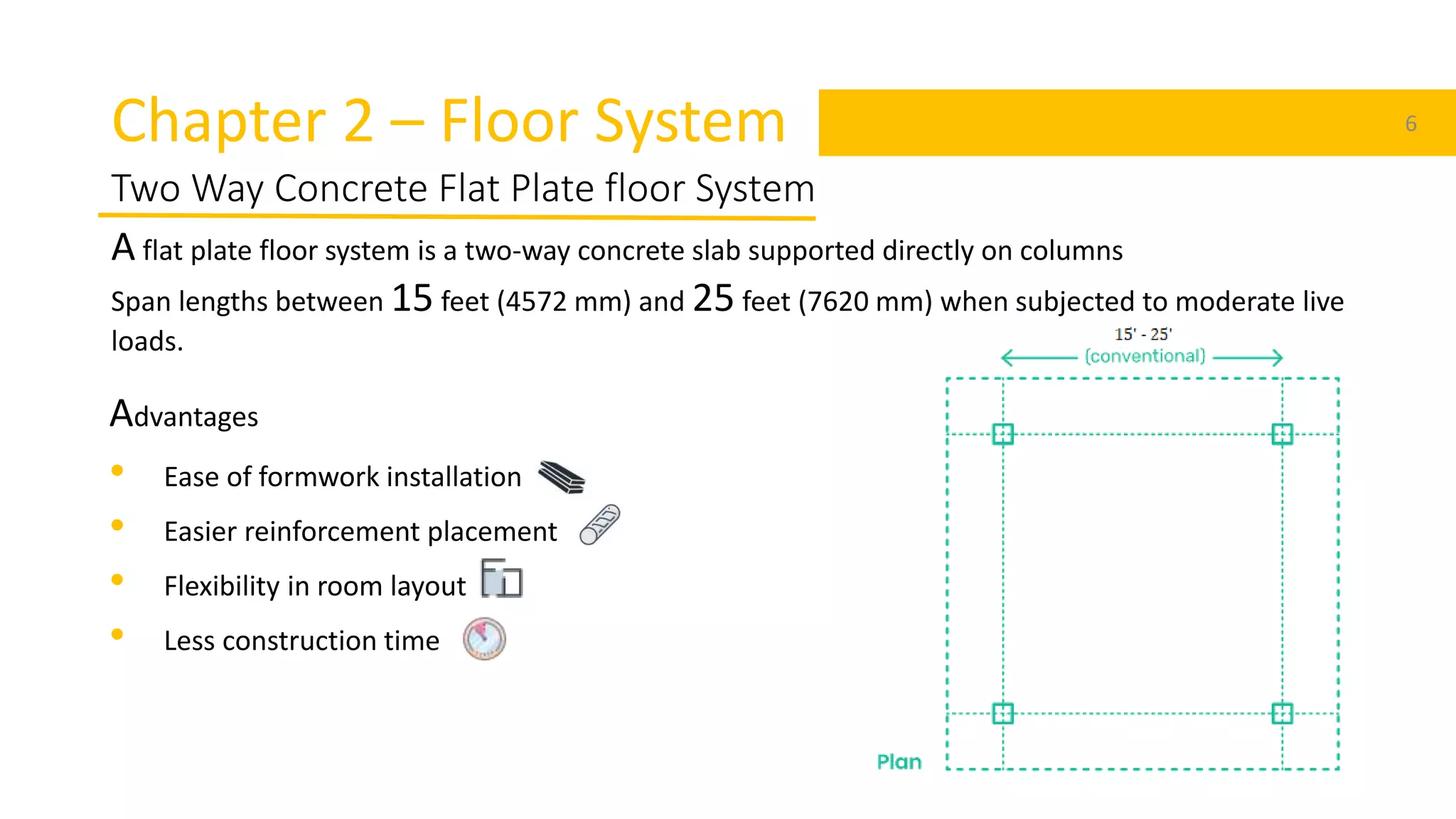

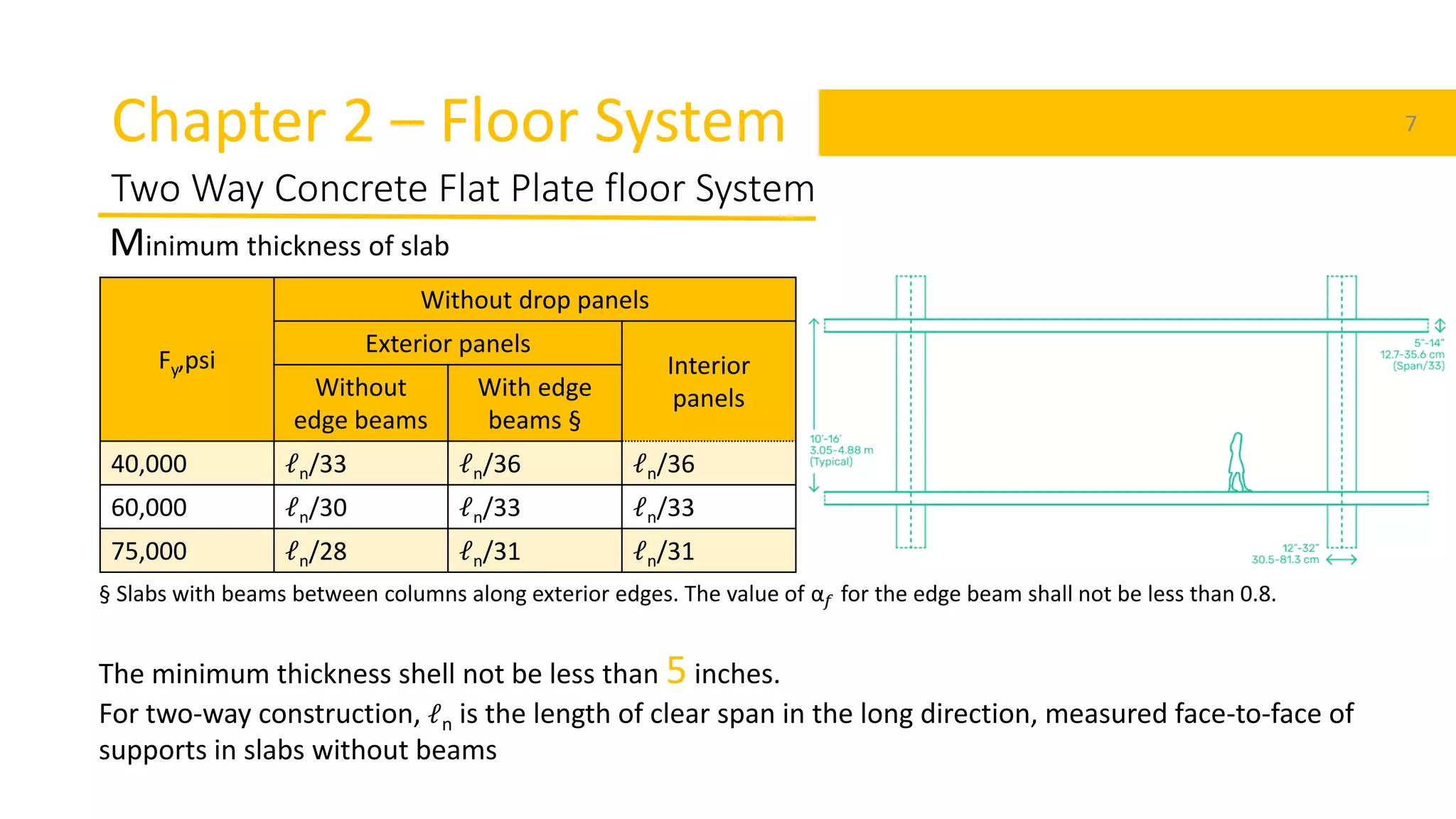

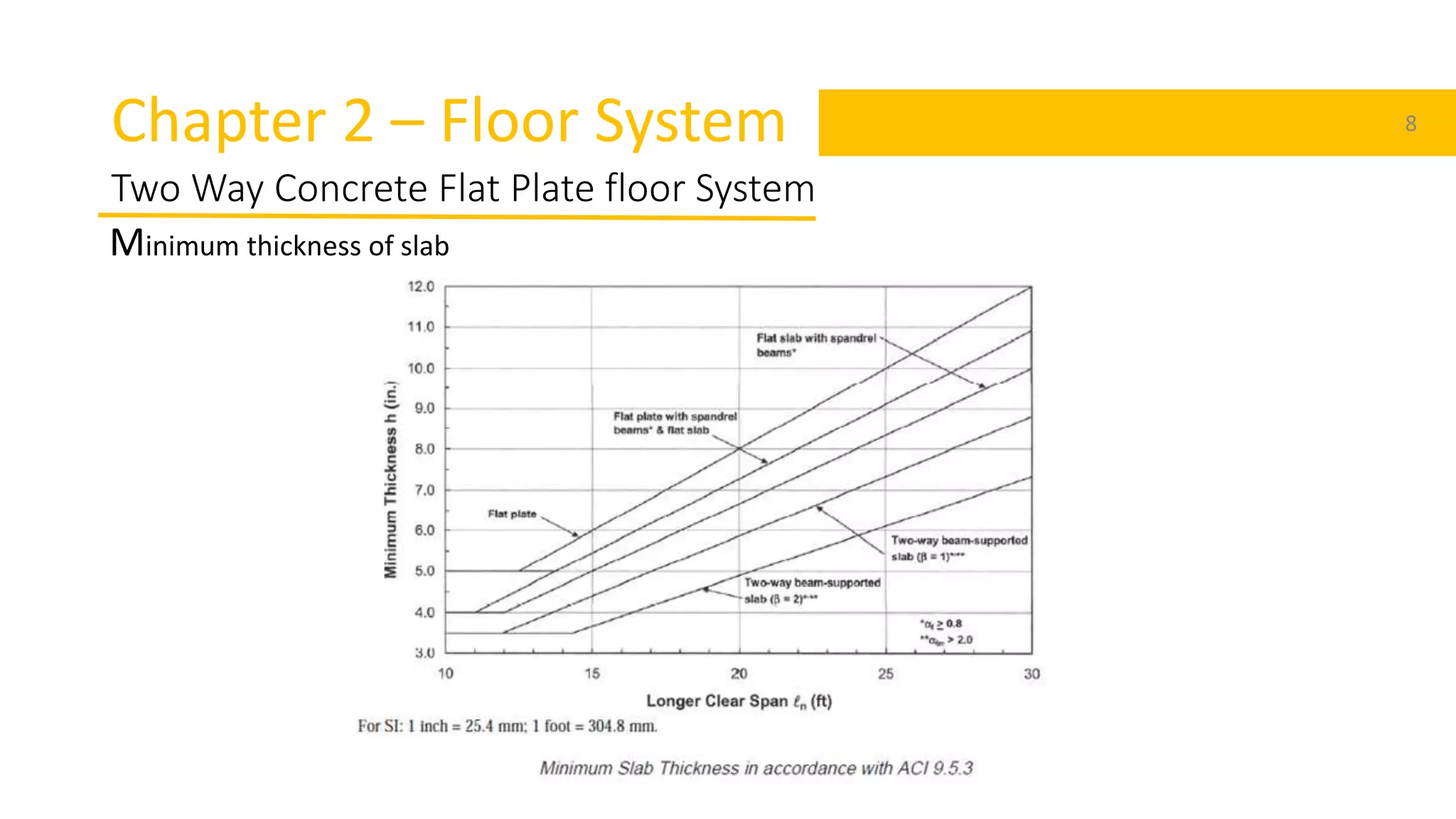

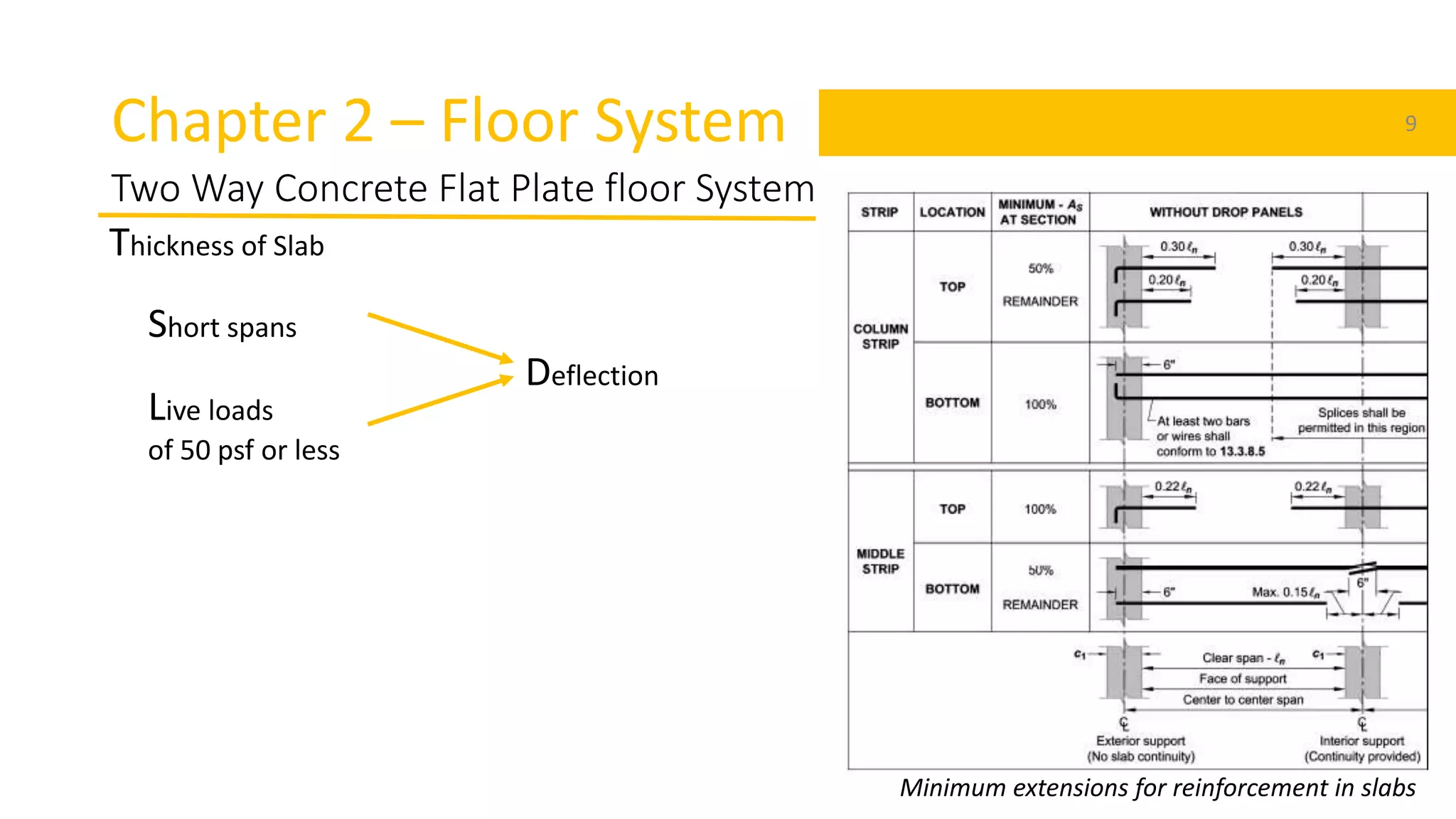

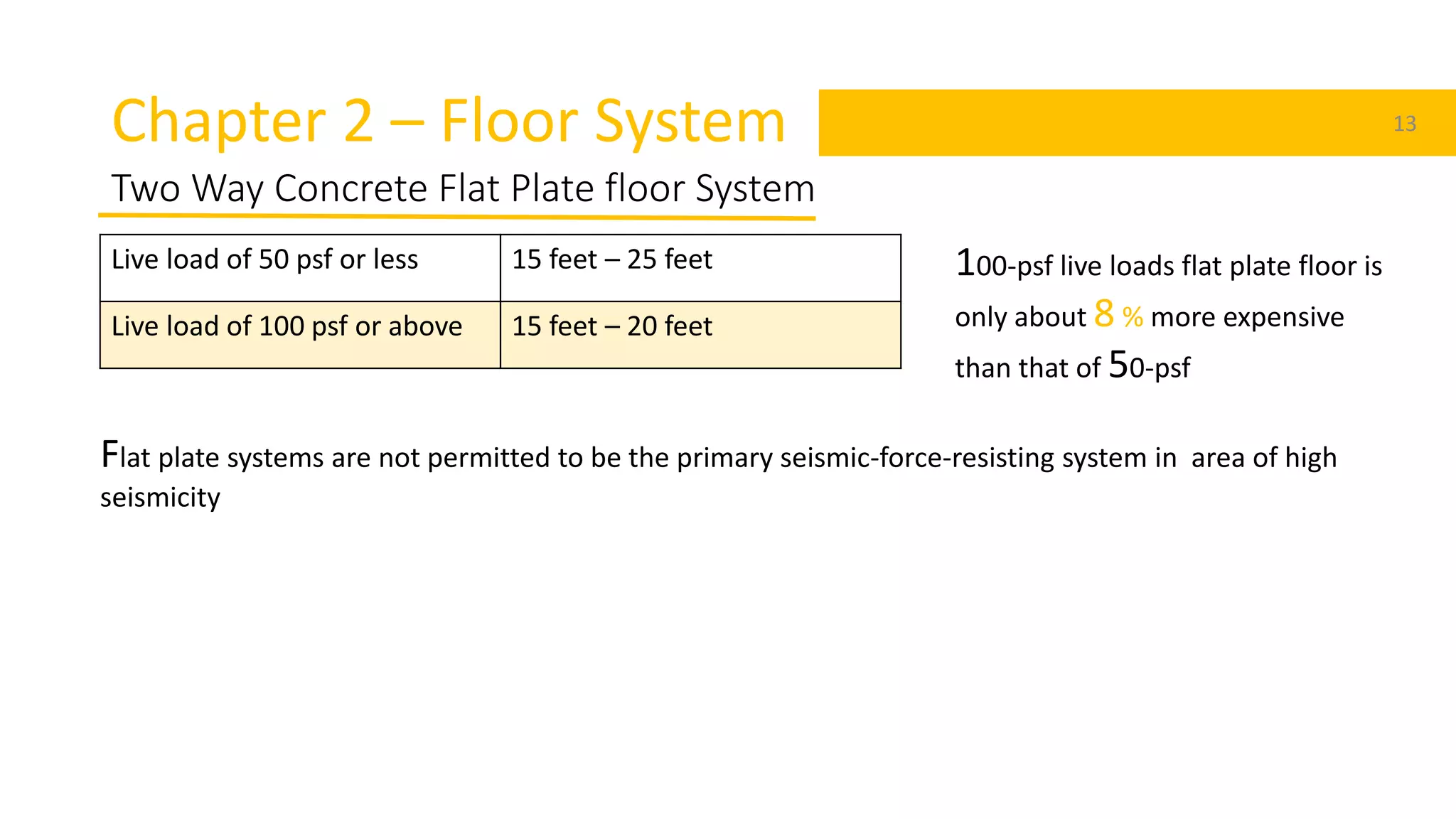

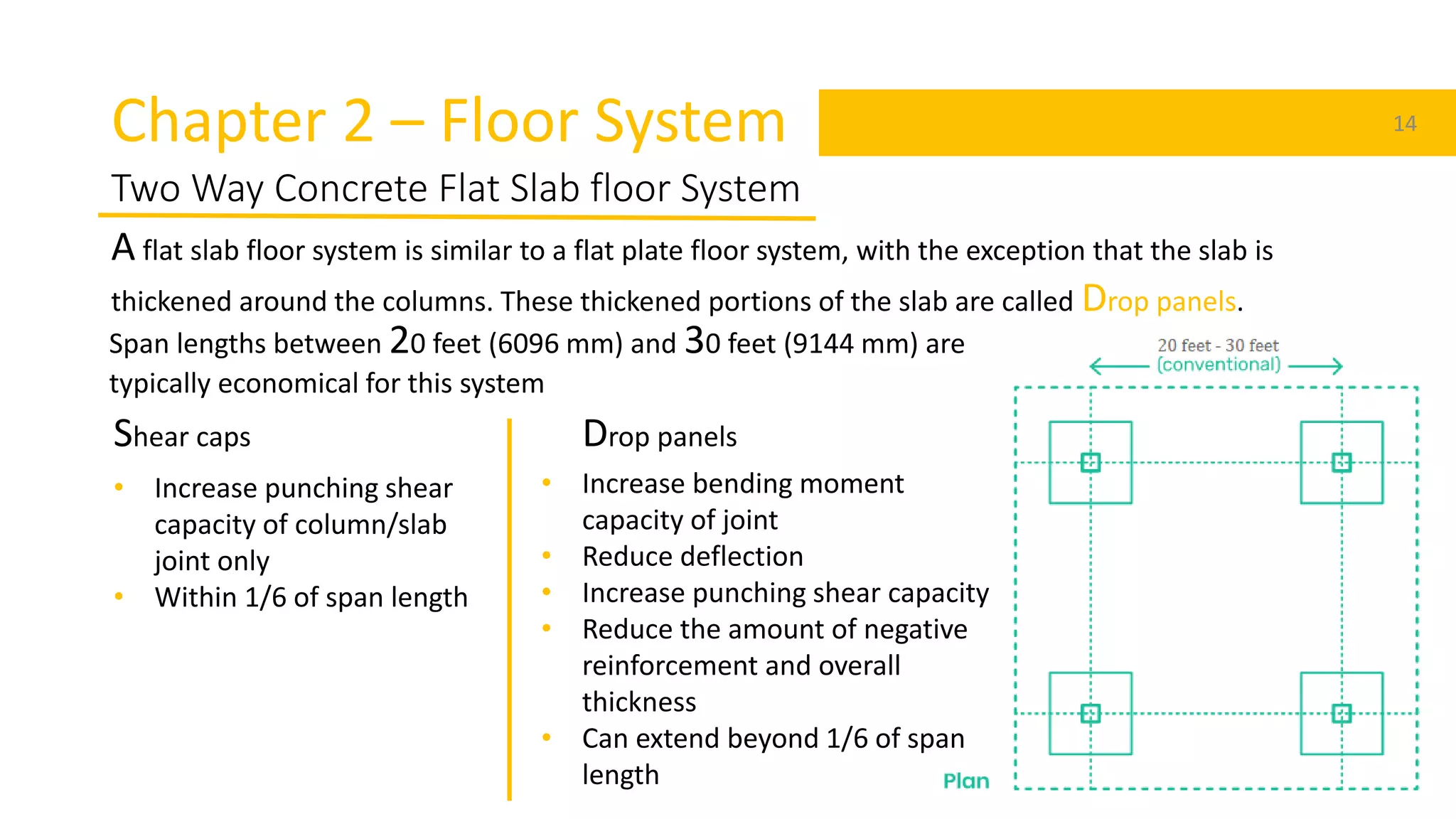

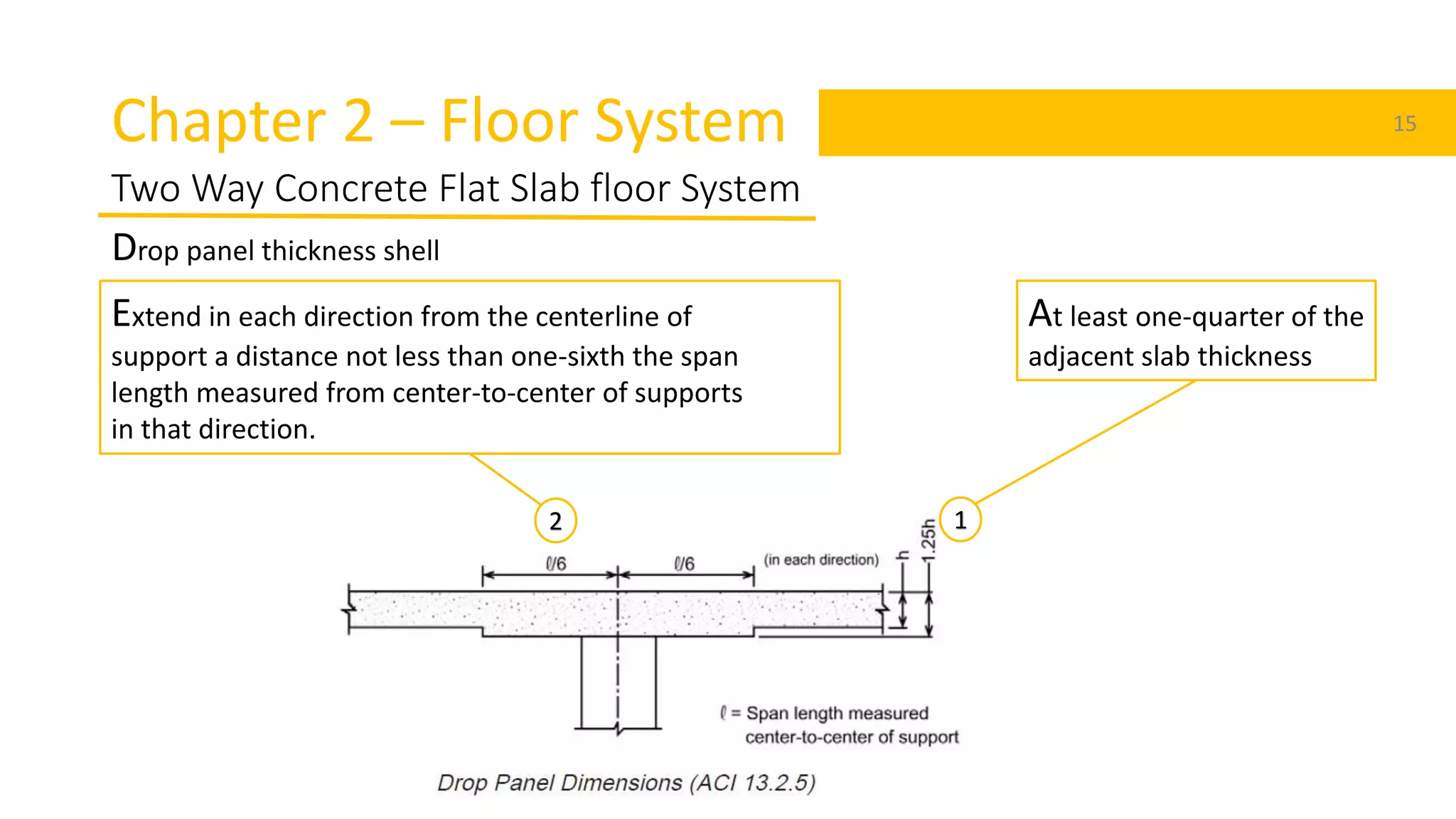

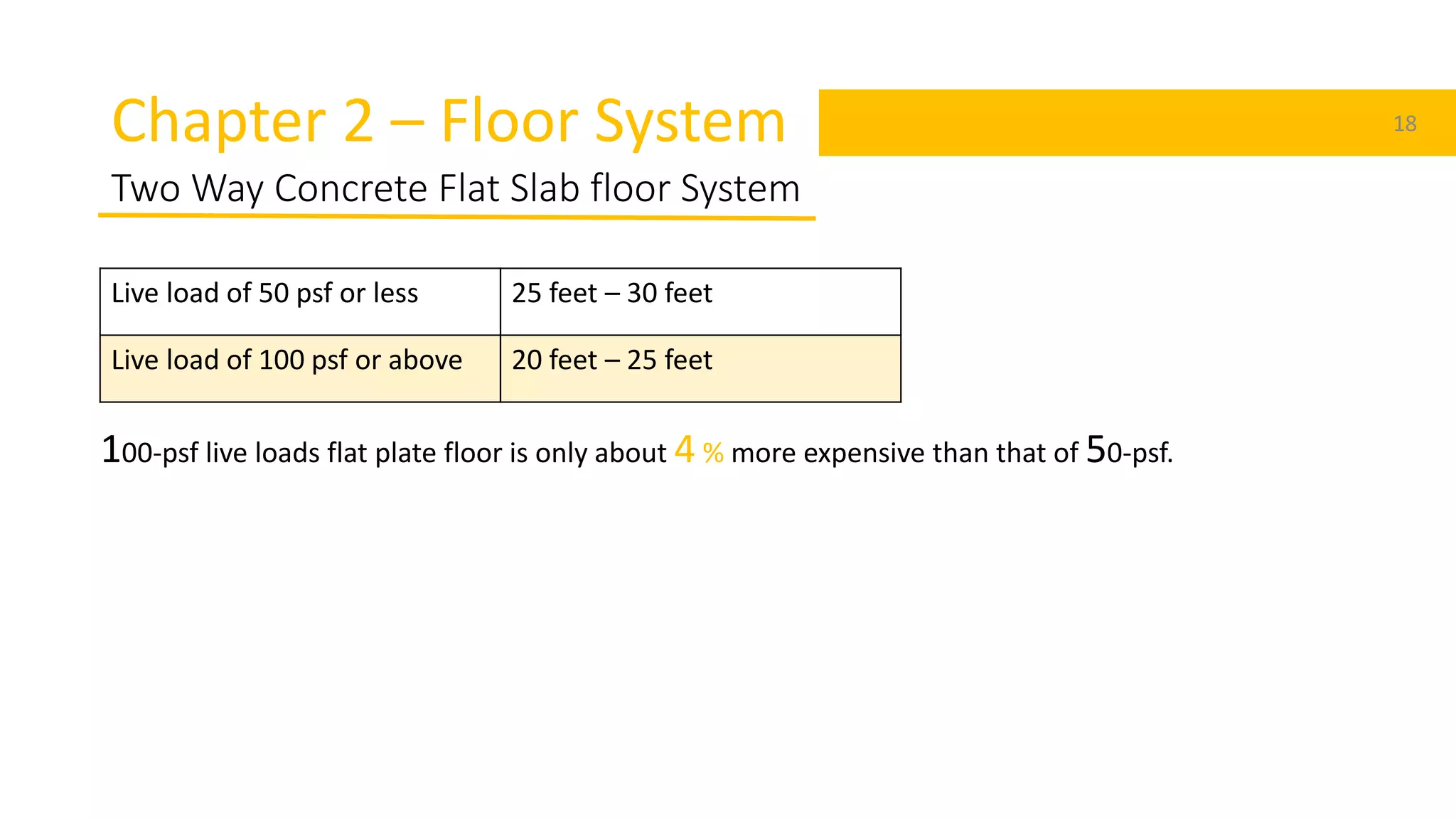

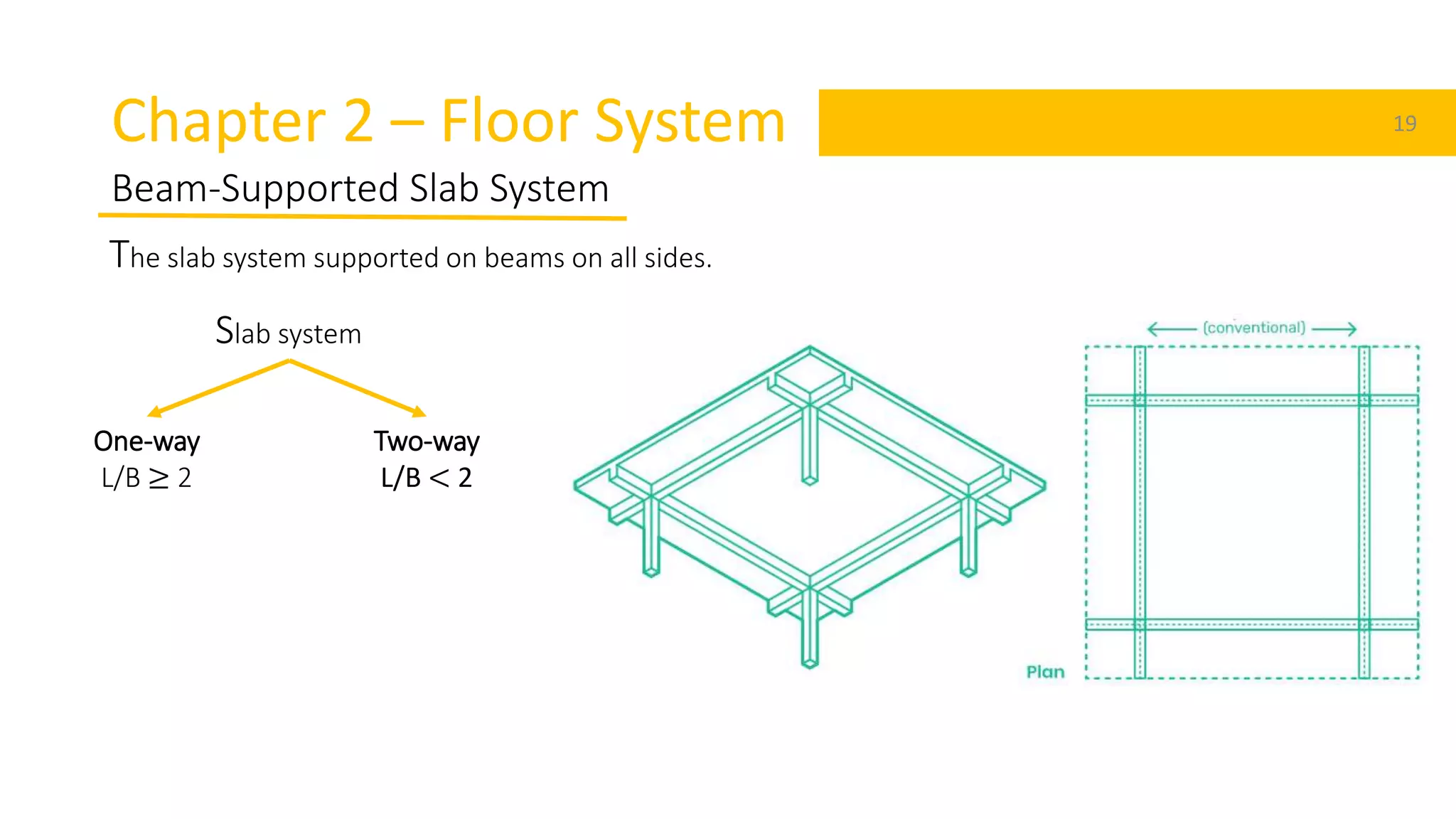

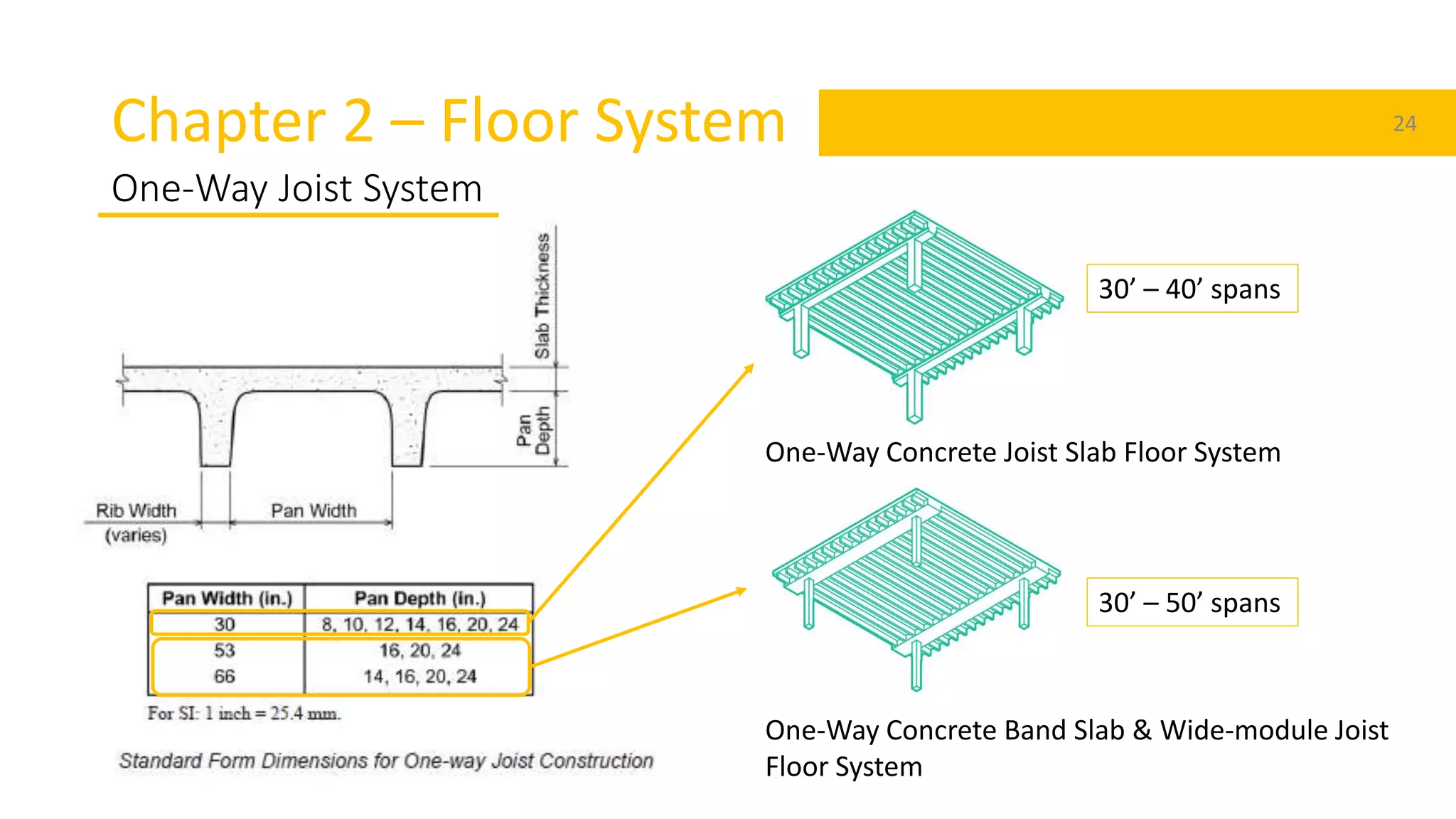

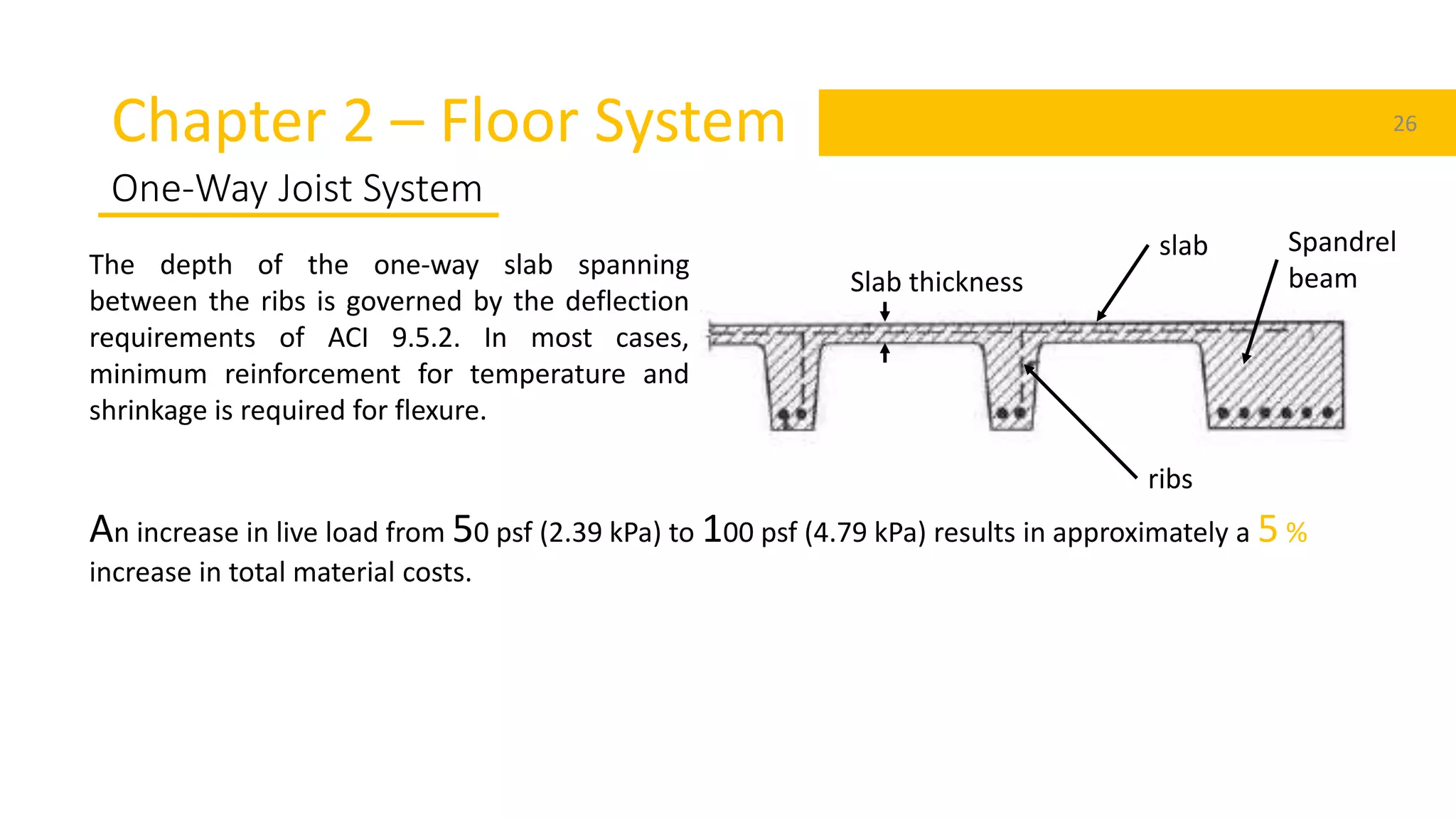

This document discusses various floor systems for low-rise reinforced concrete buildings. It describes flat plate, flat slab, beam-supported slab, and one-way joist systems. For each system, it covers advantages and disadvantages, span lengths, minimum thickness requirements, reinforcement considerations, and other design details. The primary focus is on optimizing design for economy while meeting strength and serviceability requirements.