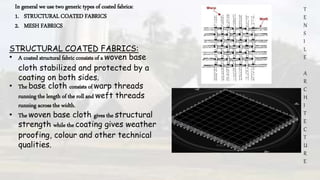

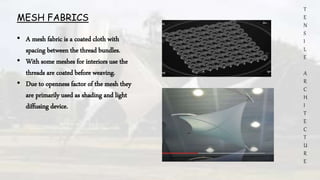

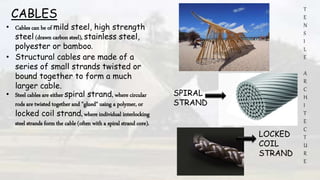

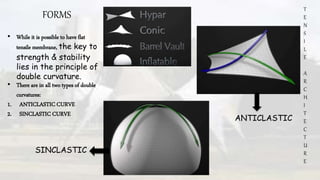

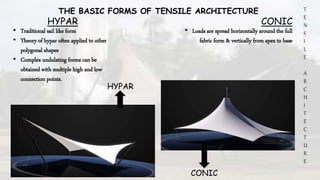

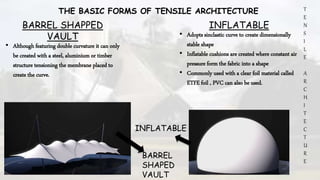

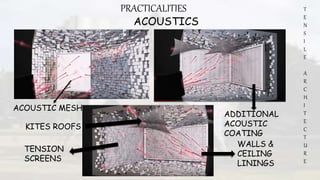

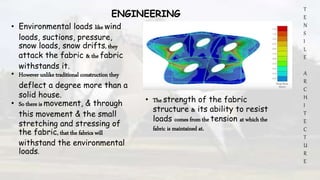

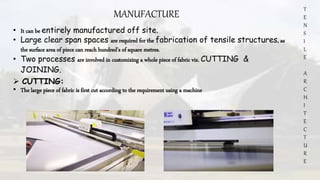

The seminar document provides information on tensile architecture. It discusses how tensile structures carry only tension and use double curvature for strength and stability. Key concepts covered include the history of tensile structures from tents to modern designs by Frei Otto, common materials like tensile fabrics and cables, and basic forms like hypars and conics. Benefits are highlighted such as dynamic shapes, solar control, and use for temporary installations. The document also outlines design, engineering, manufacturing, and installation processes.