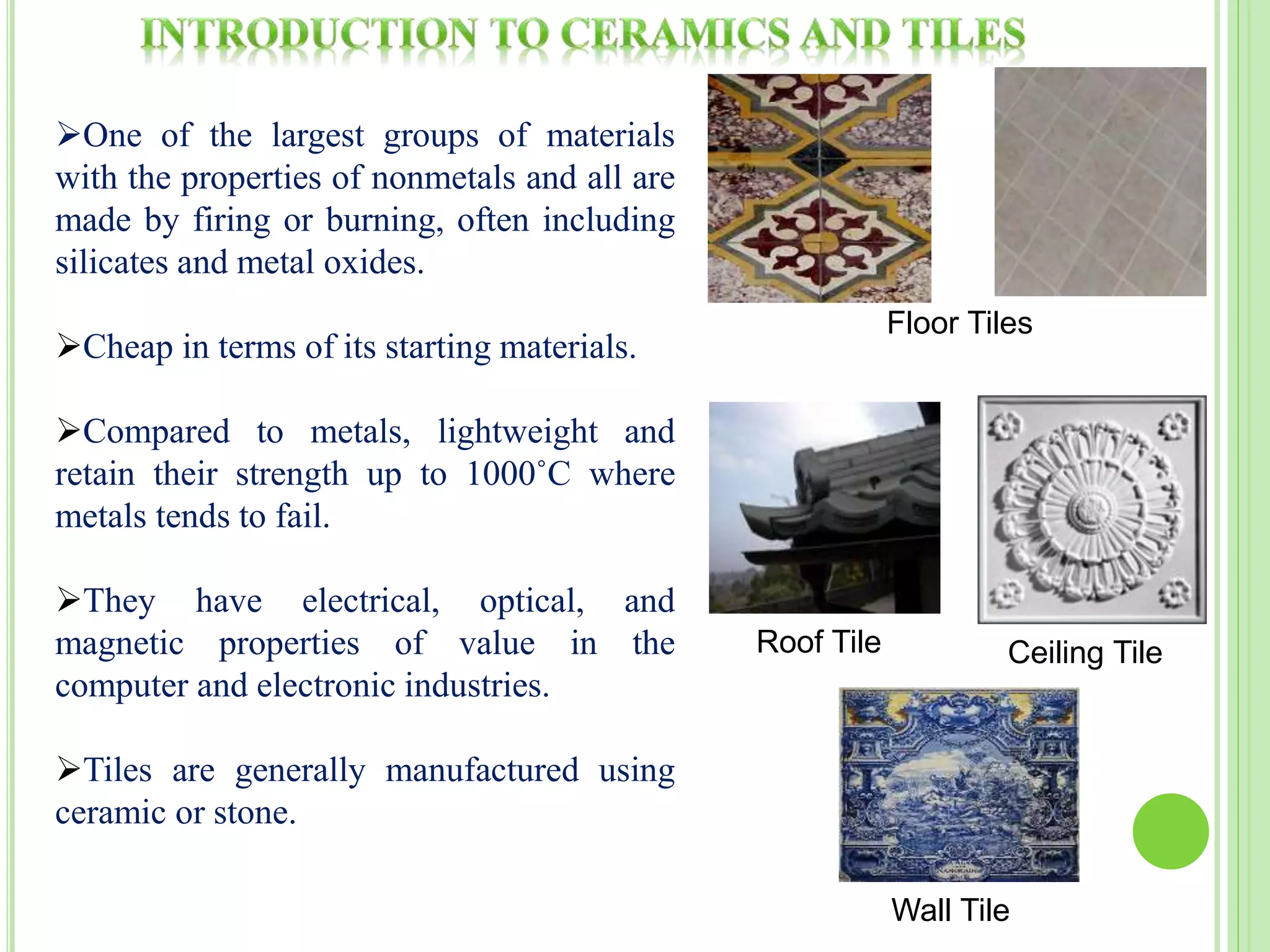

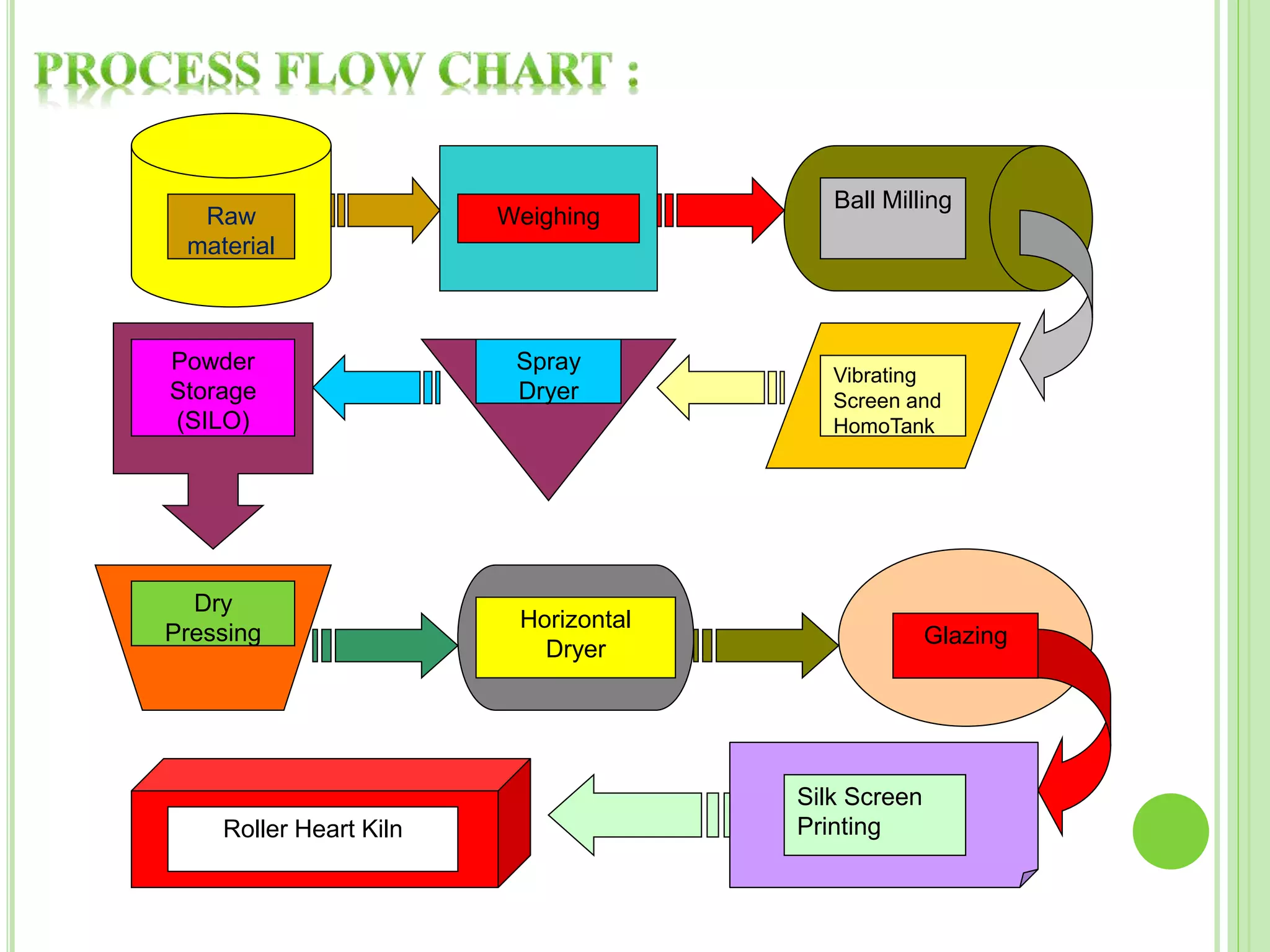

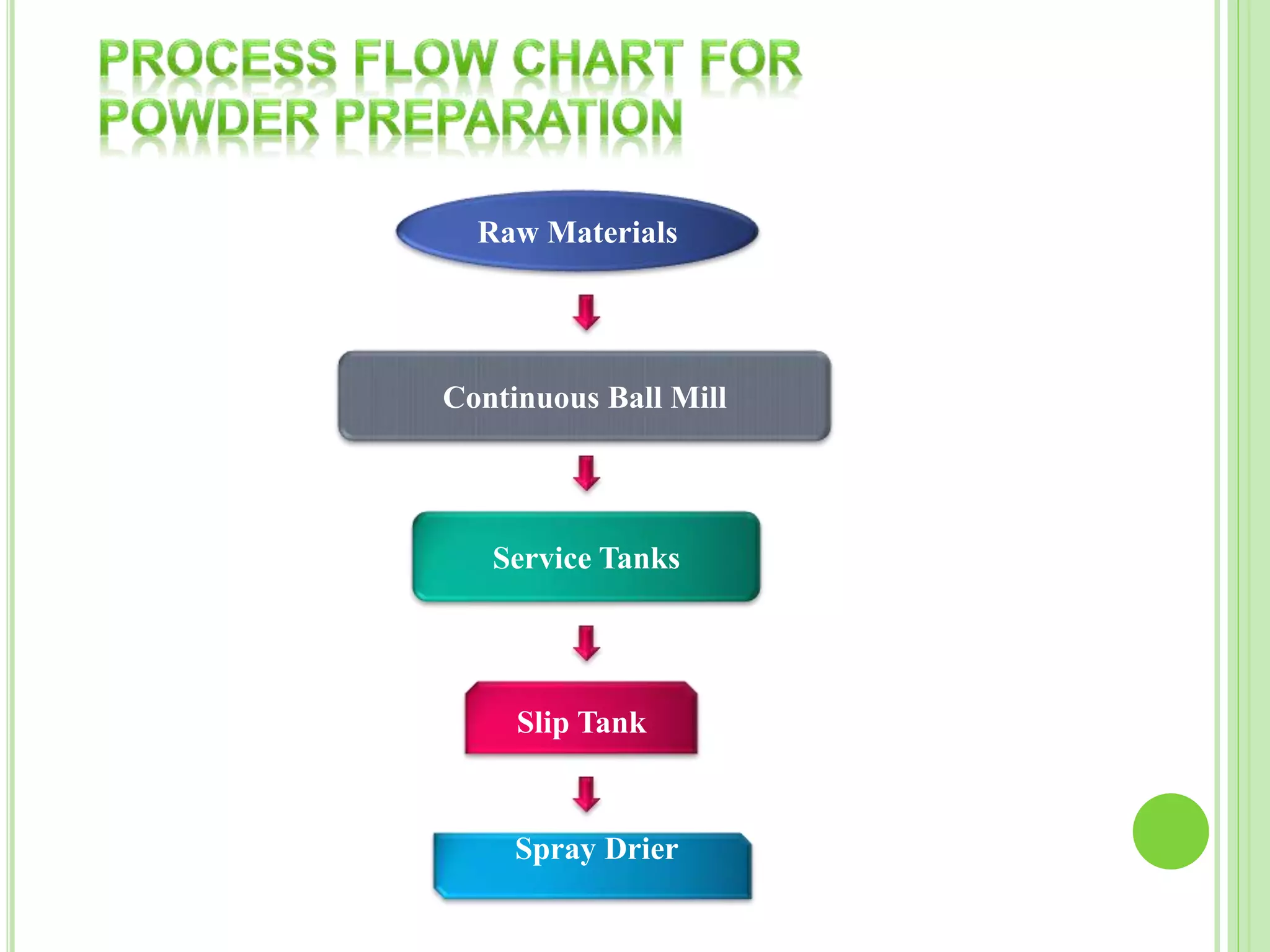

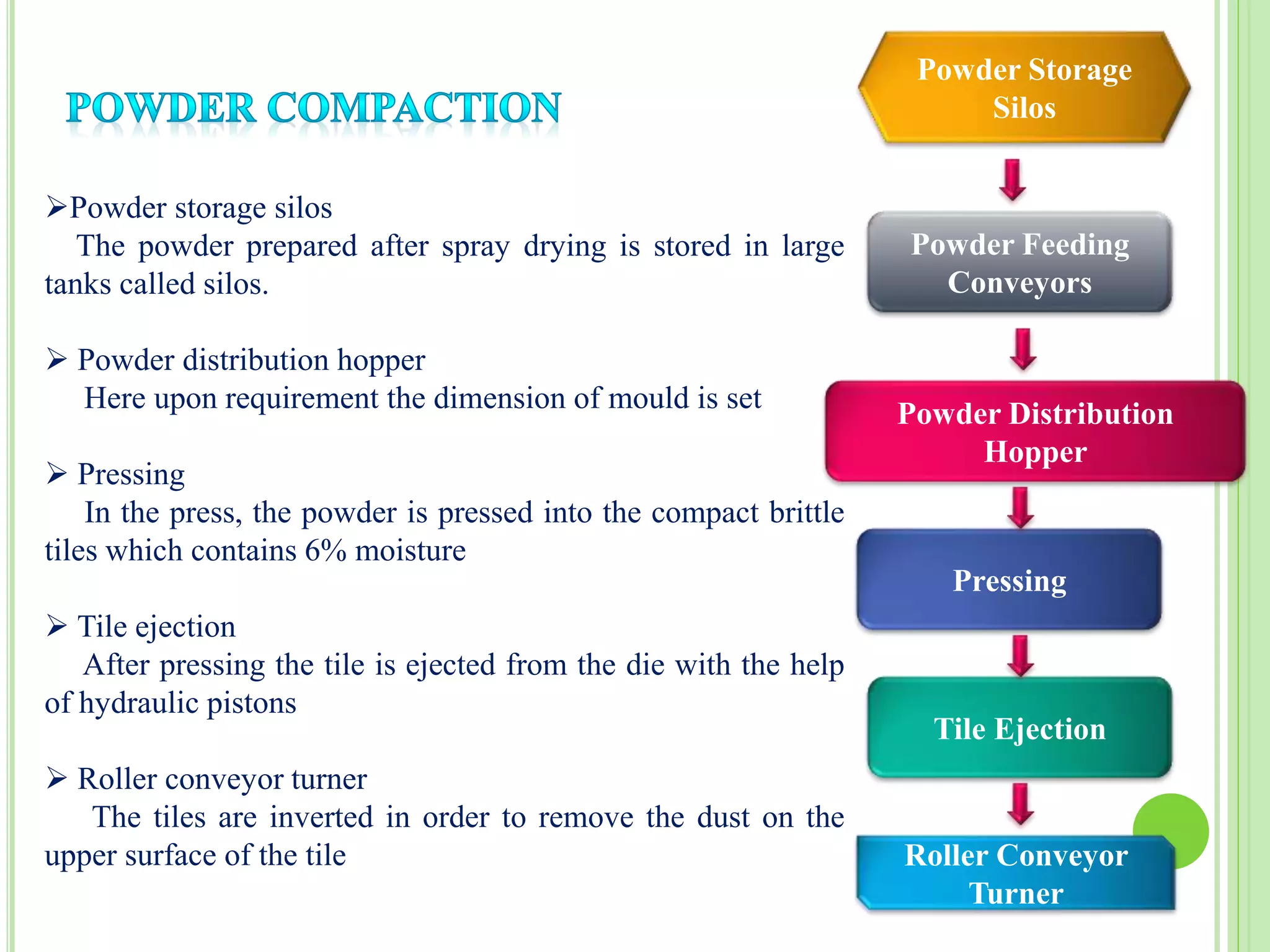

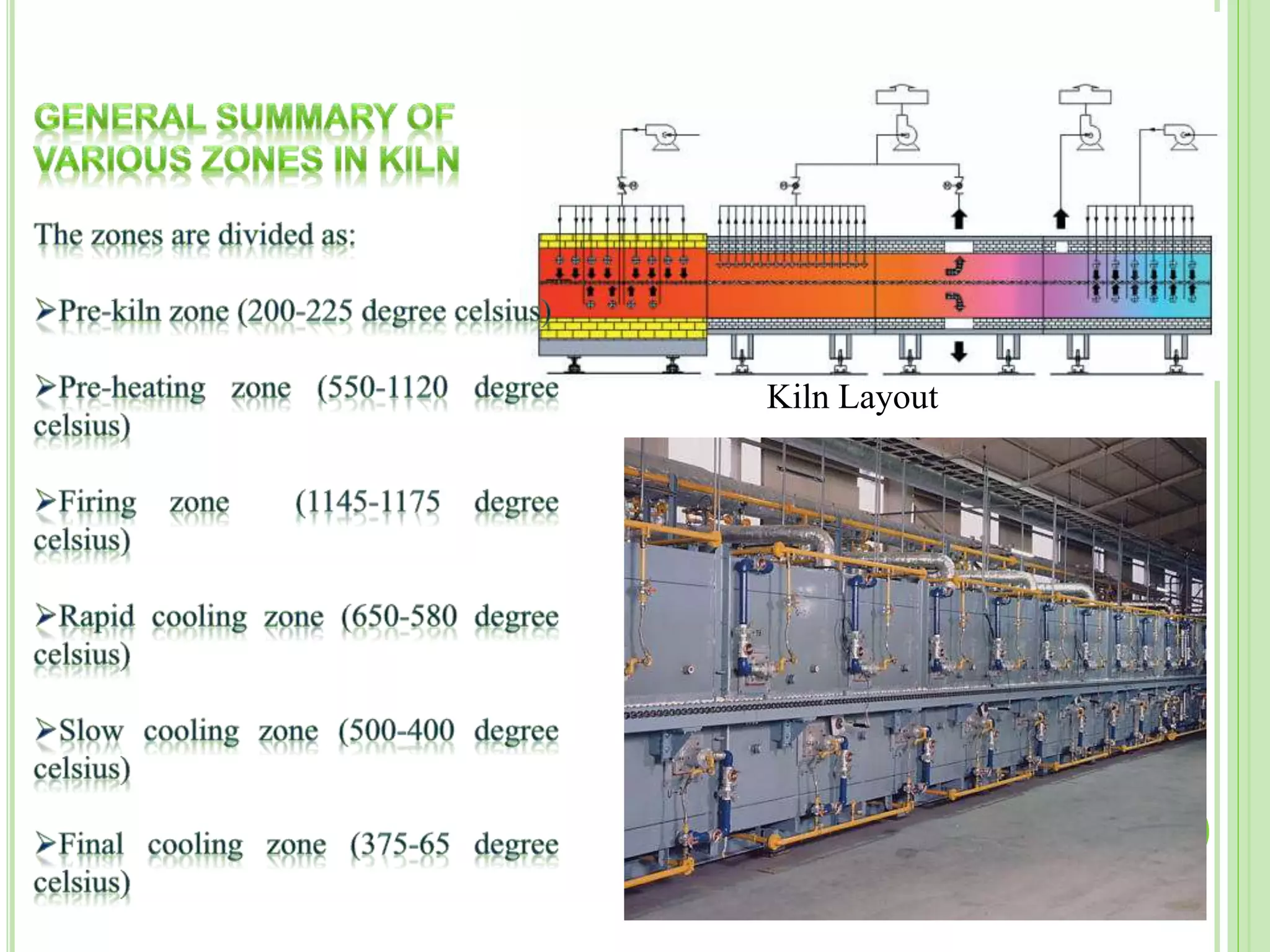

The document summarizes the manufacturing process of ceramic tiles. Raw materials like clay, silica, and talc are ground into a slurry using a continuous ball mill. The slurry is spray dried into a fine powder and stored in silos. The powder is pressed into tiles using hydraulic presses and dried. Tiles are glazed, printed, and fired in a roller kiln to increase strength. The finished tiles are sorted, packaged, and shipped for use in floors, walls, roofs, and ceilings.