The document provides an overview of the sand casting process in 13 steps:

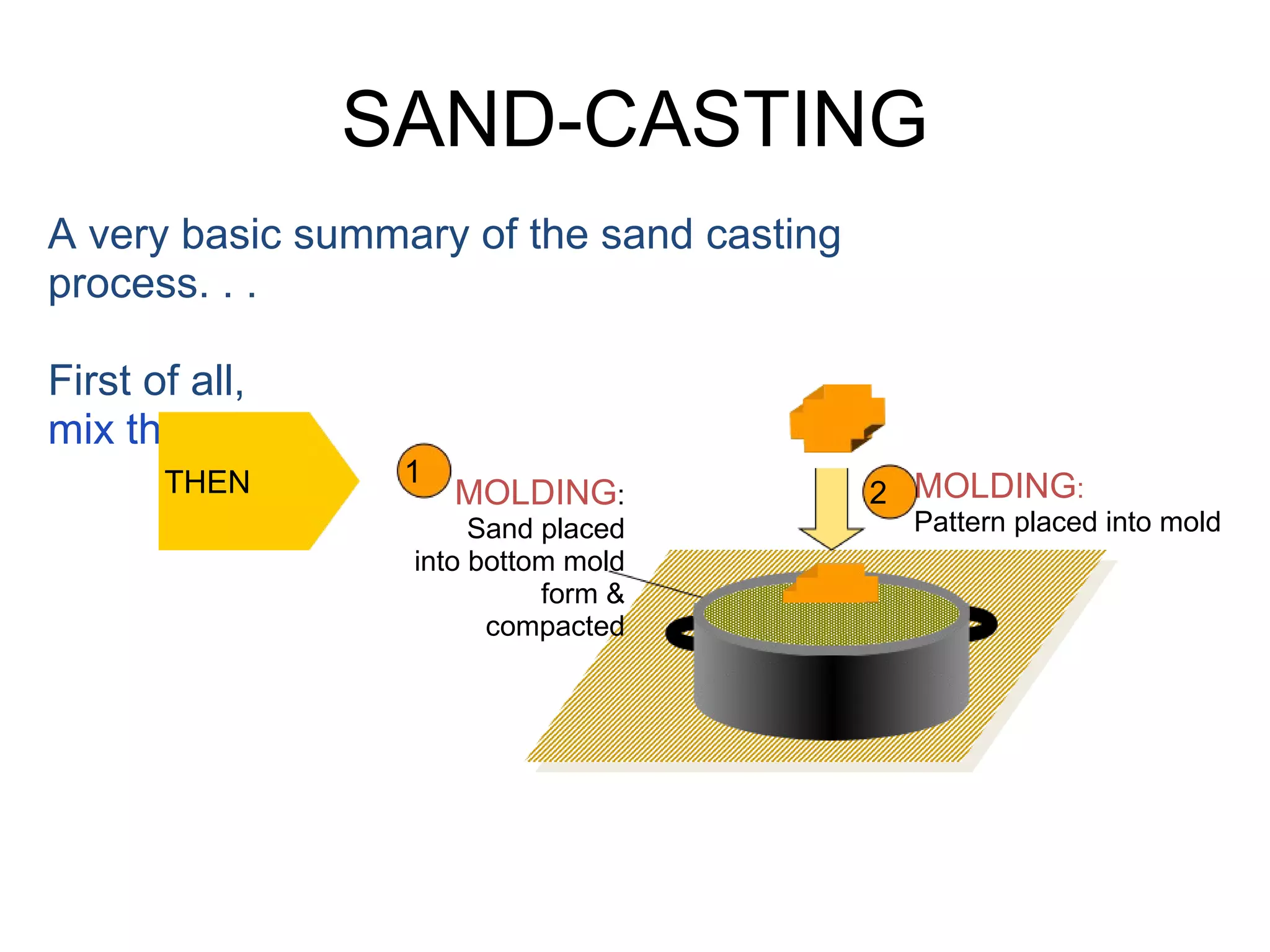

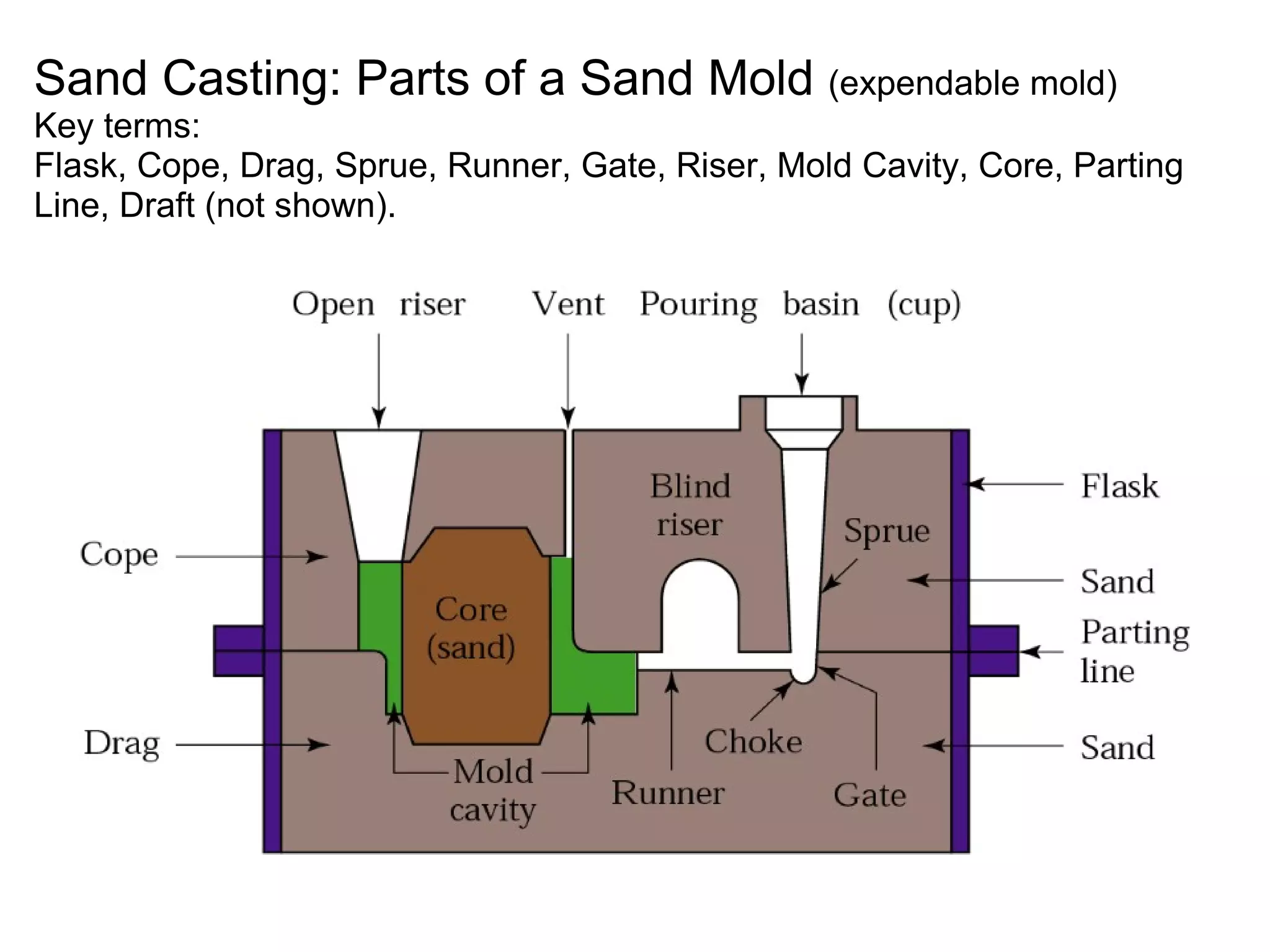

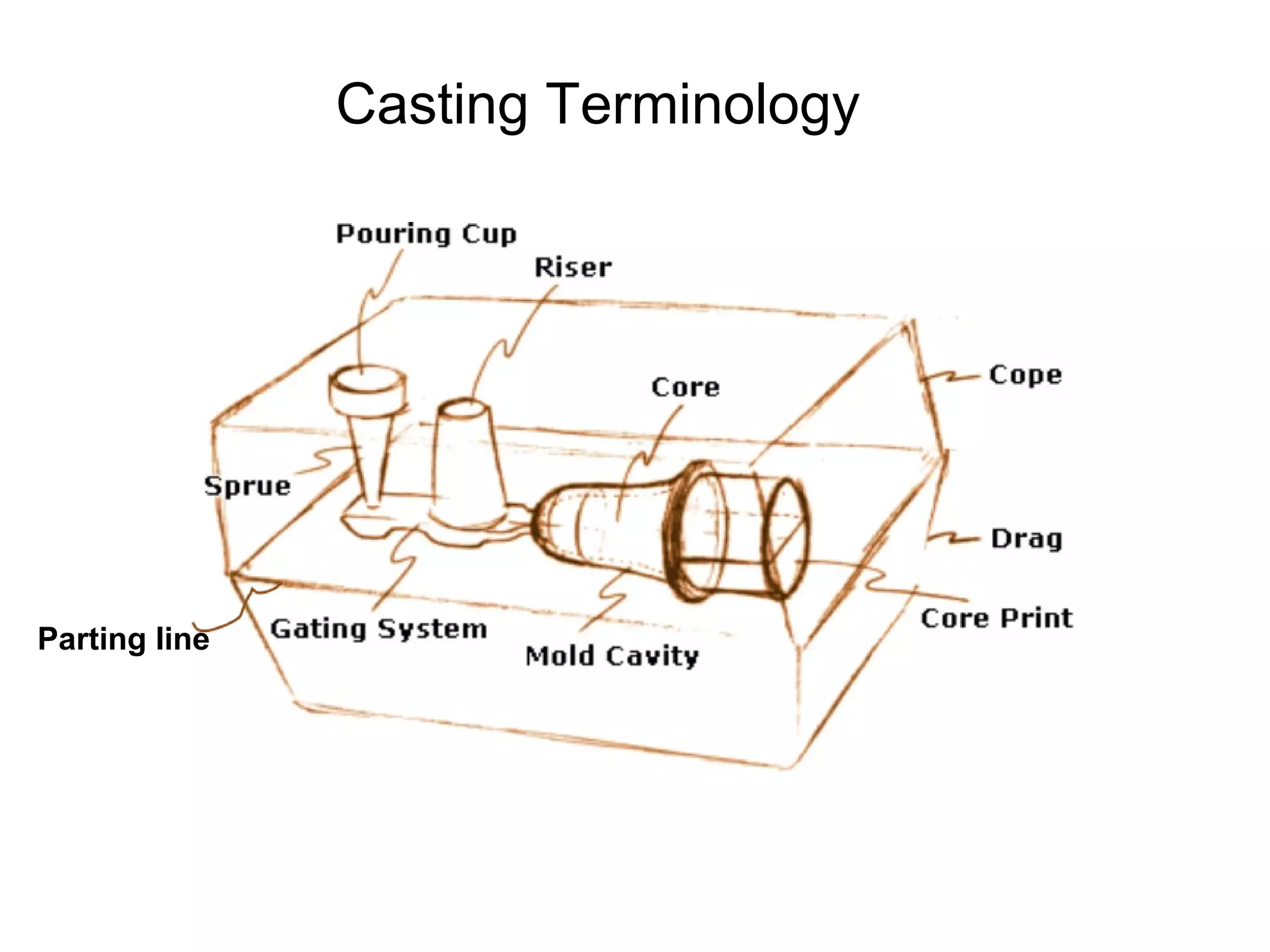

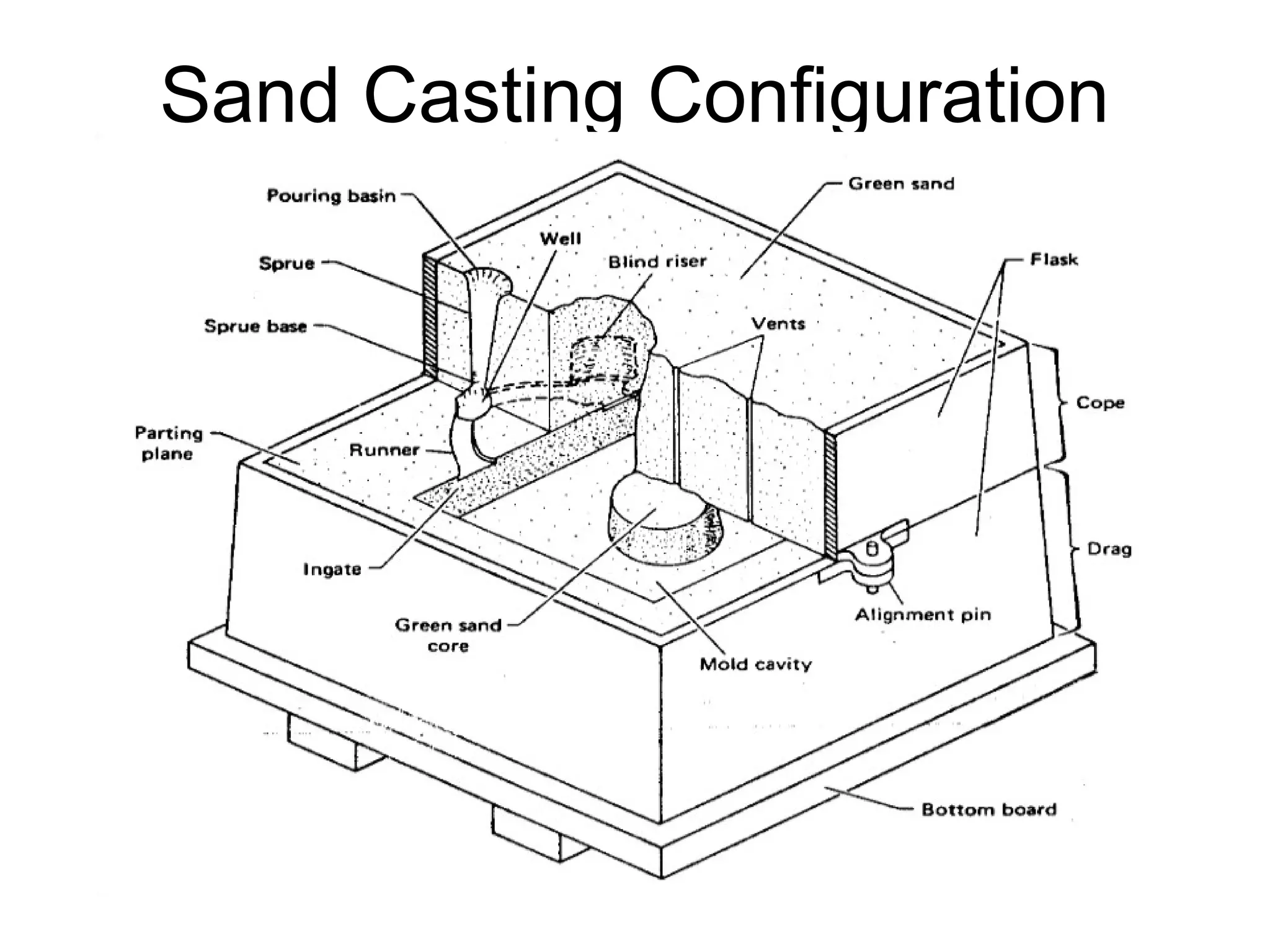

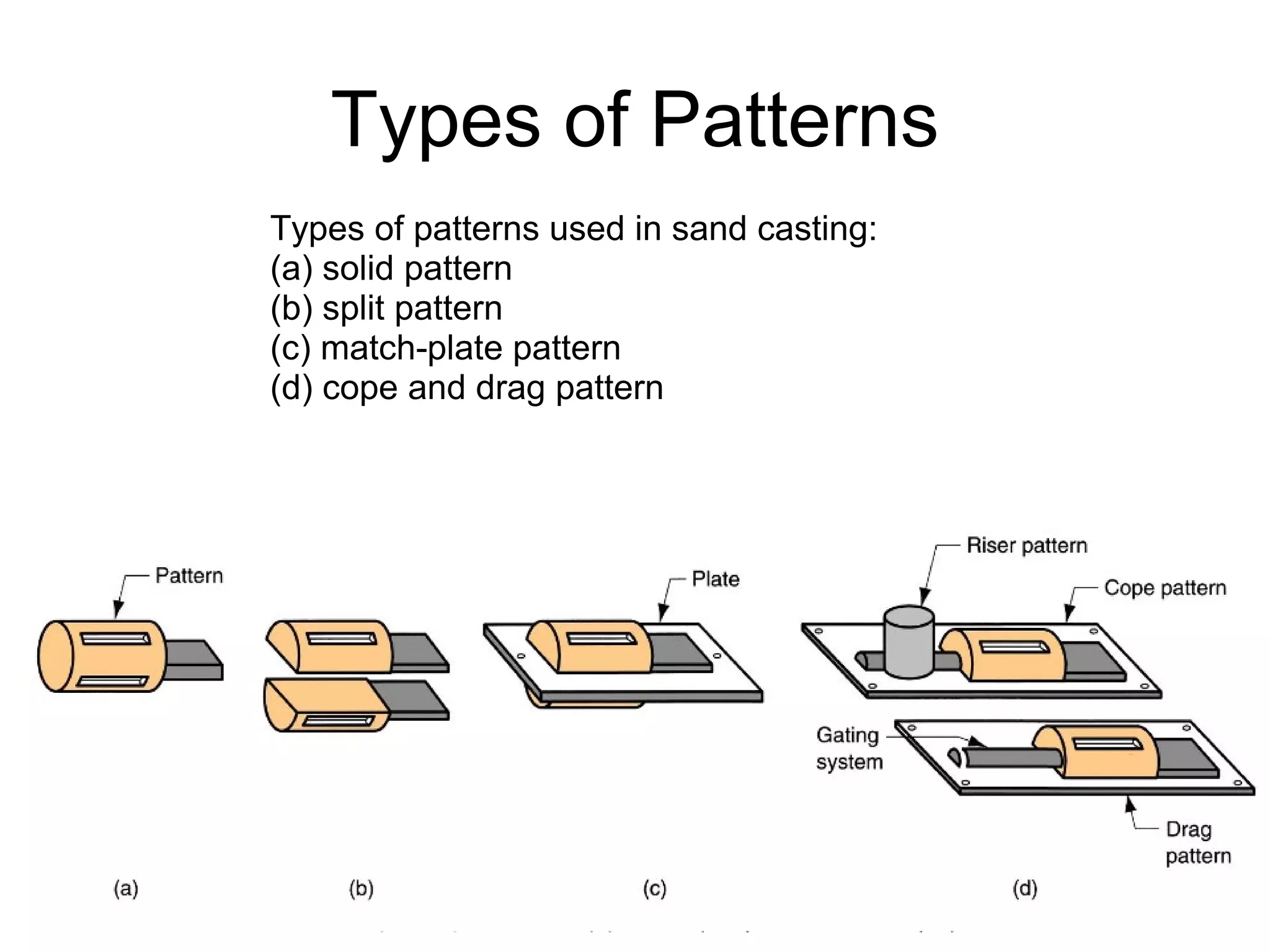

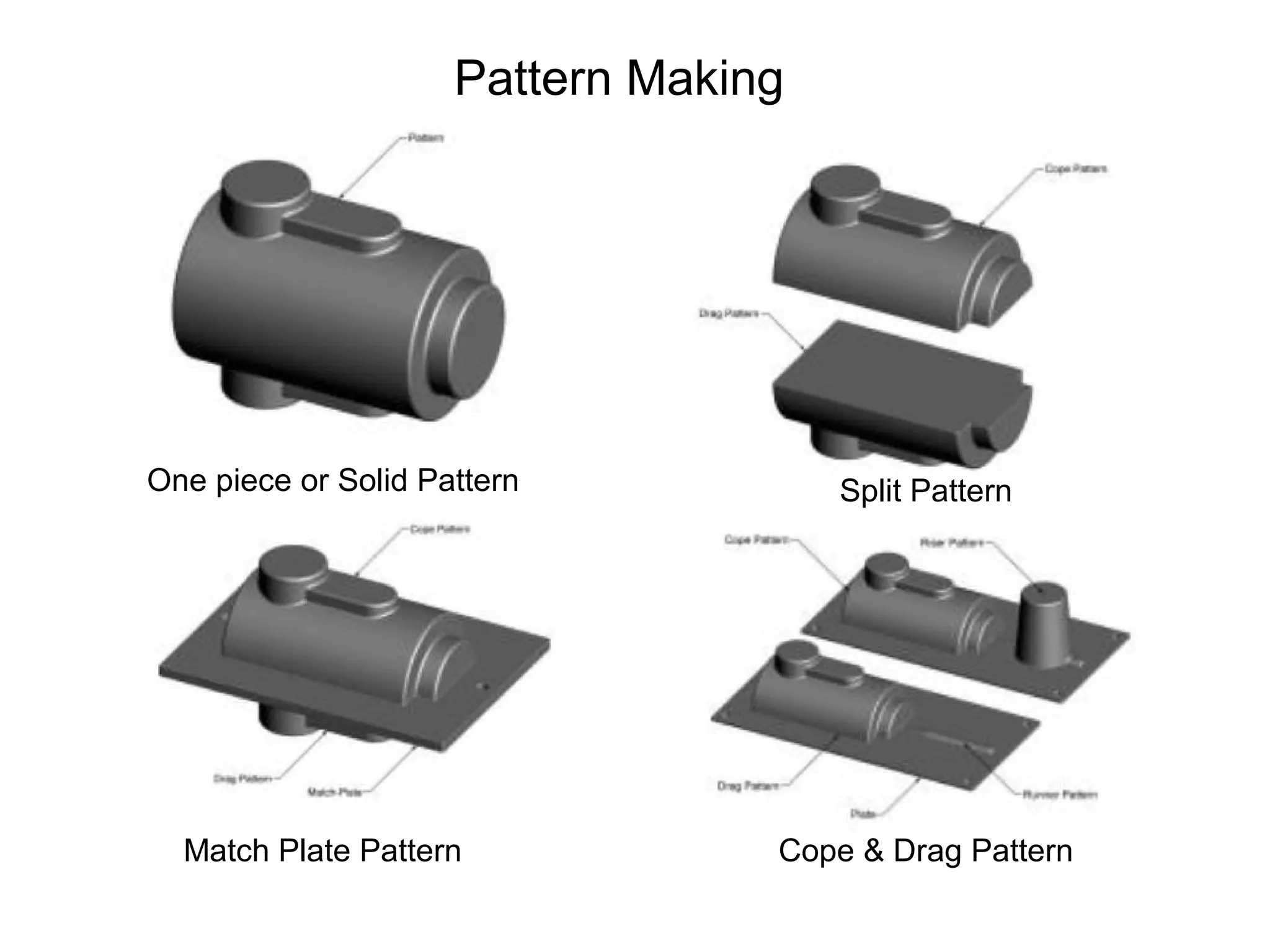

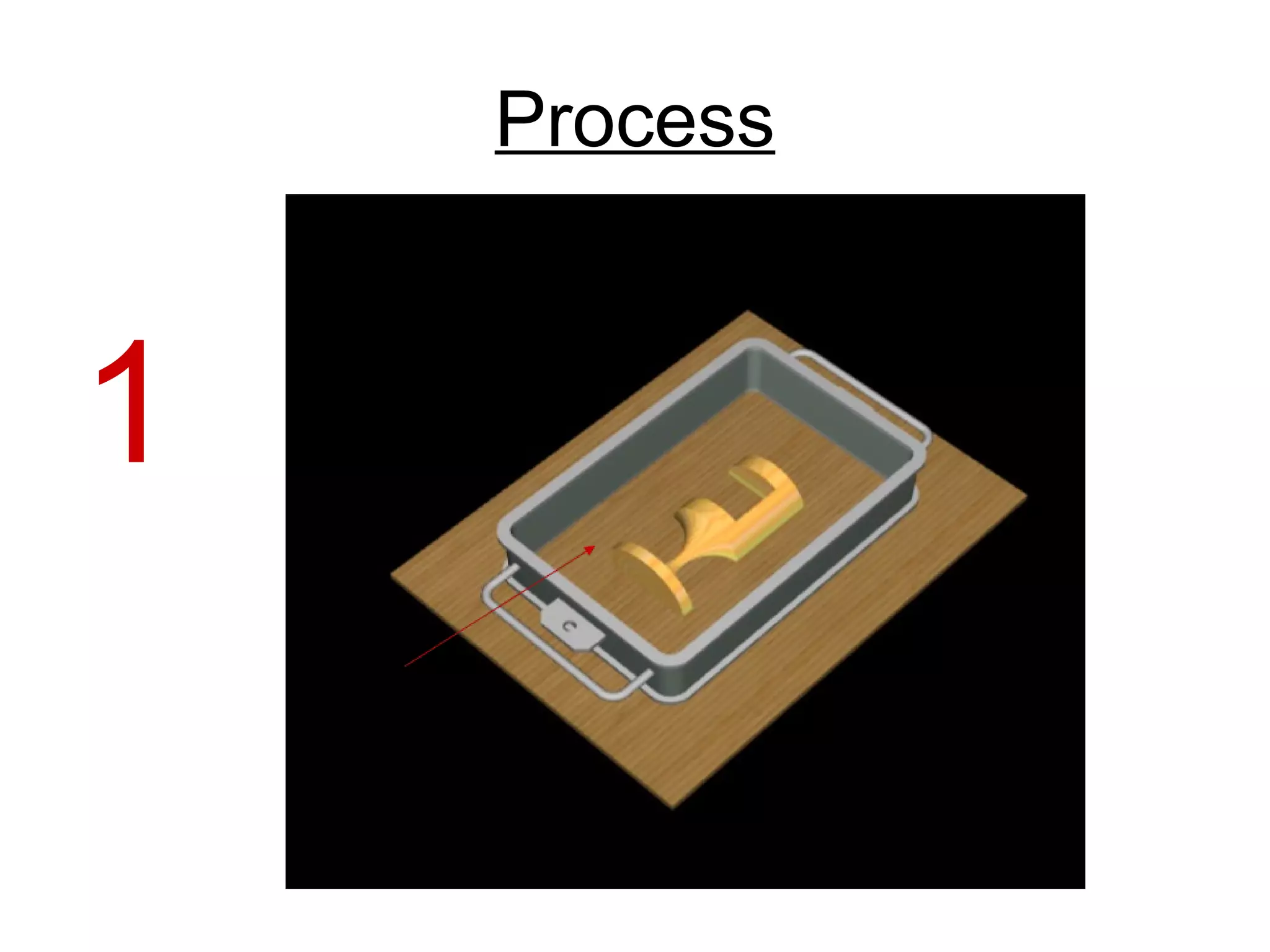

1. Mix sand and create molds using patterns.

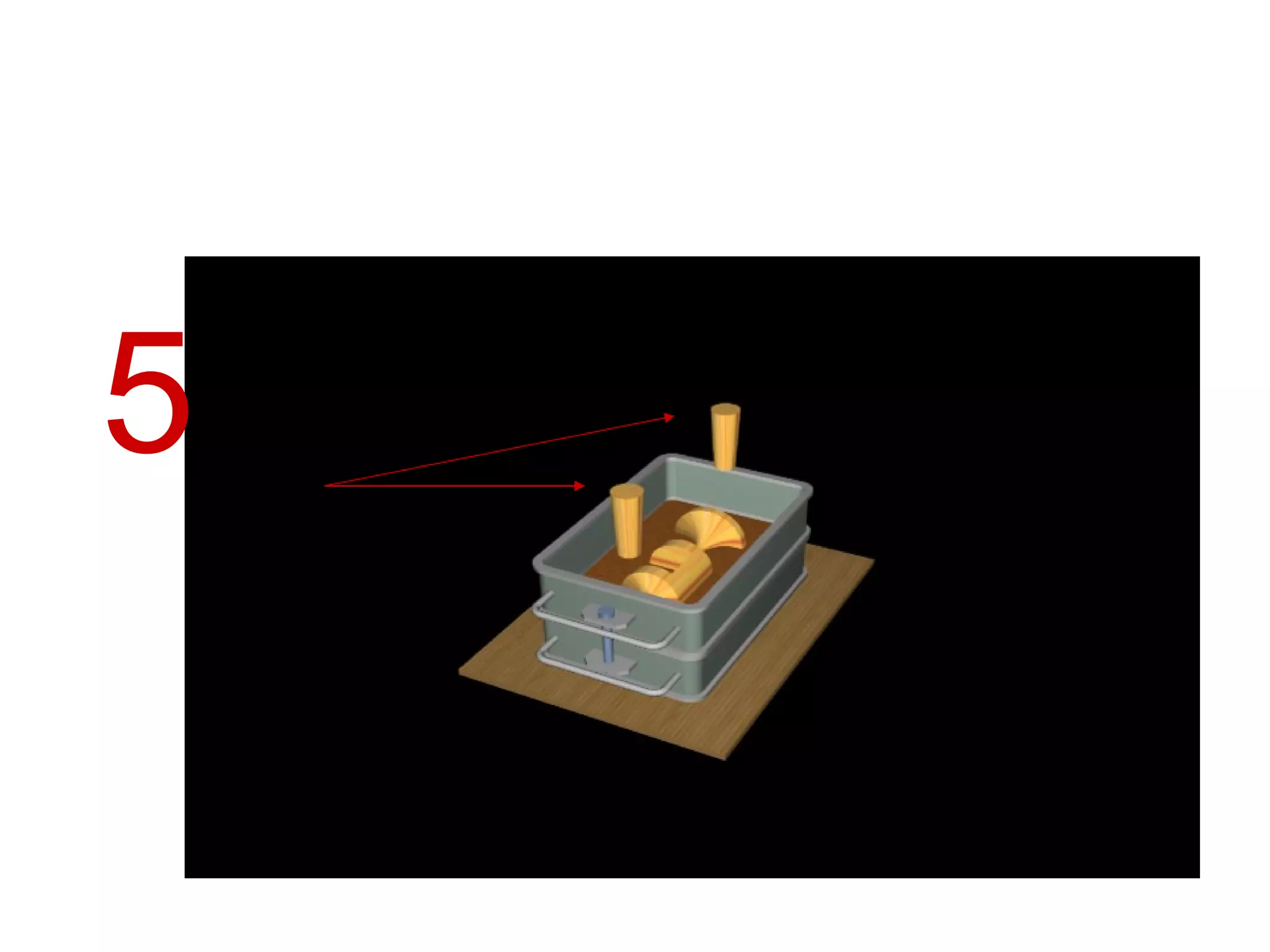

2. Place pattern in bottom mold and compact sand.

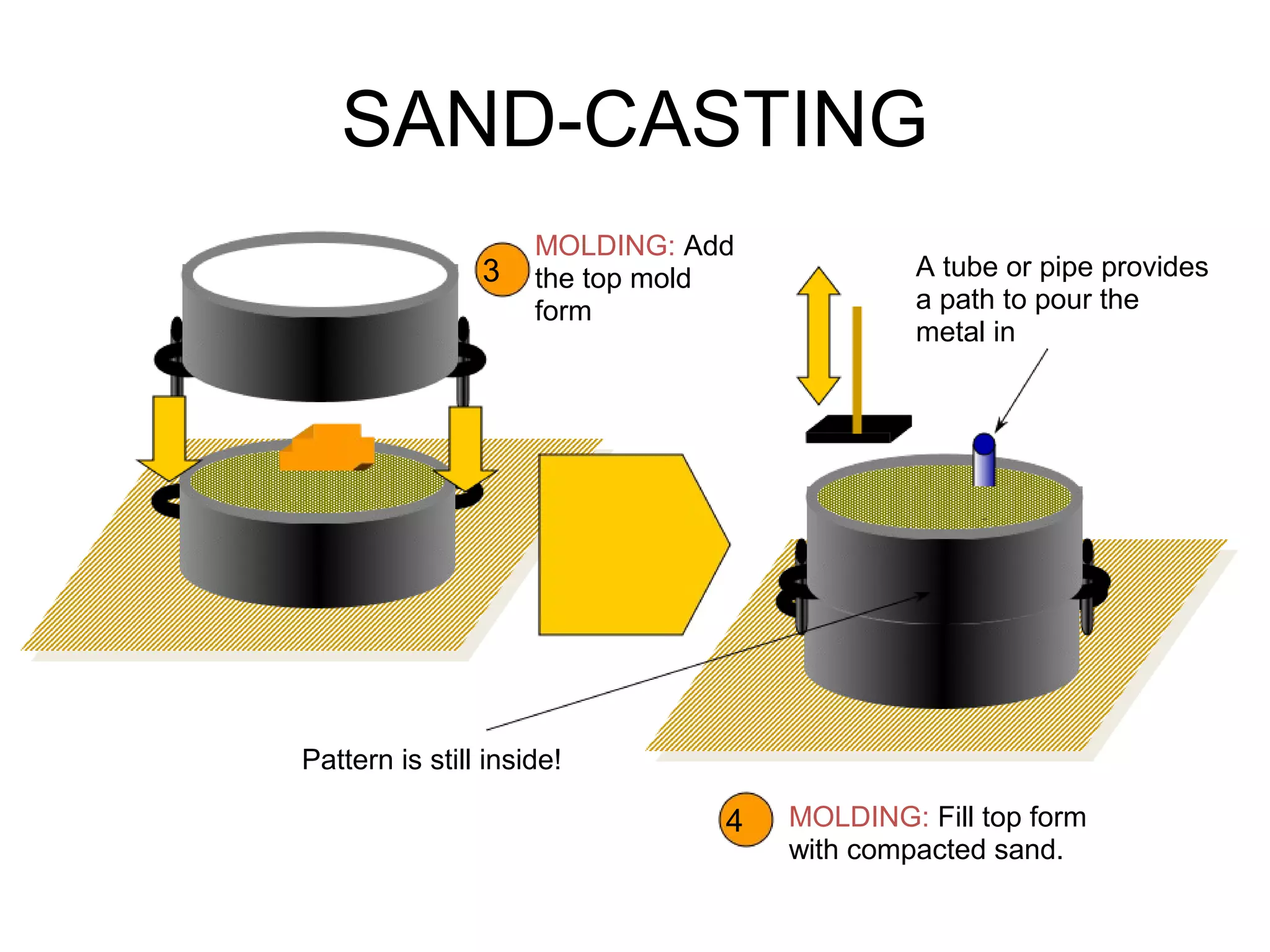

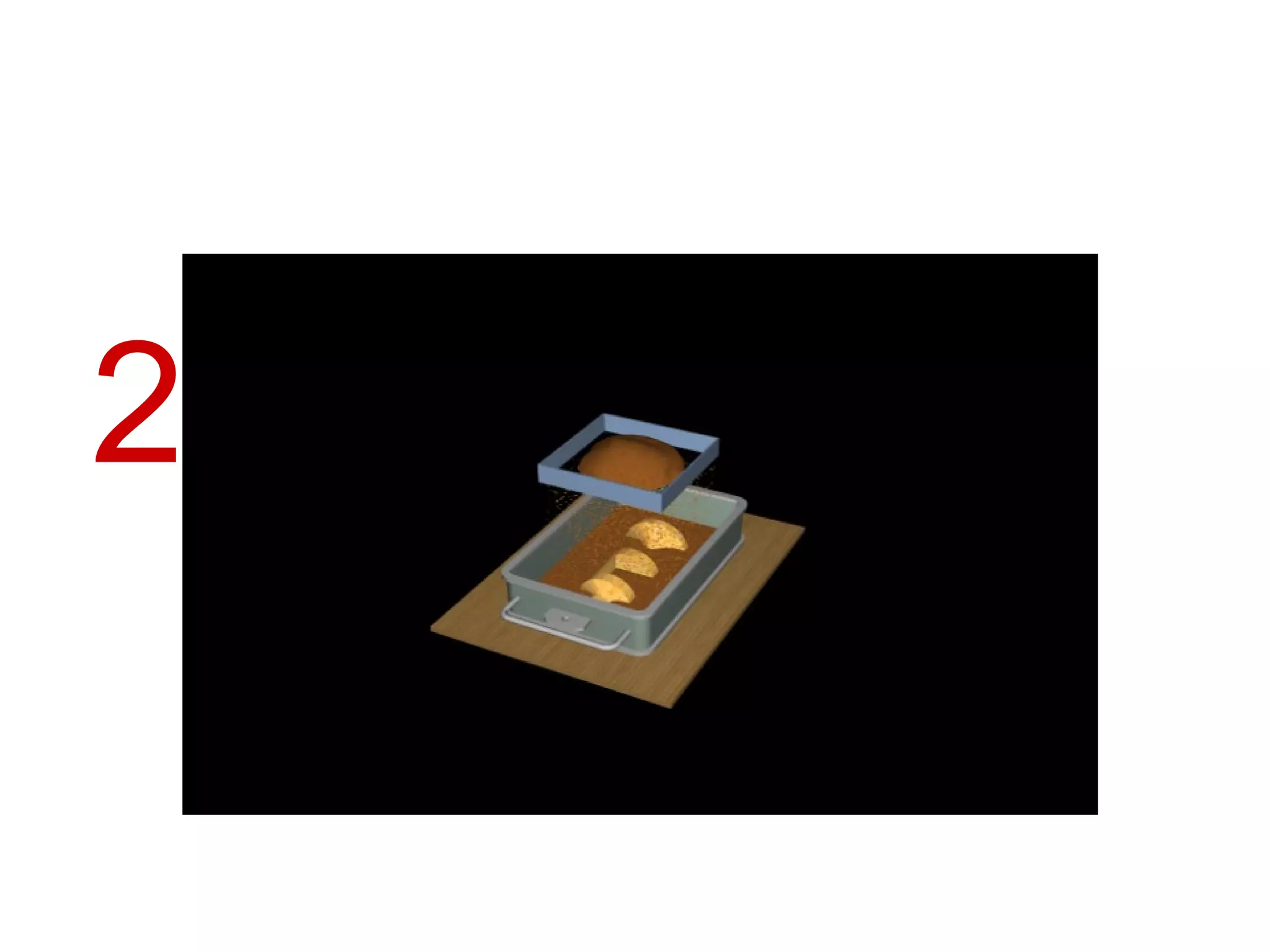

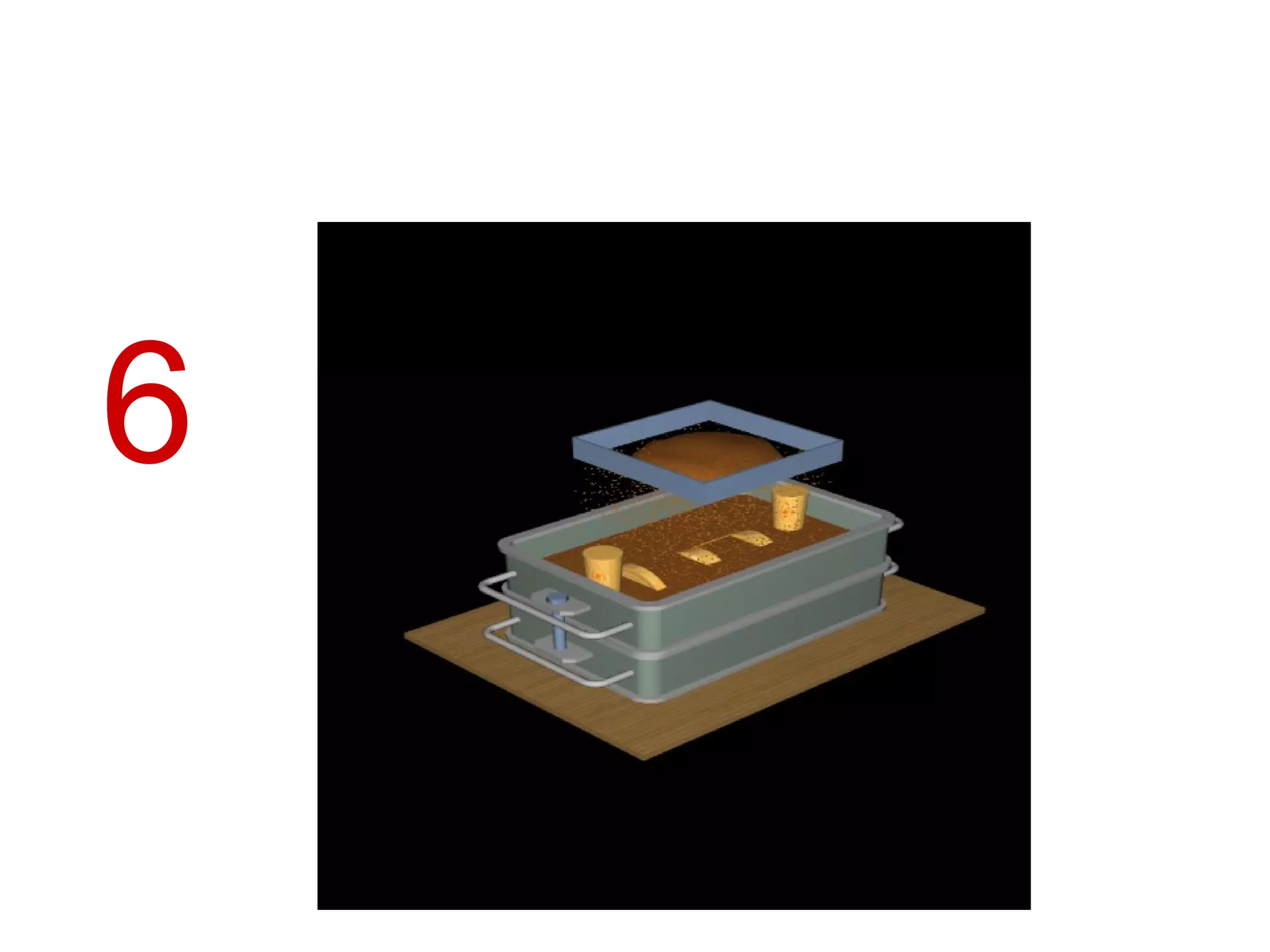

3. Add top mold and fill with compacted sand.

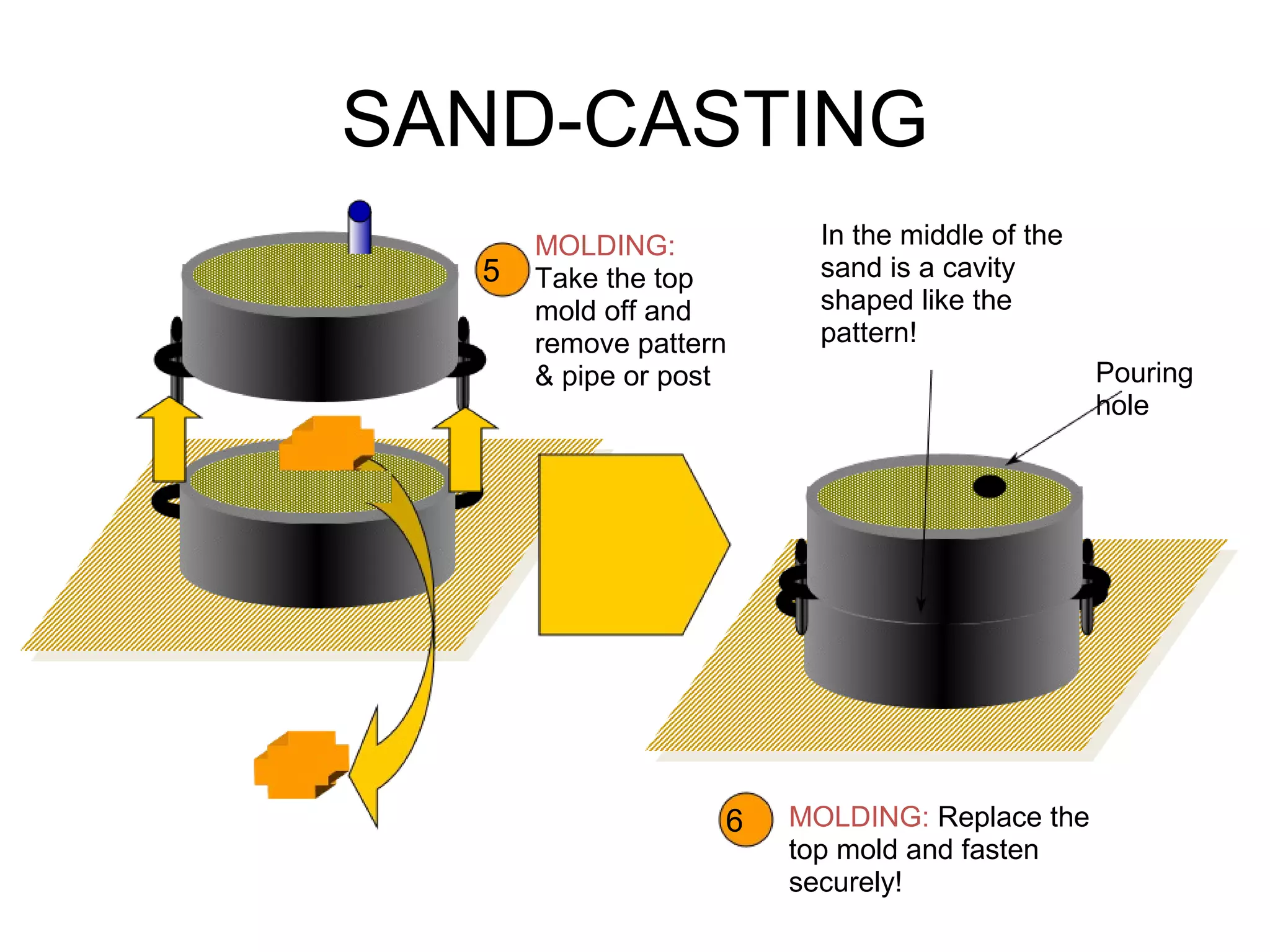

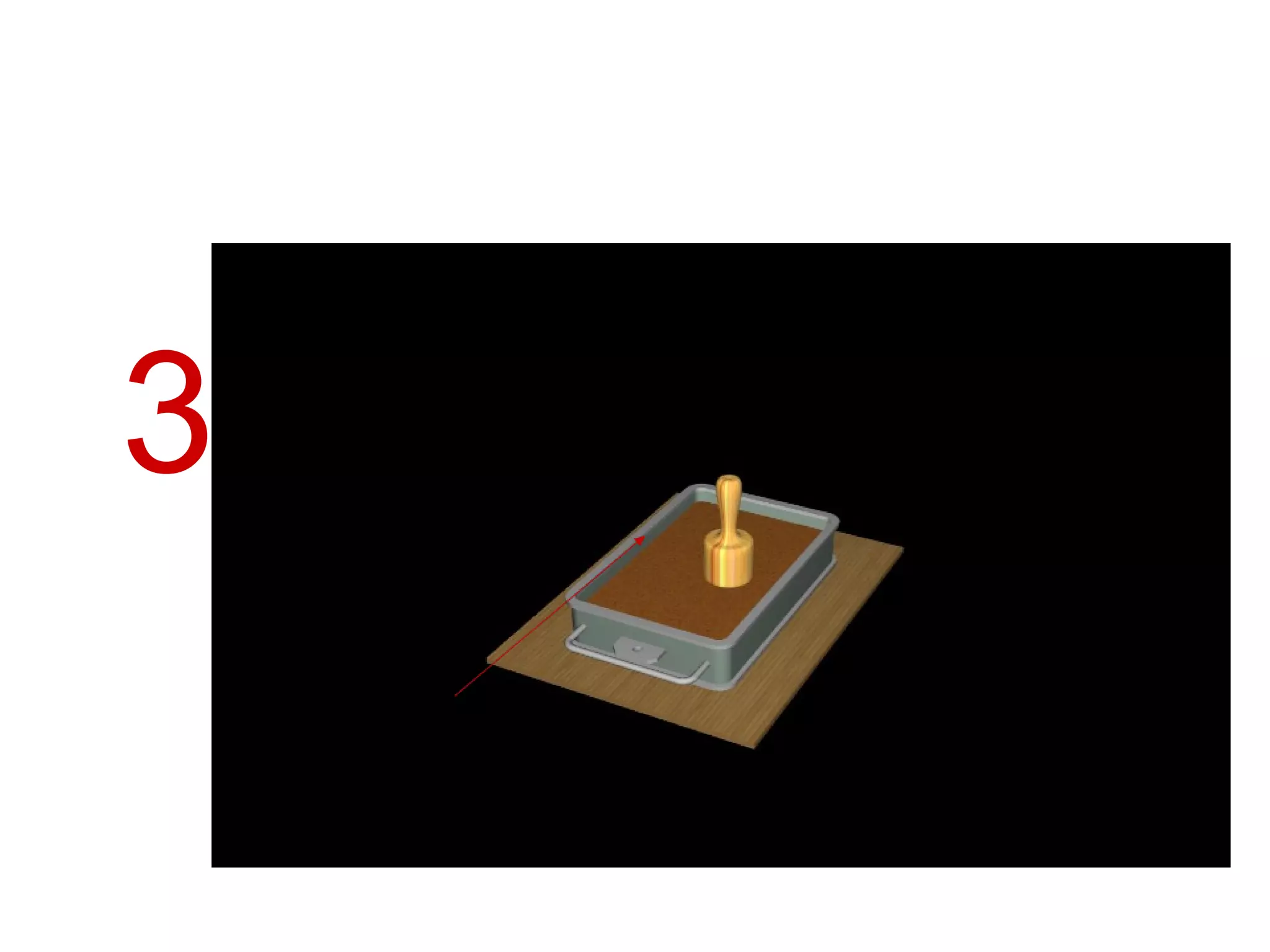

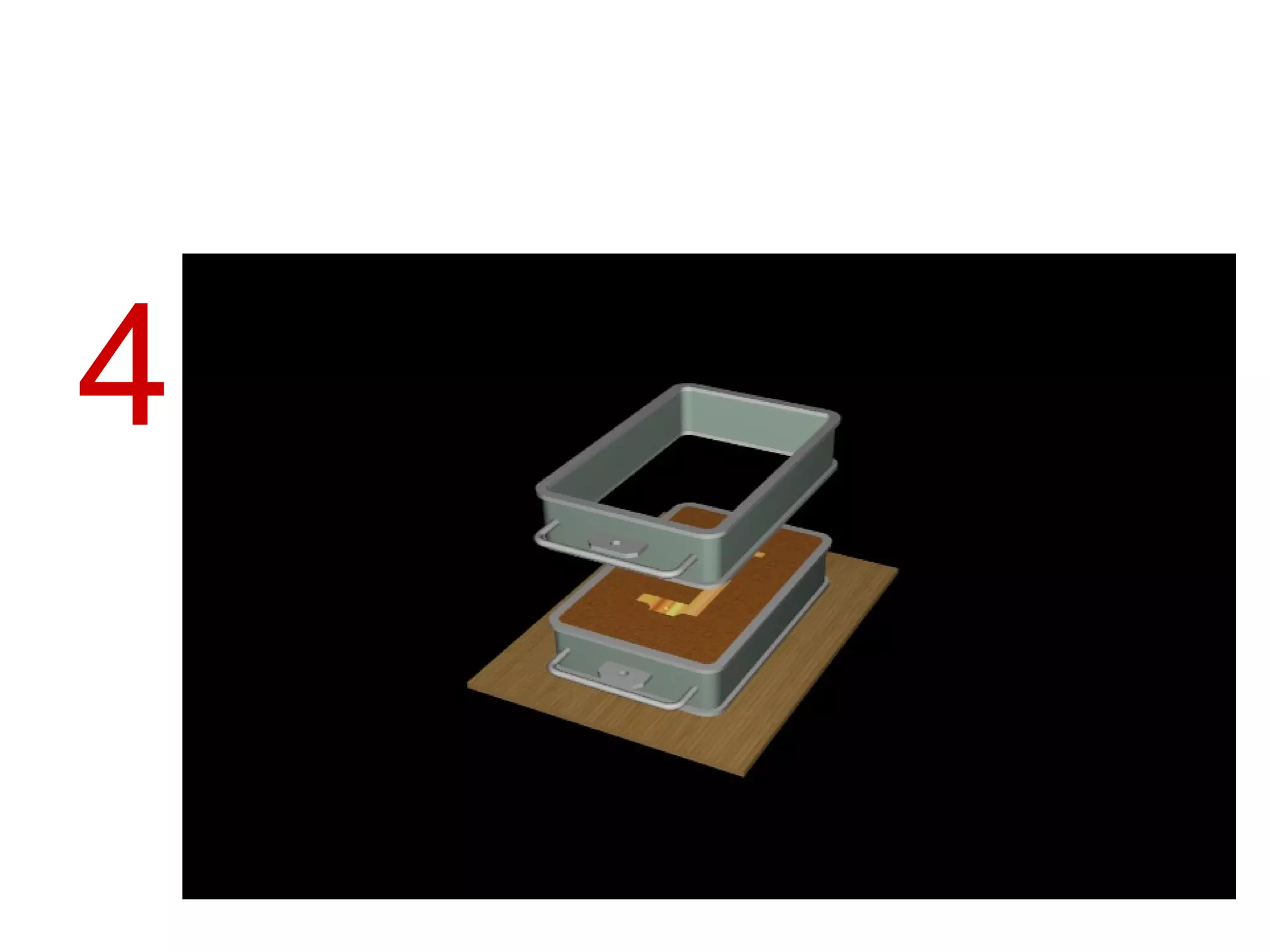

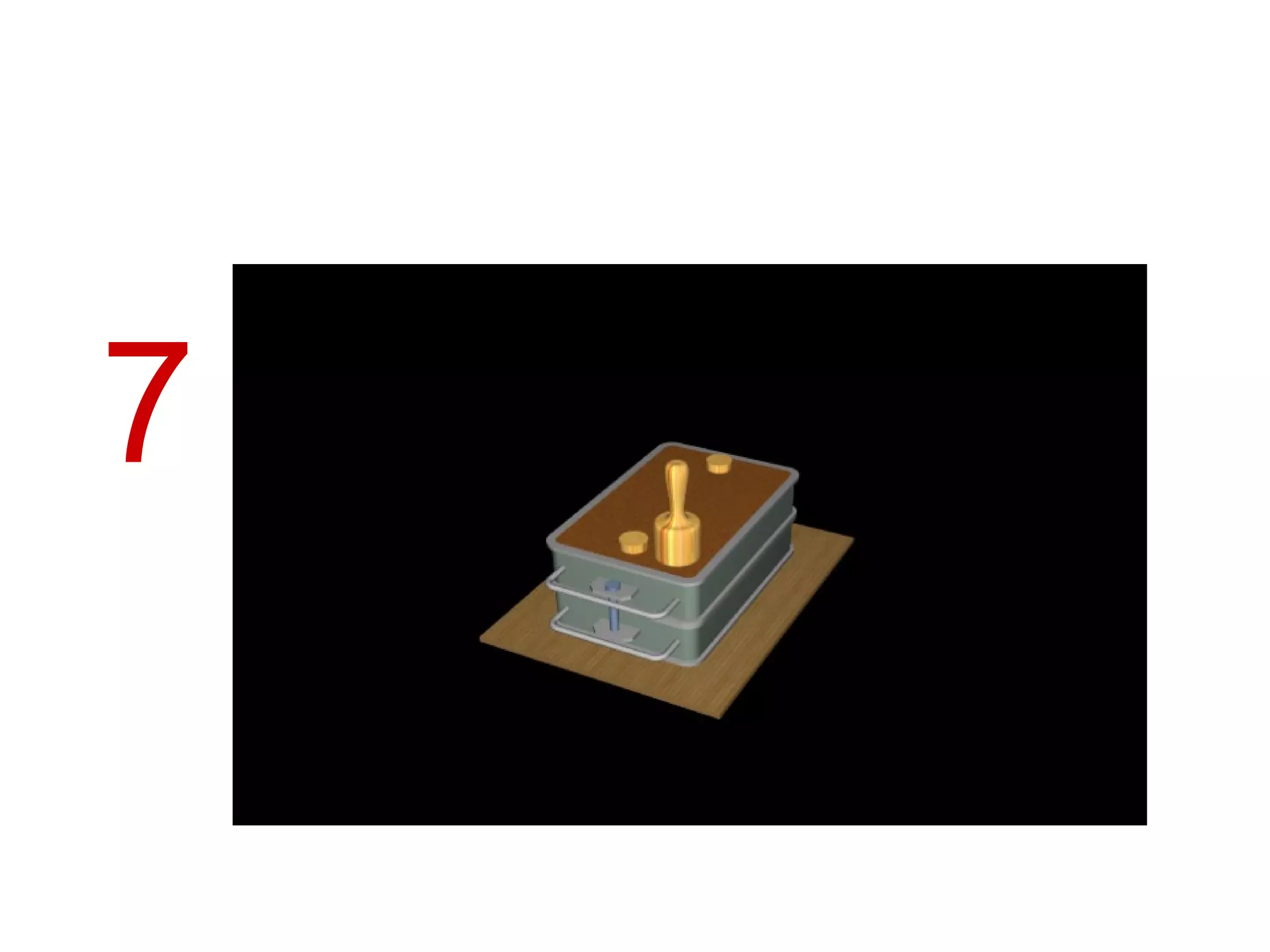

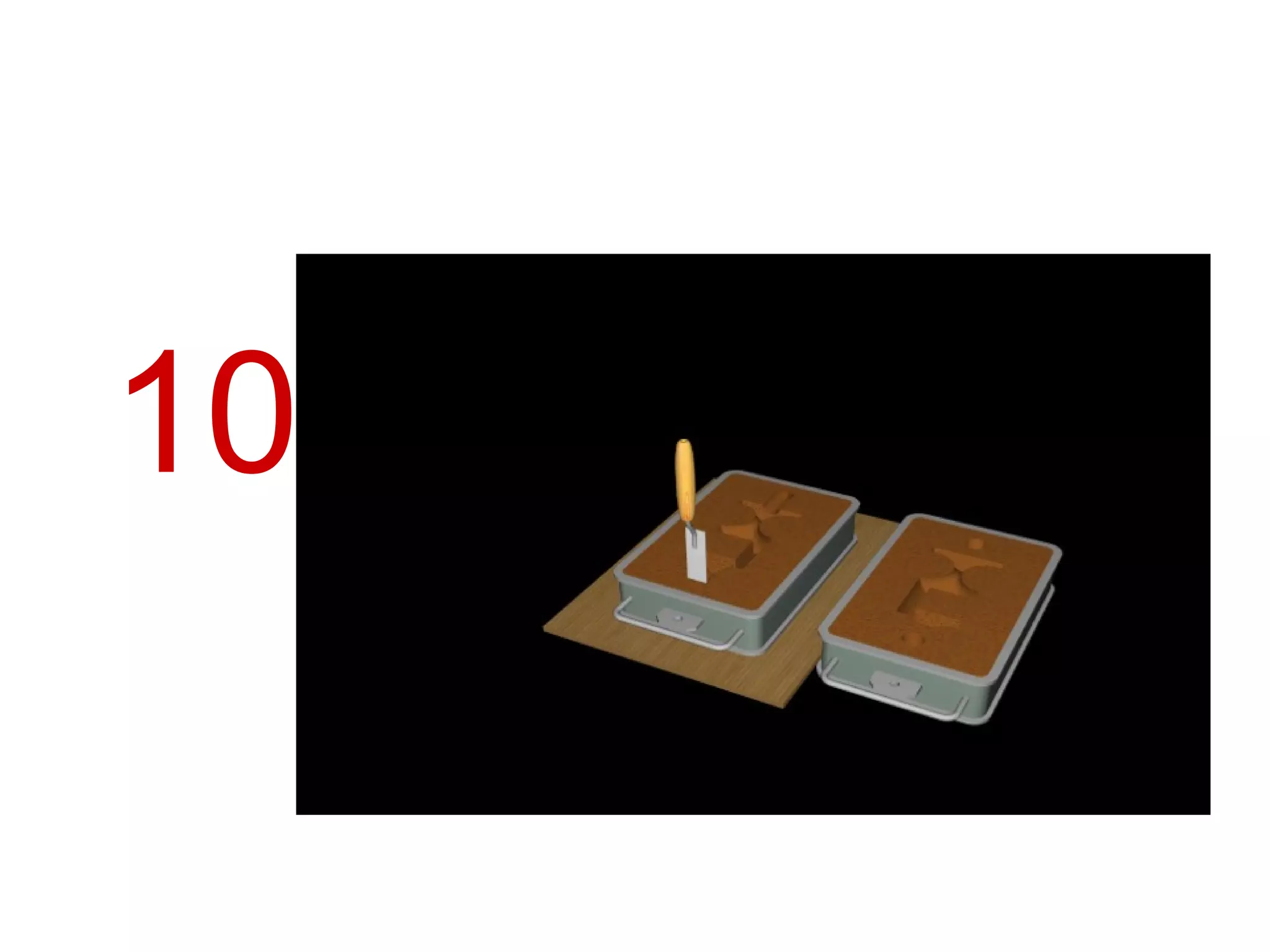

4. Remove pattern to leave a cavity in the sand.

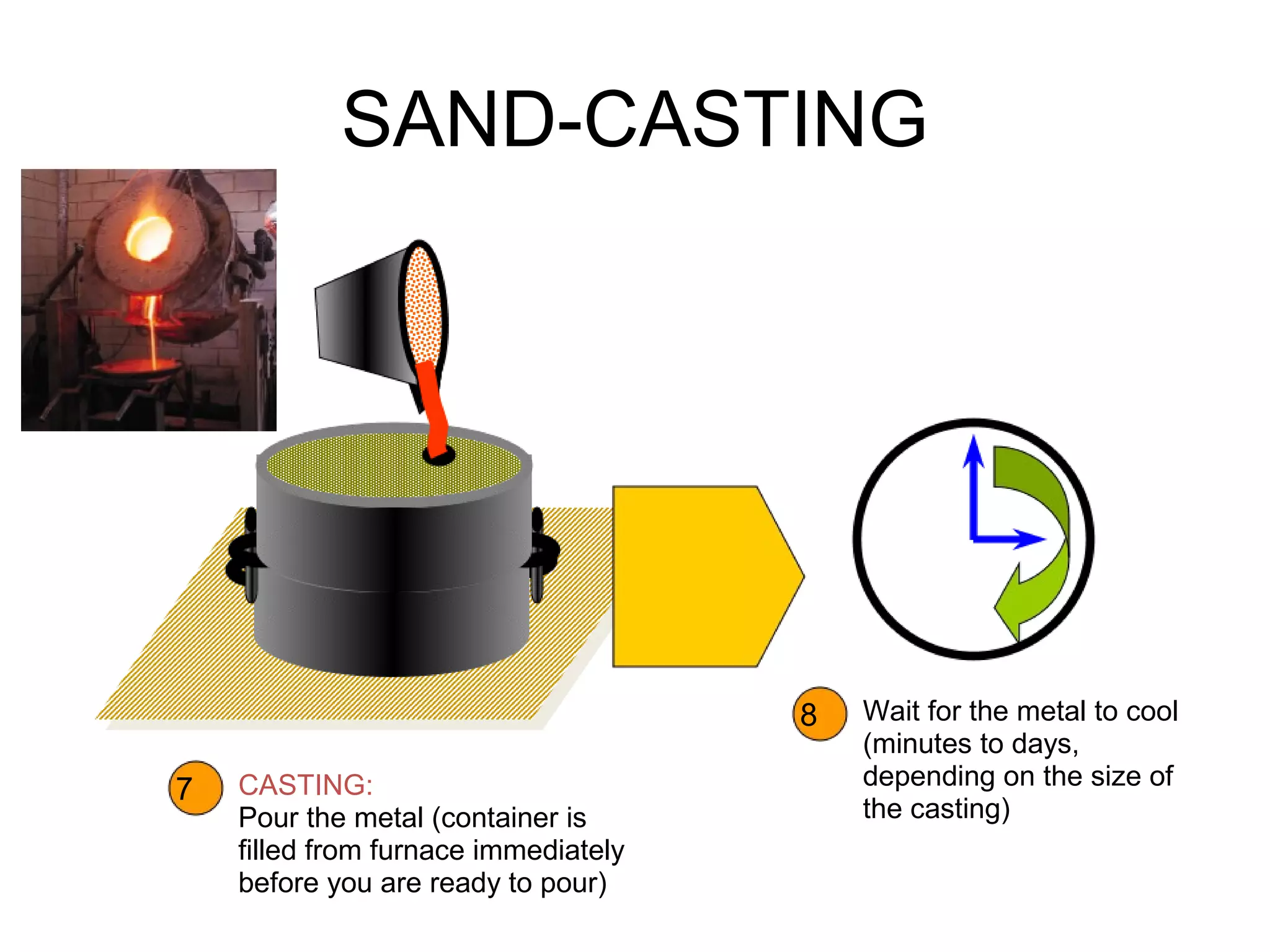

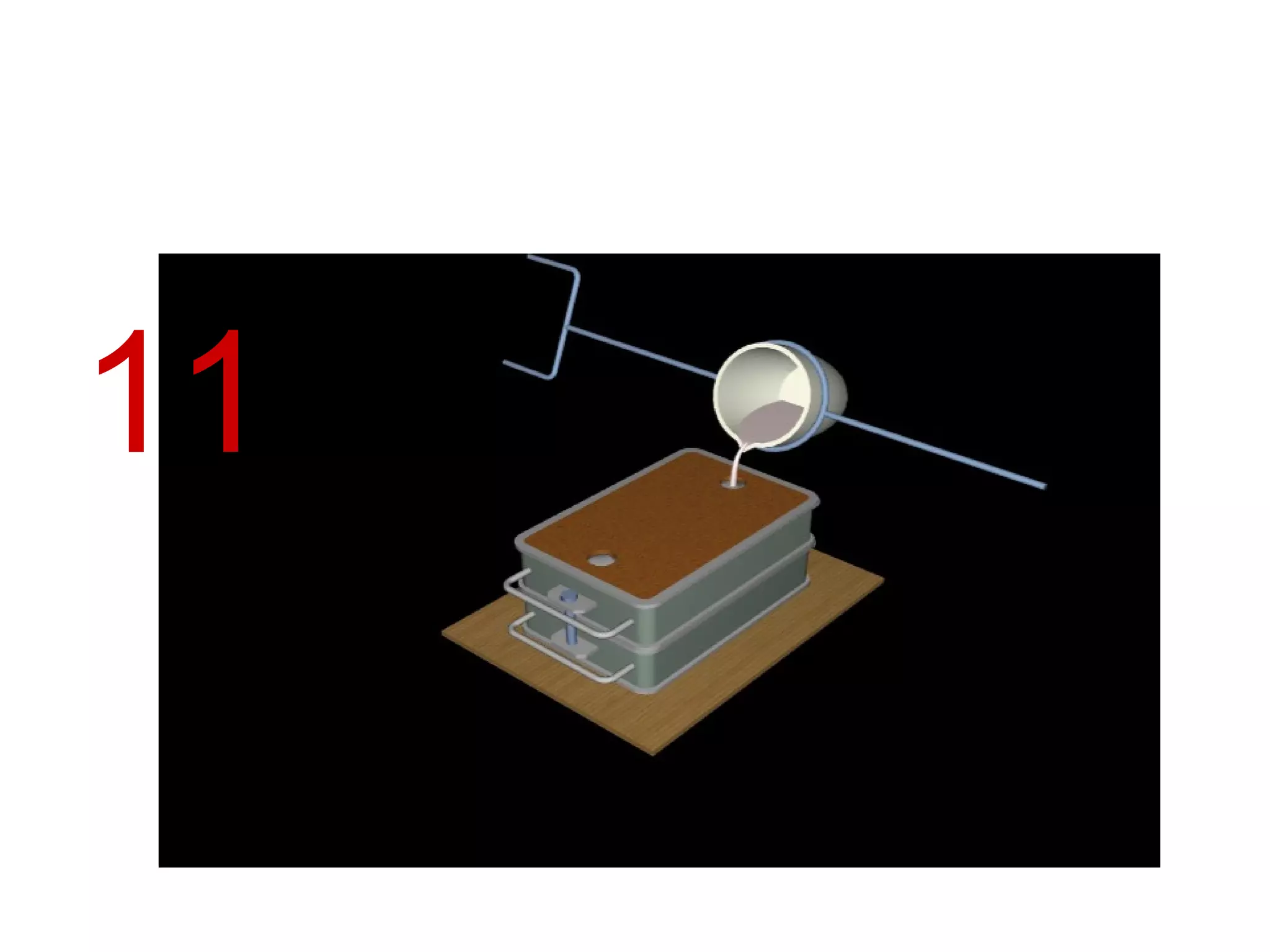

5. Pour molten metal into the mold.

6. Allow metal to cool and harden.

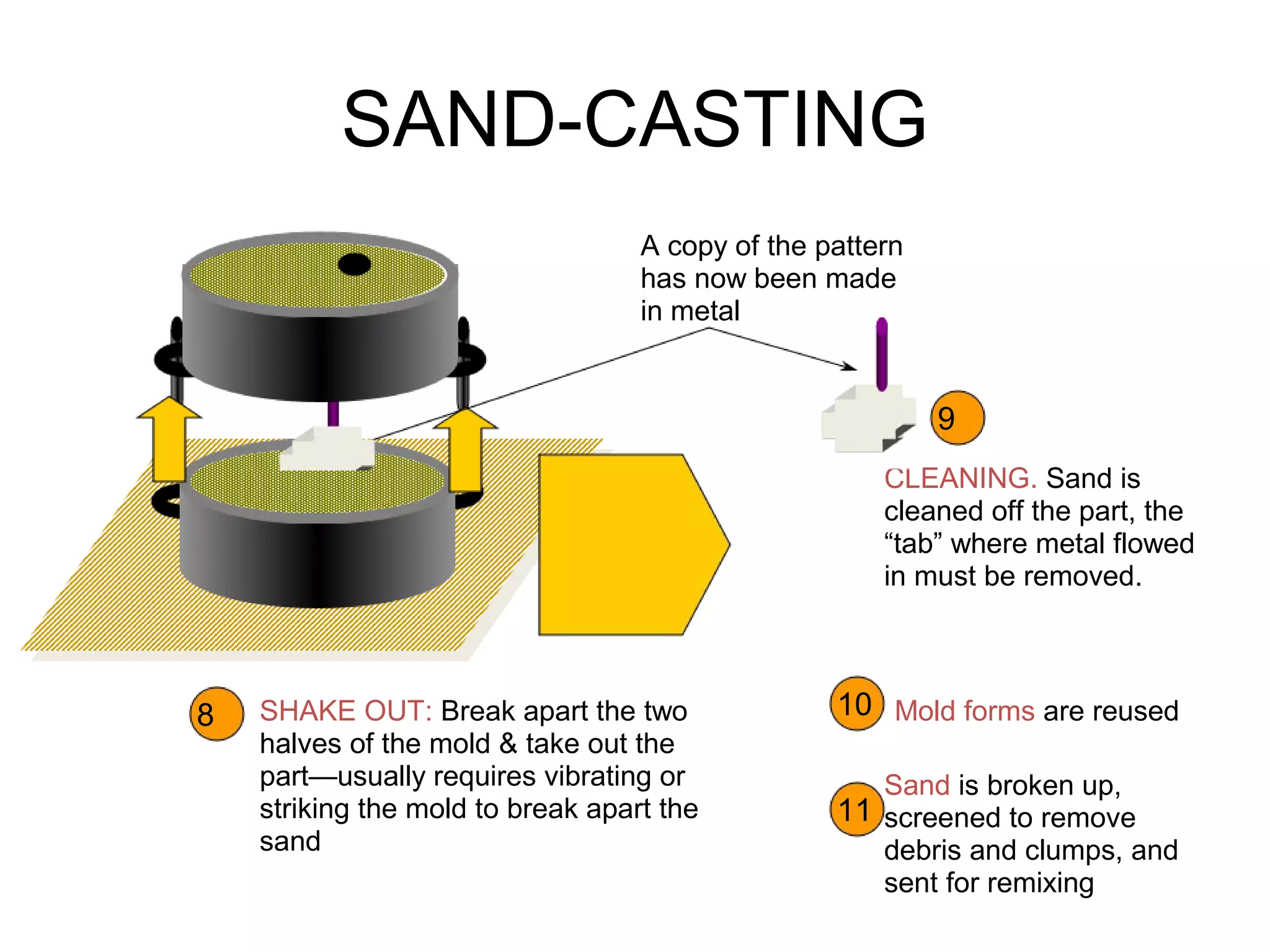

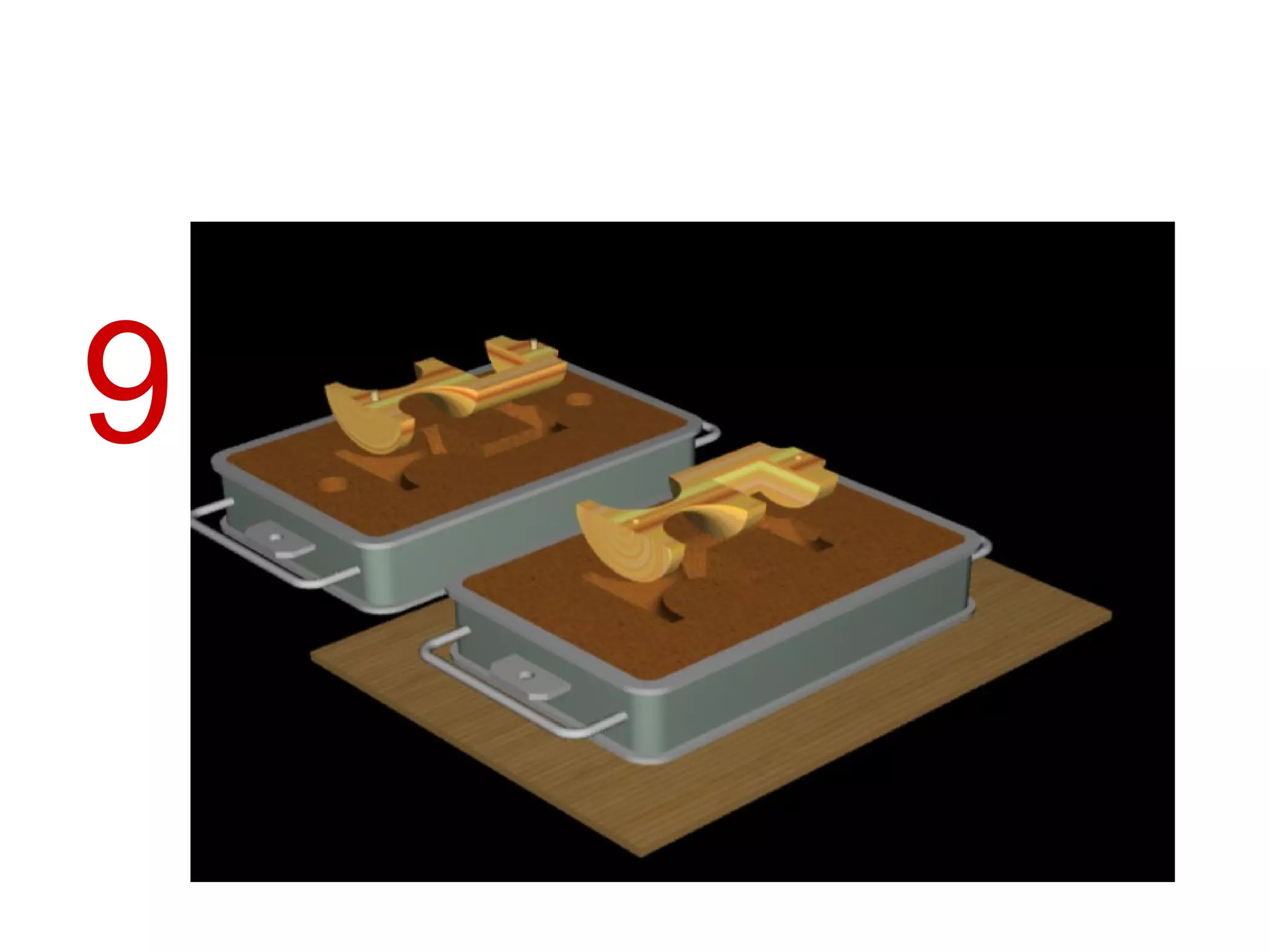

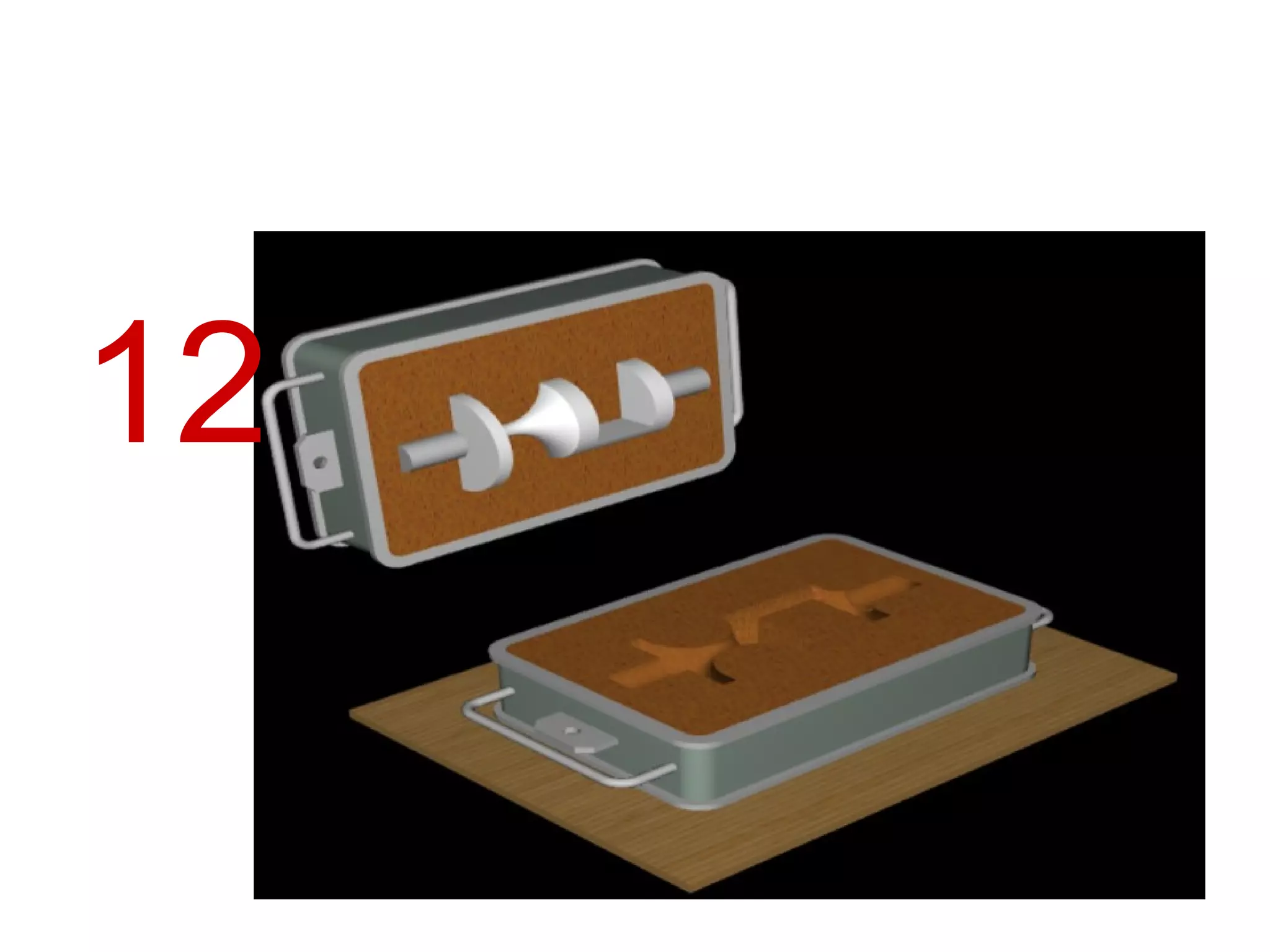

7. Break apart mold and remove the new cast part.