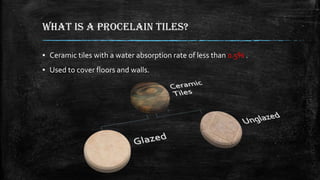

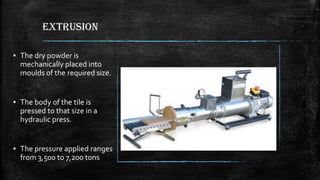

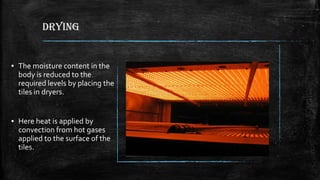

The document outlines the manufacturing process for porcelain tiles, which begins with mixing raw materials like sand, clay, and minerals. The dry powder is then extruded into molds and dried before being fired at high temperatures, which gives the tiles strength, stability, and resistance. Statistical process control is used throughout to monitor dimensions, density, and other parameters to ensure quality.