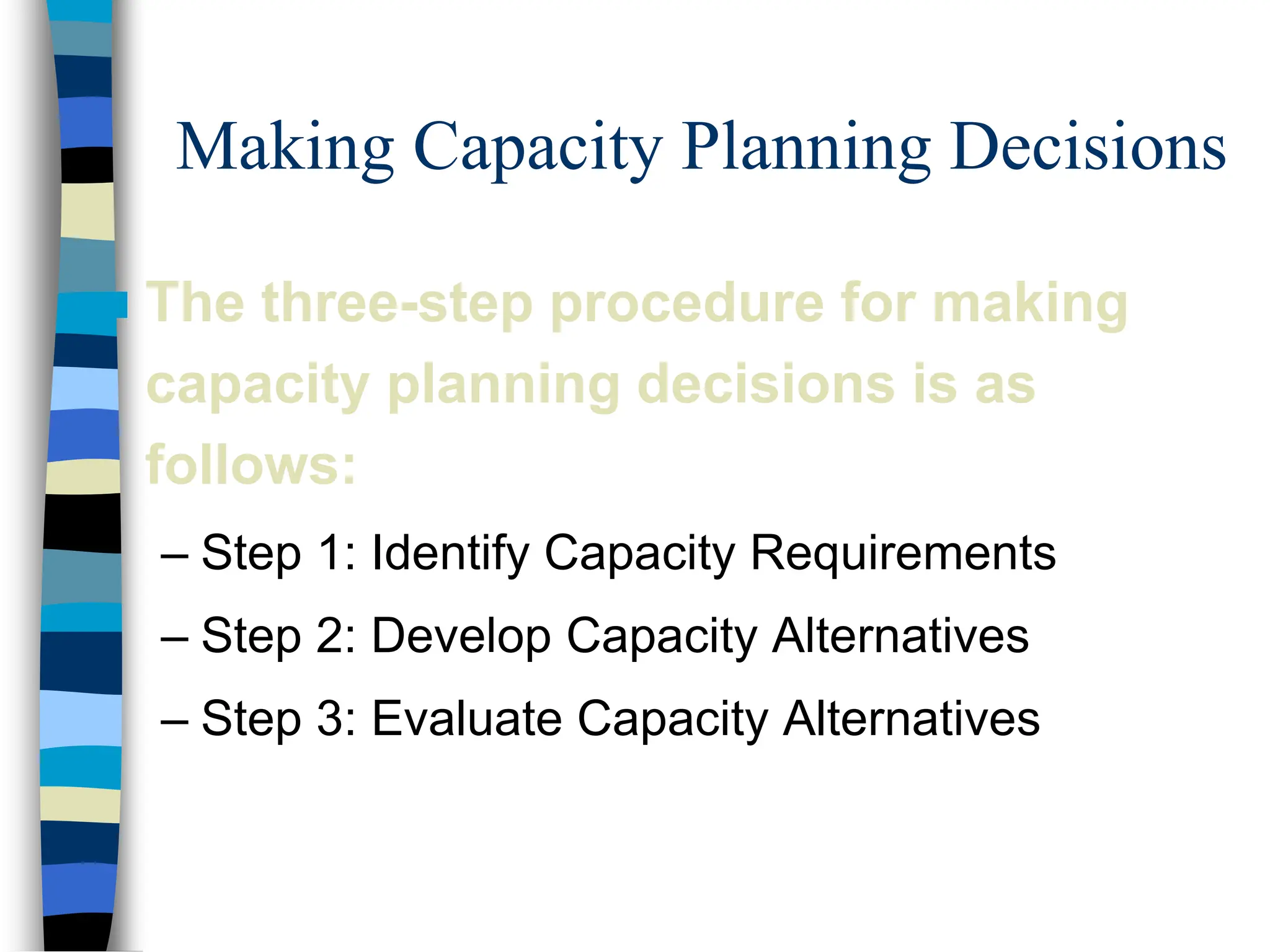

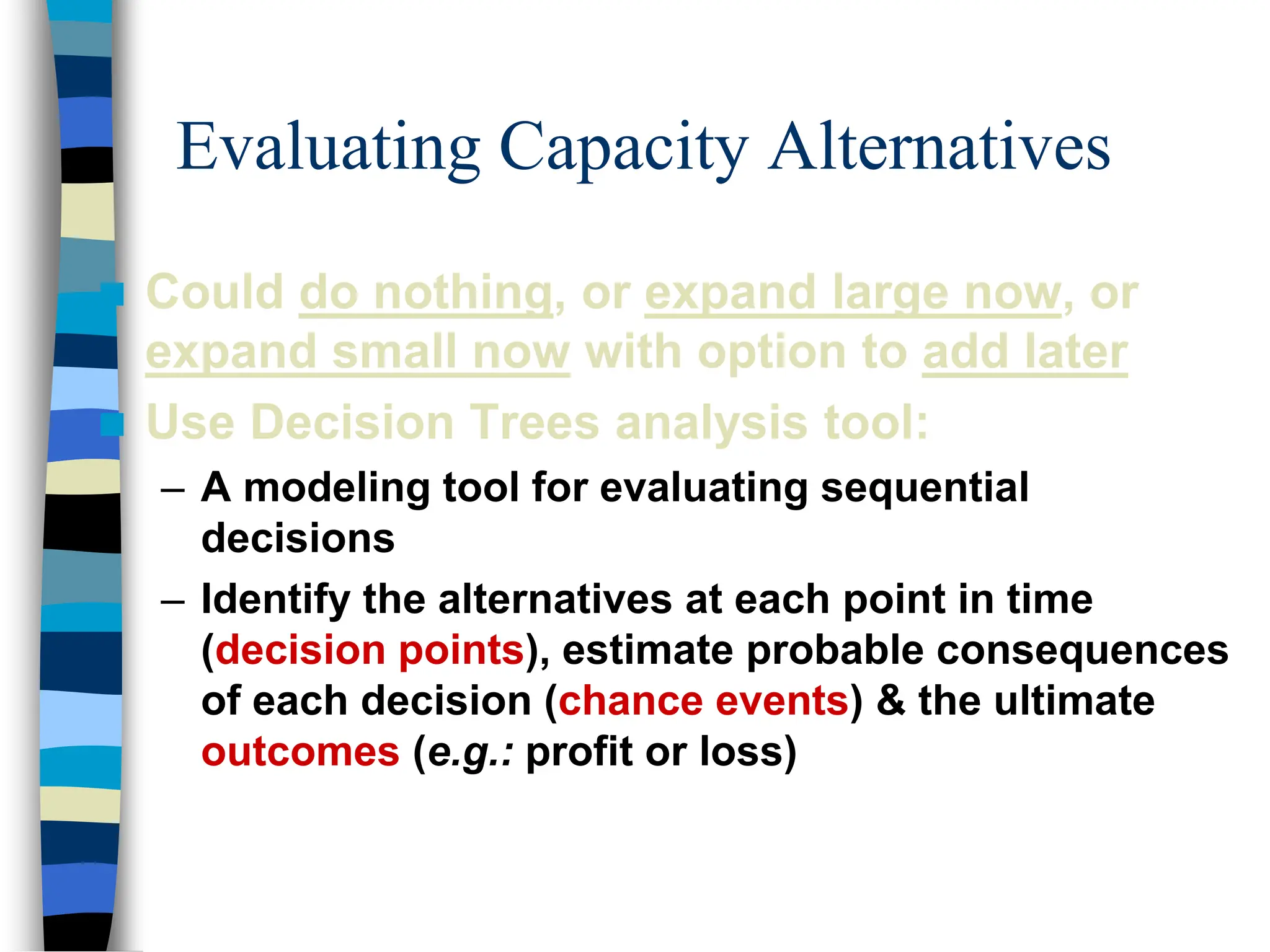

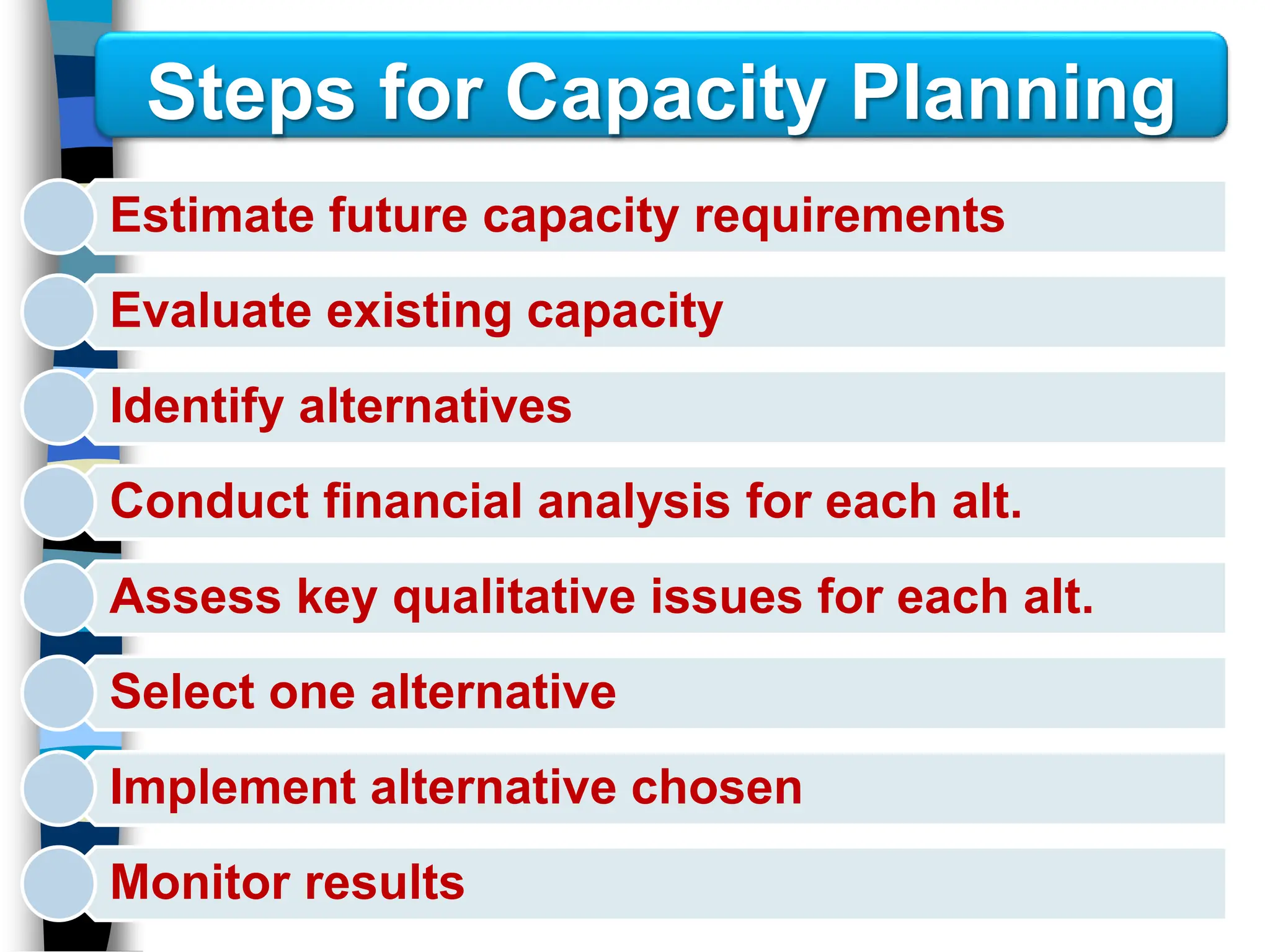

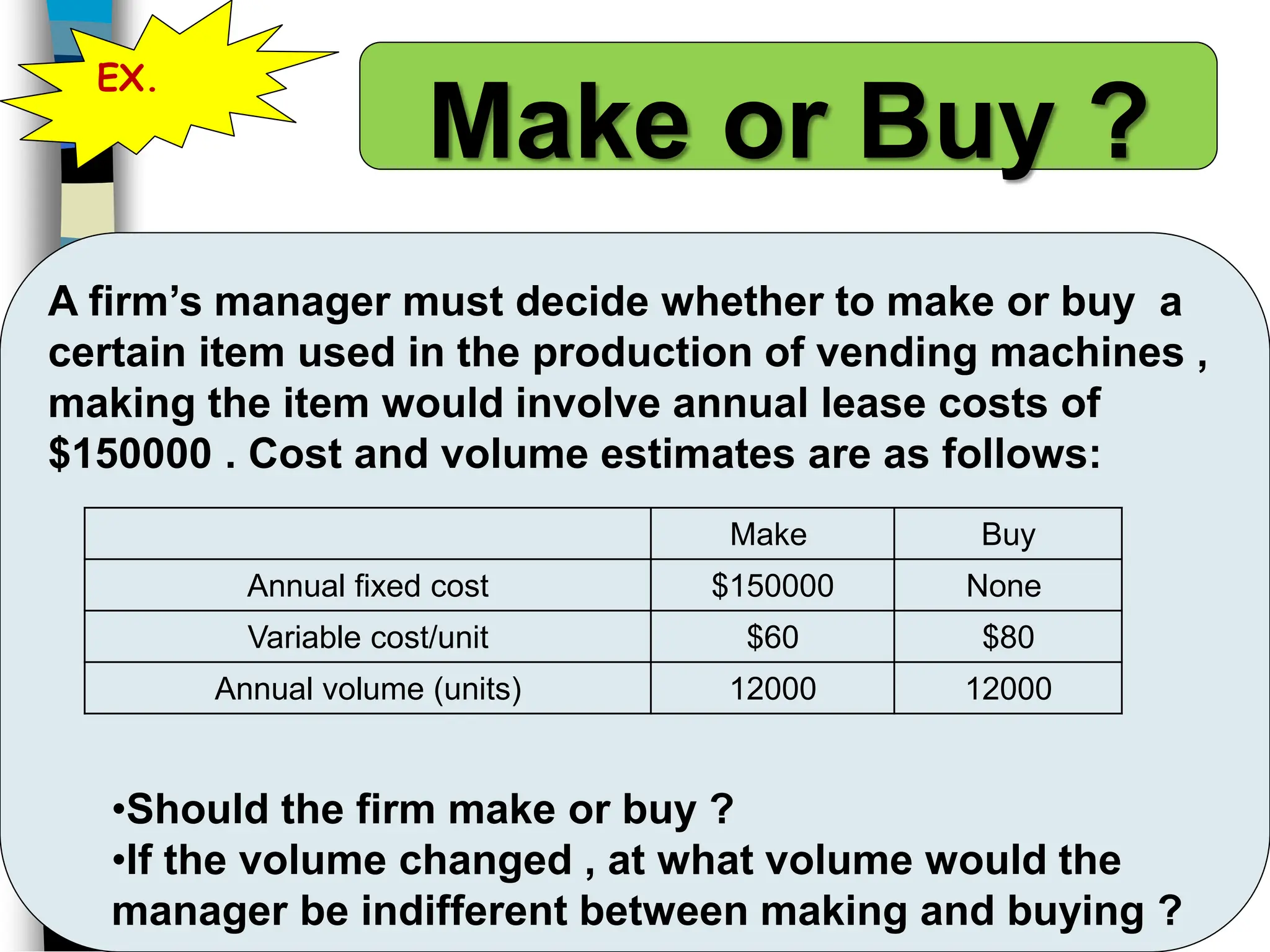

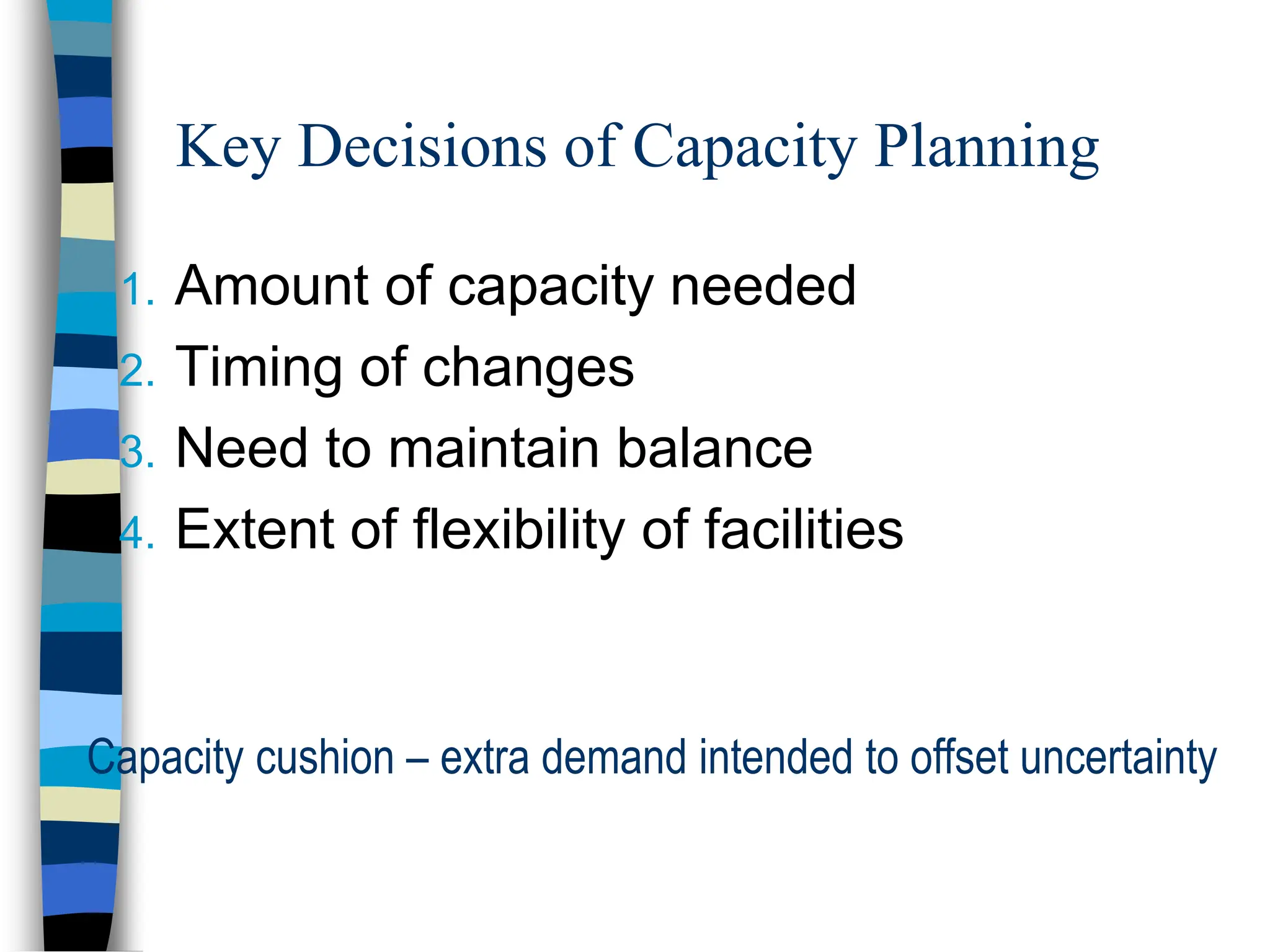

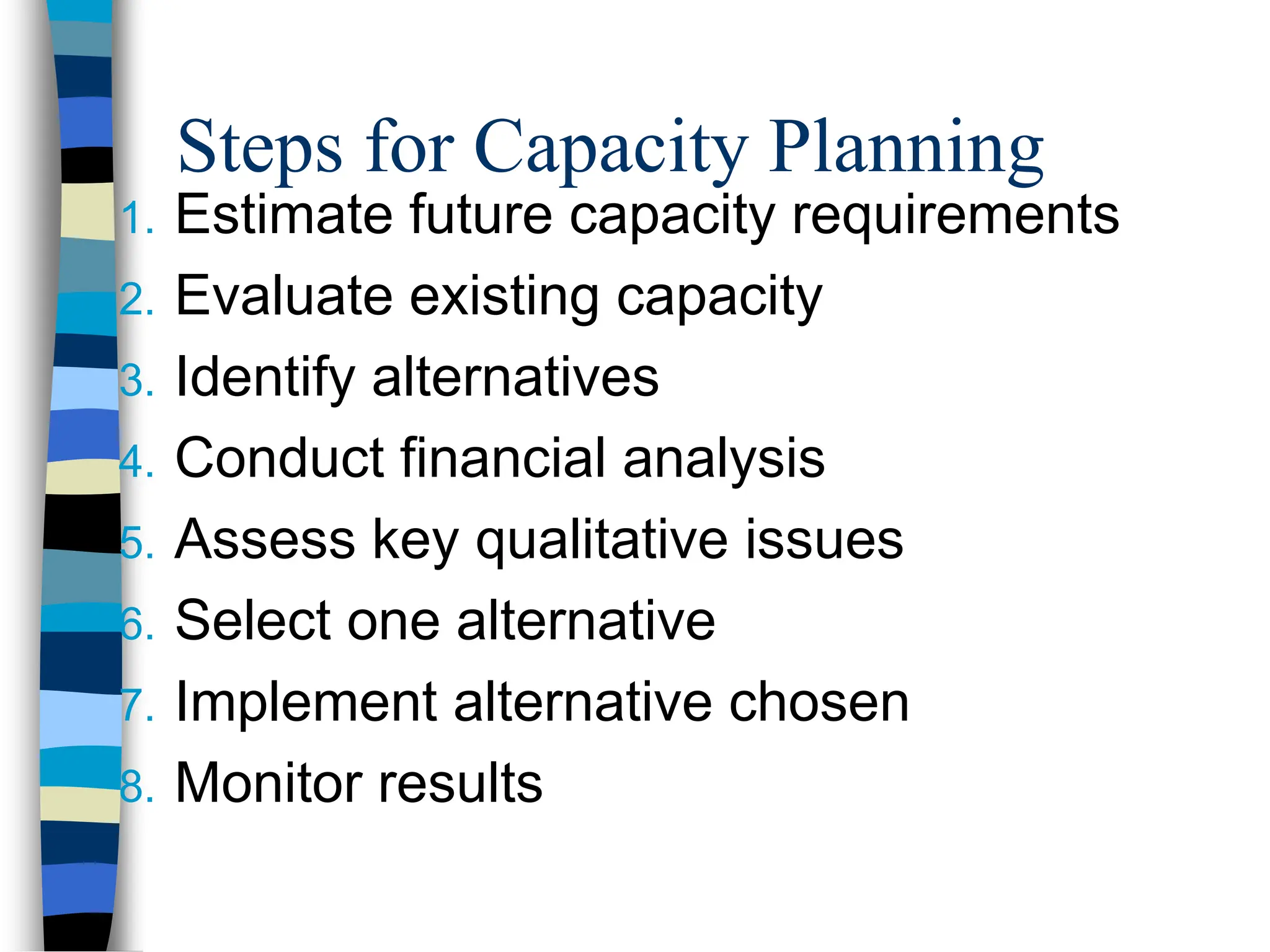

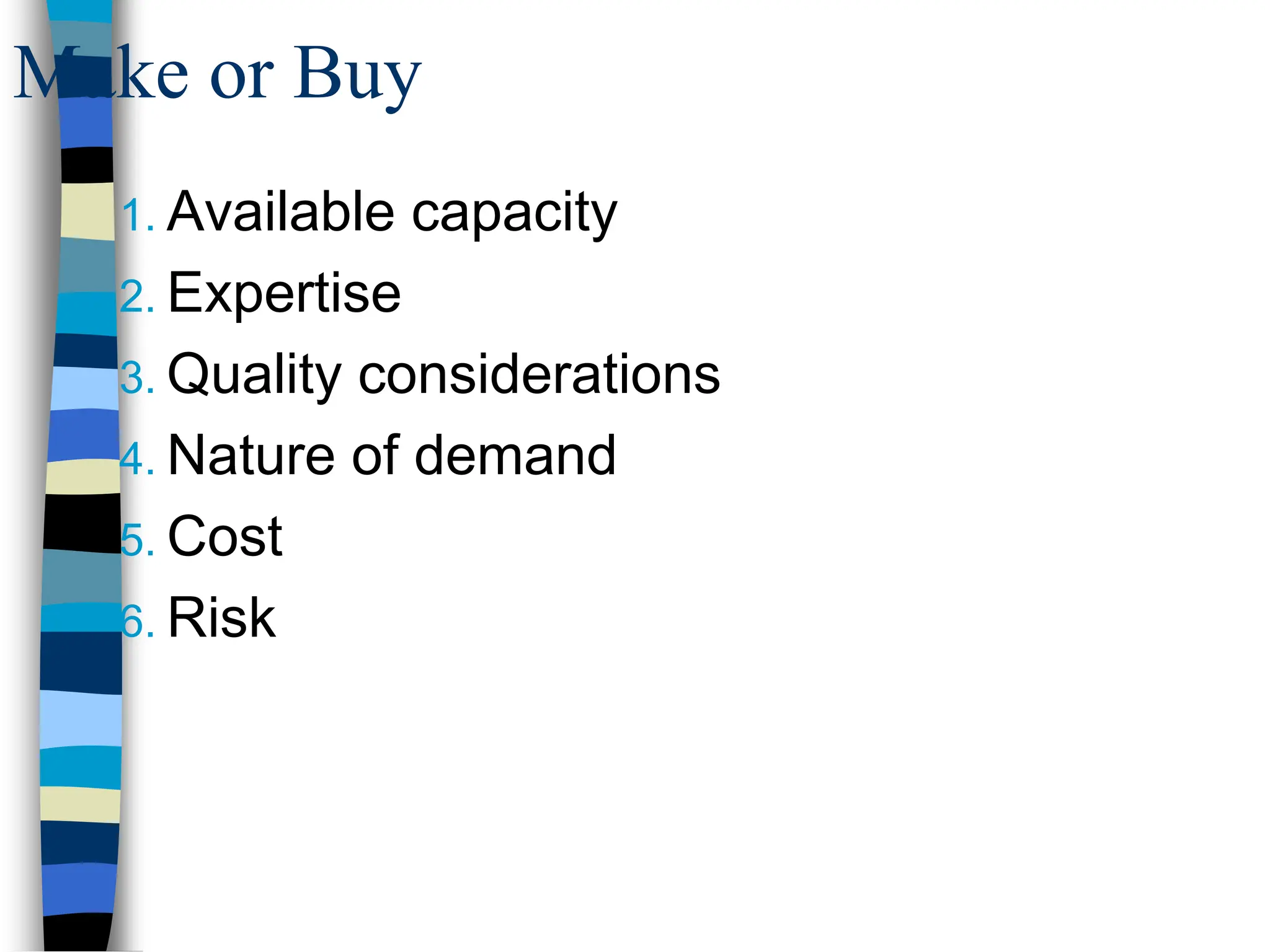

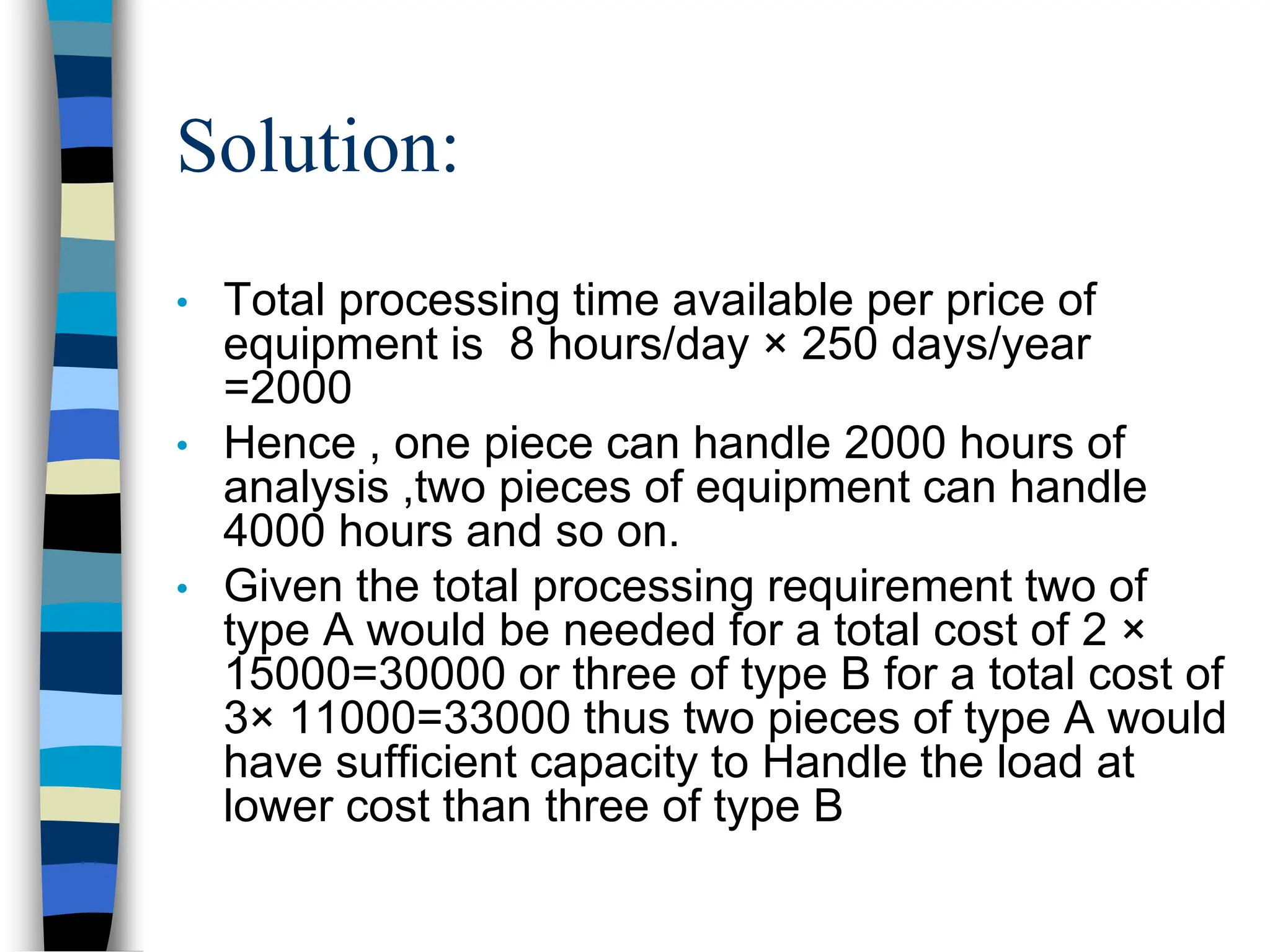

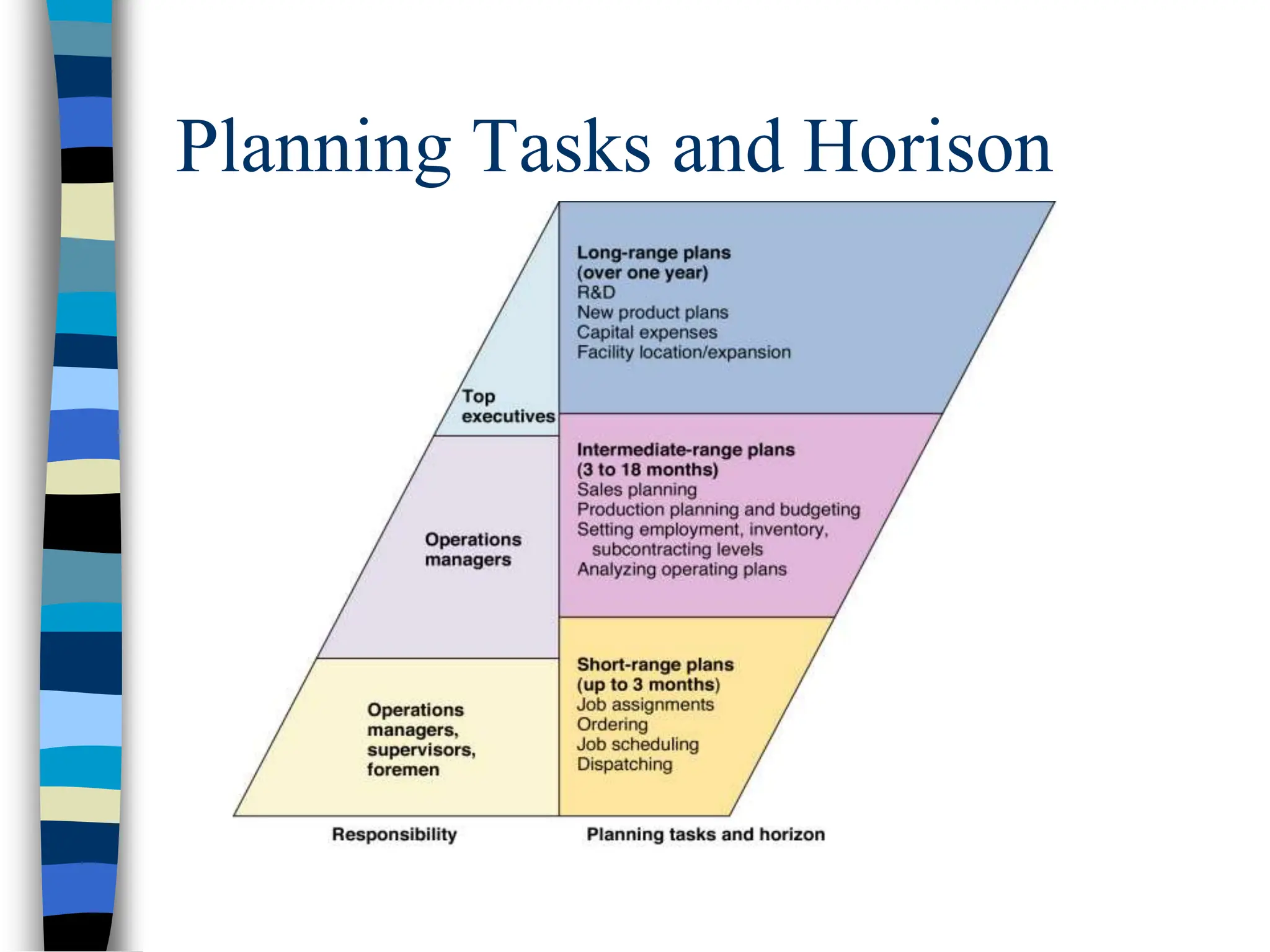

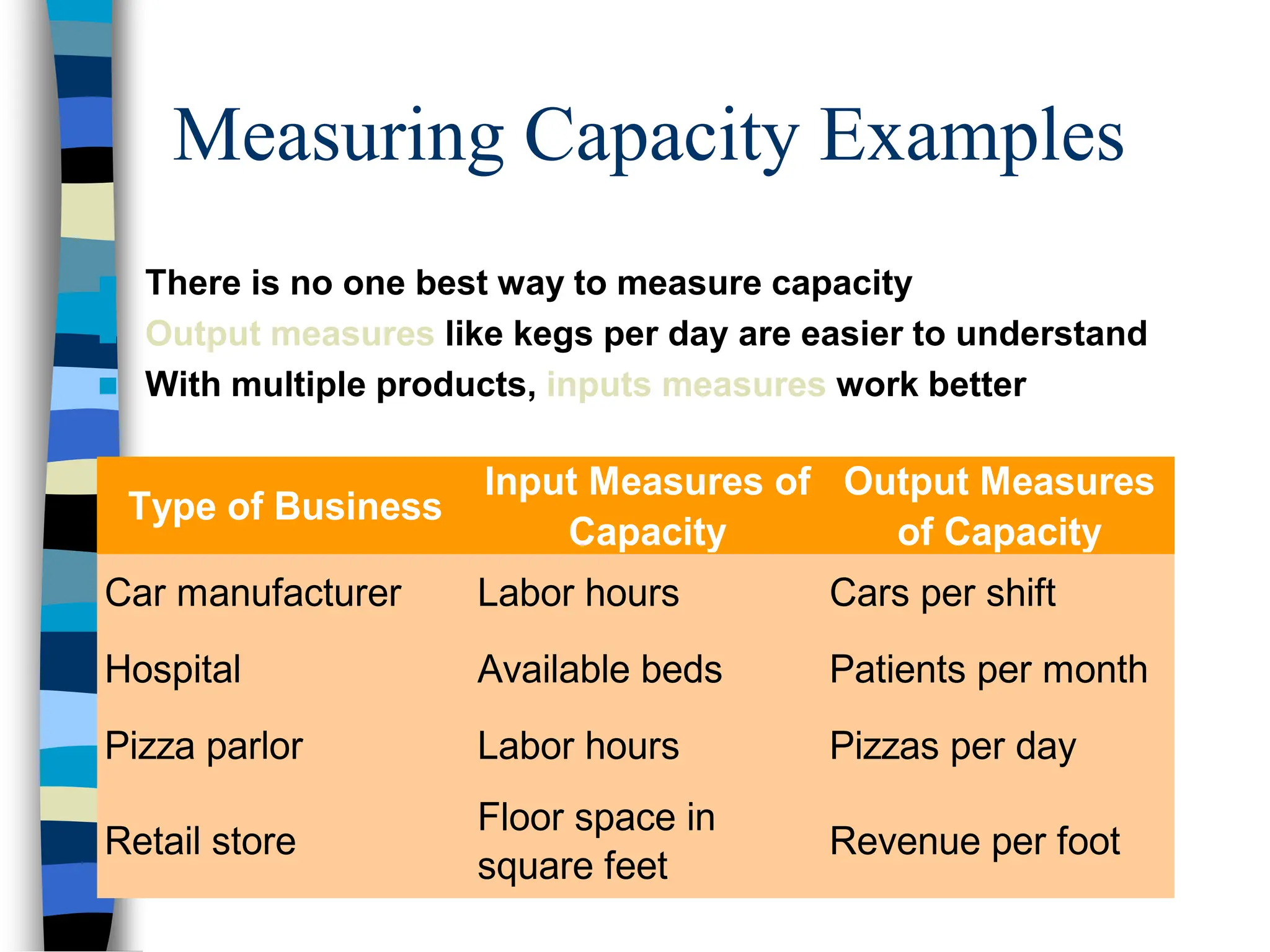

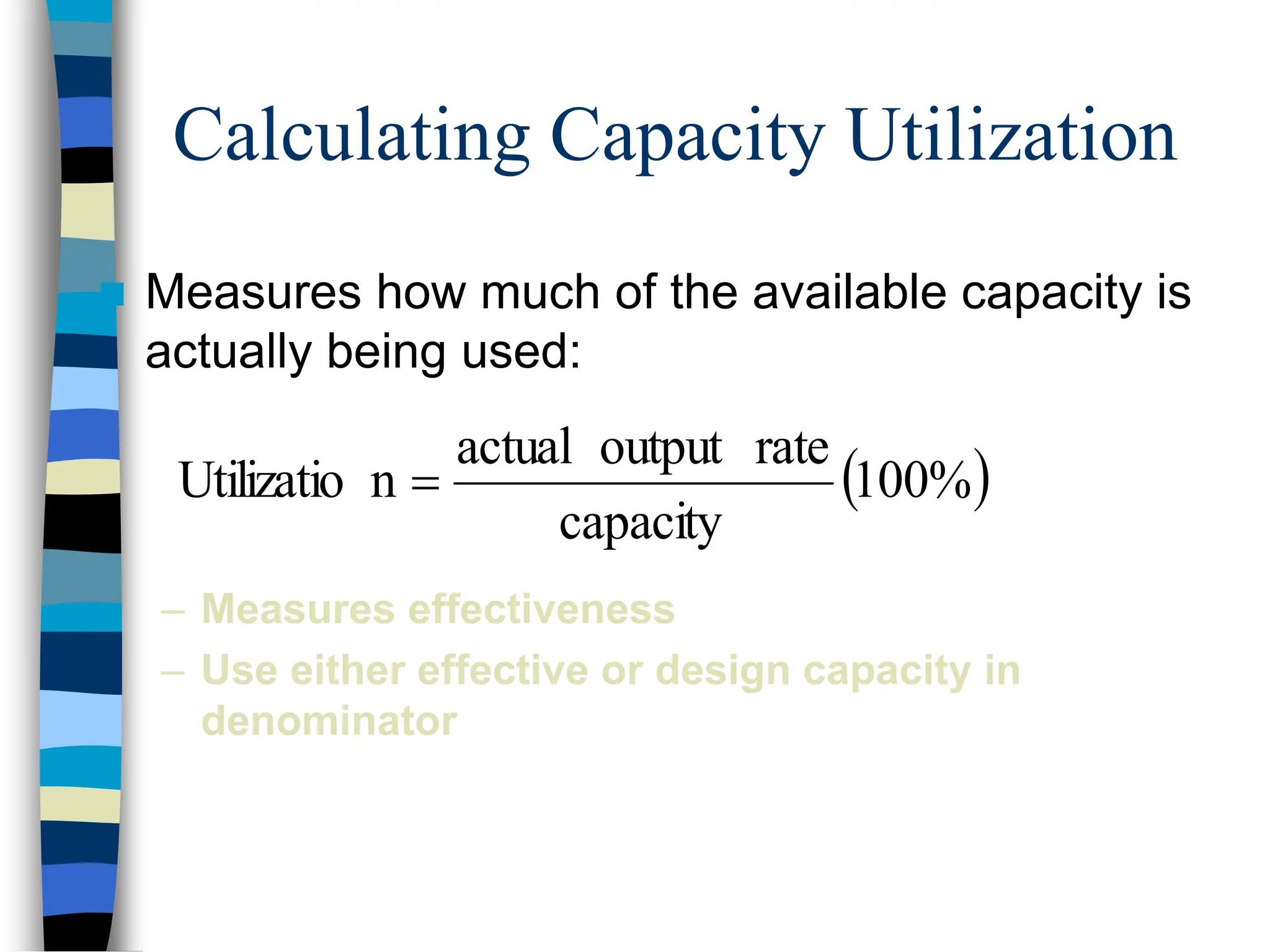

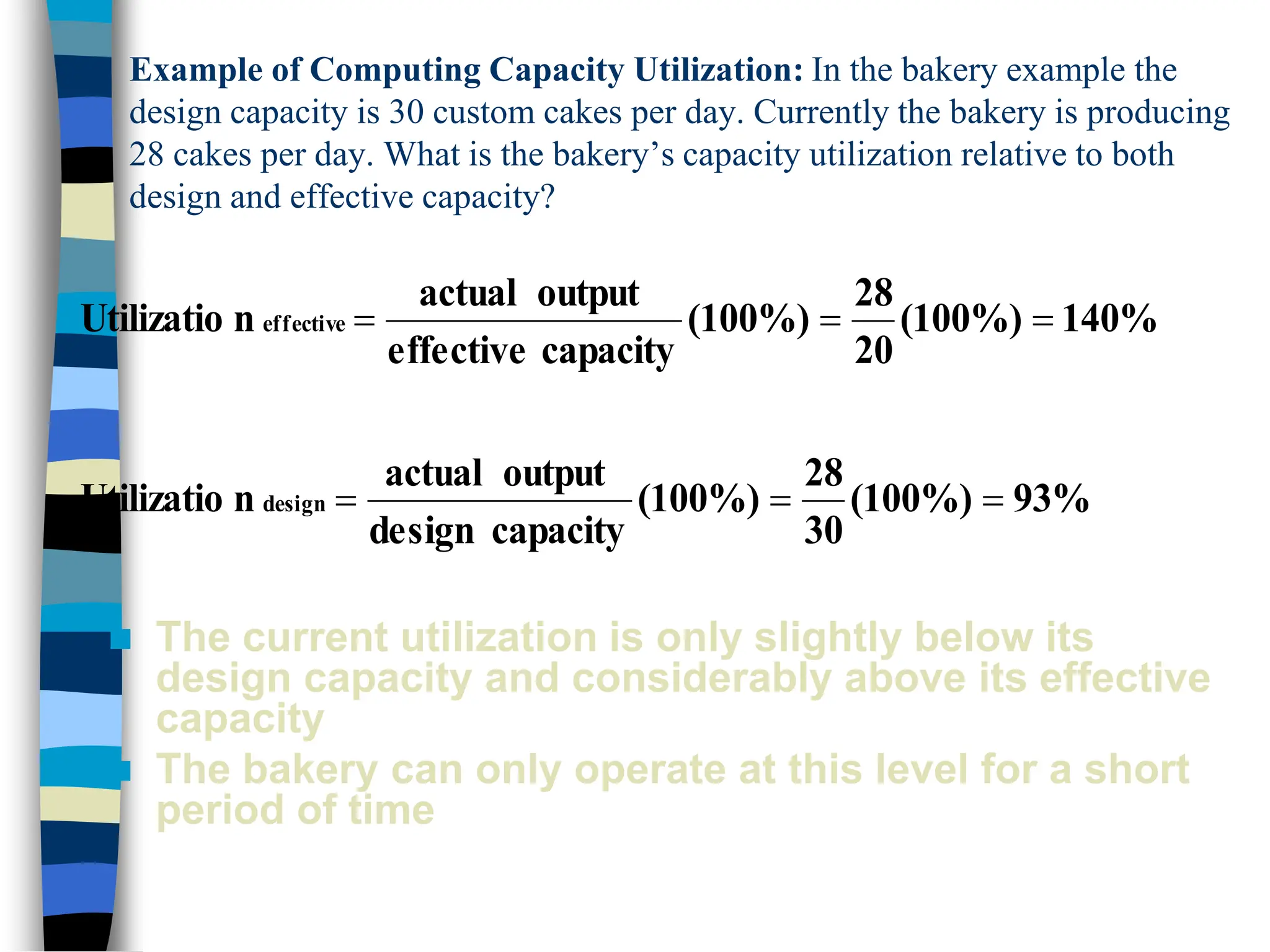

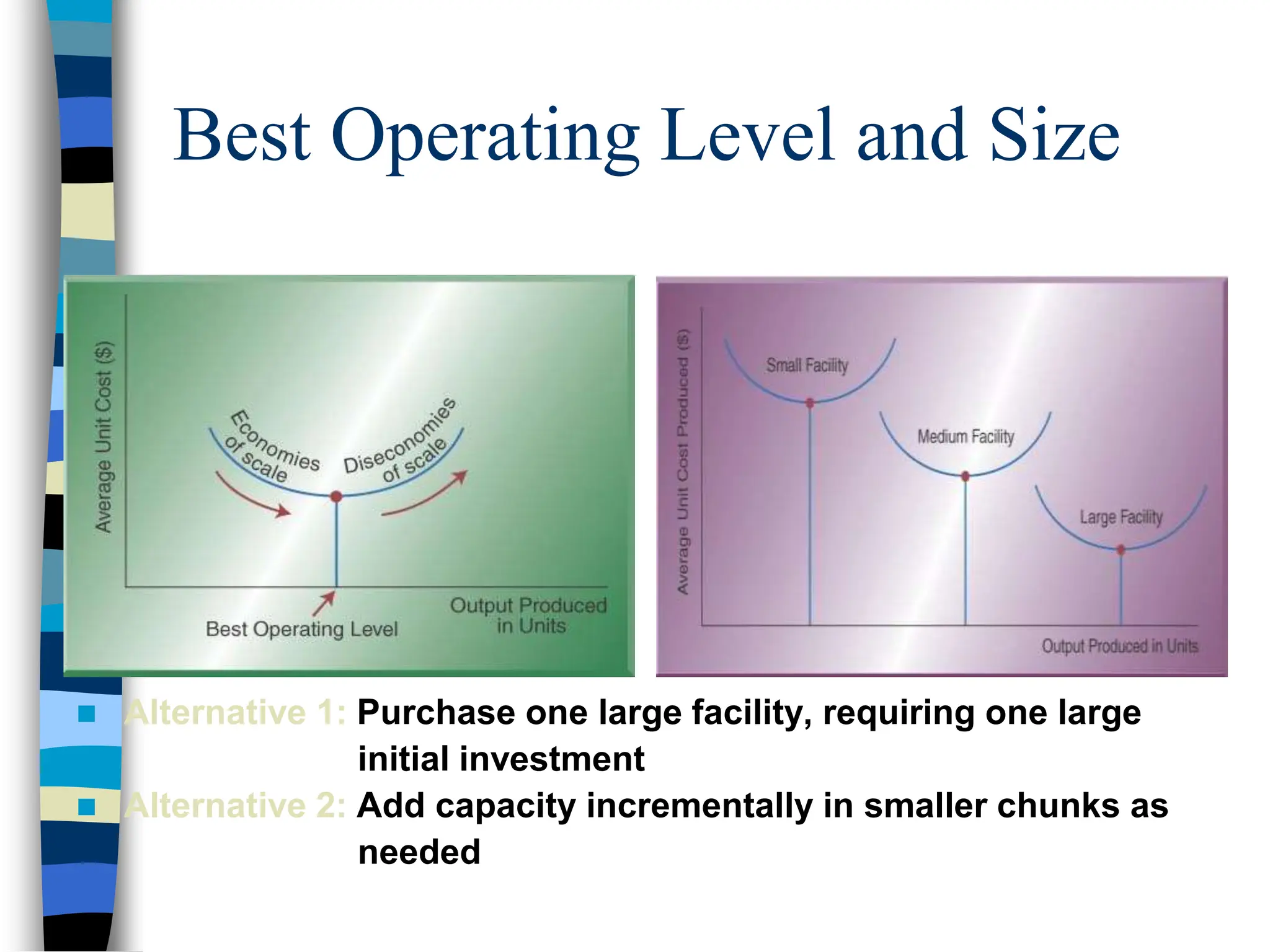

Aggregate planning involves determining a company's production capacity needs. Capacity planning establishes the optimal output rate for facilities and involves strategic decisions about capital investments. Measuring capacity depends on the type of business and inputs or outputs. Effective capacity is the maximum output under normal conditions, while design capacity is the maximum under ideal conditions. Capacity utilization compares actual output to capacity to measure effectiveness. When determining optimal capacity levels, companies consider economies and diseconomies of scale. Timing capacity changes and maintaining flexibility are also important planning decisions.

![Implementing Capacity

Decisions

Capacity flexibility

– Plant, process, workers, outsourcing

Amount of capacity cushion

– important in -to-order and services

Timing the capacity change

– Leading [proactive]

– Concurrent [neutral]

– Lagging [reactive]

Size of the capacity increment](https://image.slidesharecdn.com/aggregateplanning-240408062000-9fbc1182/75/Aggregate-Planning-for-industrial-engineering-10-2048.jpg)