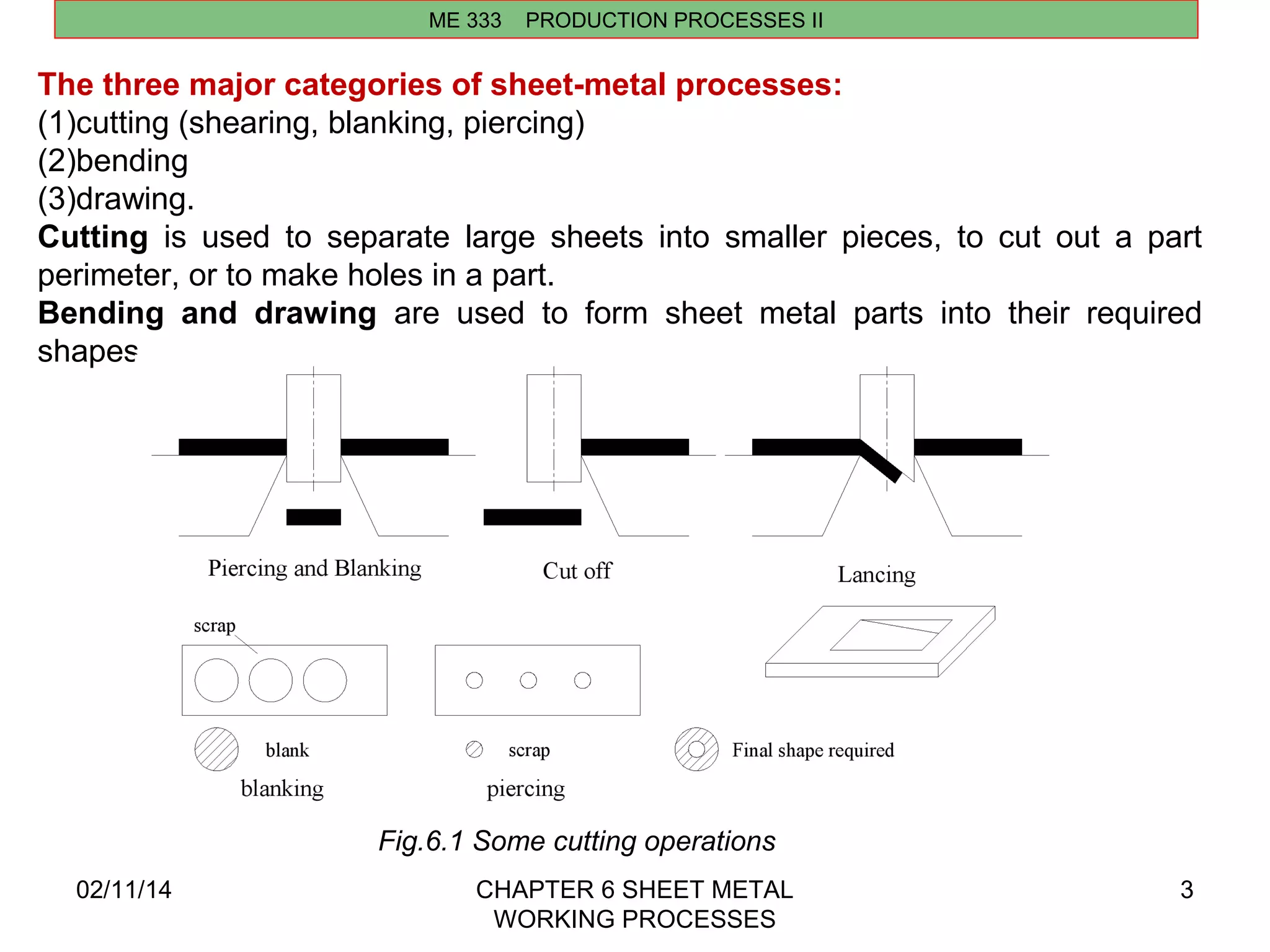

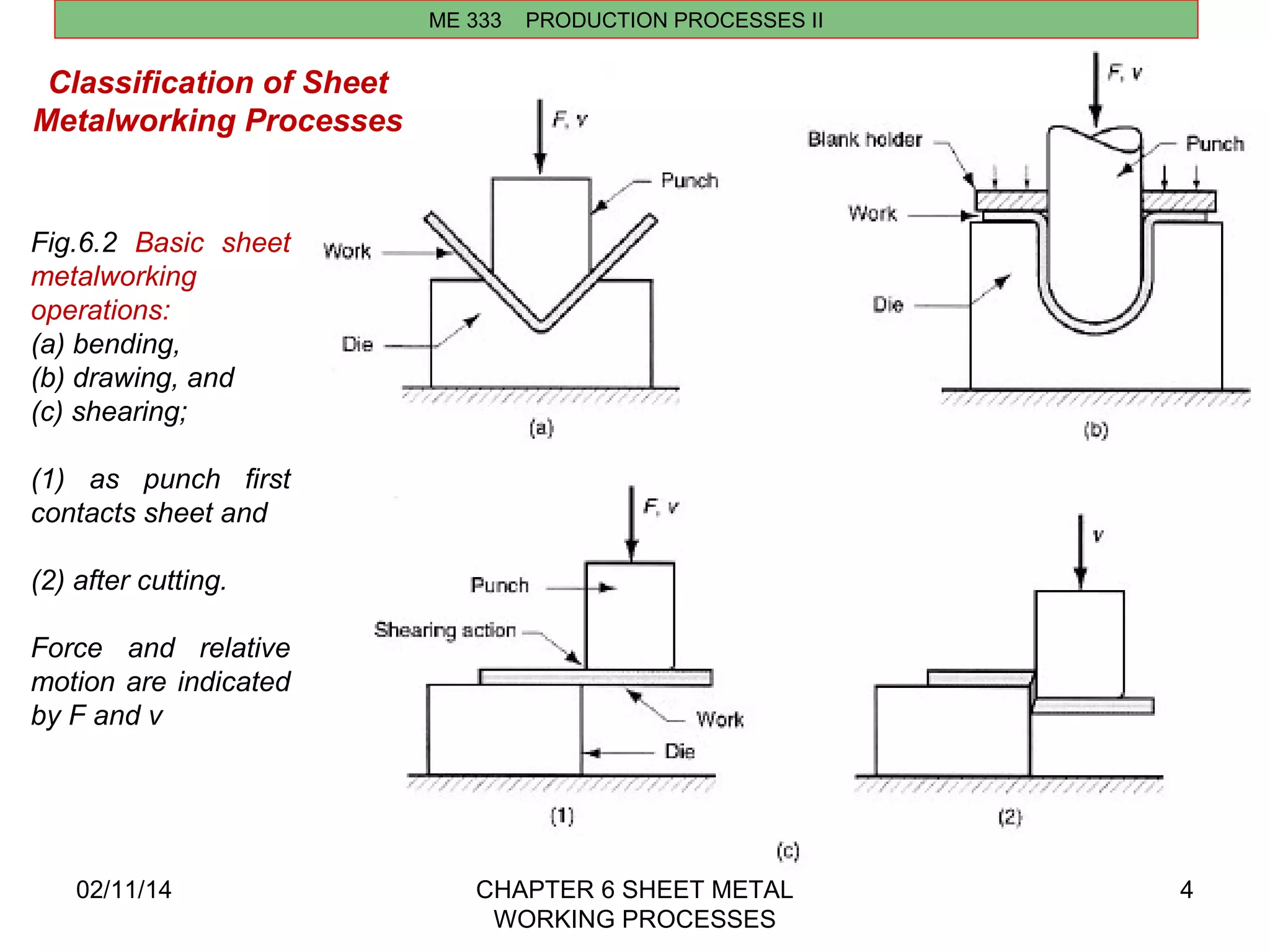

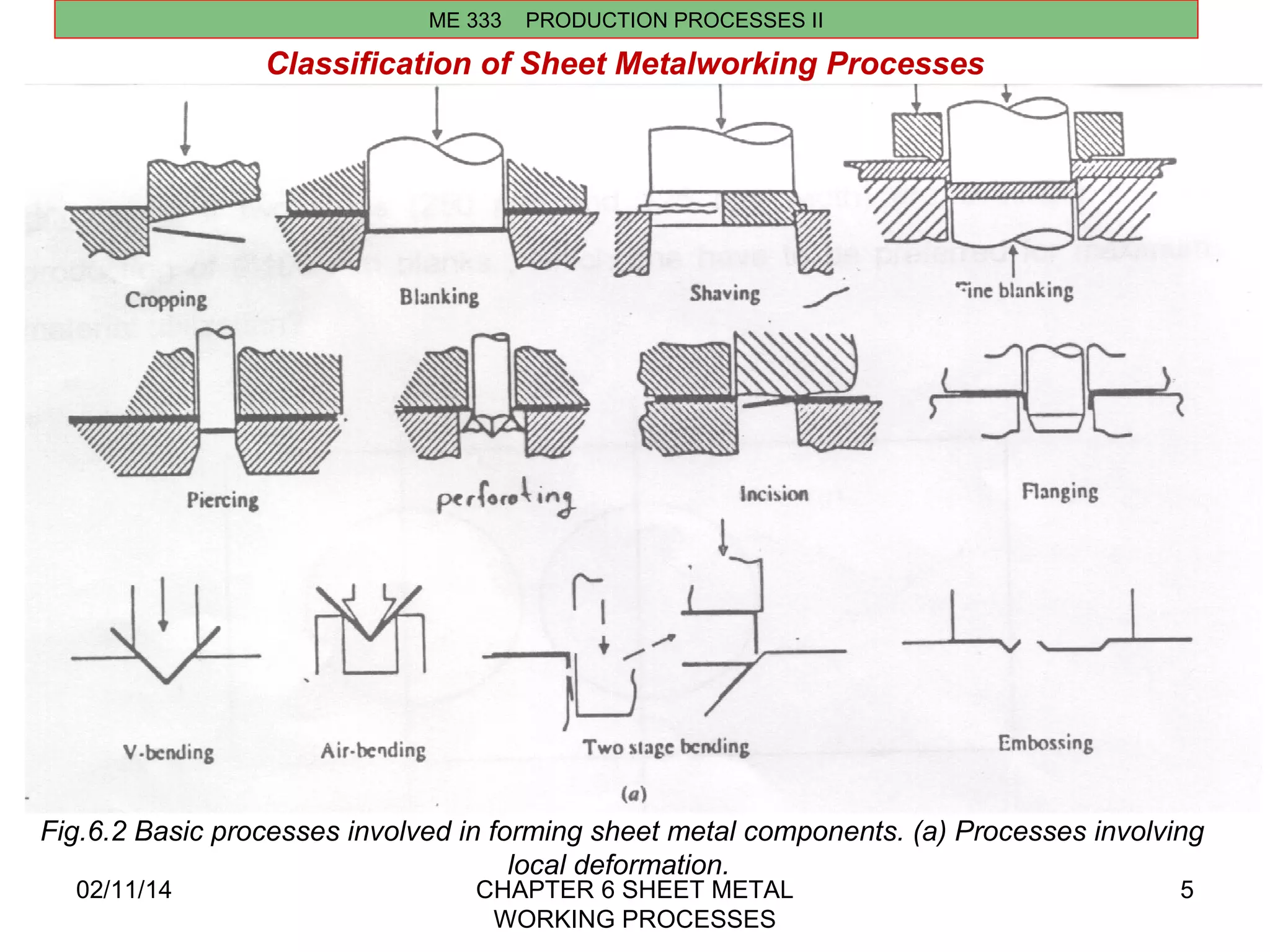

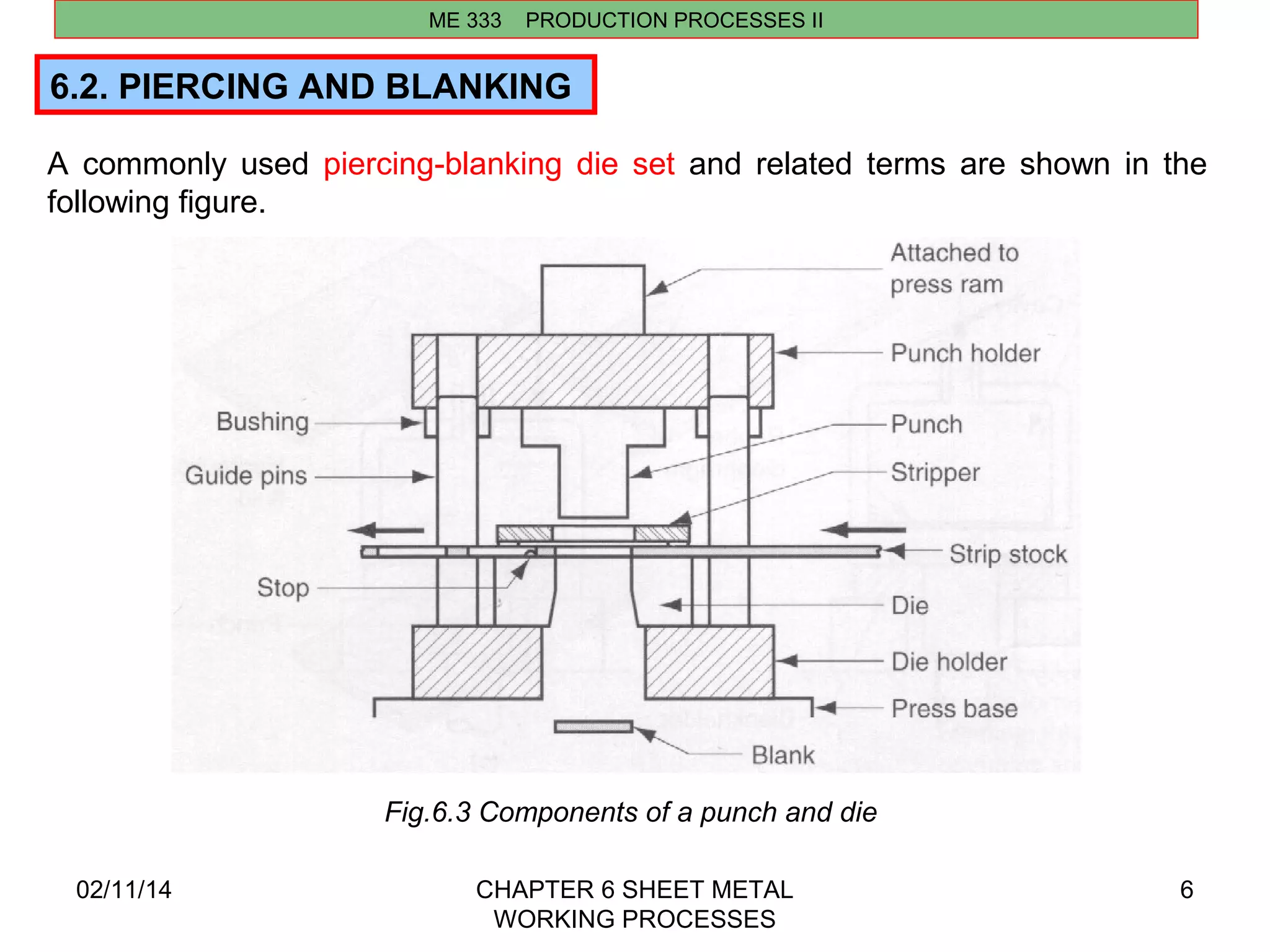

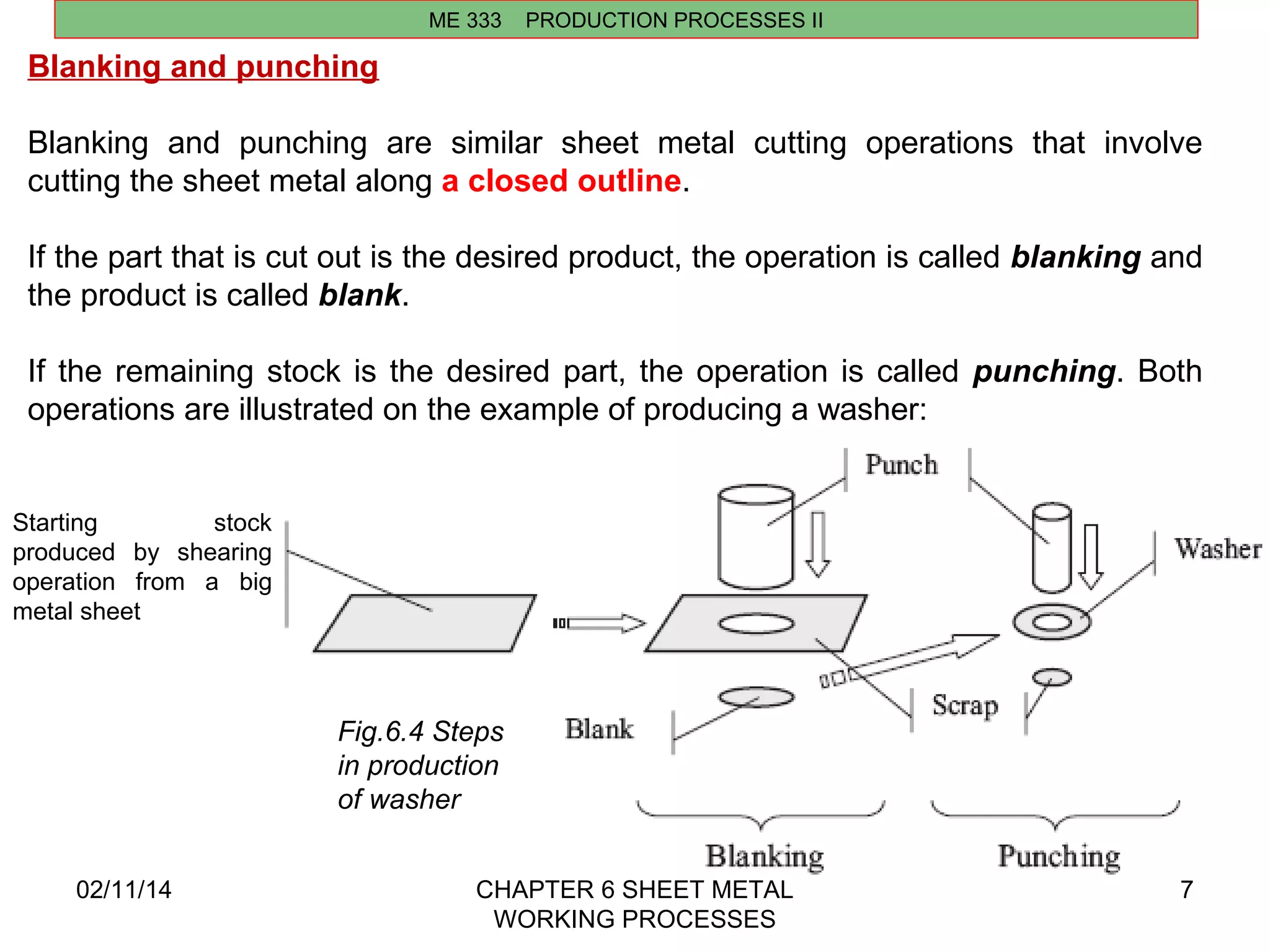

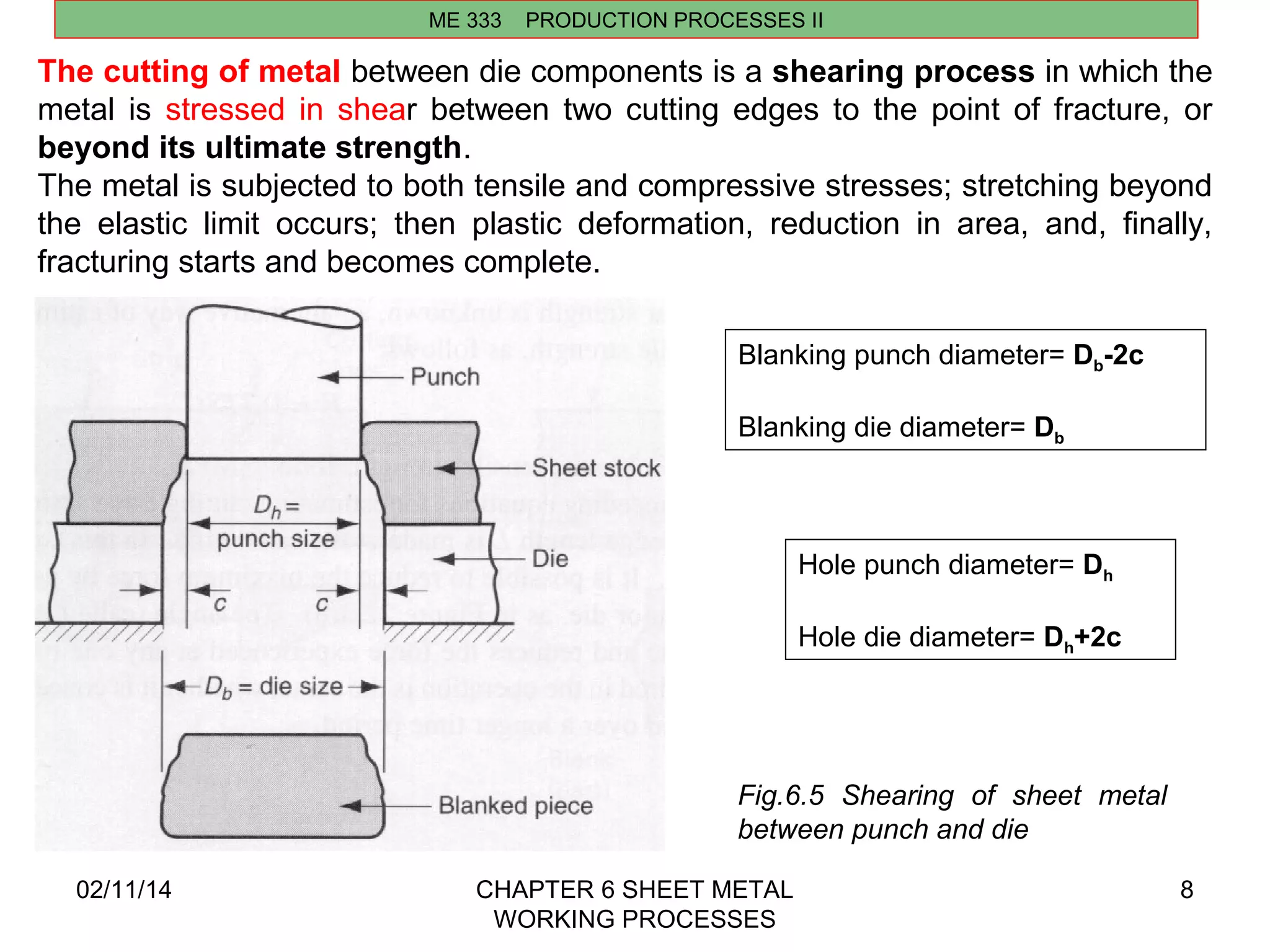

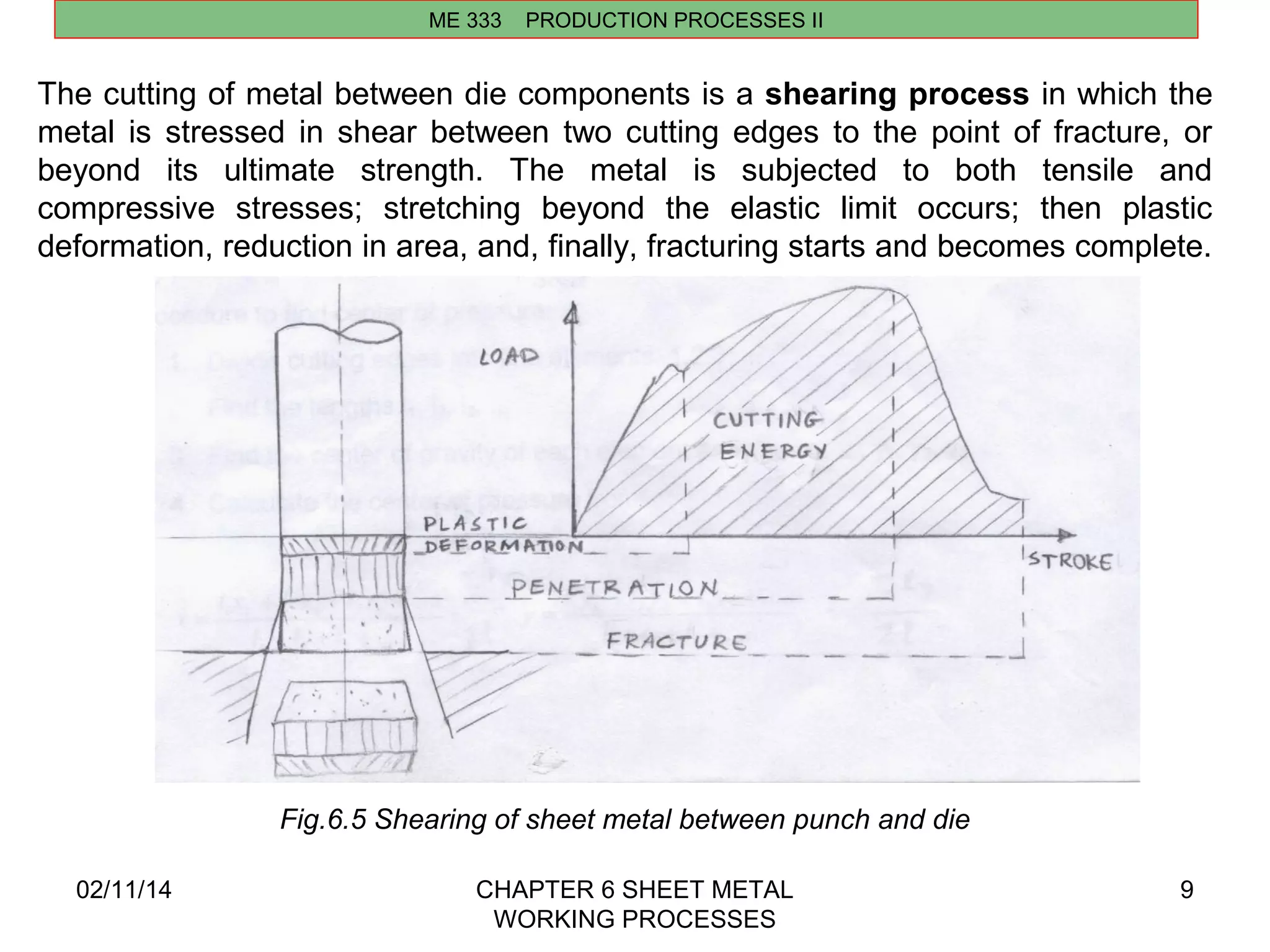

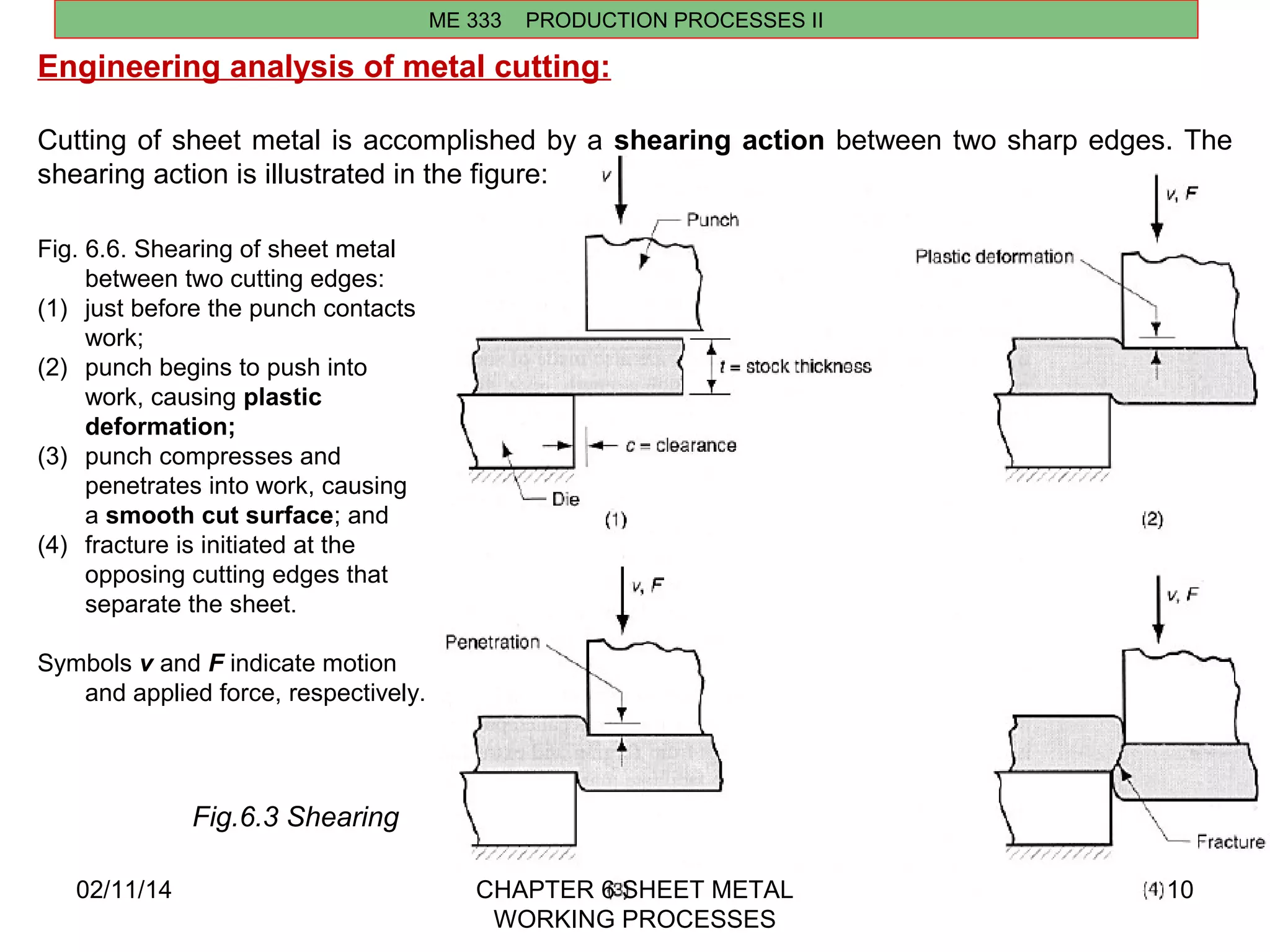

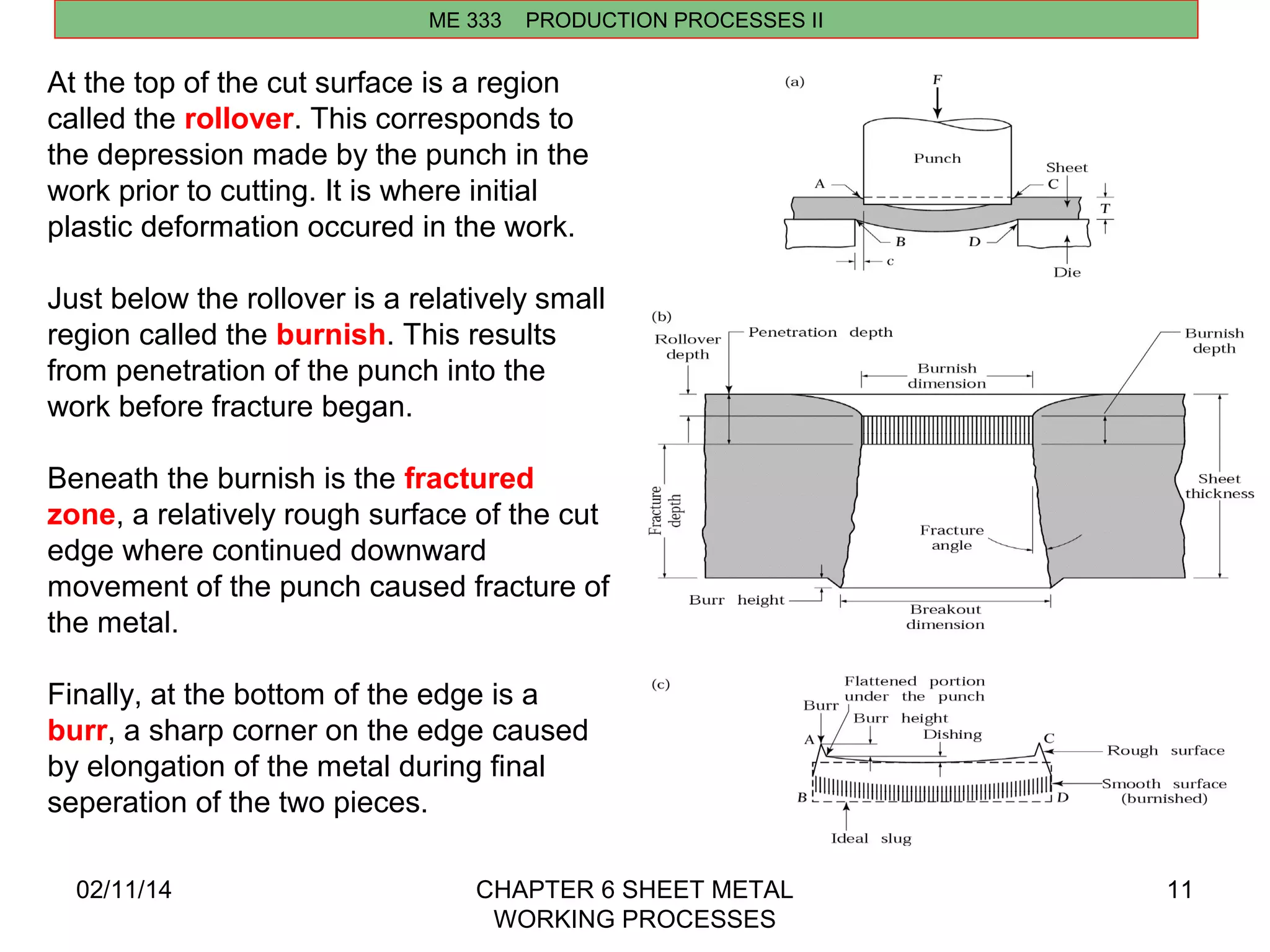

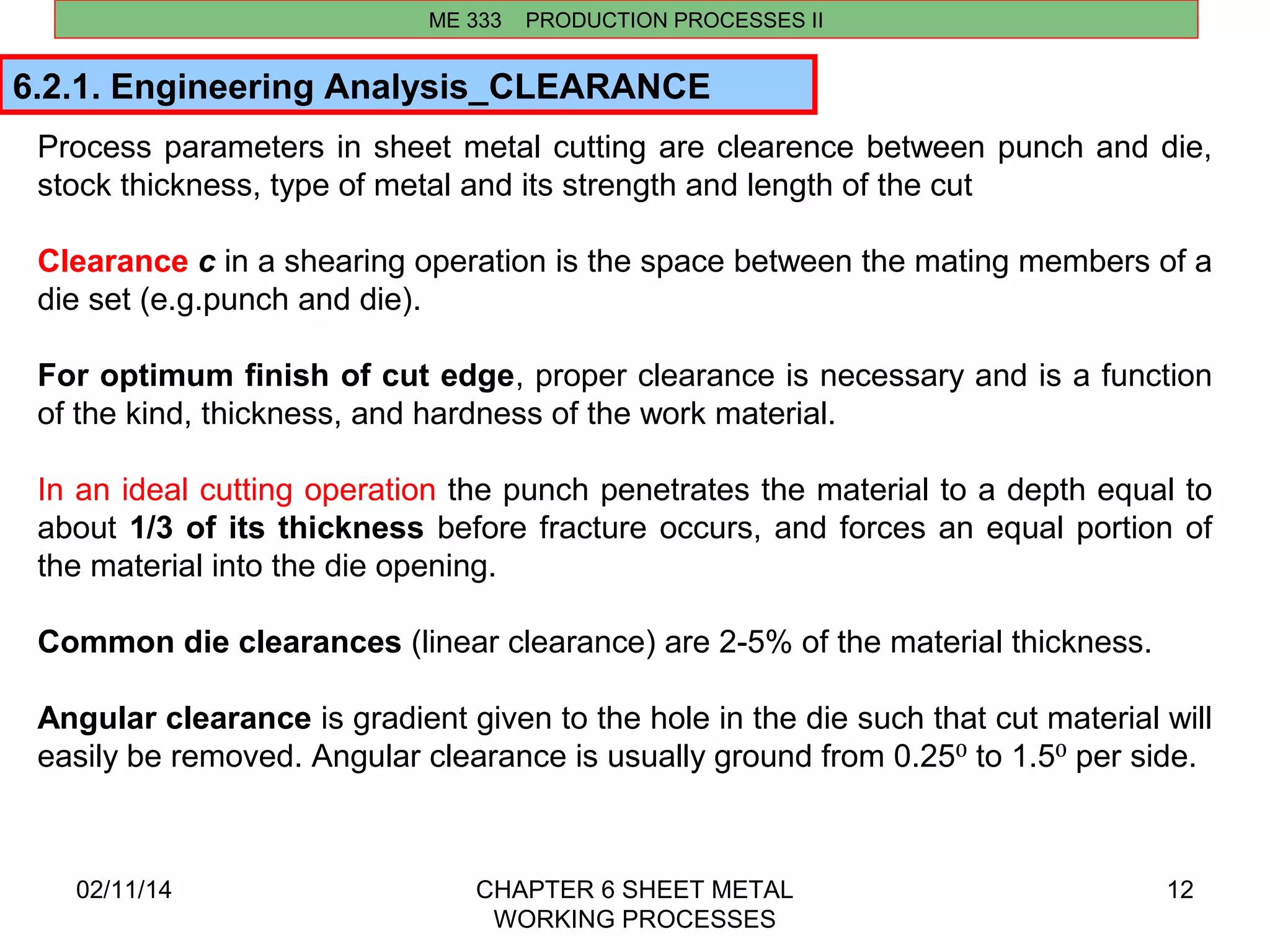

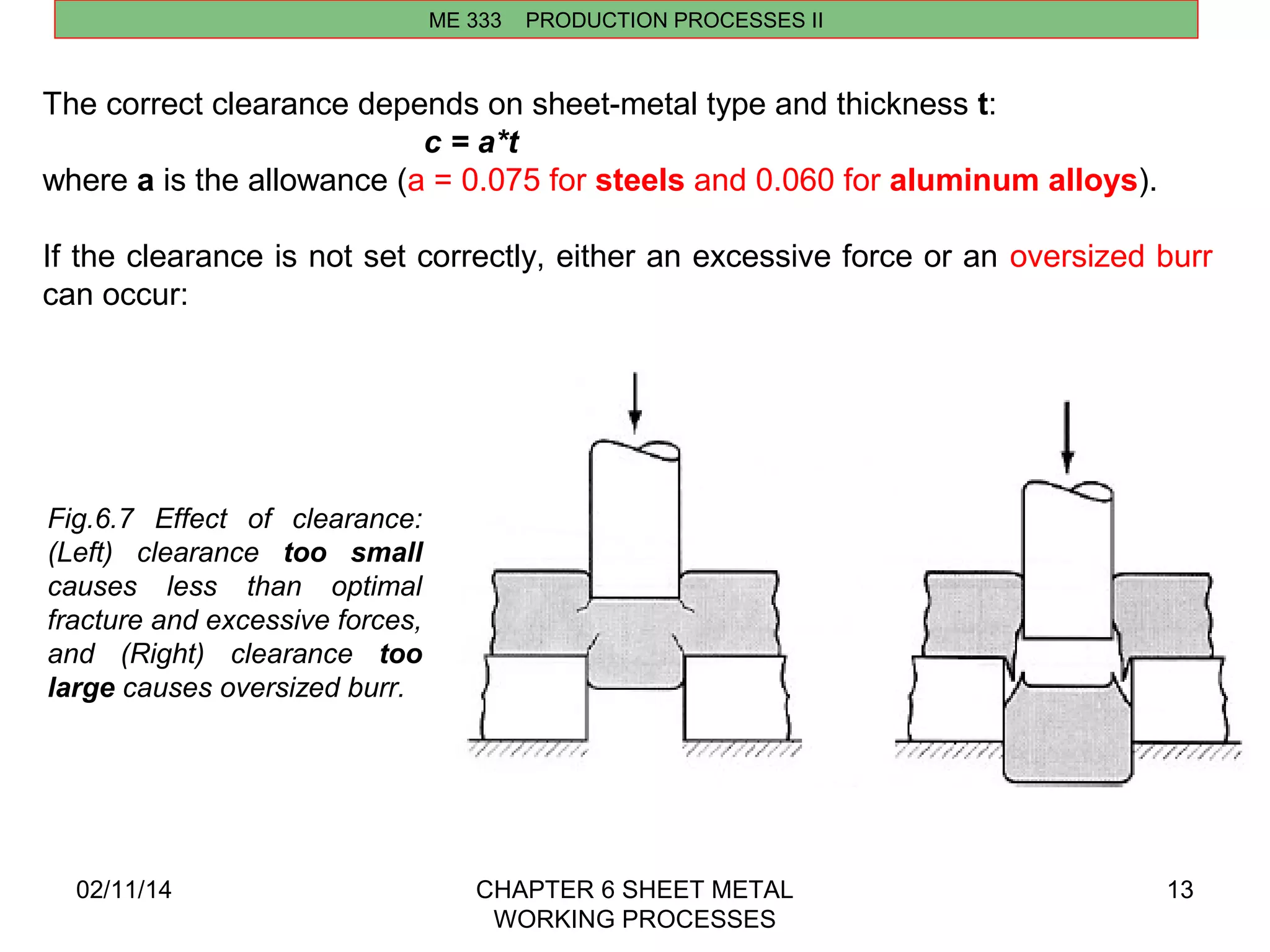

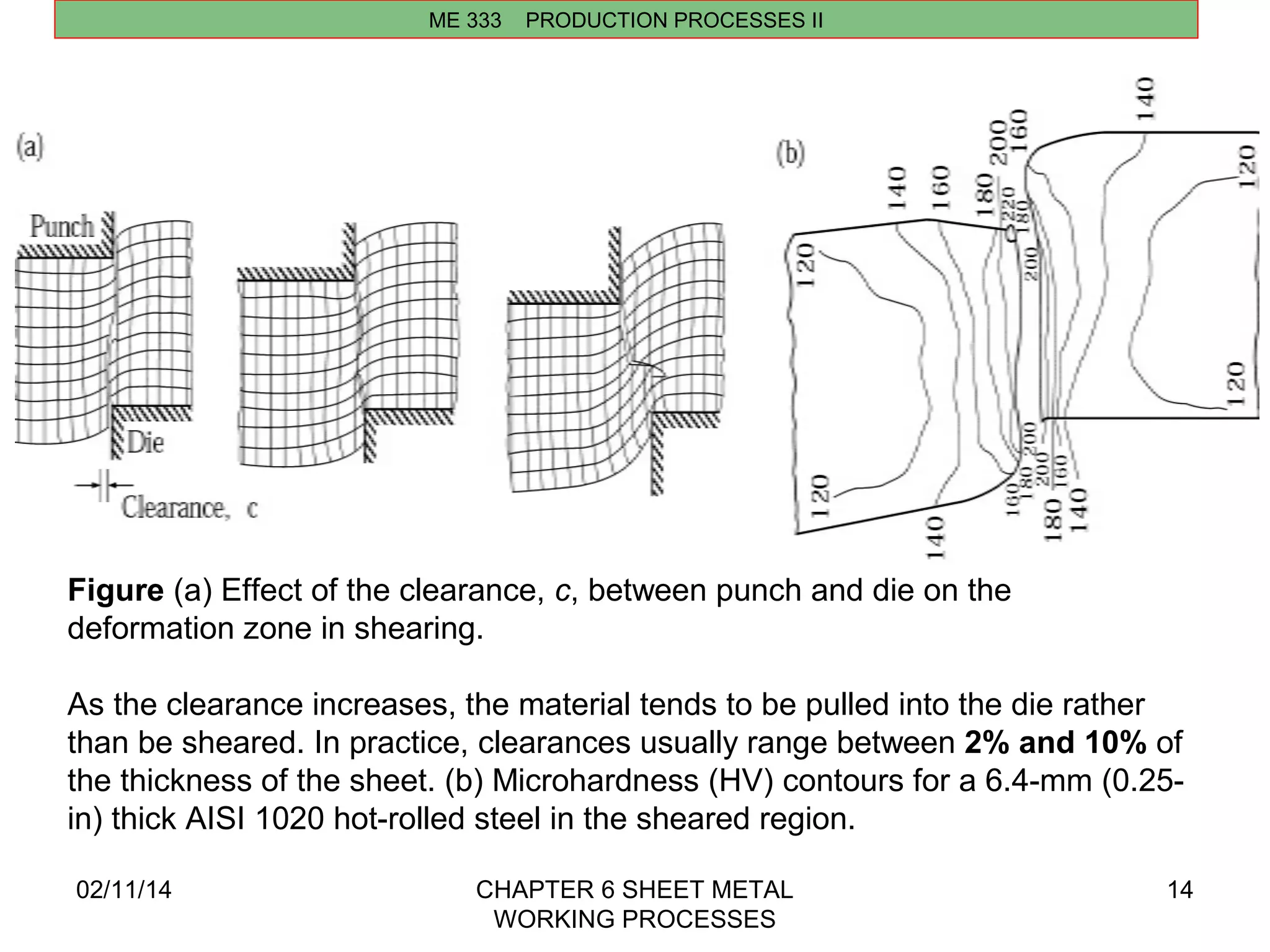

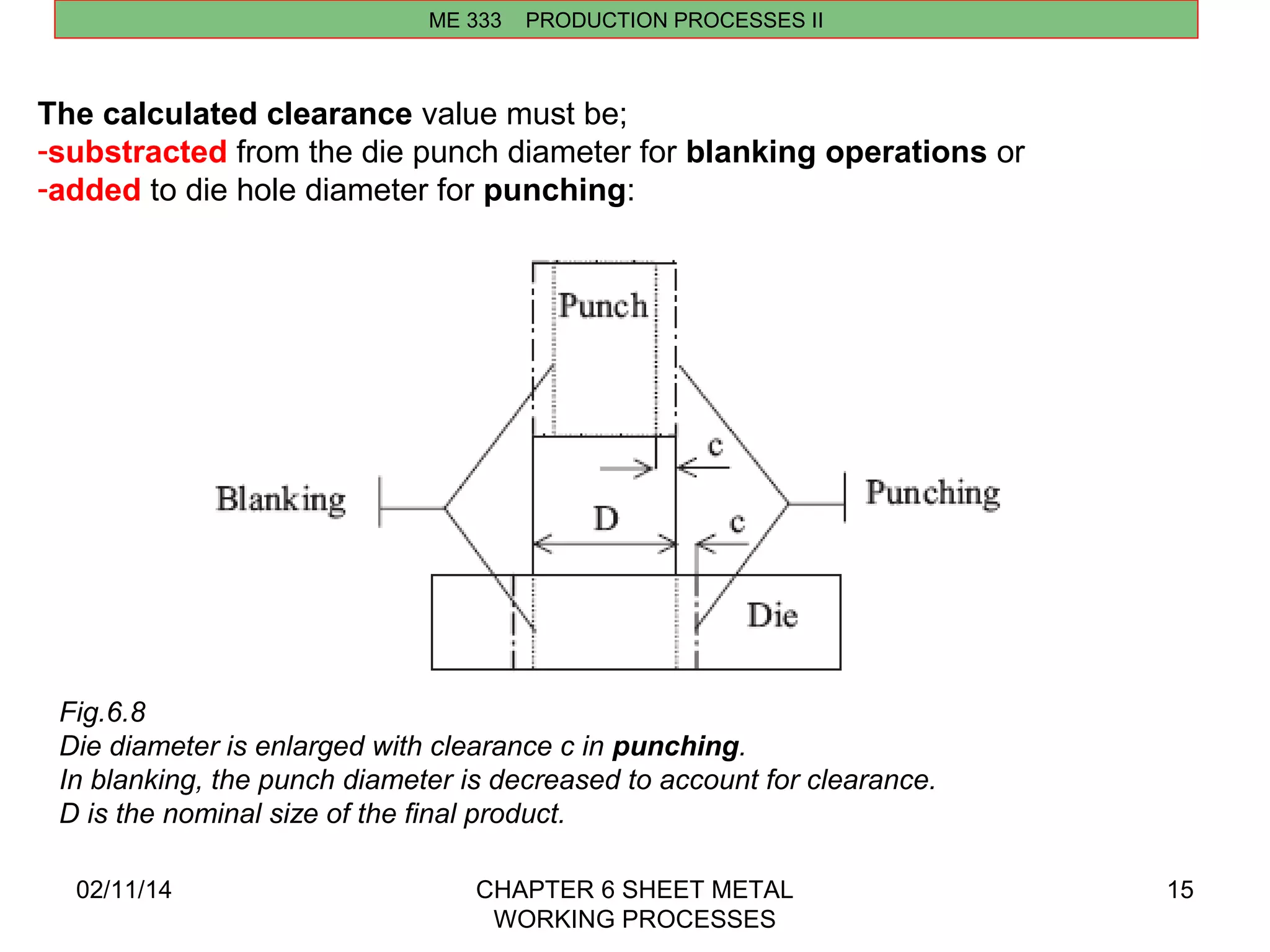

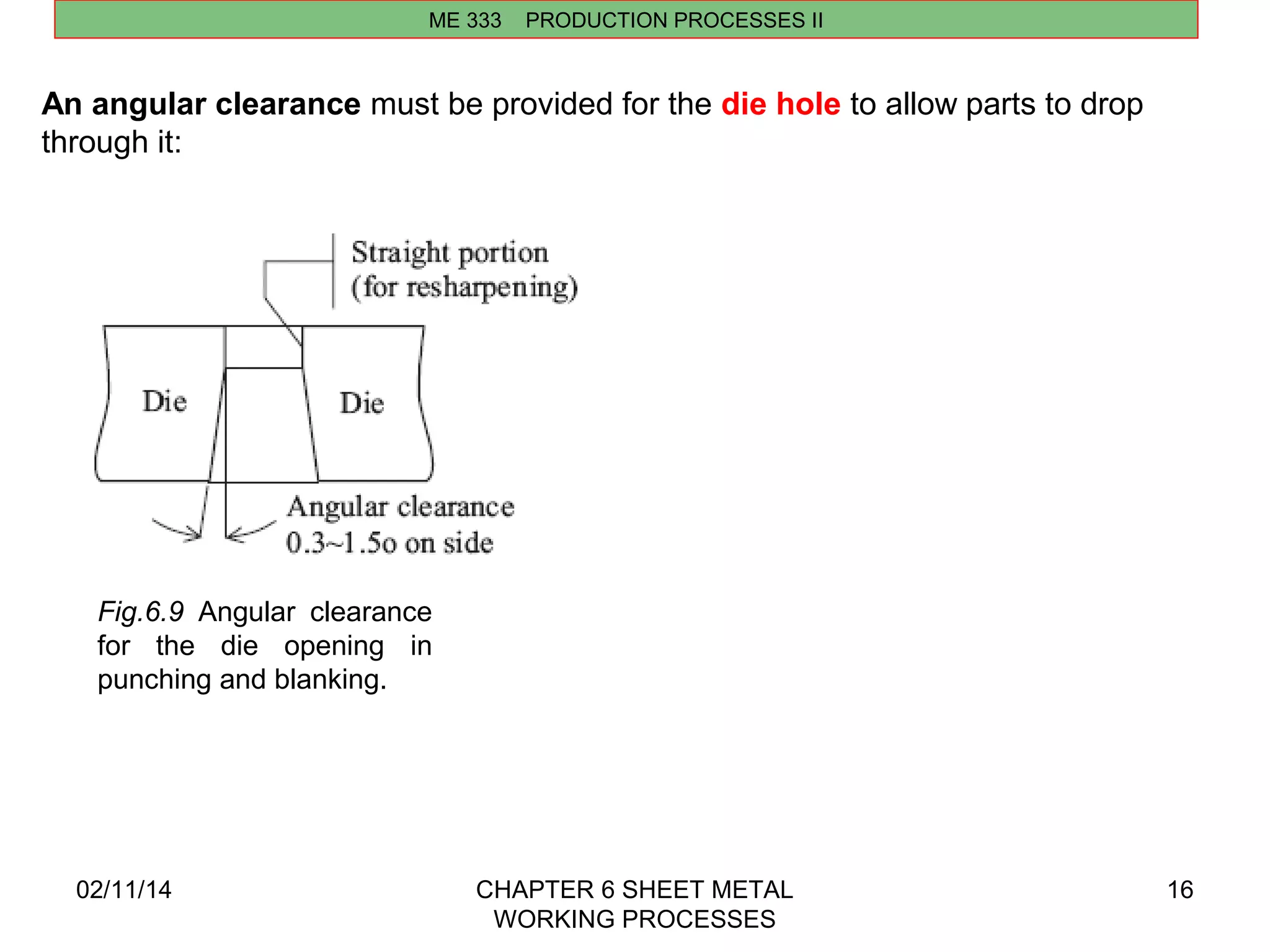

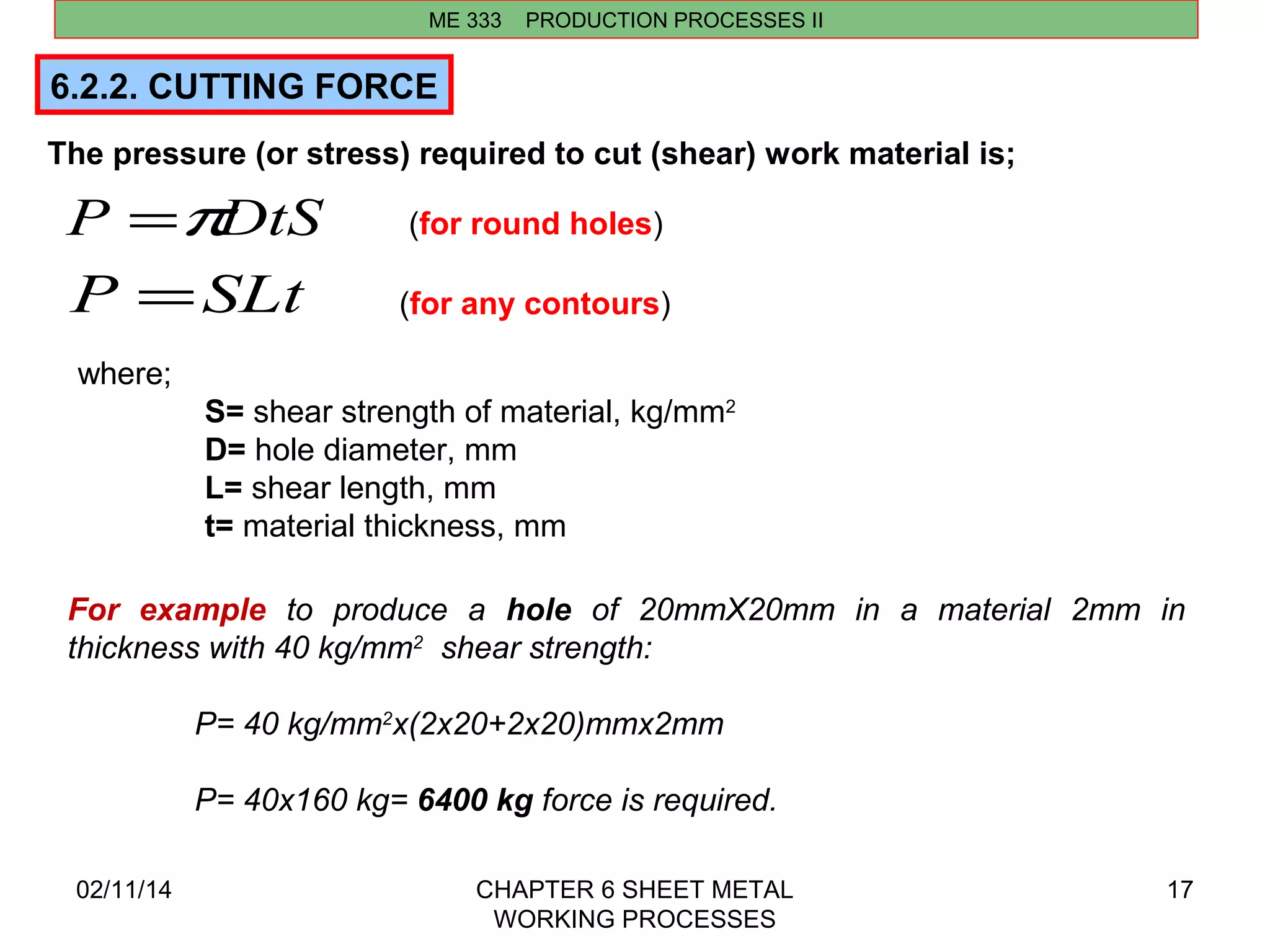

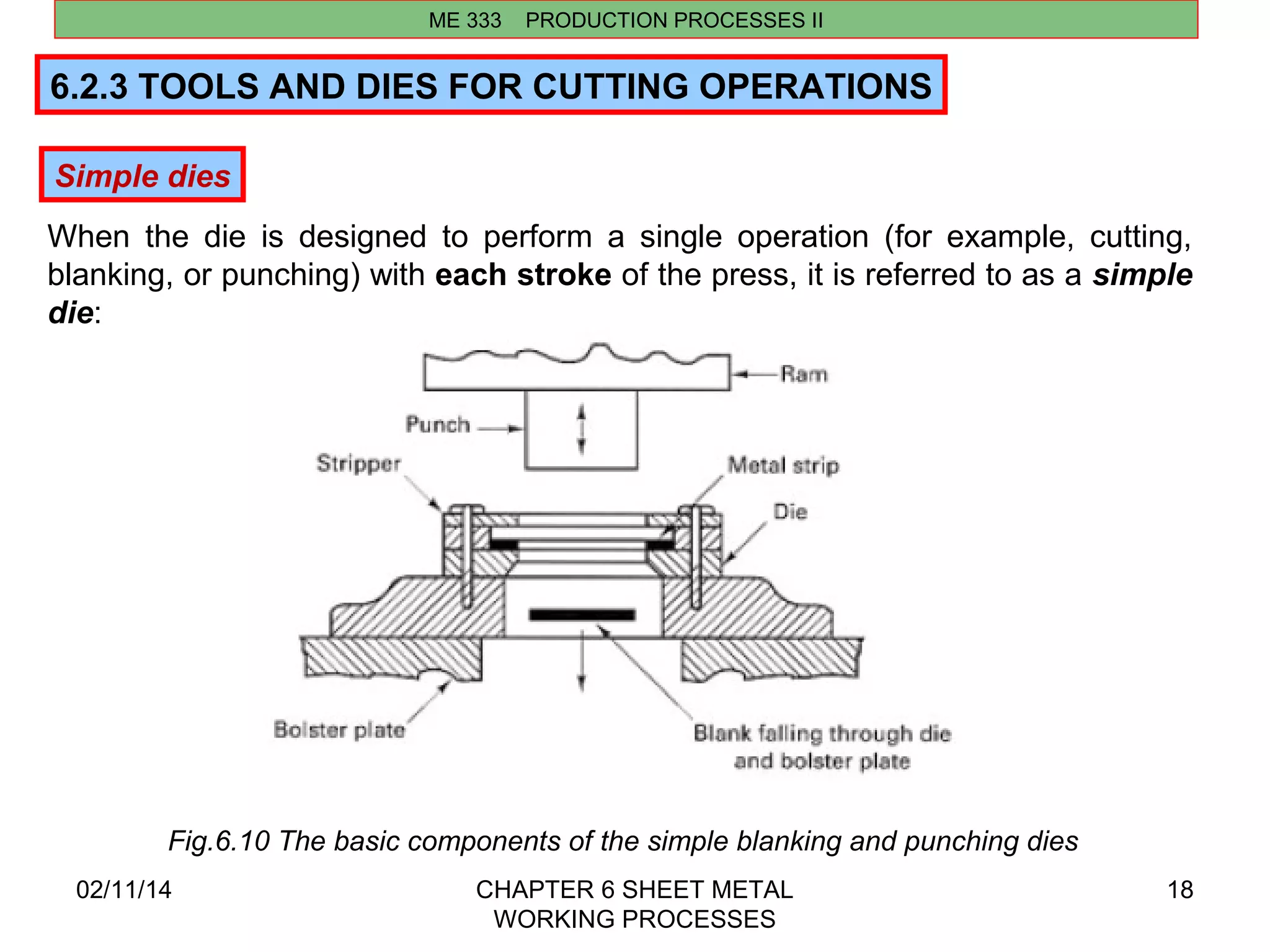

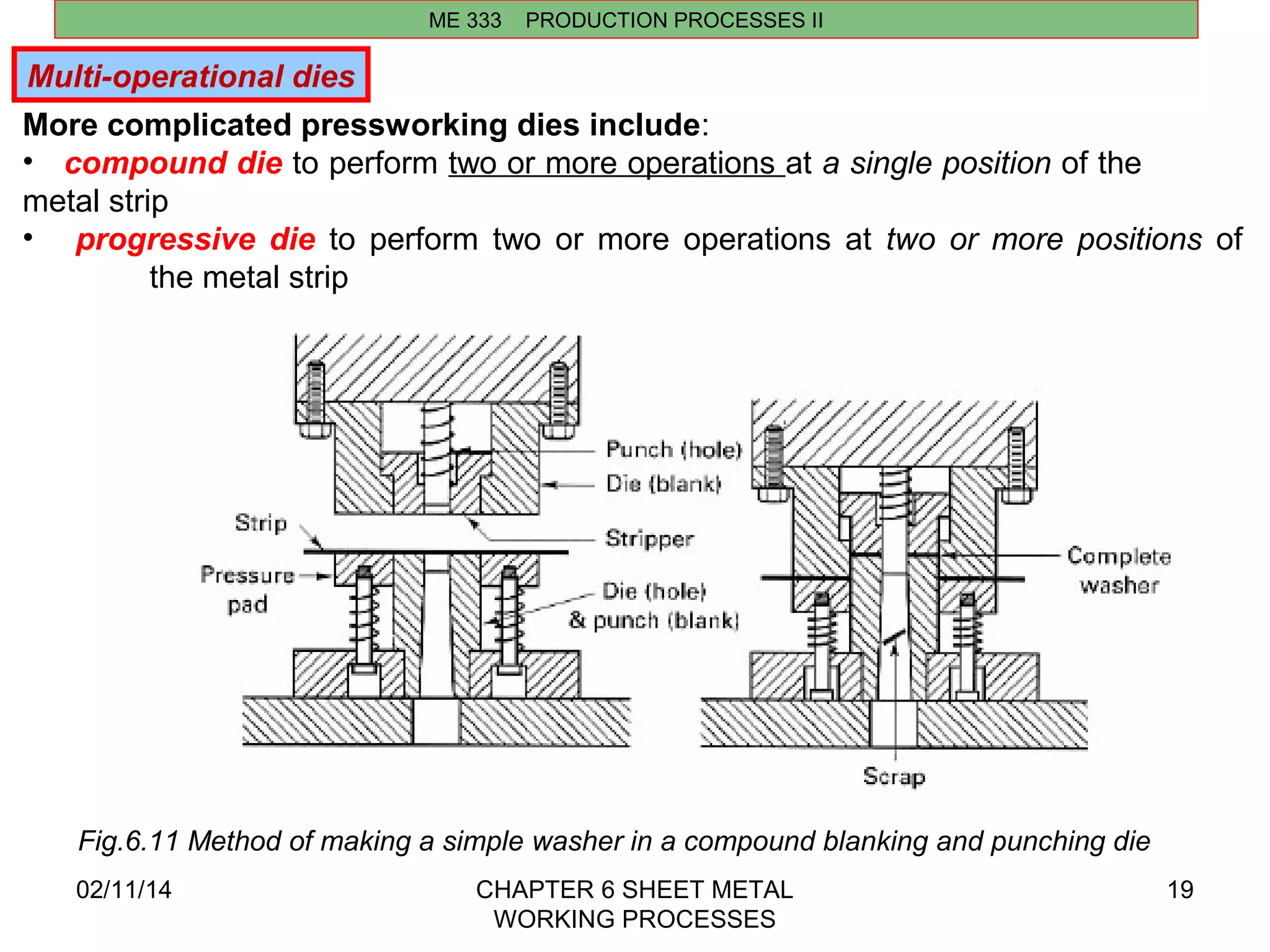

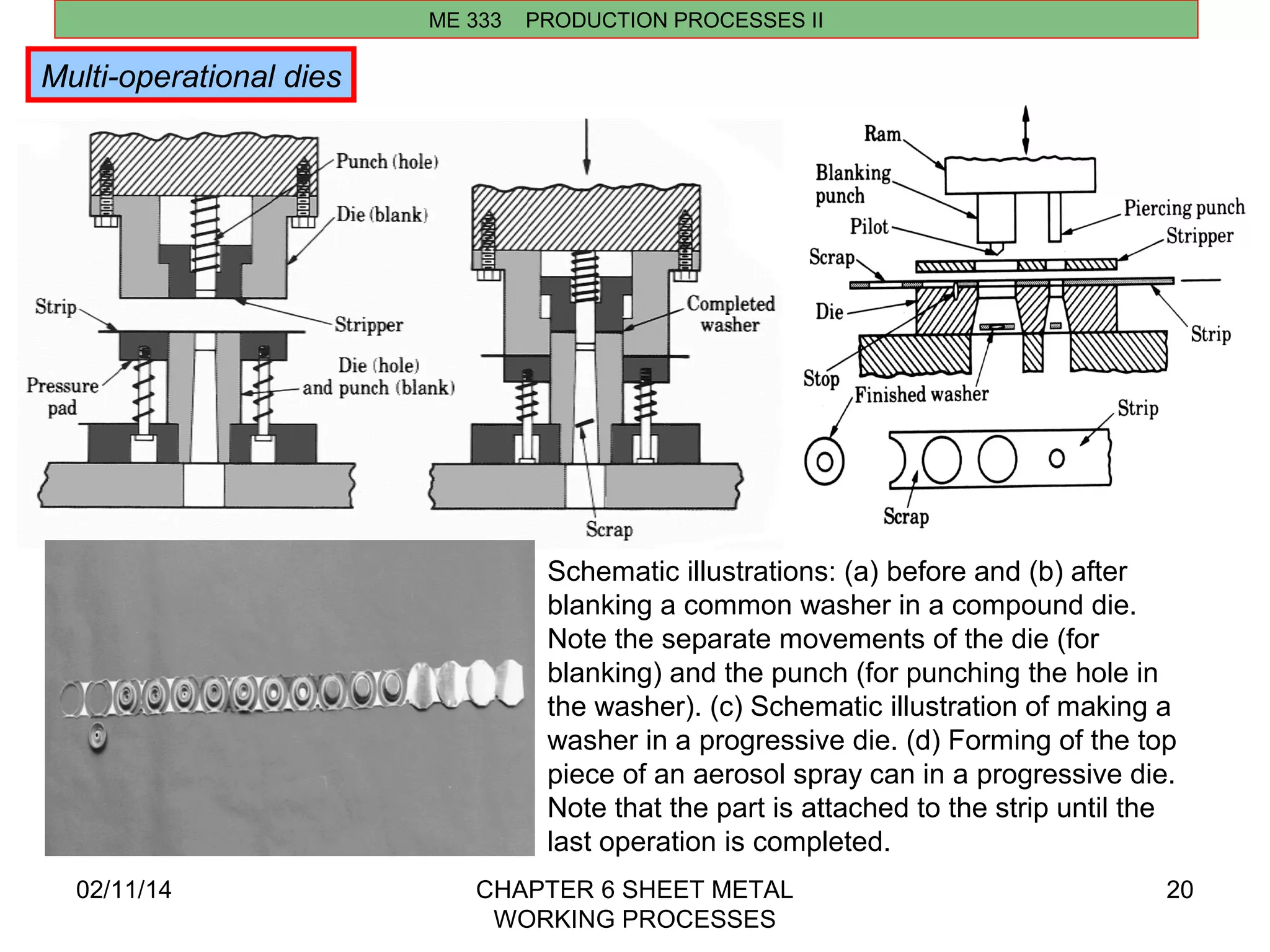

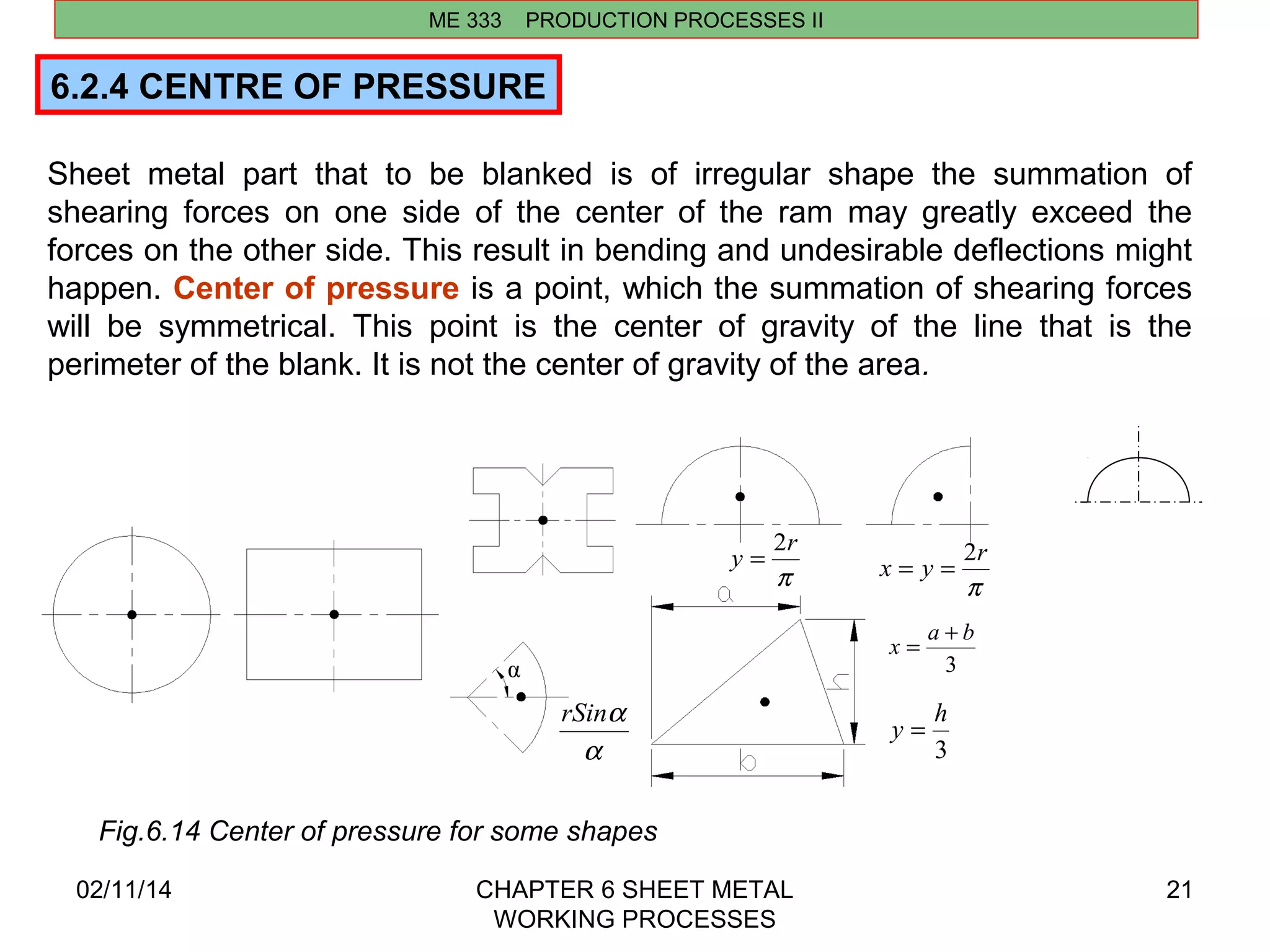

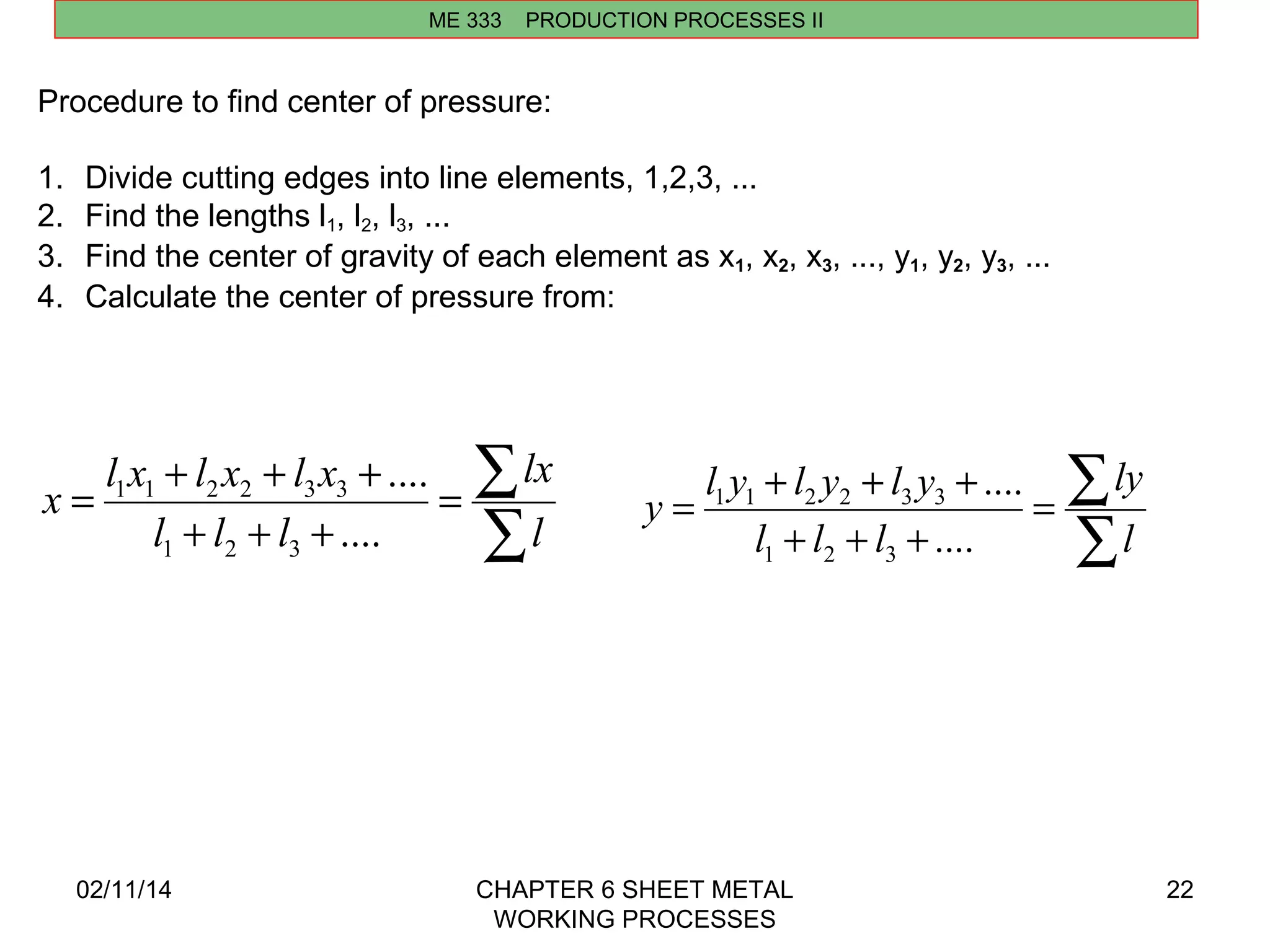

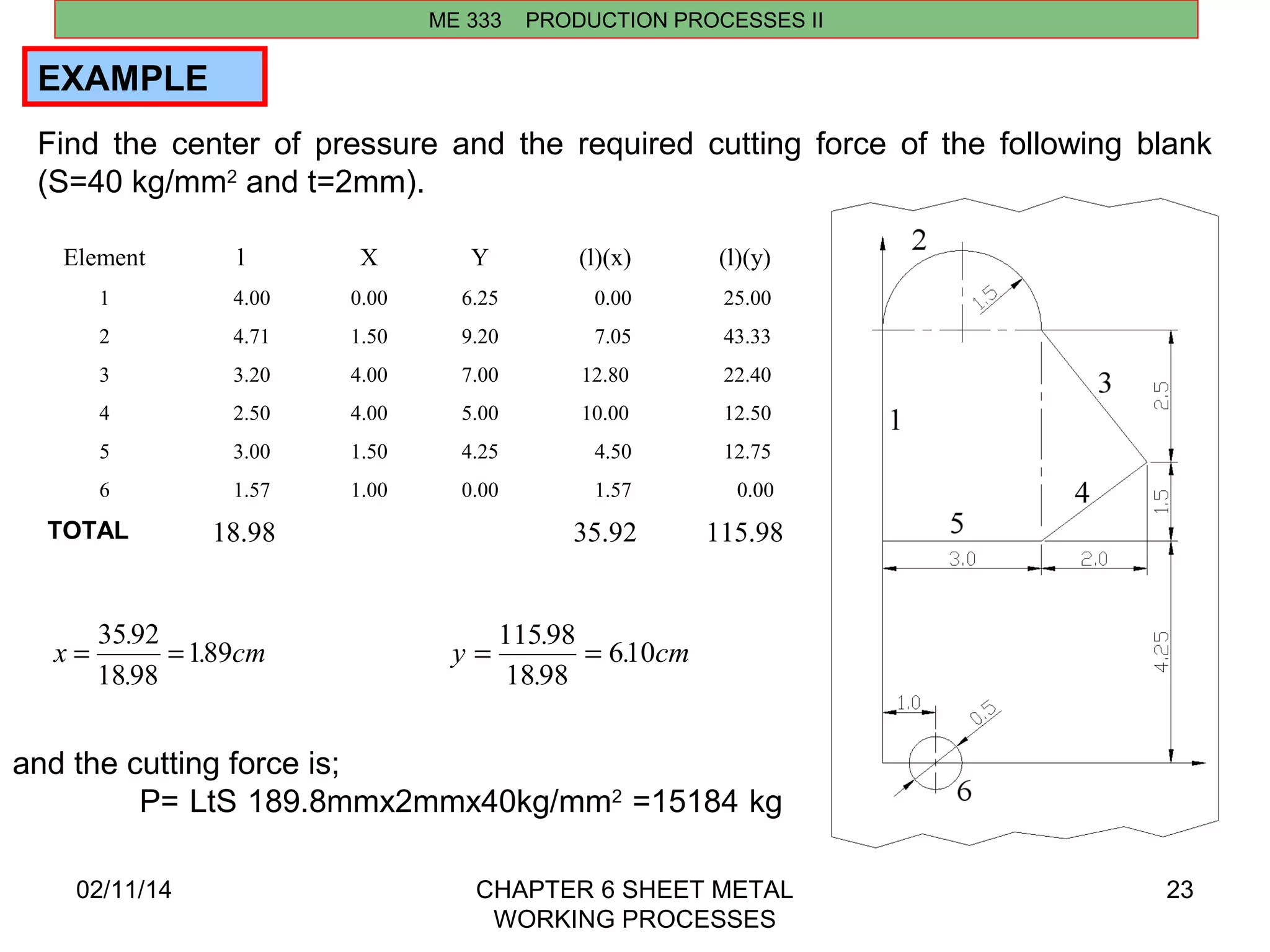

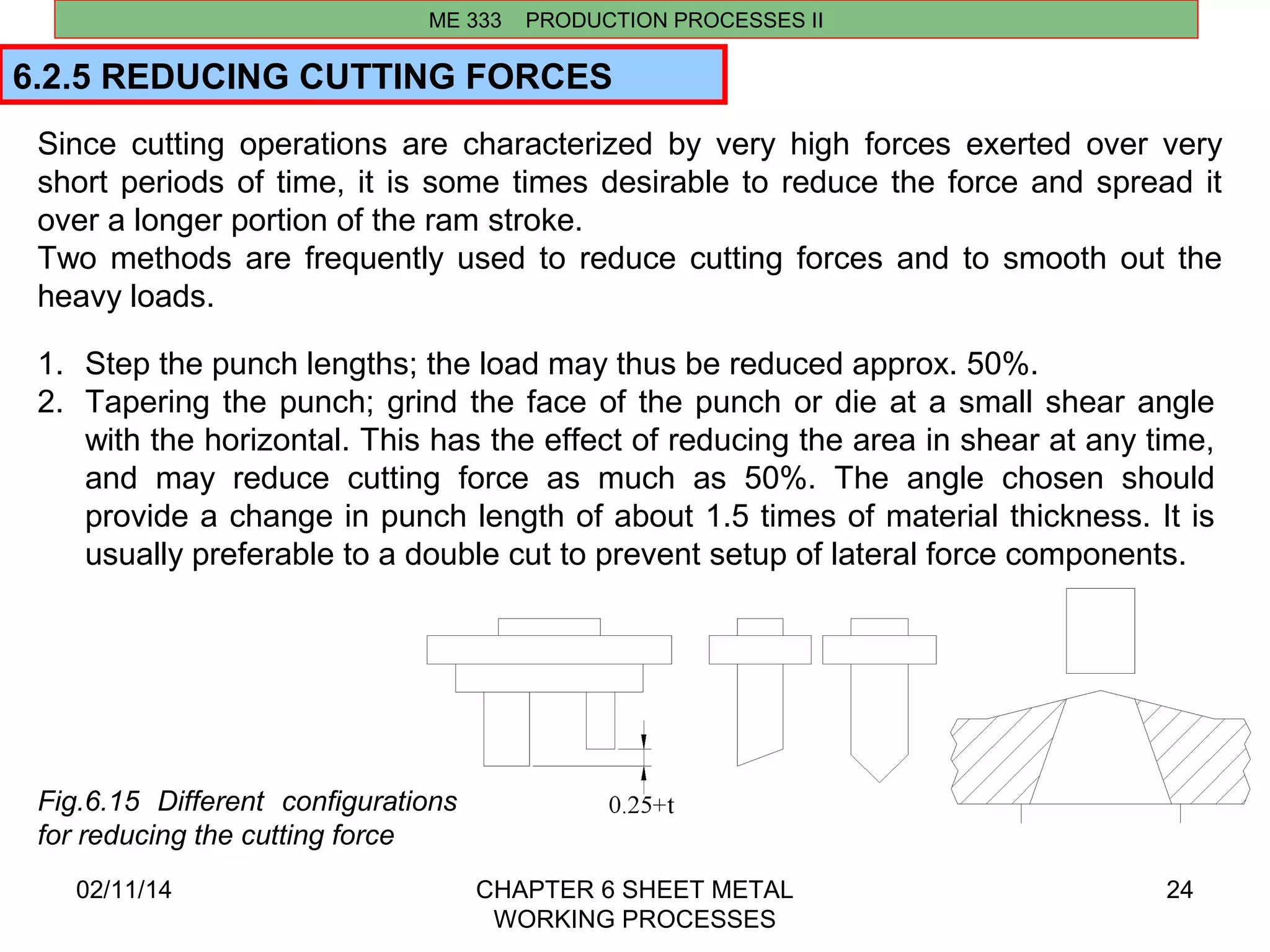

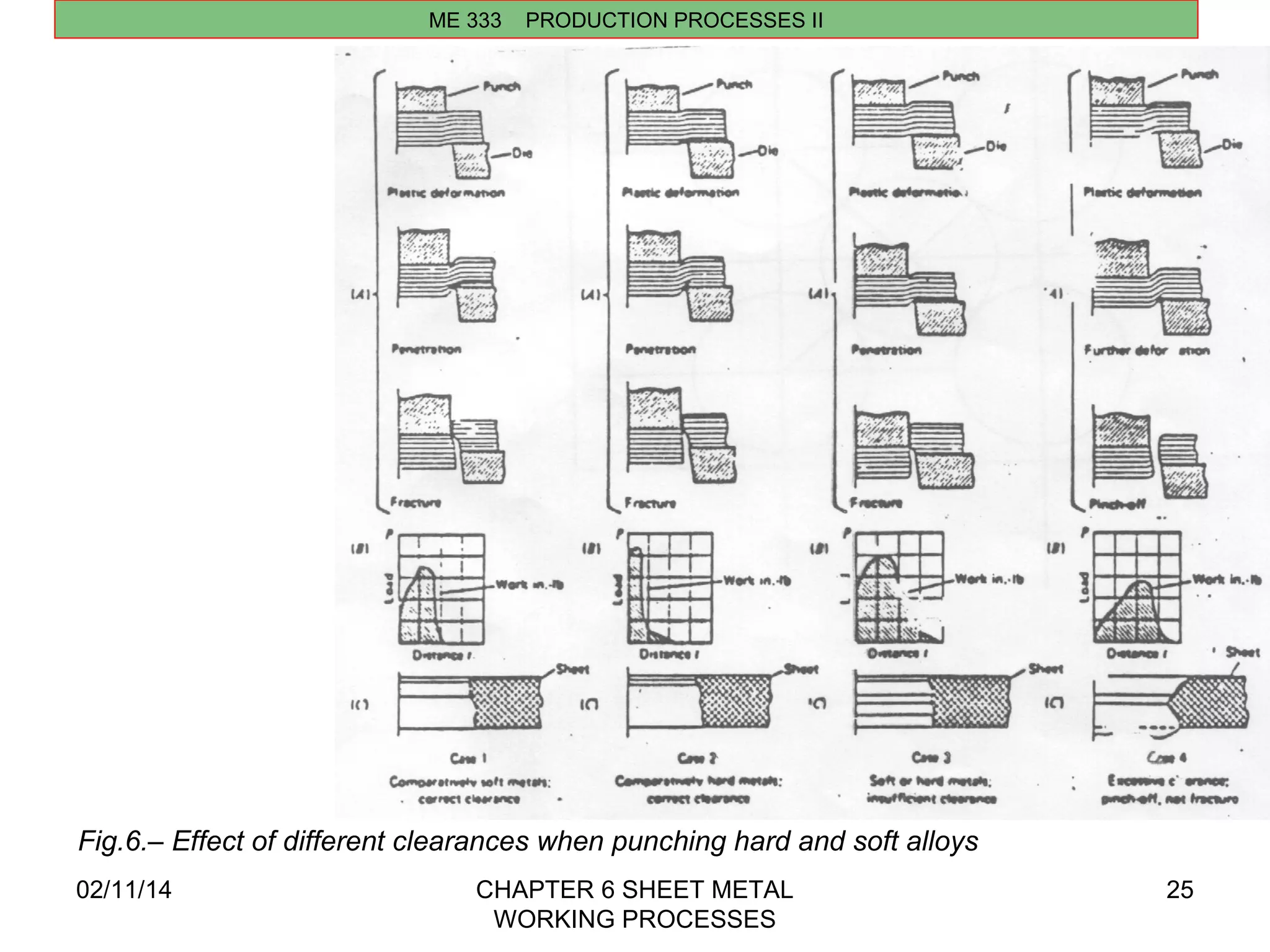

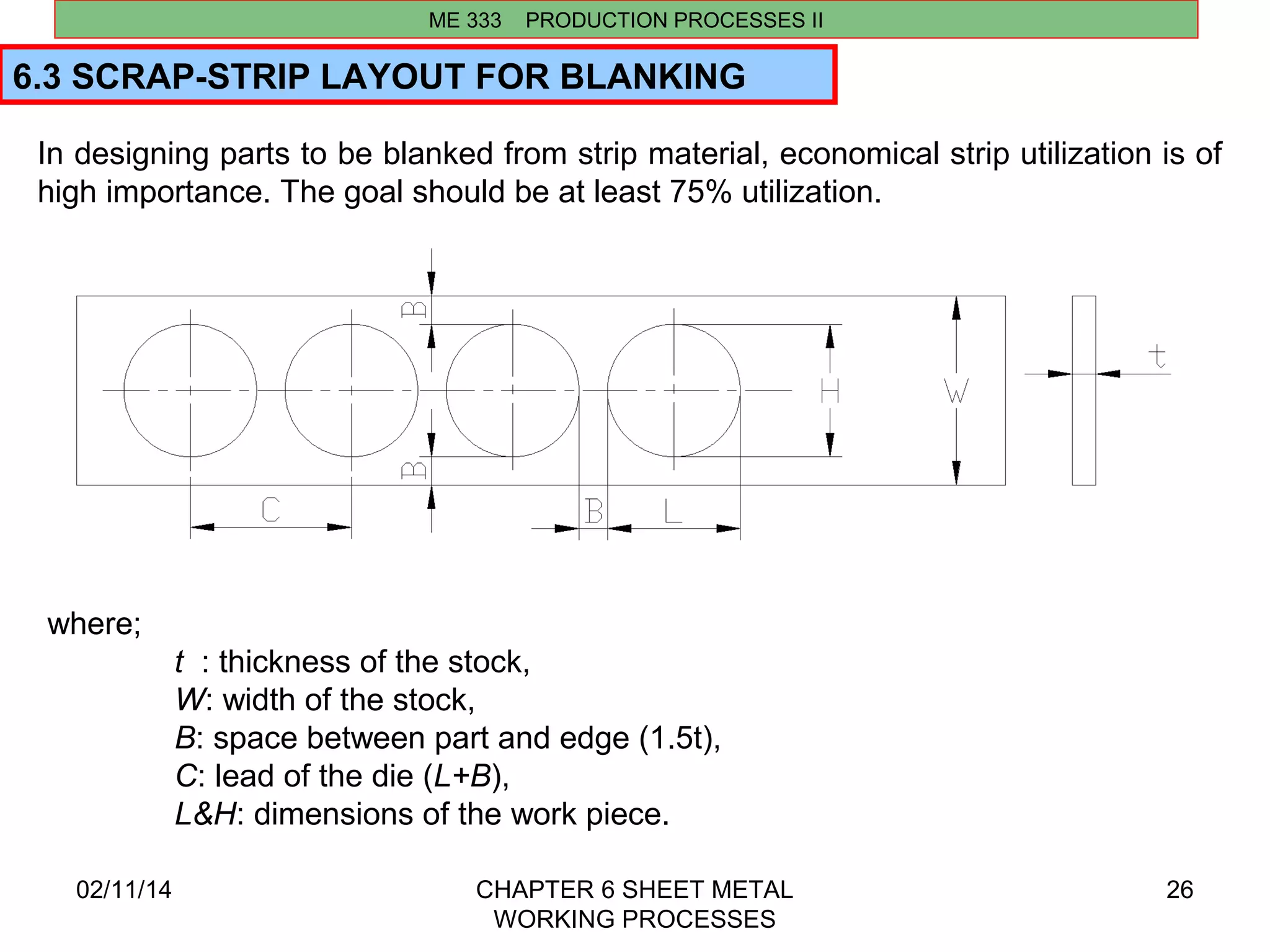

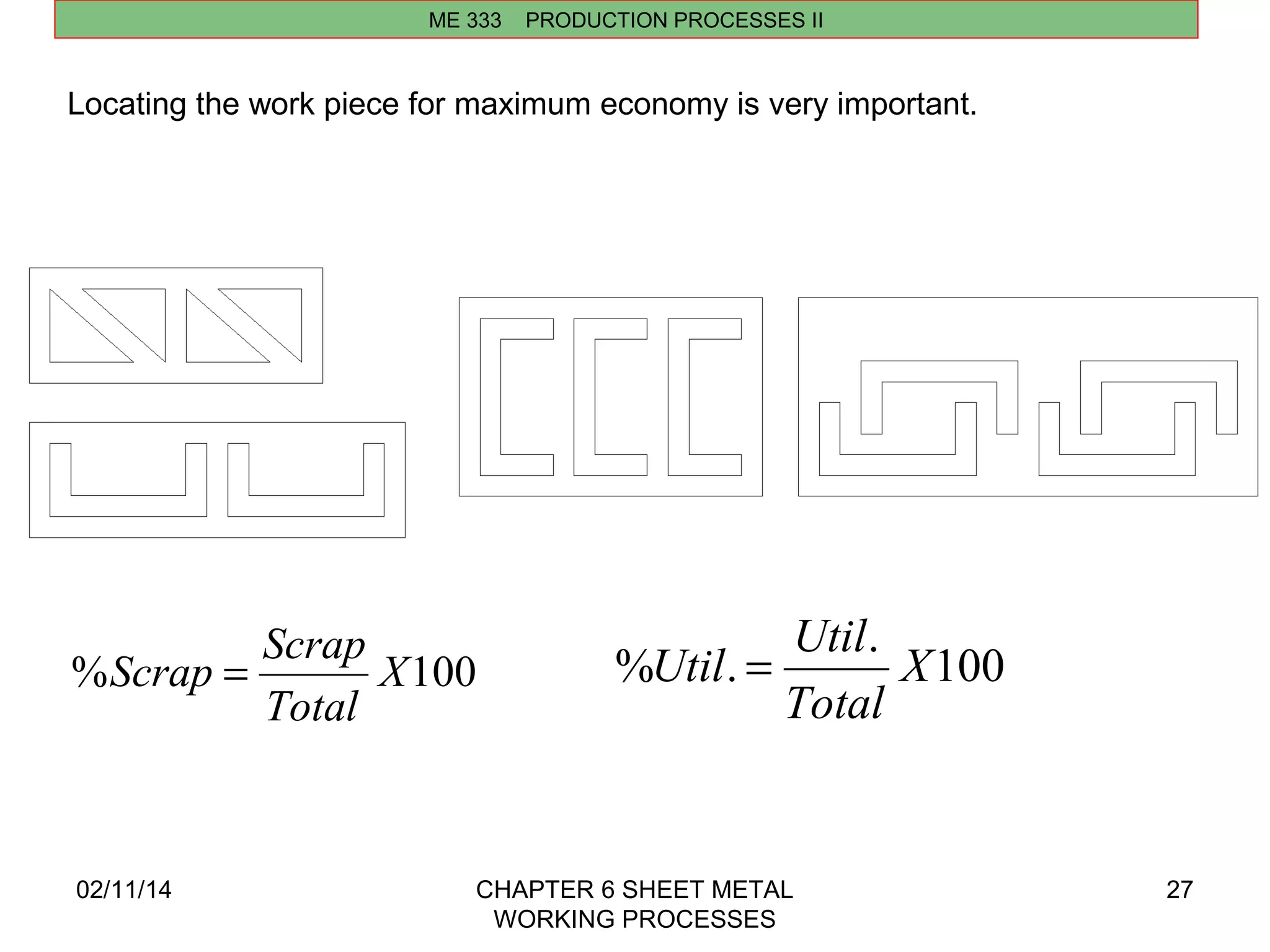

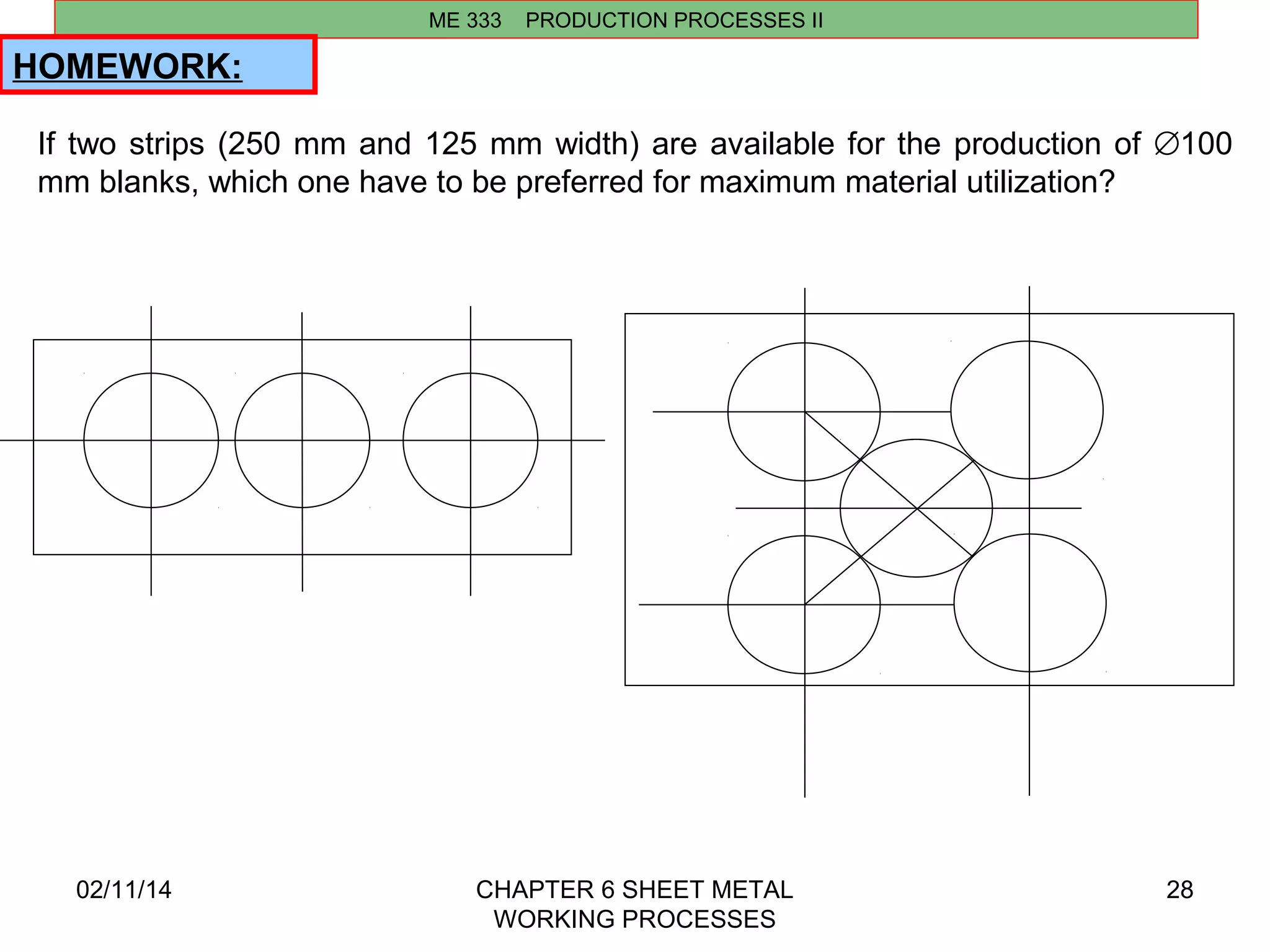

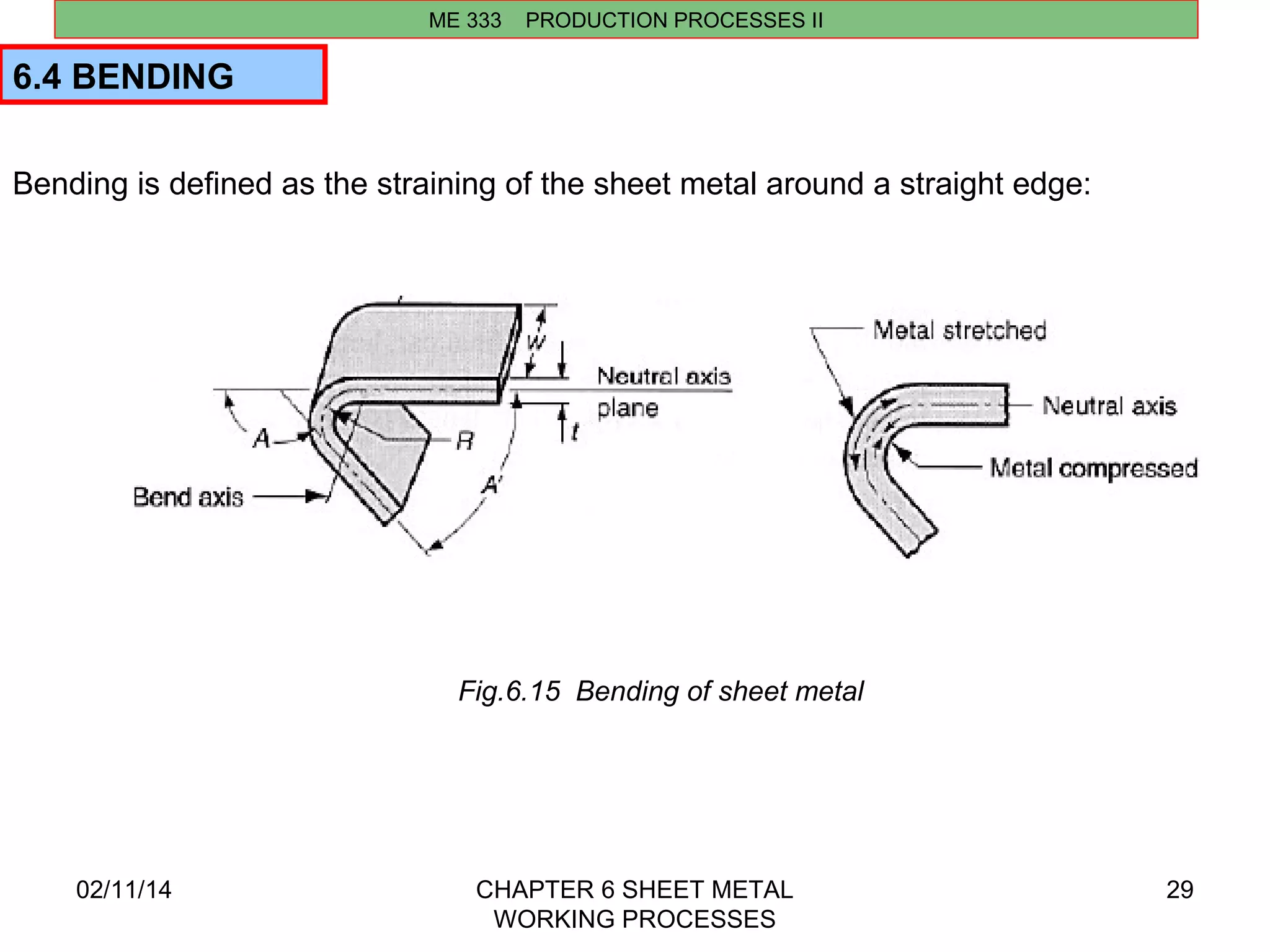

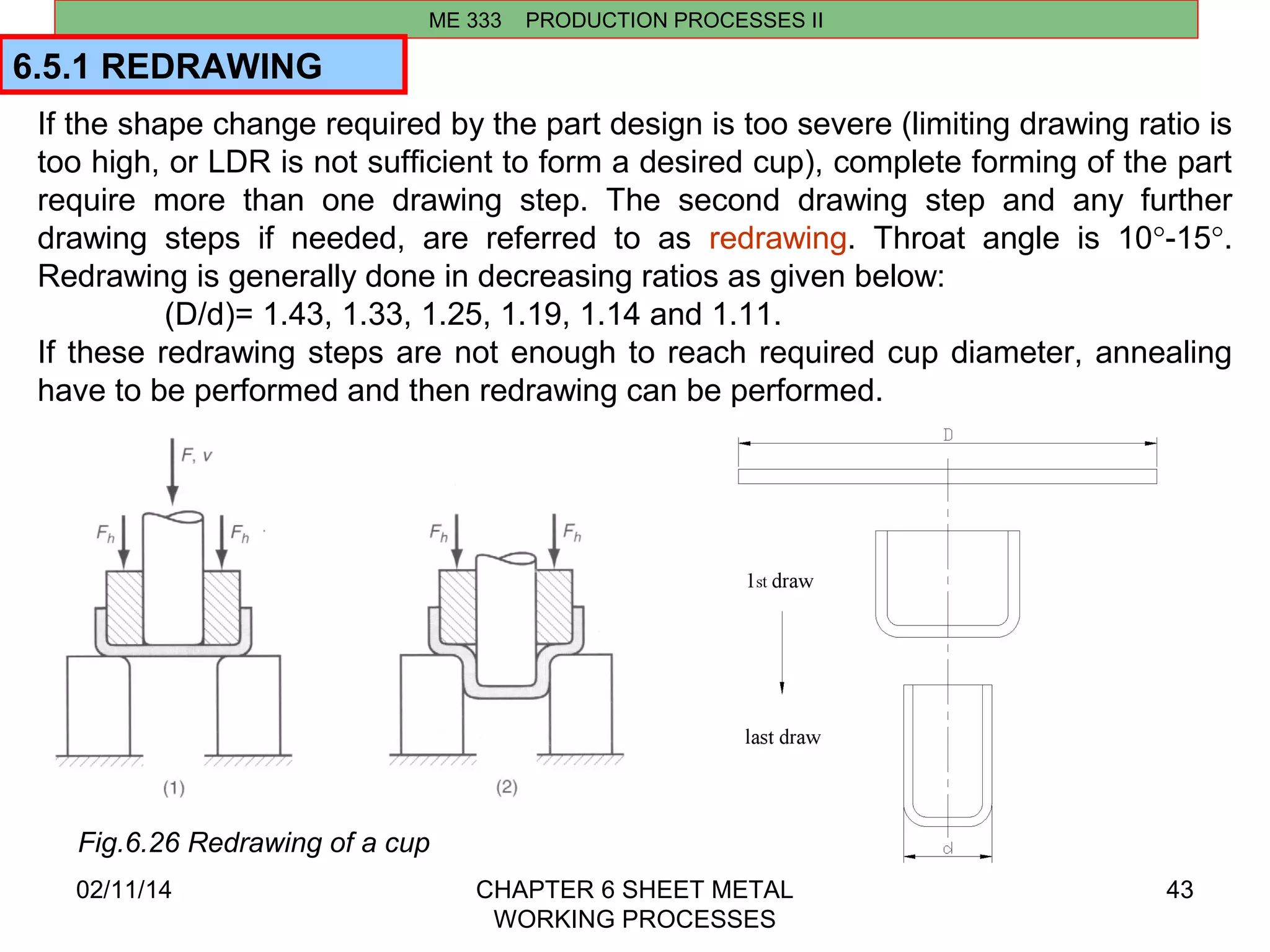

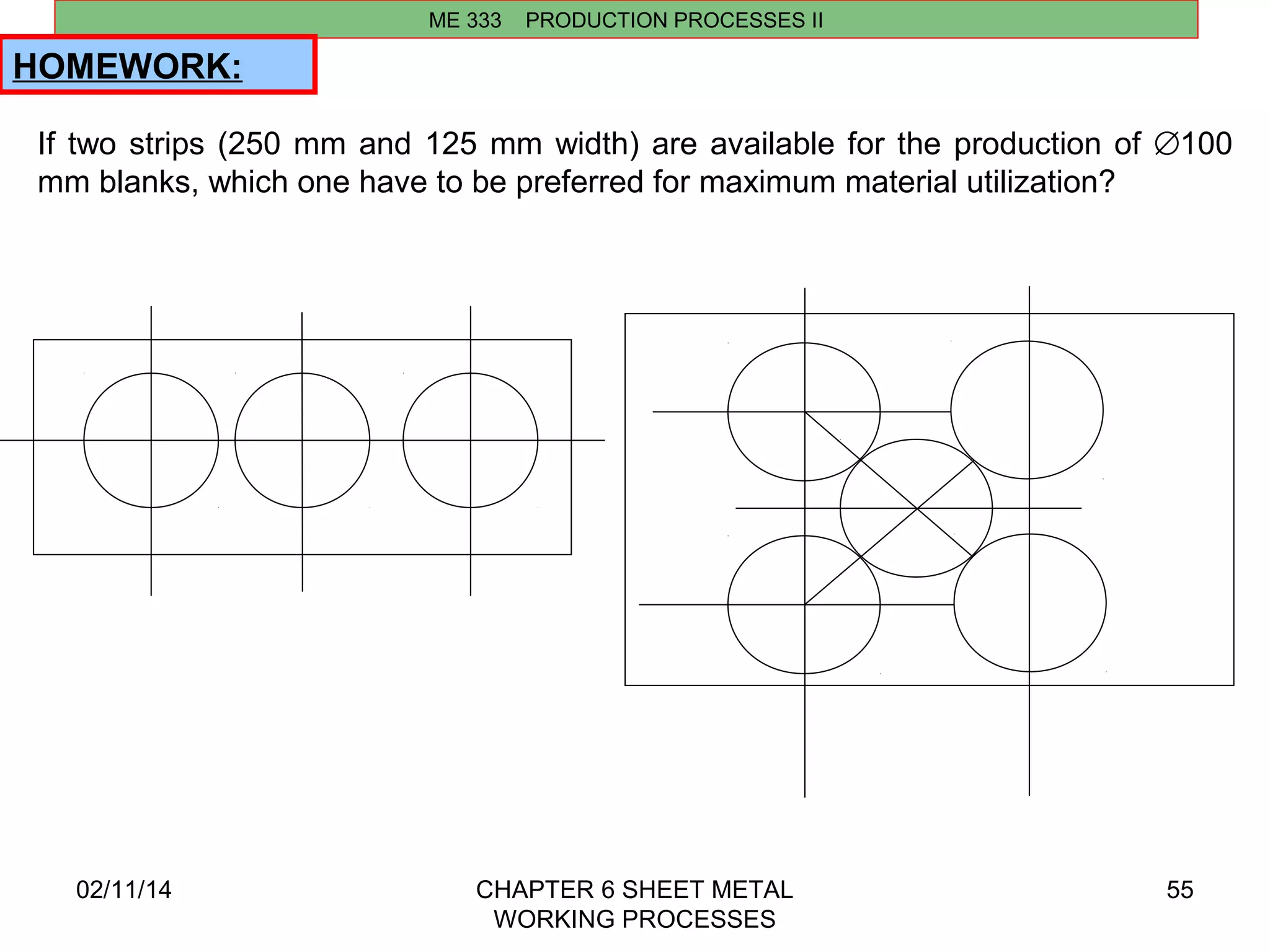

The document discusses sheet metal working processes and focuses on cutting operations like blanking and punching. It describes how sheet metal is cut using punch and die tools on presses. The cutting involves shearing the metal between sharp edges of the punch and die. Process parameters like clearance between the tools and stock thickness determine the cutting forces and quality of cut edges. Techniques like stepped punches and tapered edges can reduce high cutting forces. The document also covers determining the center of pressure for irregular shapes and optimizing scrap strip layout for blanking operations.