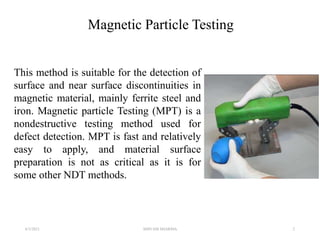

Magnetic particle testing (MPT) is a nondestructive testing method used to detect surface and near-surface discontinuities in ferromagnetic materials. It uses magnetic fields and iron particles to reveal cracks and defects.

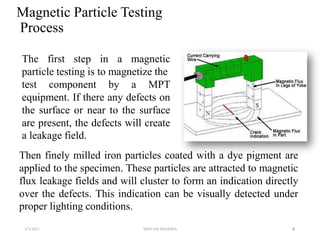

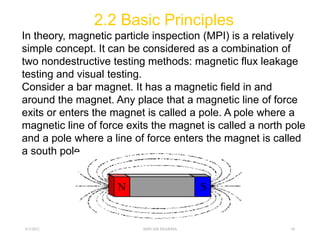

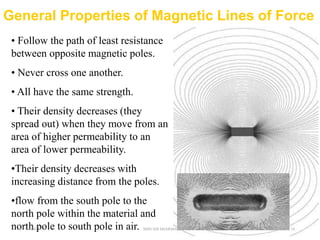

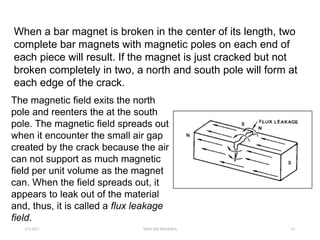

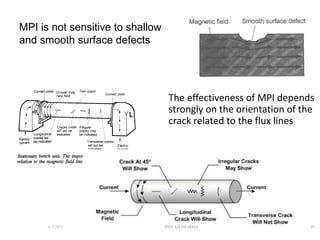

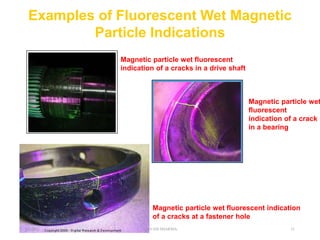

The basic principle is that a part is magnetized, causing magnetic field lines within the material. Any cracks or defects will cause some of the field lines to leak out and form additional magnetic poles at the defect. Iron particles are applied and attracted to these leakage fields, clustering at defects and making them visible.

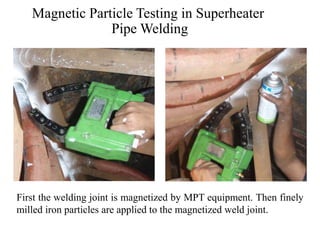

The MPT process involves cleaning and magnetizing the part, applying iron particles coated with dye, and visually inspecting under lighting to detect particle clusters