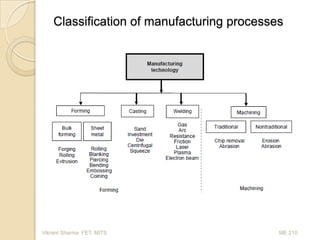

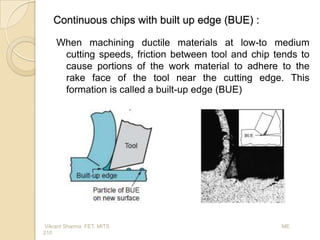

This document provides information about the ME 210 "Machine Tools and Machining" course taught by Vikrant Sharma at MITS University. The course objectives are to understand basic machining parameters, tool wear, machine tools, and methods for generating surfaces. Recommended textbooks are listed. Manufacturing is defined as the process of converting raw materials into products through value-adding processes. Machining involves gradually removing excess material from a workpiece in the form of chips using cutting tools. Machine tools are powered devices that facilitate machining processes. Chip formation and types of chips formed are also discussed.