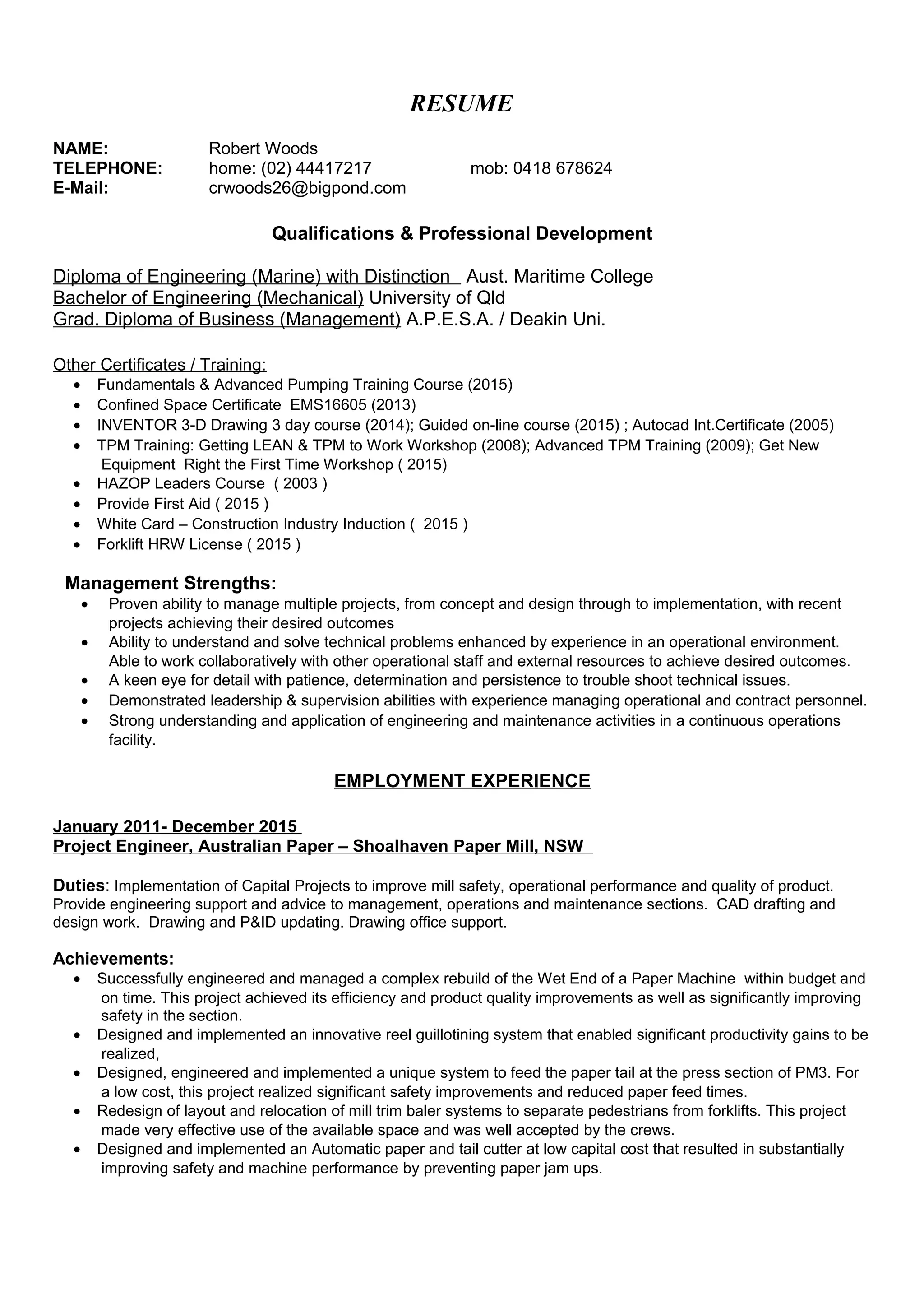

Robert Woods has over 25 years of experience in engineering roles within the paper industry. He holds multiple qualifications including a Diploma of Engineering, Bachelor of Engineering, and Graduate Diploma of Business. Woods has a history of successfully managing projects to improve safety, operations, and product quality. He is also experienced in leadership, technical troubleshooting, and maintaining continuous operations.