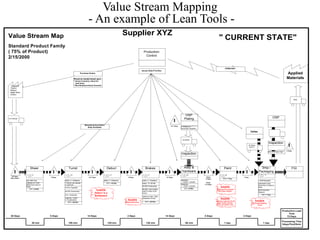

Value Stream Mapping Example

- 1. Value Stream Mapping - An example of Lean Tools - Value Stream Map Supplier XYZ " CURRENT STATE" Standard Product Family ( 75% of Product) Production Control 2/15/2000 FORECAST Issues Daily Priorities Purchase Orders Applied Placed as needed based upon: Materials * Gross inventory check for spot buys Suppliers * Bus-Route(contract) forecast - Trident - Reliant - Metal West - Others Daily OSP As Ordered Plating OSP I Manufacturing Orders 2 -5 Da ys 2 Primary & 2 Shop Schedule Secondary Suppliers Dallas 2X Month Inspection 3X Week M,W,F 1 I 2 D ays 95% First Pass Yield Inspection Sheer Turret Deburr Brakes Assy & Paint Ship / FGI I I I I I Hardware I I Packaging 1 3 11 7 6 6 7 30 Da ys Paint 5 Da ys 1 4+ D ay s 2 D a ys 14 D ays 1 Day Ra w Stoc k .5 Da ys C /T = 1 Da y Day Shift Only Shifts: 2 + Weekend Shifts: 2 + Weekend Shifts: 2 + Weekend Hardware: 1 Shift Operation 2 shifts / 3 people Cle an Capacity at Turret 1 Person can operate C/T = 12 0 M in Setup: 10-120 Min Dedicated to Bus determines when to 2 machines Assembly: 3 -5 D ays 1 shifts / 3 people Route from 5:30am to Sheer 40-50% Productivity Hi-Flex Capability KAIZEN Noon C /T = 3 0 Min 98-99% Yield (buffers C /T = 6 0 Min Im plem e nt Ph os pha te 40-50% Productivity KAIZEN used to make up for D ip C le an System No Productivity Measure Deburr is a scrap) C/O = 45-60 Min C /T = 1 D a y Bottleneck Uptime is High - PM's Capacity: 1 job/hr scheduled on W/E KAIZEN (~10 planks/job) KAIZEN In cre a se Ca pa city X3 a t KAIZEN C /T = 1 05 Min Se tup R e duc tions C /T = 12 0 Min paint booth, pow de r D e dica te d Staging pa in t, an d batch ove n Are a s Production Lead Time 30 Days 5 Days 14 Days 2 Days 14 Days 5 Days 2 Days 72 Days Processing Time 30 min 105 min 120 min 120 min 60 min 1 day 1 day 2days7hrs25min

- 2. Value Stream Mapping - An example of Lean Tools - Value Stream Map Supplier XYZ " FUTURE STATE" Standard Product Family ( 75% of Product) Production Control 2/25/2000 FORECAST Issues Daily Priorities Purchase Orders Daily Orders - EDI Pull Applied Orders are launched at Materials calculated re-order points for Raw Good Kanbans Daily Pull Orders Suppliers - Trident - Reliant - Metal West - Others Daily Manufacturing Orders OSP OSP Plating Based on Finished Goods Replenishment Triggers & I Spot Buy Orders 2-5 D ays 2 Primary & 2 Shop Schedule Secondary Suppliers As Ordered k oc St w Ra 3X / Week Dallas Inspection 3X Week M,W,F 1 Sho p ord ers ar e Lo ad Le ve led b as ed on Pr oduc t F am ily Sch edu lin g Ru le s 95% First Pass Yield Inspection Sheer Turret Deburr Brakes Assy & Paint Ship / Hardware Packaging ? ?? D ay s 1 Day Shift Only .5 Da ys 3 Shifts: 2 + Weekend .5 D ay s 11 Shifts: 2 + Weekend .5 D ay s 7 Shifts: 2 + Weekend .5 Da ys 6 Hardware: 2 shifts / 3 people .5 D a ys 6 C /T = 1 D ay .5 D ay s 7 1 Shift Operation Capacity at Turret 1 Person can operate C /T = 1 20 Min Setup: 10-120 Min Dedicated to Bus 30 D a ys Assembly: determines when to 2 machines Route from 5:30am to Finished Goods ? Ra w Stoc k 40-50% Productivity 1 shifts / 3 people Sheer Hi-Flex Capability C /T = 6 0 M in Noon Inventory C /T = 3 0 Min 98-99% Yield (buffers No Productivity 40-50% Productivity used to make up for Orders are launched at Measure scrap) Inventory Sizing of Dallas provided gas C /T = 1 Da y calculated re-order points for C/O = 45-60 Min Uptime is High - PM's panel enclosures & gas panel piece Finished Good Kanbans Capacity: 1 job/hr scheduled on W/E parts (gas panel parts & spares ) (~10 planks/job) C /T = 1 05 Min C/T = 12 0 M in Production Lead Time 30 Days .5 Days .5 Days .5 Days .5 Days .5 Days .5 Days 33 Days Processing Time 30 min 105 min 120 min 120 min 60 min 1 day 1 day 2days7hrs25min