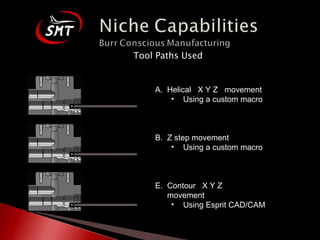

Southern Manufacturing Technologies is an aerospace and defense manufacturing company located in Tampa, FL with 90 employees. They have capabilities for machining metals like aluminum, titanium, and stainless steel. They also have certifications like AS9100 and ISO9001. The document provides details on their manufacturing processes, customers, capabilities, and awards.