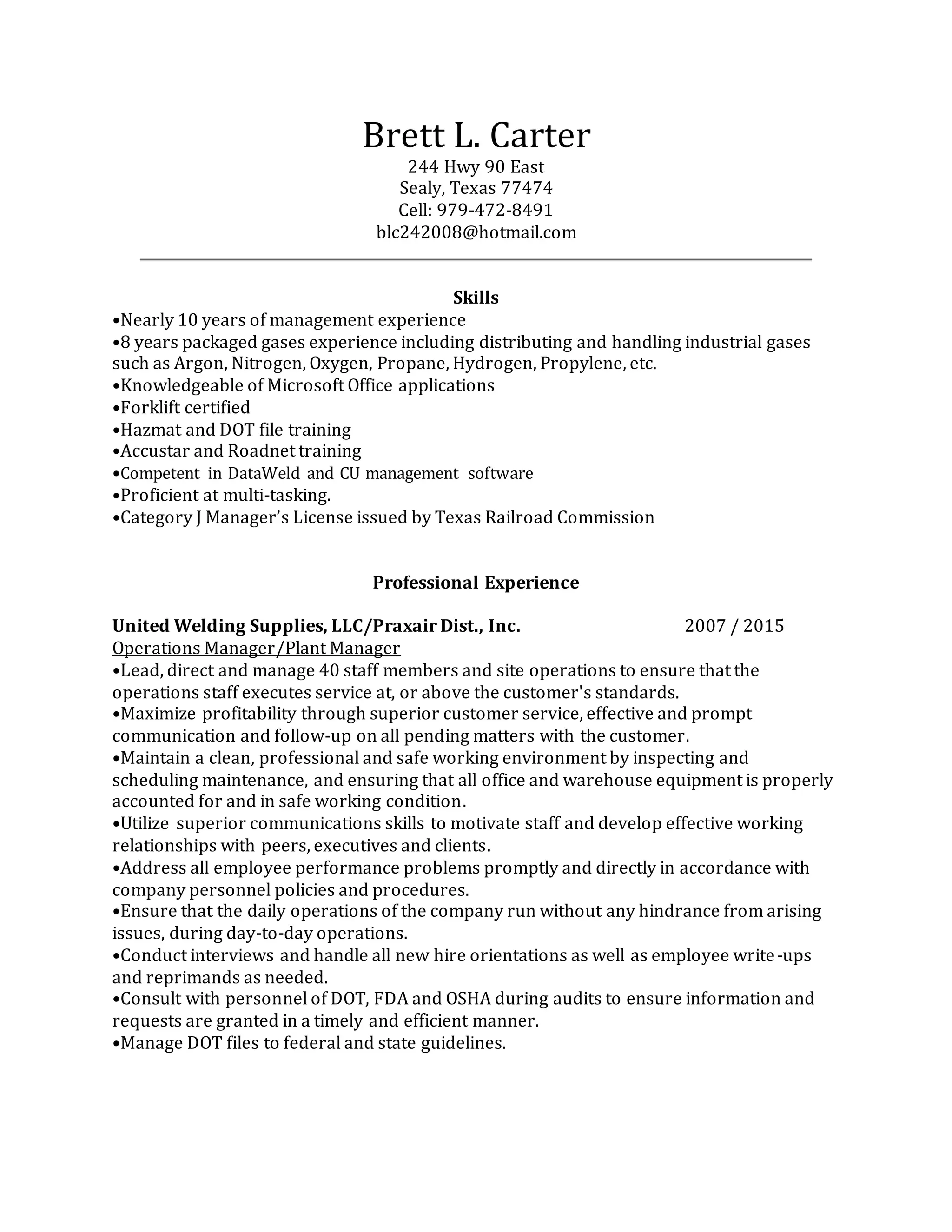

This document is a resume for Brett L. Carter that summarizes his professional experience and qualifications. He has nearly 10 years of management experience, including 8 years working with industrial gases. His most recent role was as Operations Manager/Plant Manager for United Welding Supplies, LLC/Praxair Dist., Inc. from 2007 to 2015, where he led a staff of 40 and ensured operations met customer standards. Prior to that, he worked as a CNC Machinist and Mold Injection Press Operator.