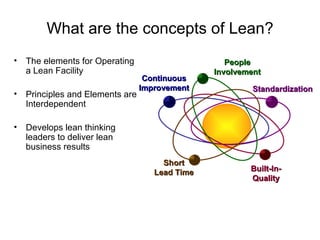

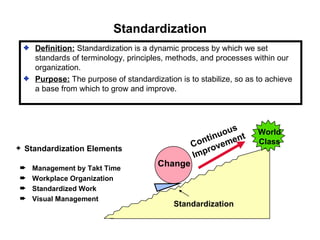

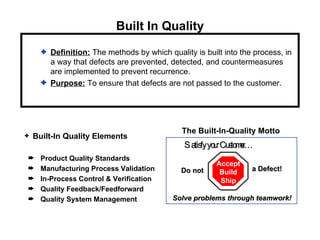

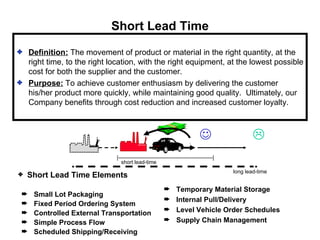

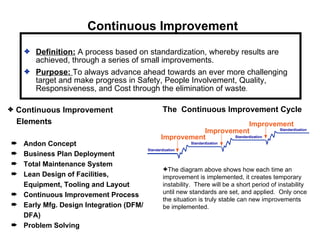

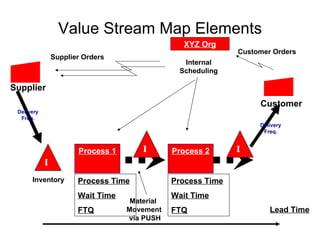

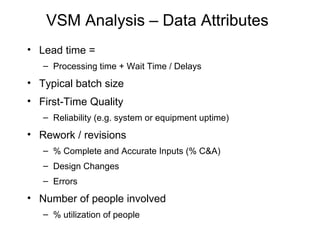

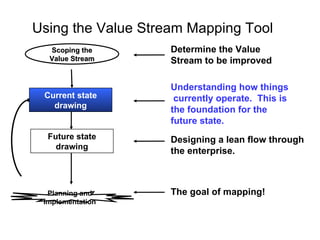

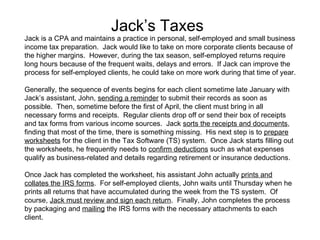

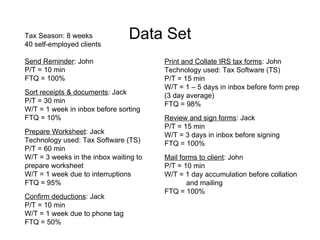

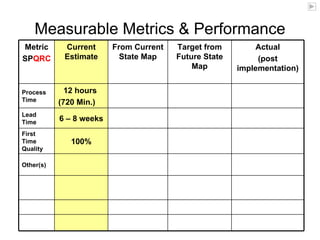

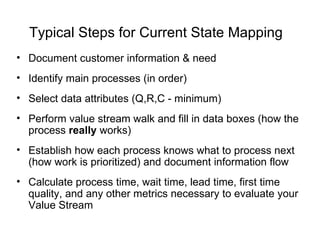

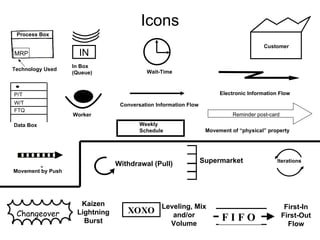

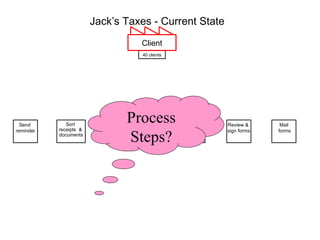

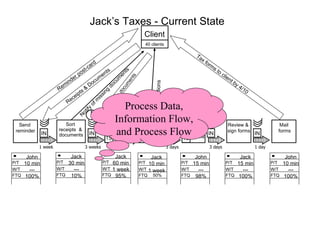

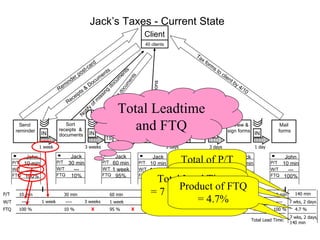

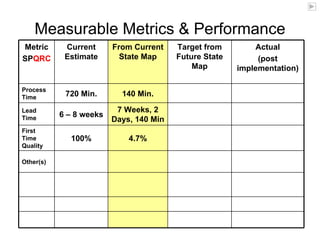

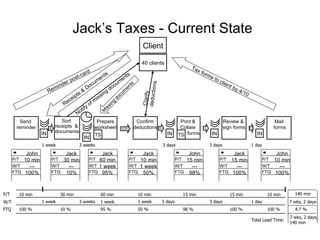

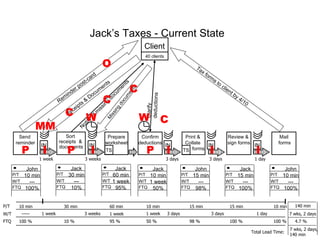

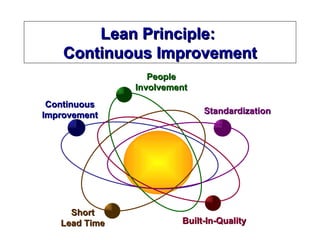

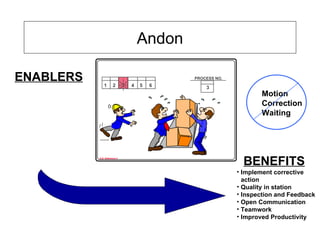

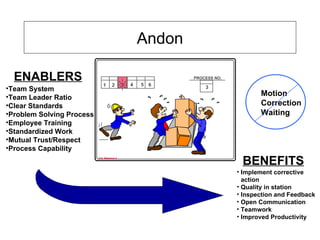

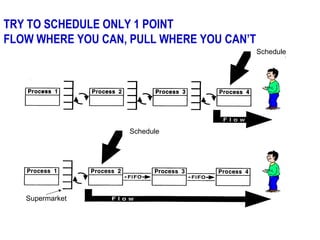

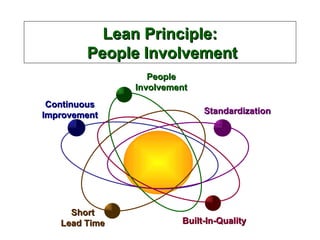

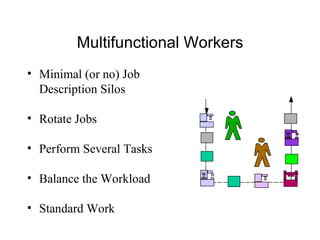

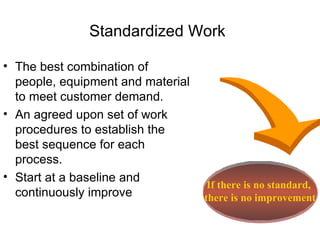

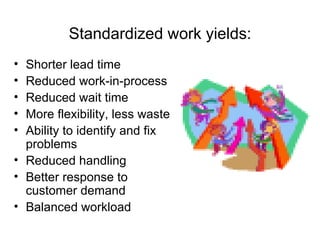

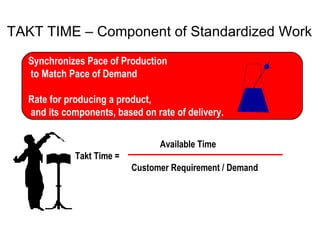

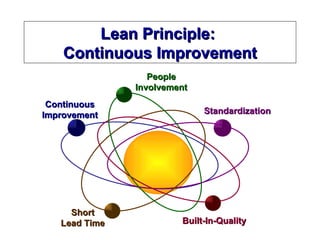

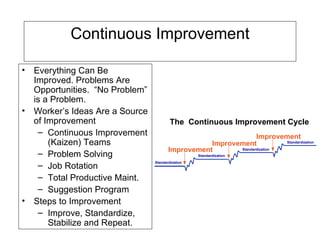

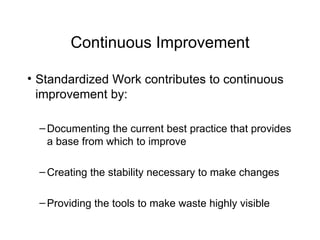

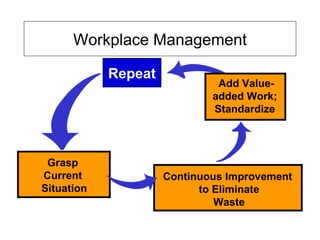

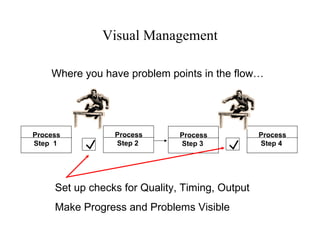

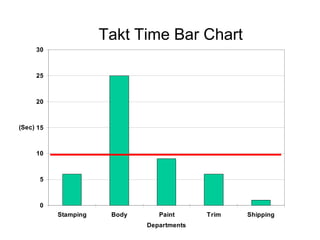

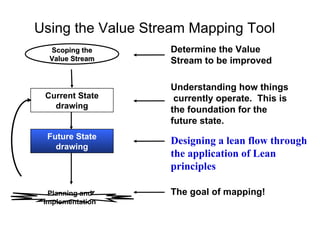

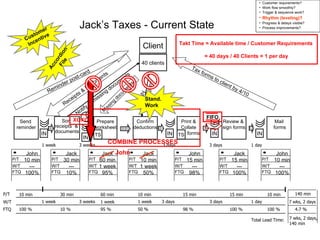

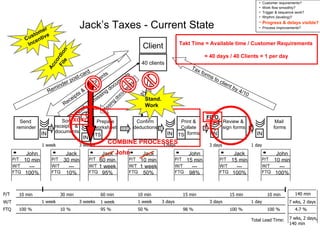

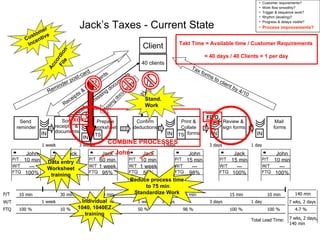

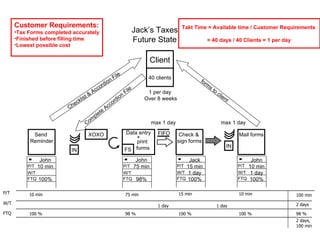

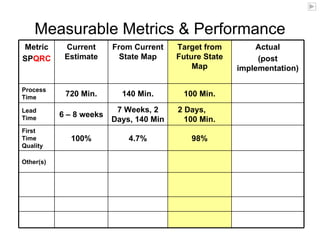

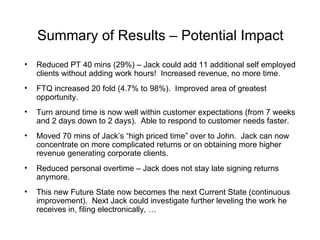

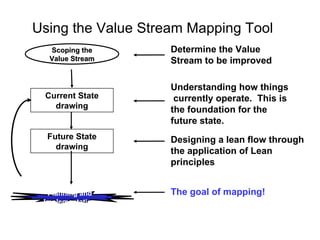

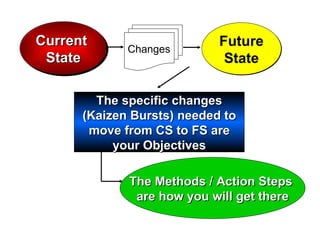

The document outlines the objectives and fundamentals of value stream mapping (VSM) as a key tool for implementing lean principles in various operational areas. It discusses the significance of standardization, built-in quality, short lead time, and continuous improvement, while highlighting their interdependent nature and practical applications. An illustrative case study of a CPA's tax preparation process exemplifies how VSM can identify and reduce waste, improve efficiency, and enhance customer satisfaction.