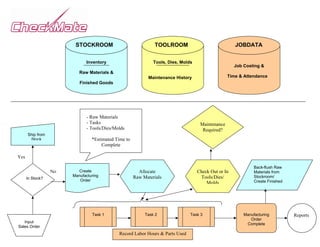

This document outlines the key steps and components in a manufacturing process from inventory and raw materials to job costing and completion. It shows the flow from a sales order triggering tasks that may require tools, dies or molds from the toolroom, to allocating raw materials from stock and recording labor and parts used to fulfill the order. Key stages include checking tool availability, estimating task times, creating work orders if items are not in stock, and back-flushing or recording completion to generate reports.