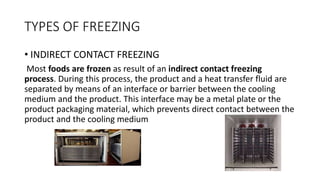

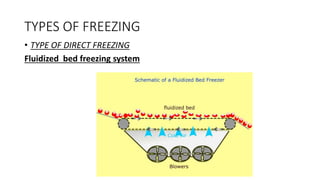

The document discusses various aspects of food freezing processes and systems, including the definitions of freezing and freezing time, Planck's equation, and Pham's modification for better estimation of freezing times. It explains different types of freezing systems, such as indirect and direct freezing, along with their advantages and application methods, including immersion and cryogenic freezing. It emphasizes the importance of accurately predicting freezing times to maintain food quality and processing efficiency.