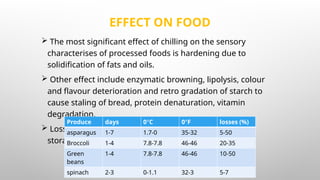

The document discusses the application of low-temperature preservation techniques for food, primarily refrigeration and super chilling, which help to slow down microbial growth and biochemical reactions. It outlines the principles of mechanical refrigerators and cryogenic systems, detailing their components and functioning. Additionally, it addresses the effects of chilling on food quality, potential undesirable consequences of improper chilling, and the benefits of super chilling for extending shelf life and maintaining food quality.