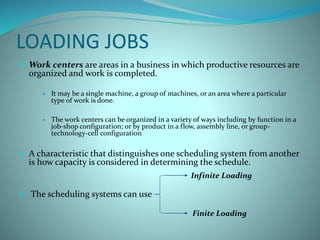

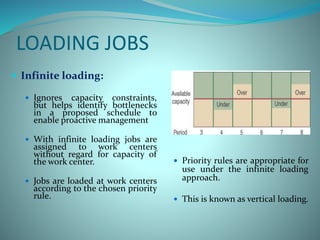

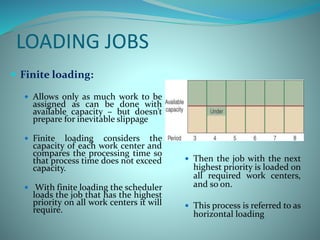

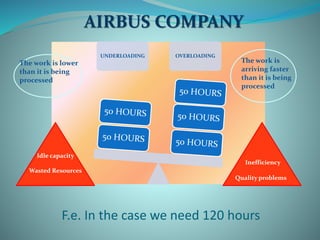

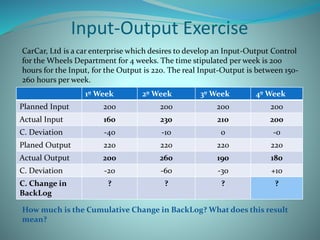

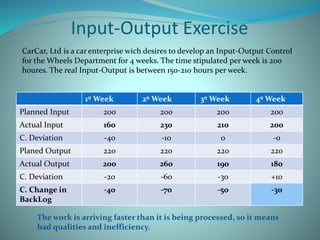

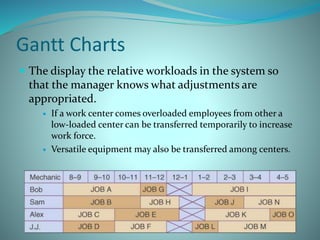

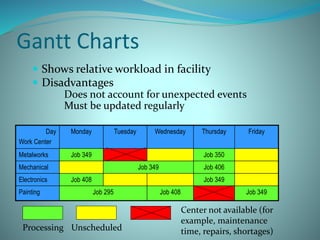

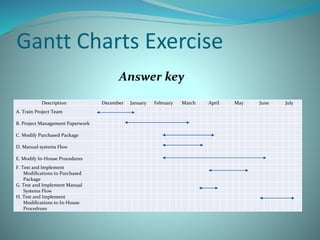

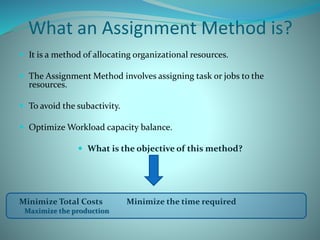

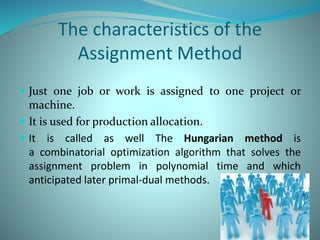

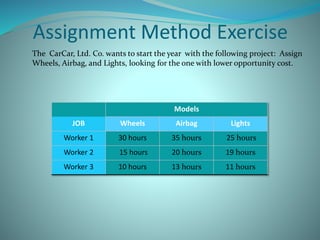

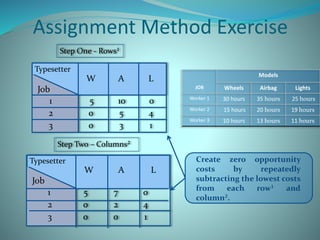

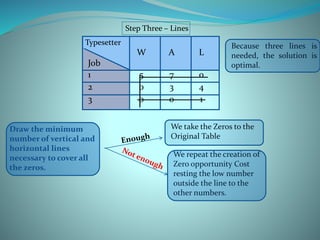

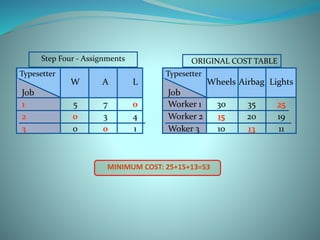

This document discusses loading jobs and scheduling work centers. It defines loading as assigning jobs to work centers to minimize costs and completion times. Infinite loading ignores capacity constraints while finite loading only assigns as much work as can be completed with available capacity. The document also discusses characteristics of high-volume and low-volume operations, input-output processes, Gantt charts, and assignment methods.