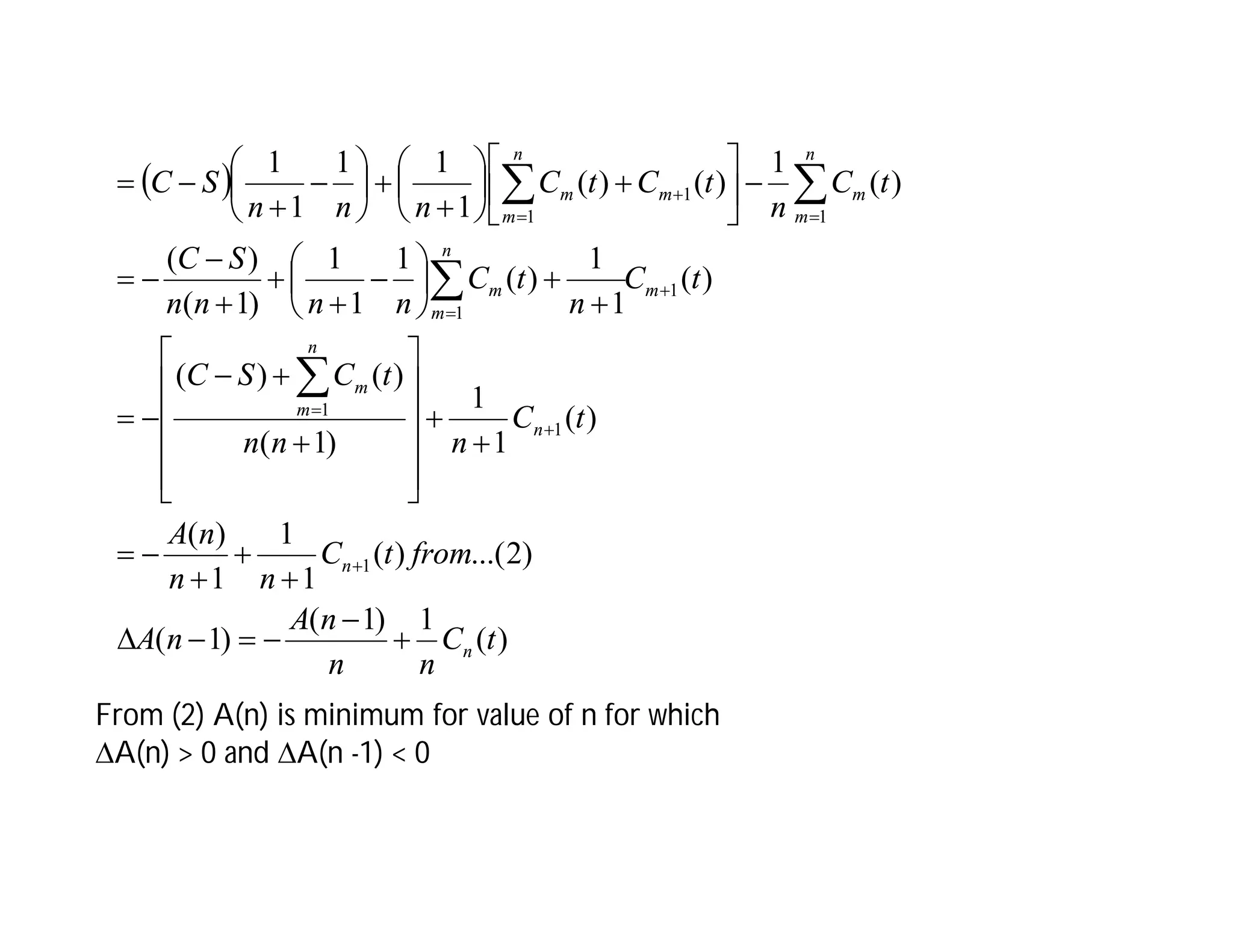

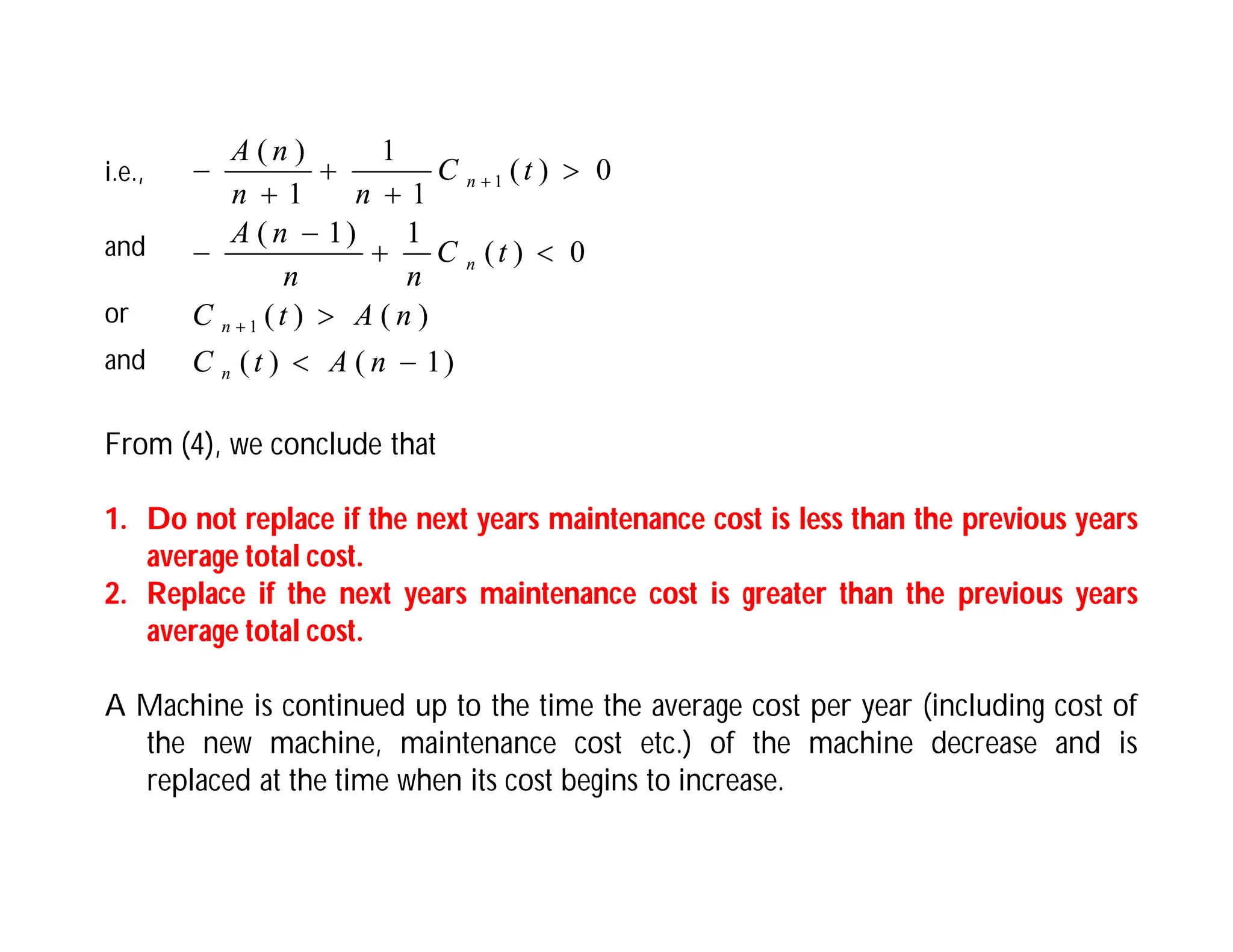

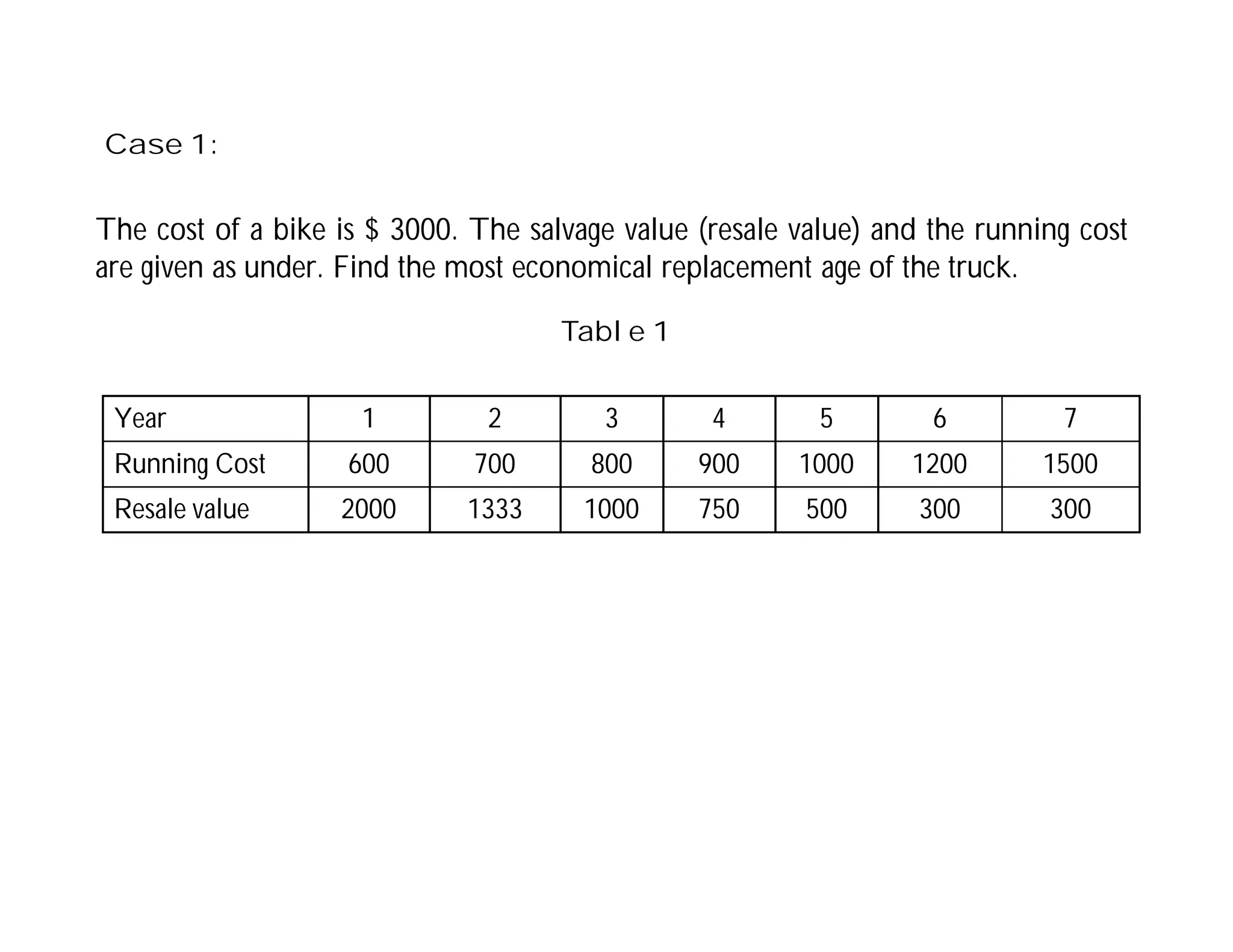

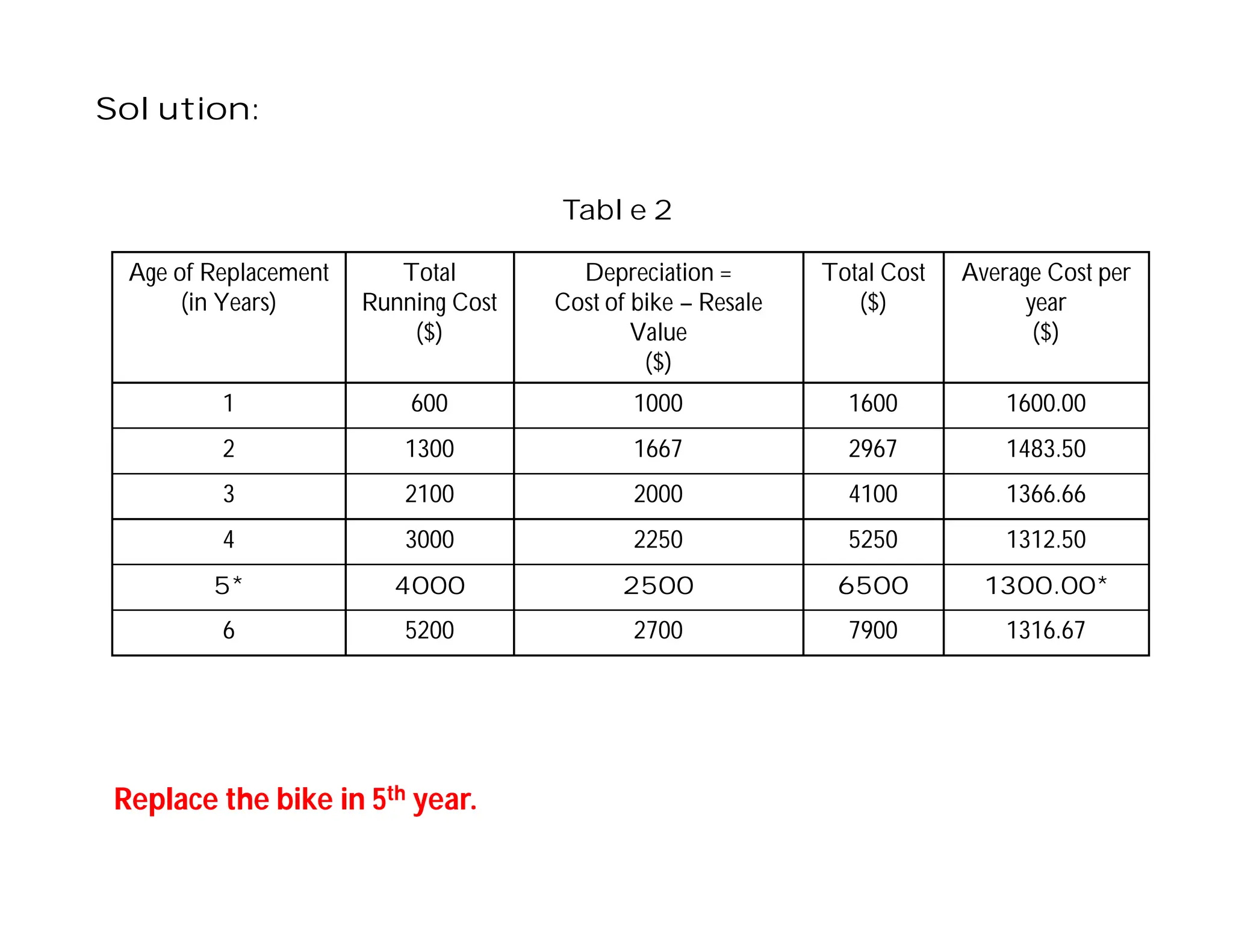

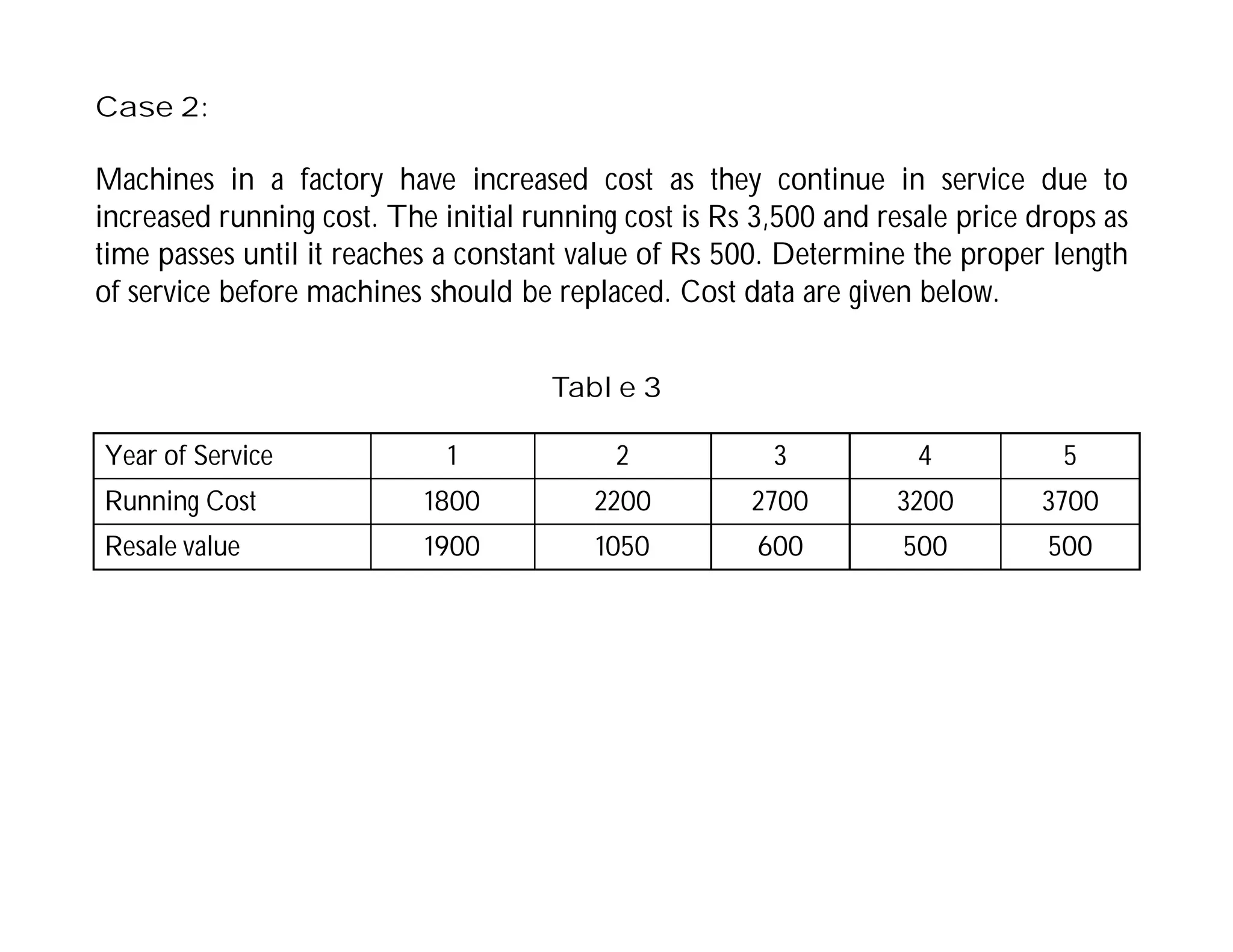

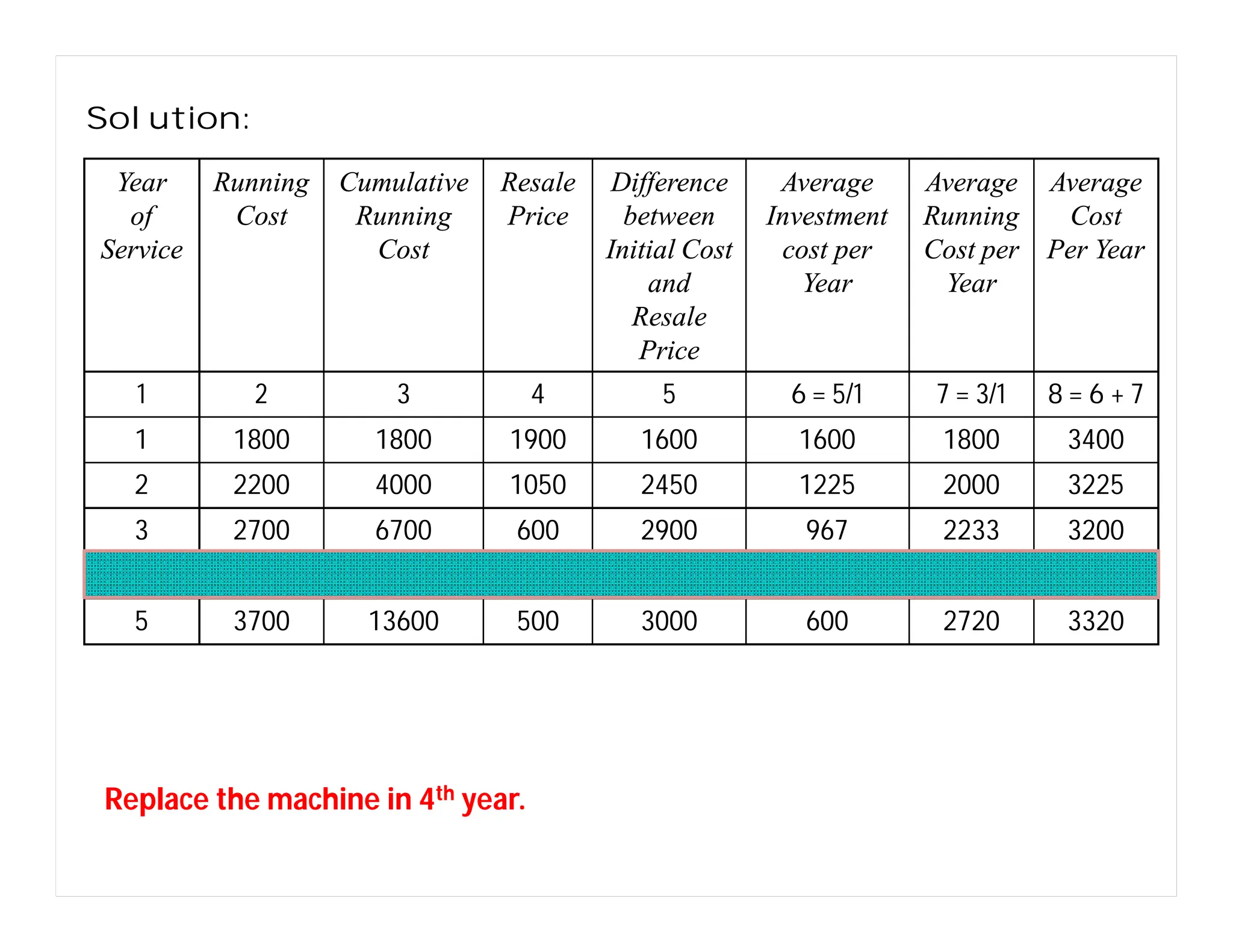

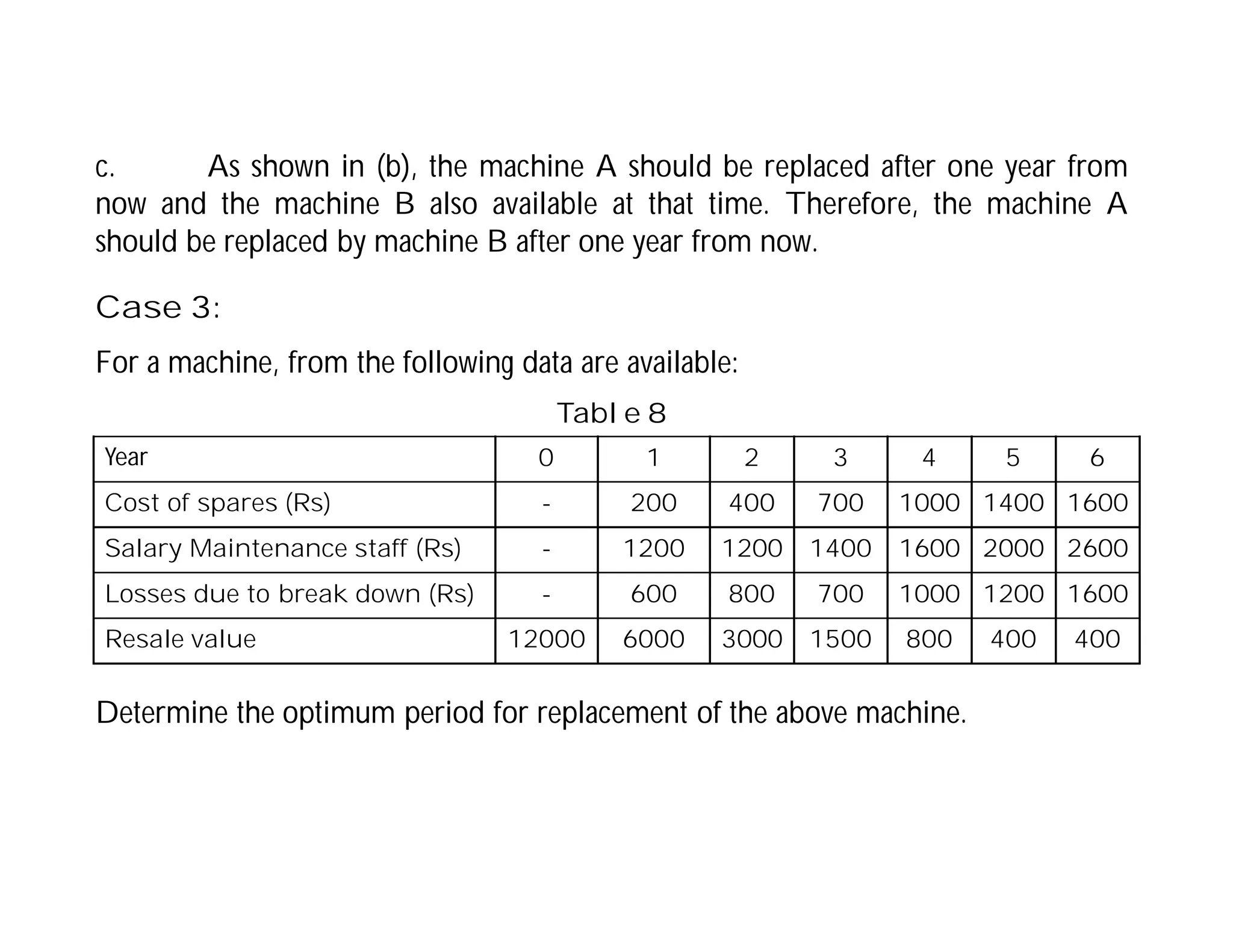

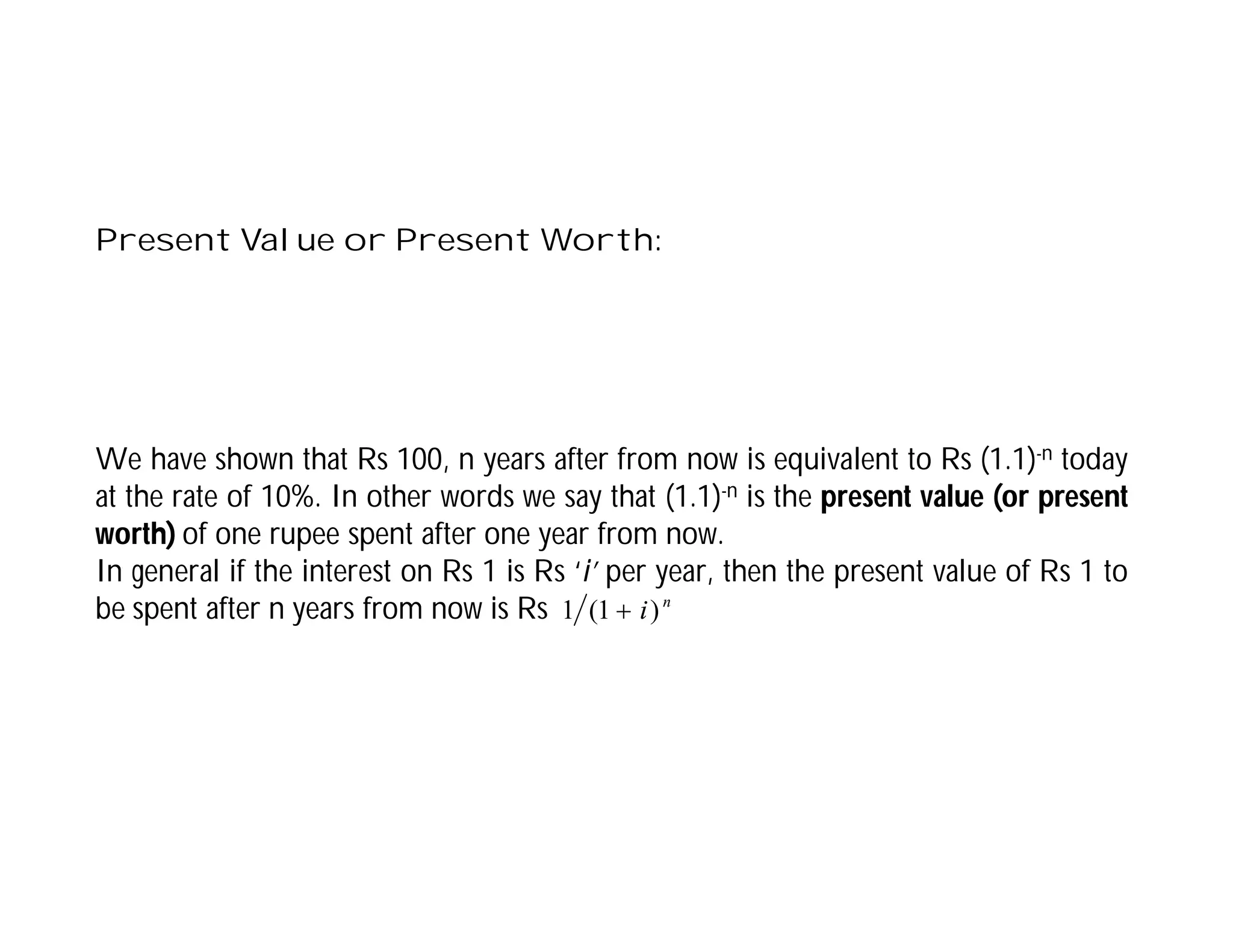

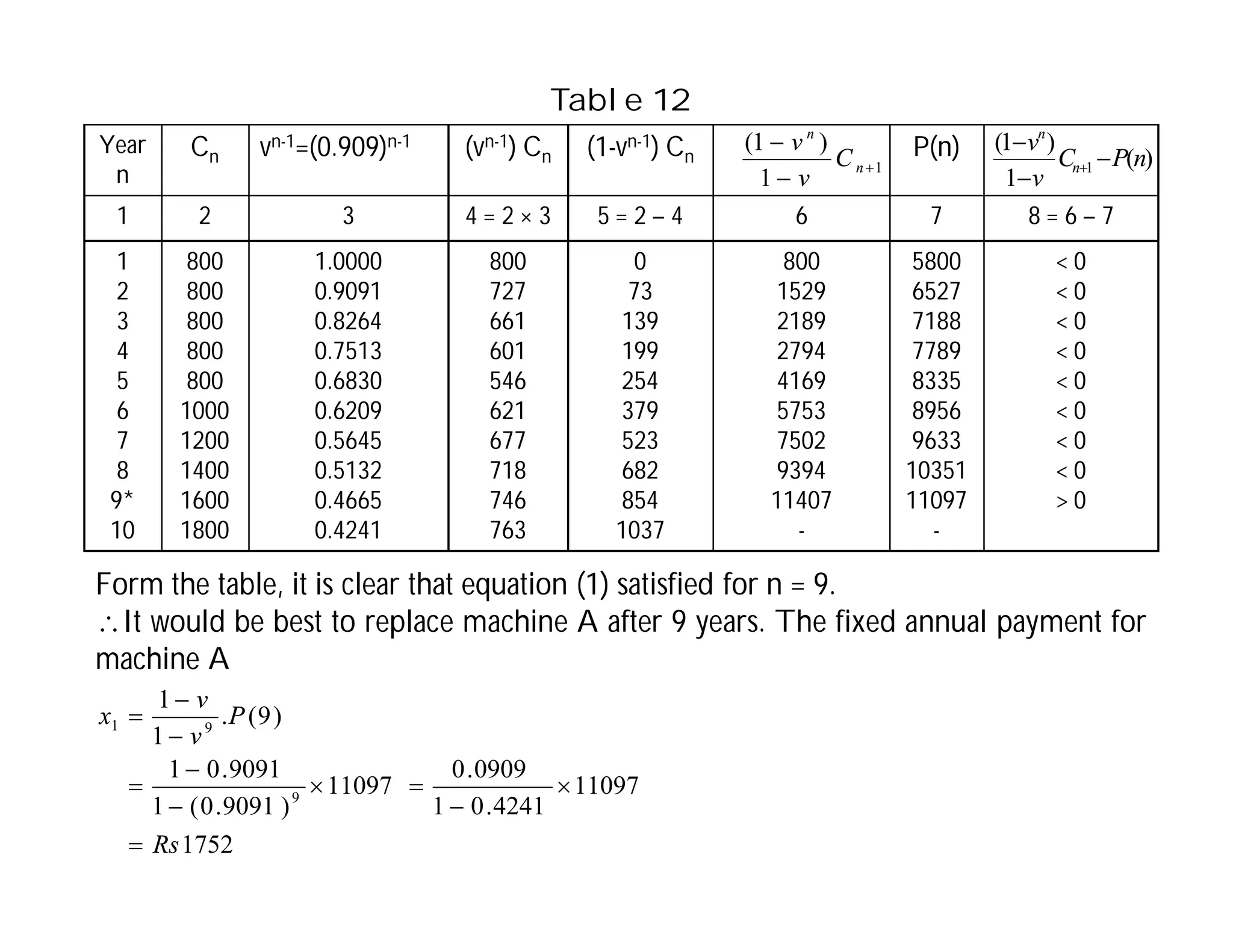

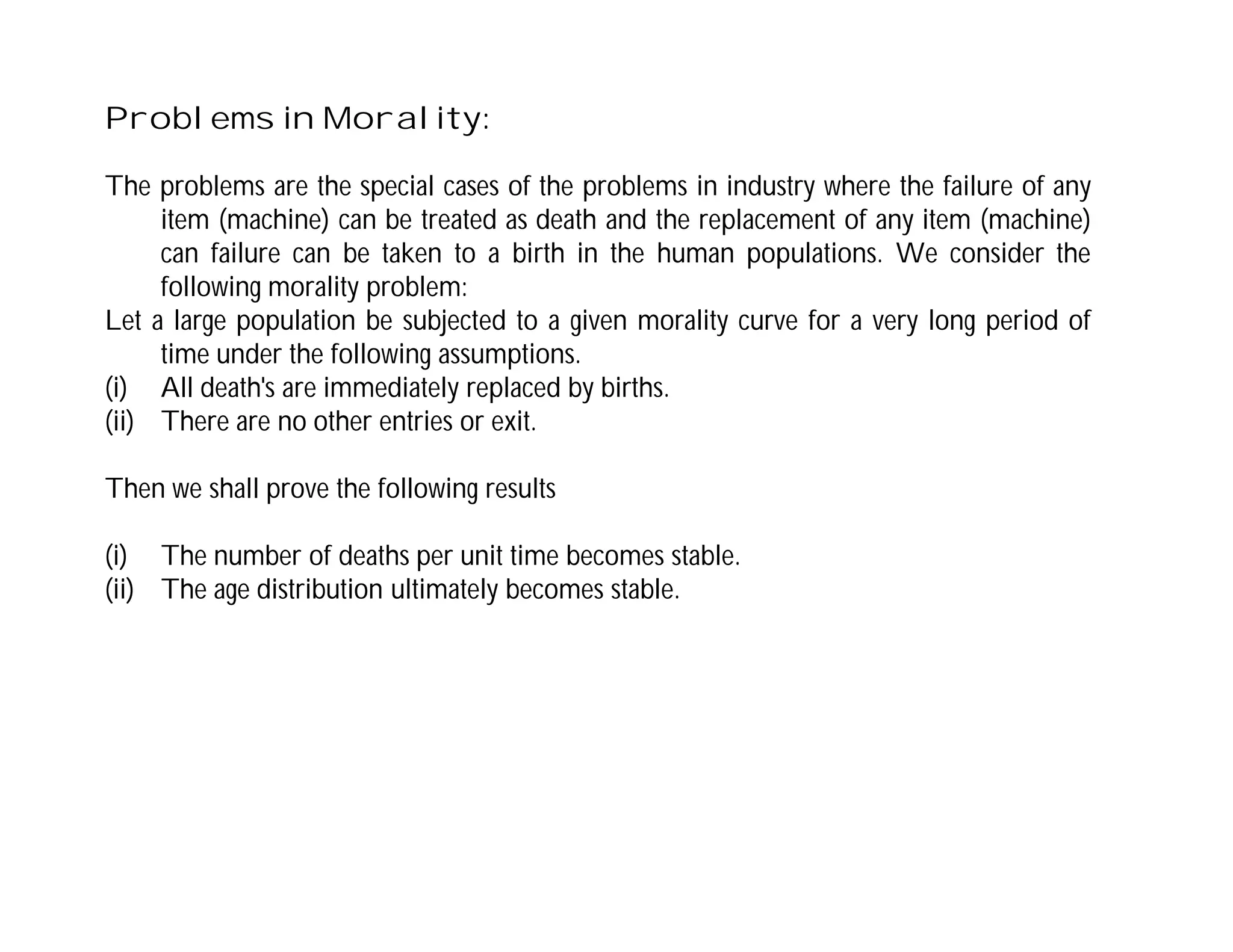

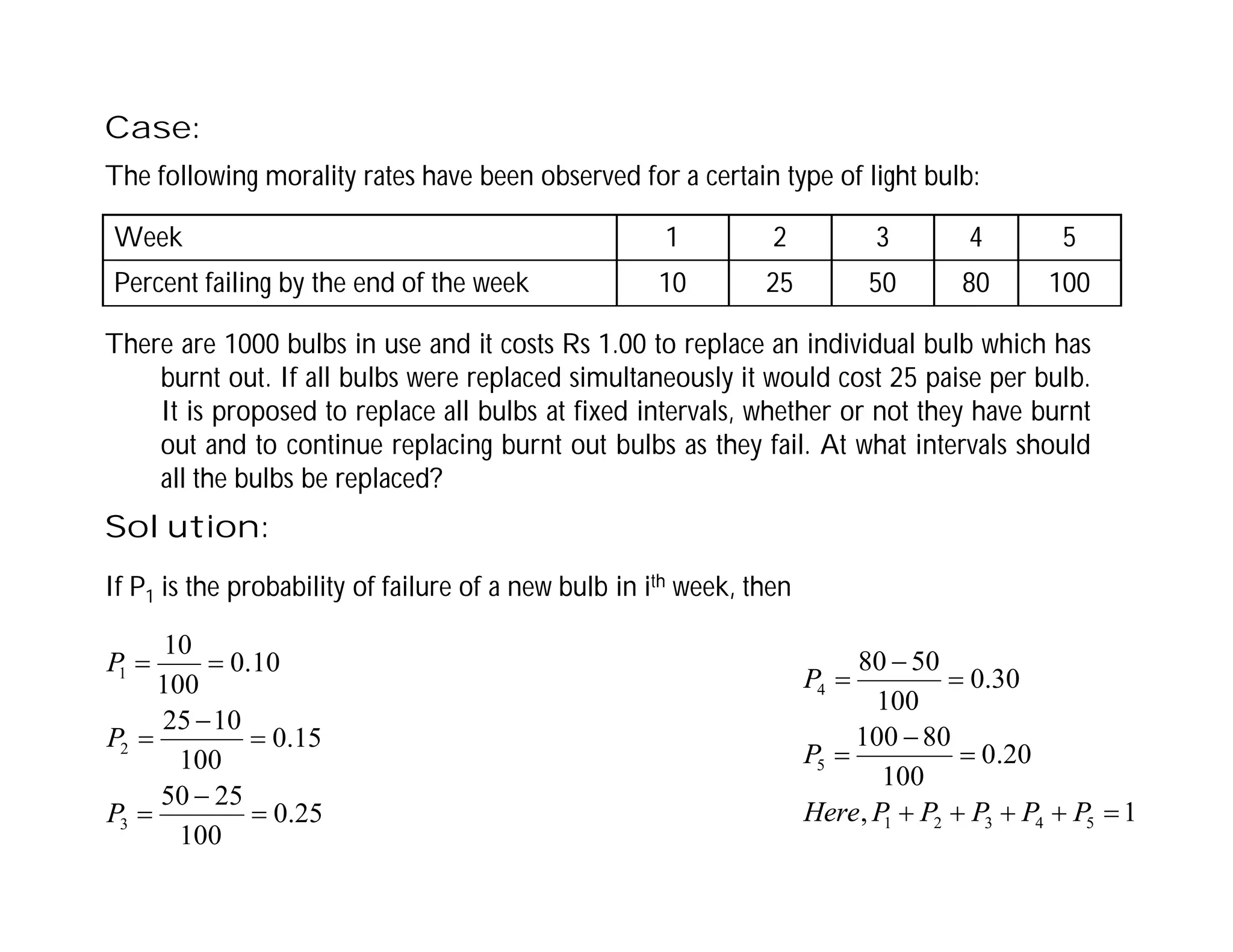

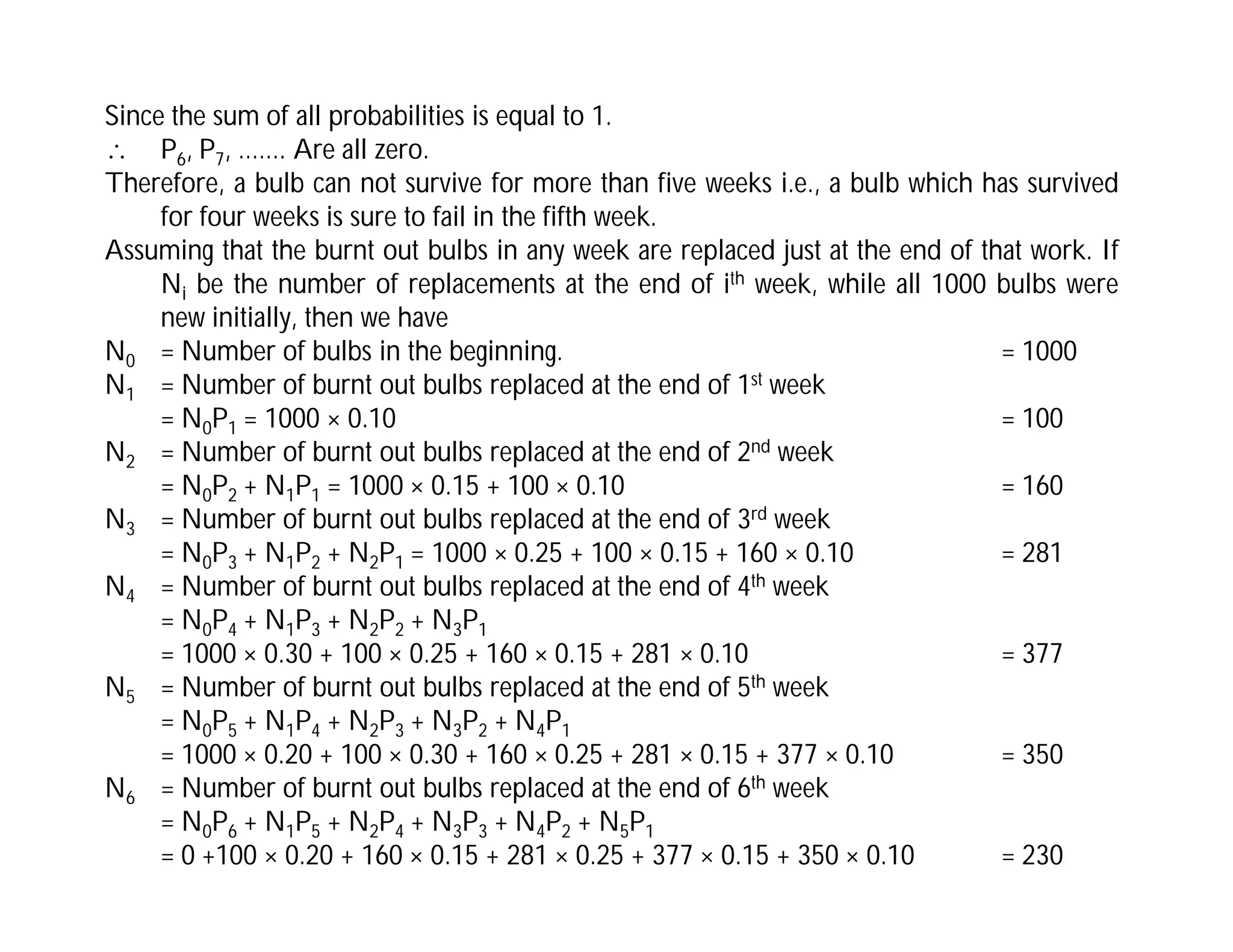

This document discusses replacement problems related to capital equipment that deteriorates over time, such as machines. It addresses determining the optimal time to replace equipment by minimizing total costs, which include the initial equipment cost, maintenance costs that increase over time, and salvage value. The document presents the replacement problem when time is continuous versus discrete and provides examples of calculating total costs and average costs per year for different equipment to determine the lowest-cost replacement age. The optimal policy is to replace equipment when the average total cost to date exceeds the current year's maintenance cost.

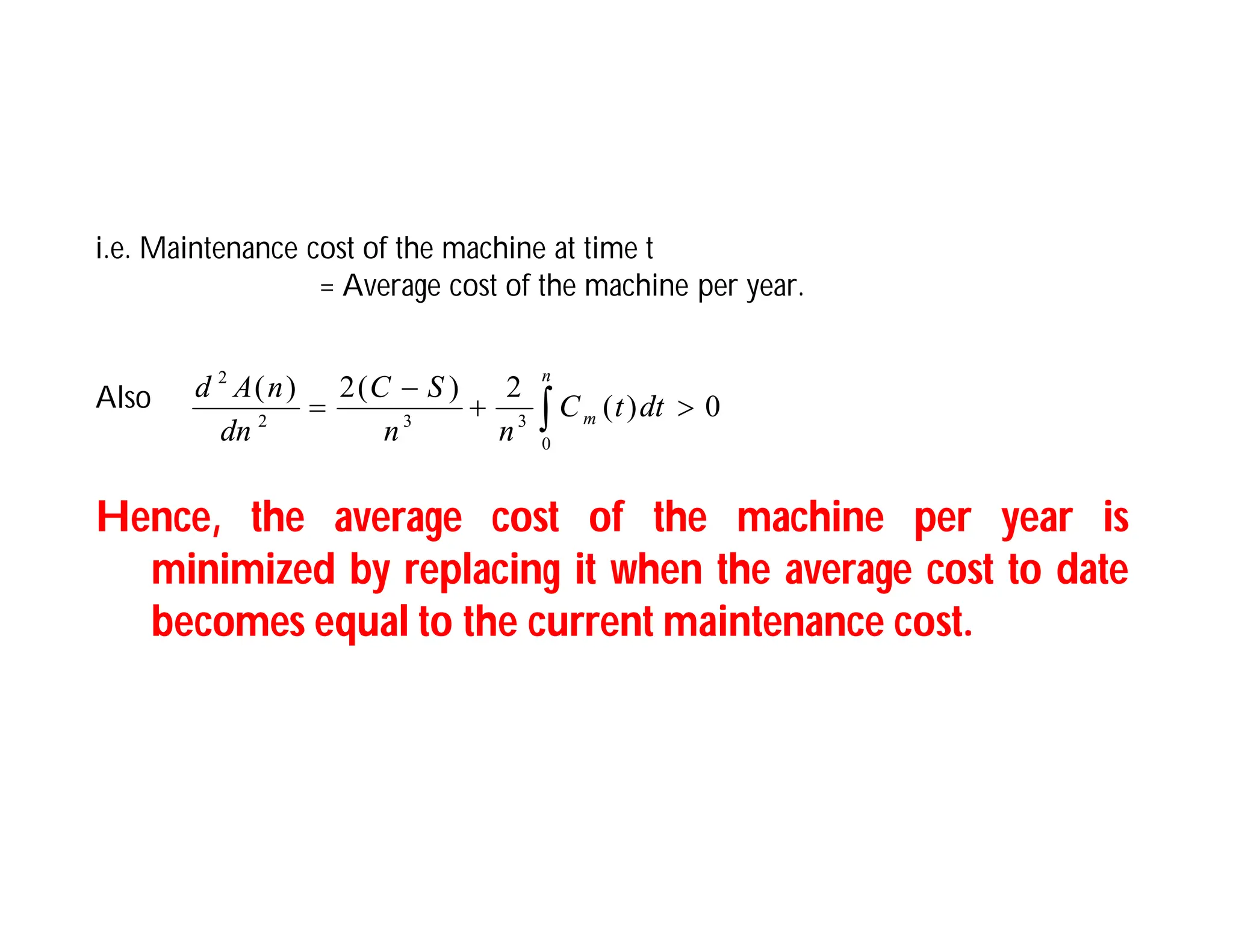

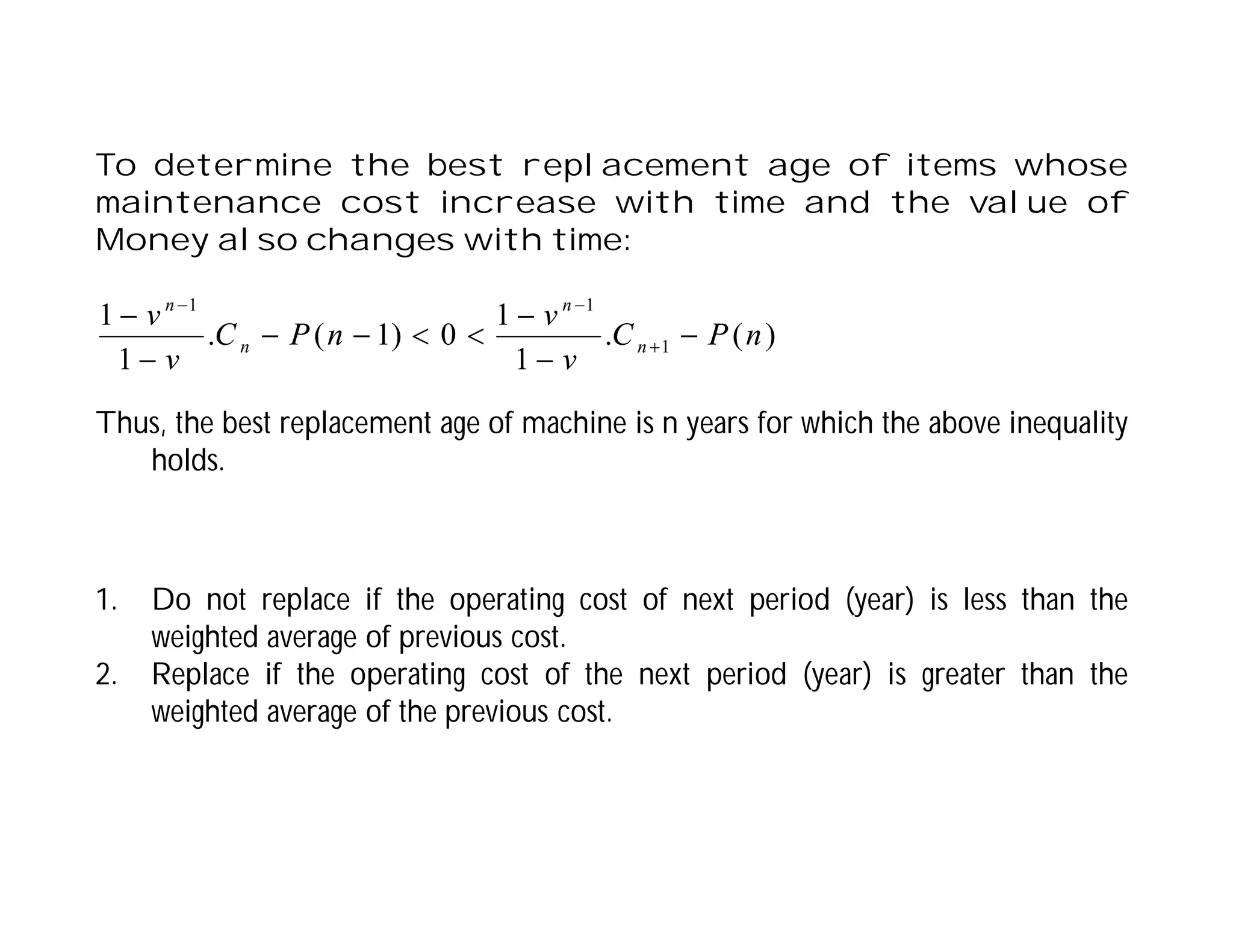

![To Find The Best Replacement Age (Time) of a

Machine When

(1) Its maintenance cost is given by a function increasing

with time.

(2) Its scrap value is constant and,

(3) The Money value is not considered.

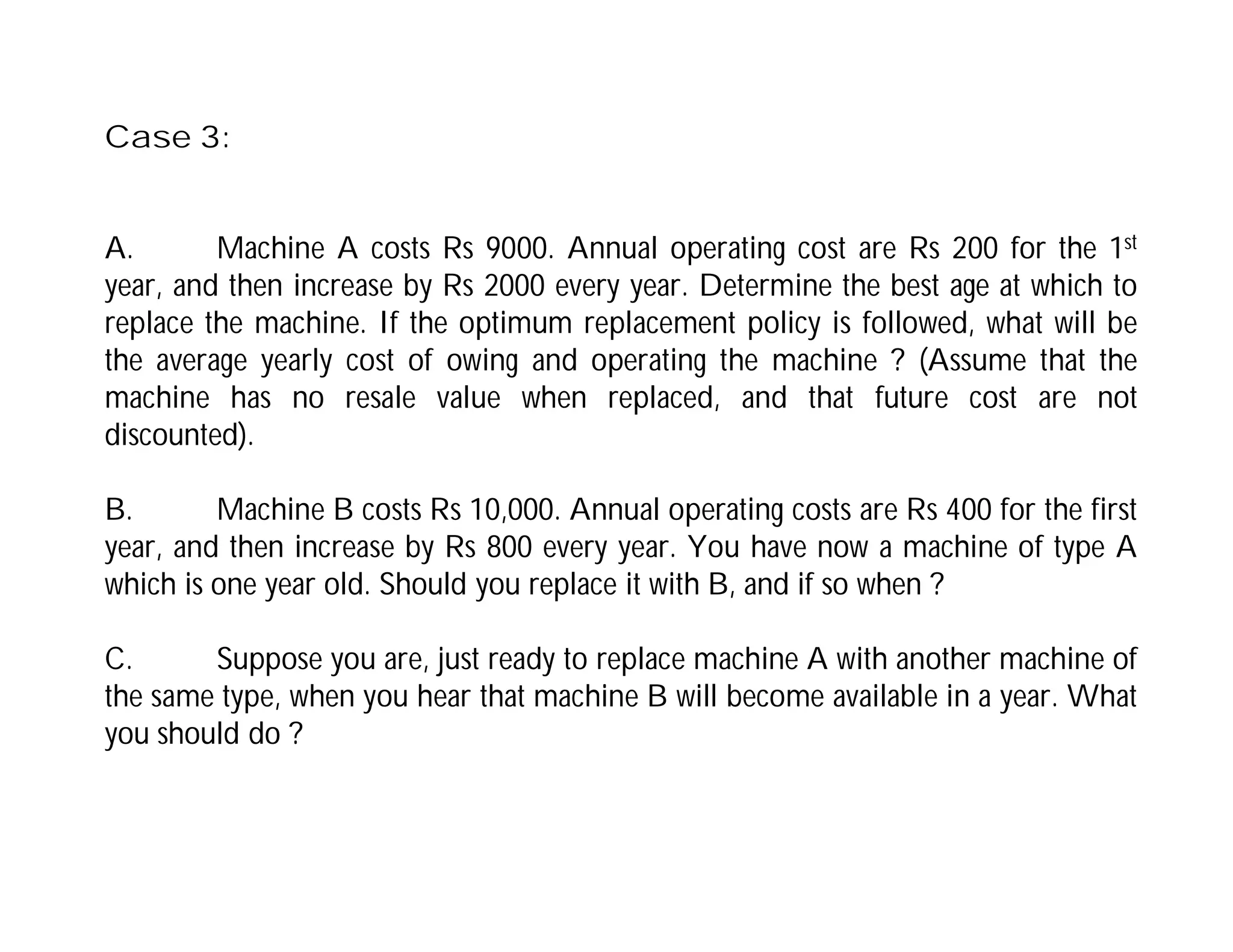

Let C = Cost of Machine

S = Scrap value of the machine at time t.

and, Cm(t) = Maintenance cost of machine at time t, [Cm(t) increases with t].

Case 1 : When time ‘t’ is a continuous variable.

Total maintenance cost of the machine in n years

The total cost of machine in n years

= Cost of machine – Scrap value of machine + Total maintenance cost in n years.

n

m dt

t

C

0

)

(](https://image.slidesharecdn.com/lecture5-replacementproblem-240222095023-d31be2e4/75/Lecture-5-Replacement-Problem-for-industrial-equipments-6-2048.jpg)

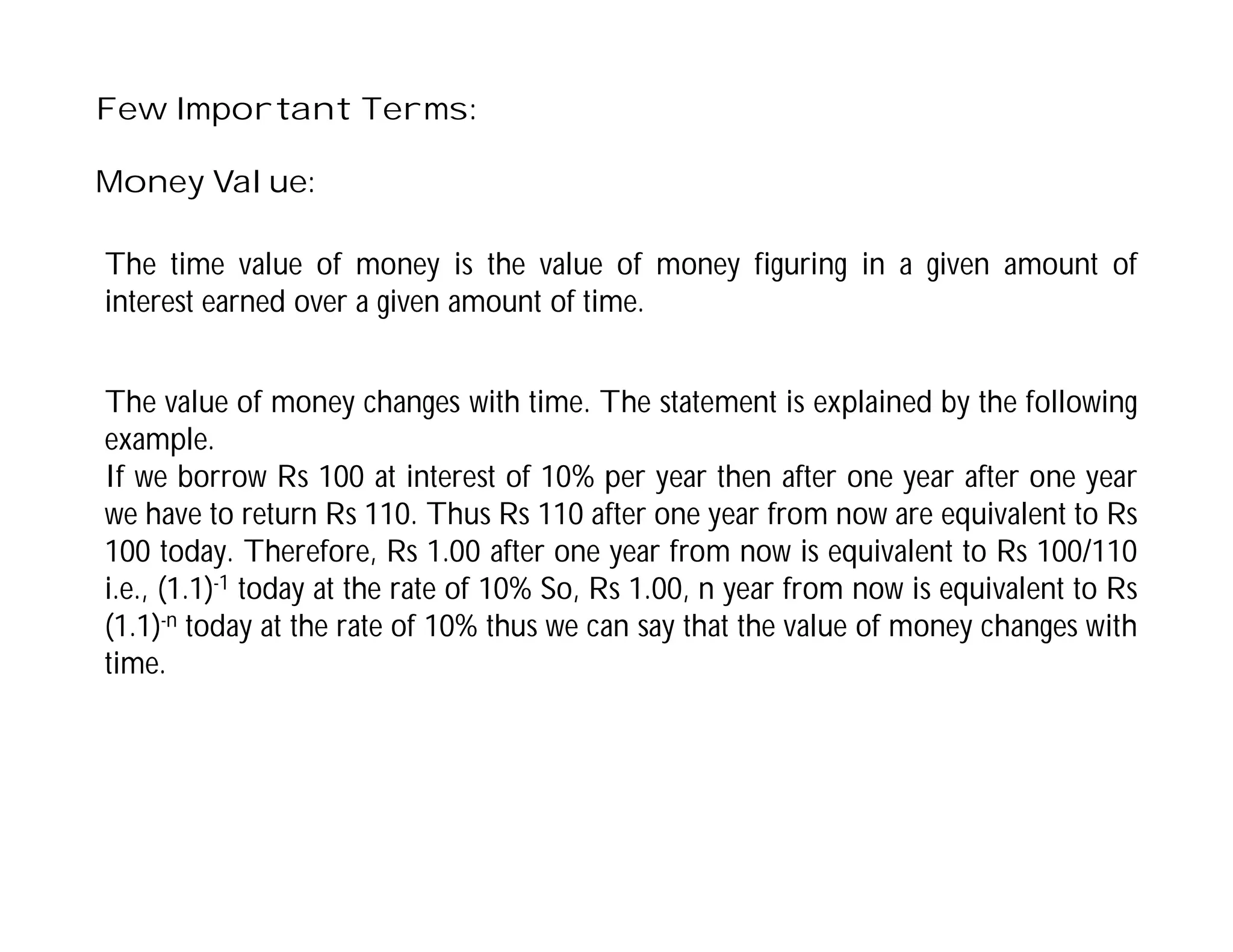

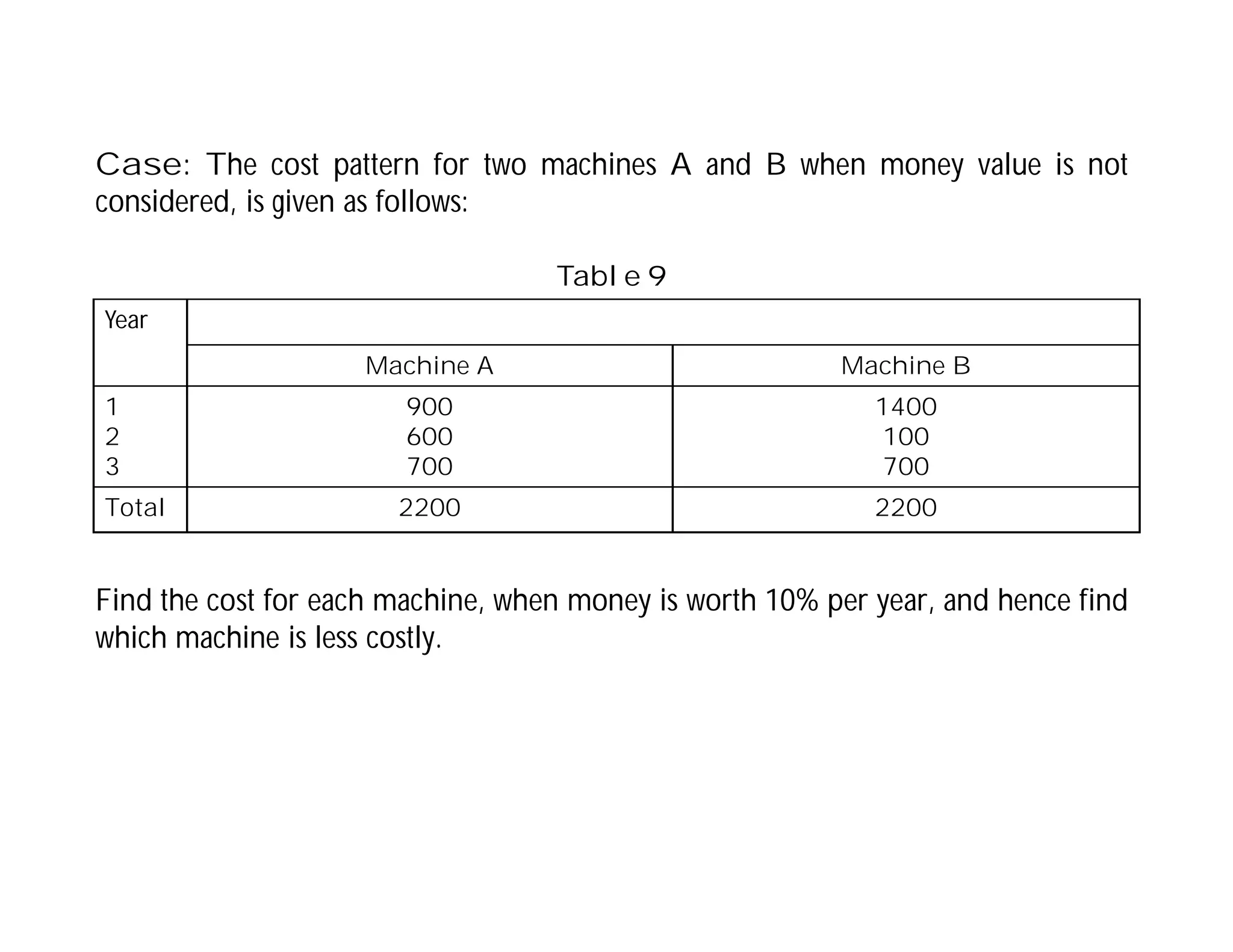

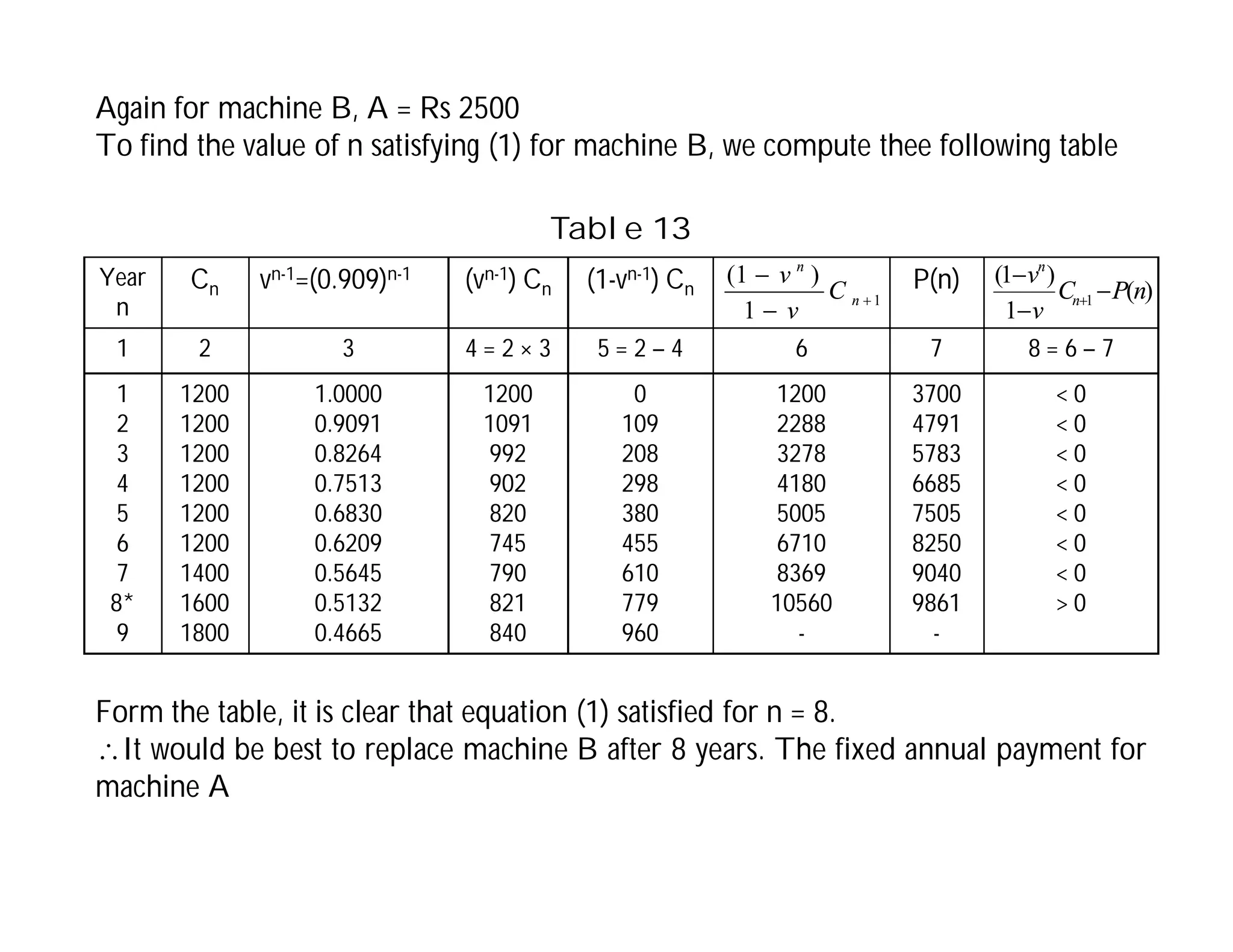

![dt

t

C

S

C

n

m

0

)

(

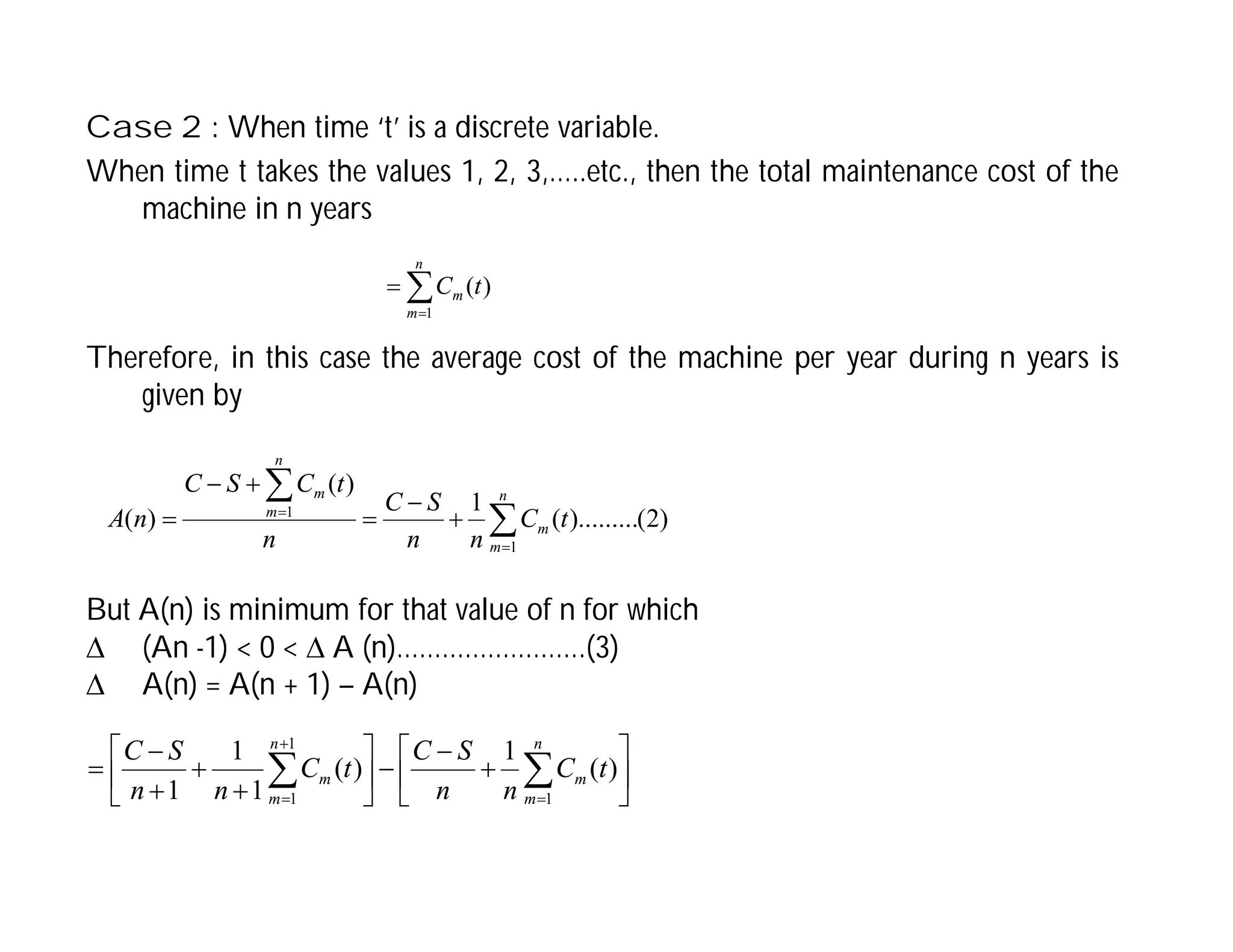

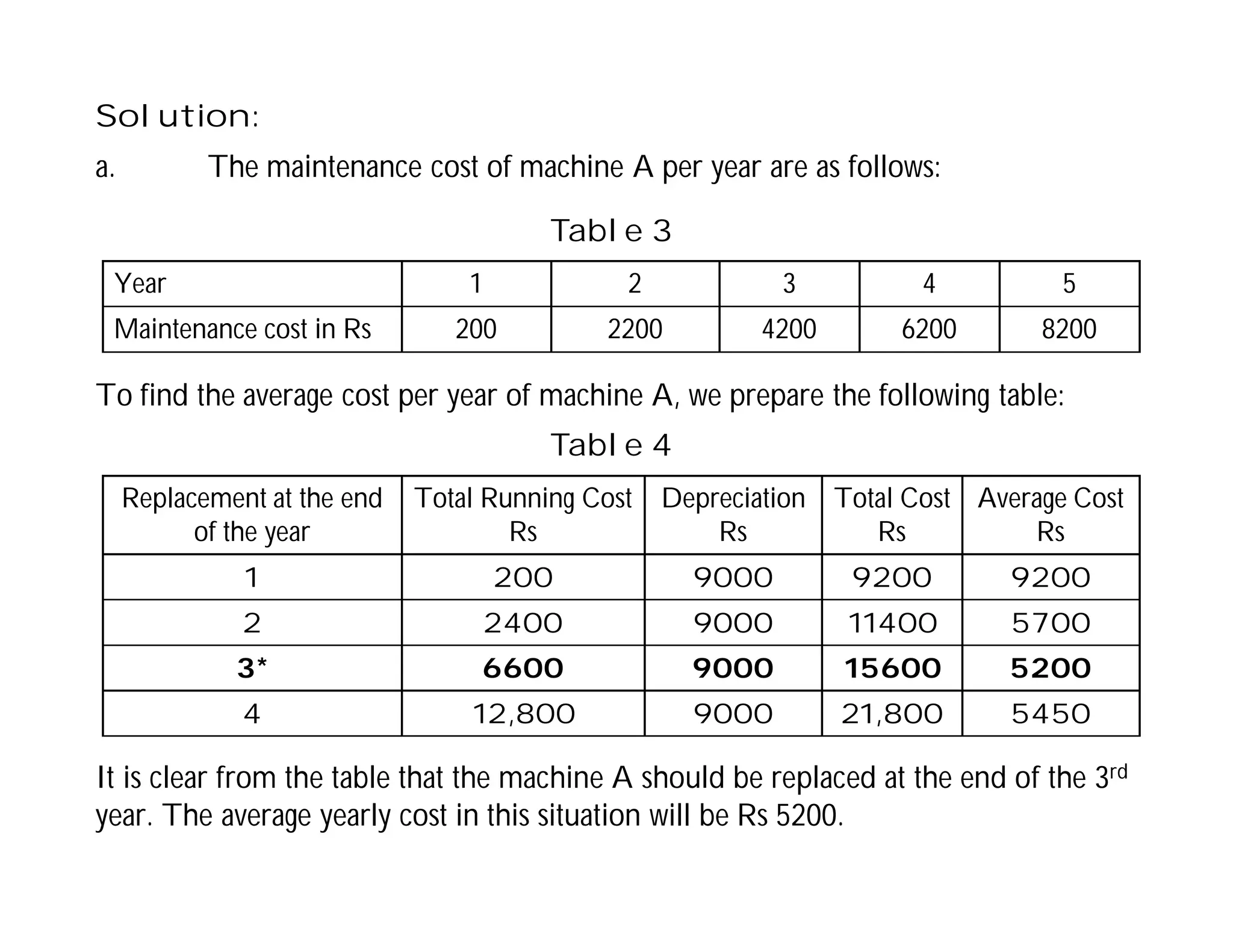

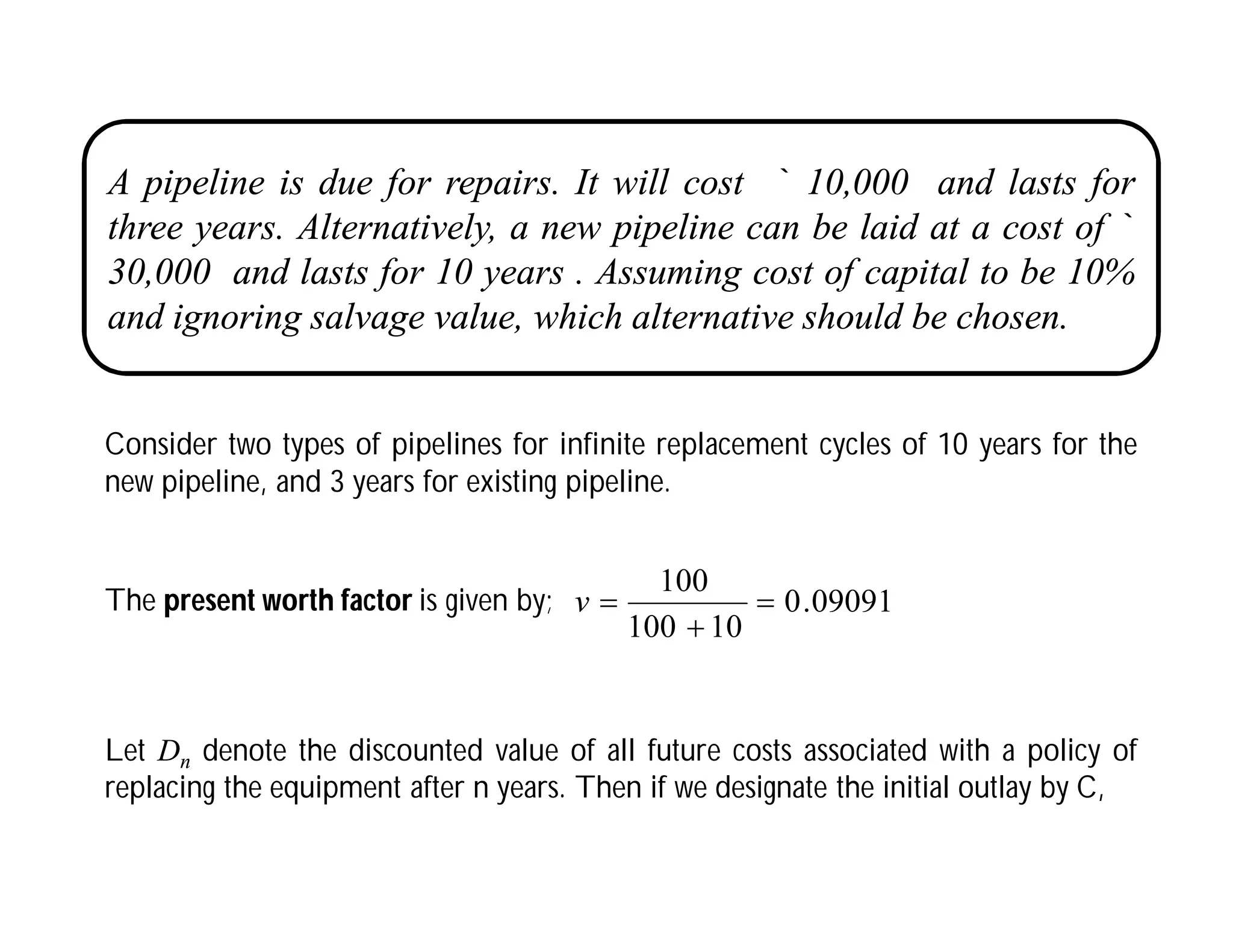

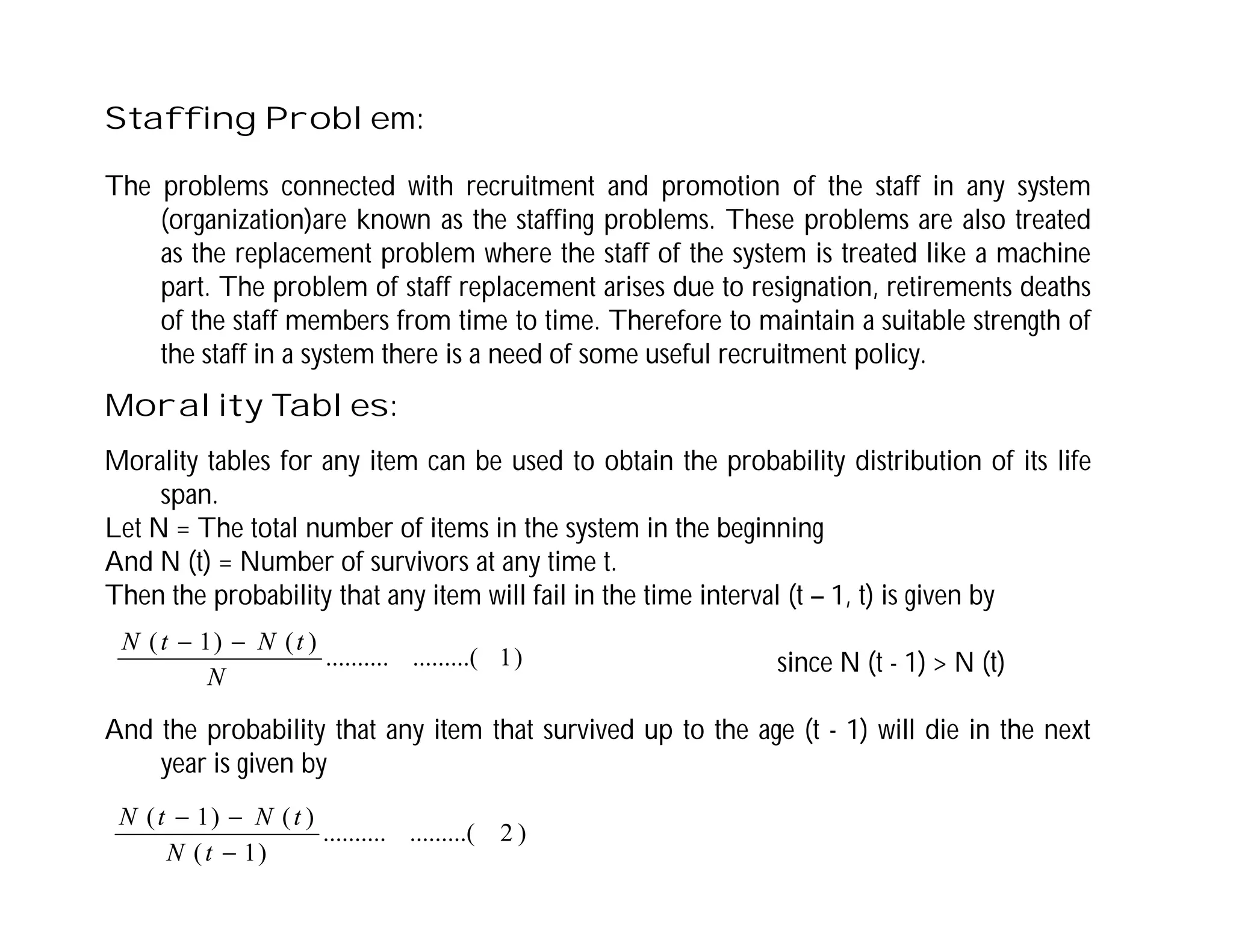

The average cost of maintenance per year during n years is given by

Now for A (n) to be minimum,

[ from (1) ]

)

1

...(

..........

..........

)

(

1

)

(

)

(

)

(

0

0

n

m

n

m

dt

t

C

n

n

S

C

n

A

n

dt

t

C

S

C

n

A

)

(

)

(

)

(

)

(

1

)

(

1

)

(

0

0

2

2

n

A

n

dt

t

C

S

C

t

C

t

C

n

dt

t

C

n

n

S

C

n

A

dn

d

n

m

m

m

n

m

](https://image.slidesharecdn.com/lecture5-replacementproblem-240222095023-d31be2e4/75/Lecture-5-Replacement-Problem-for-industrial-equipments-7-2048.jpg)