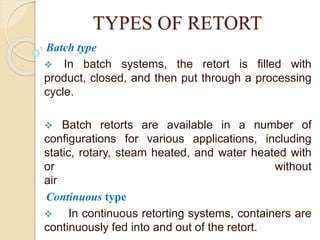

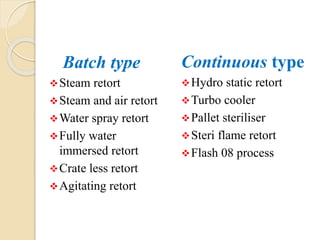

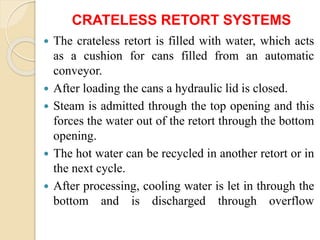

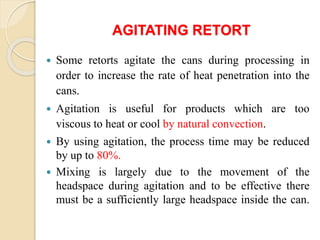

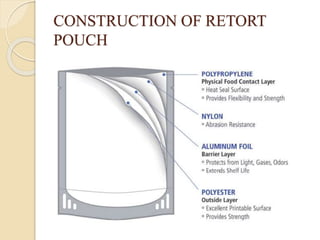

The document discusses retort packaging and processing. It defines sterilization and describes the key components of retort packaging including retorts, retort pouches, and retort operations. It discusses the different types of retorts and retort pouches as well as the materials used to construct retort pouches. The document also summarizes the advantages of retort packaging and some common products packaged using this method.