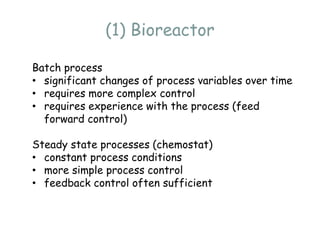

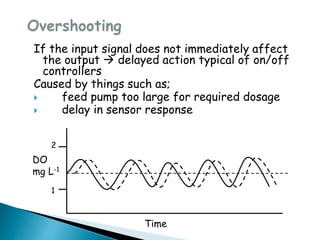

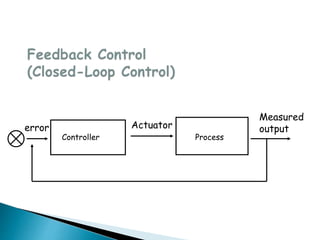

This document discusses process control for bioreactors. It defines process control and its goals of producing quality products at low cost. Process control is important for process optimization, constant product quality, early problem detection, and quality assurance. Bioreactors can operate as batch or steady state processes, with the latter allowing for simpler feedback control. Sensors enable process monitoring while actuators make changes to the process. Common control schemes include open-loop, closed-loop, inferential, and combined feedforward and feedback control.