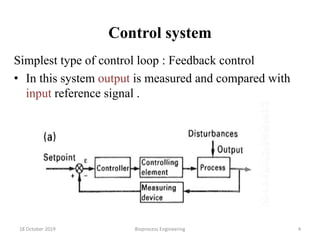

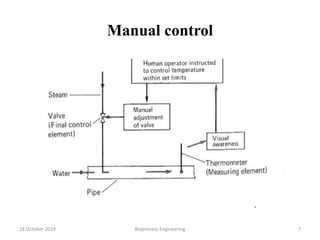

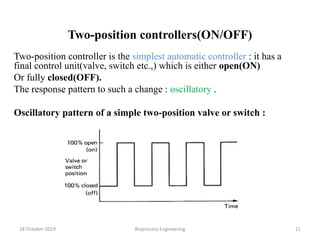

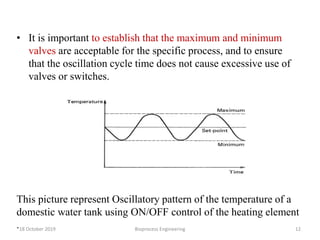

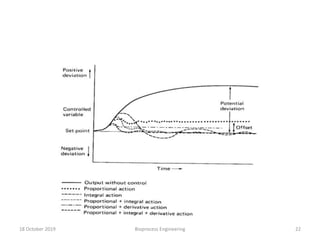

This document discusses bioreactor control systems. It describes different types of control systems including manual control, automatic control, two-position controllers, proportional control, integral control, and derivative control. It explains that automatic control systems use four basic components: a measuring element, controller, final control element, and the process to be controlled. The document also summarizes different combinations of control methods, such as proportional plus integral control and proportional plus integral plus derivative control.