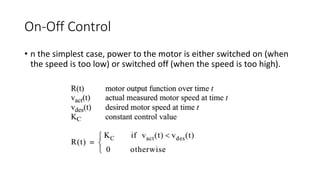

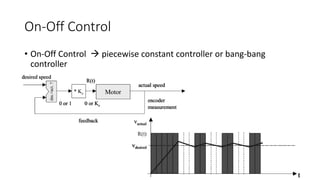

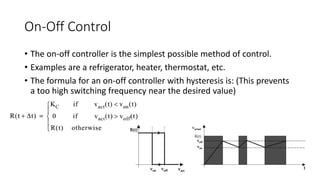

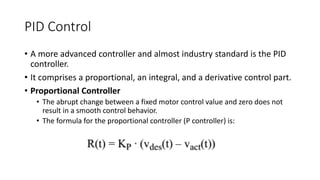

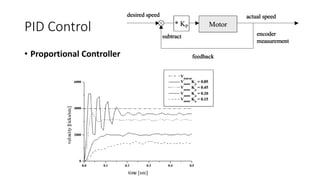

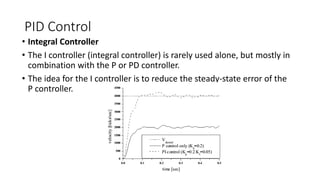

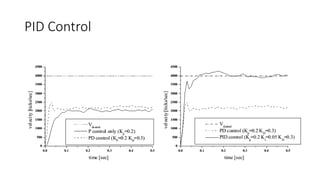

On-off control is the simplest method of feedback control where the motor power is either switched fully on or off depending on whether the actual speed is higher or lower than the desired speed. A PID controller is a more advanced control method that uses proportional, integral and derivative terms to provide smoother control compared to on-off control and help reduce steady-state error. PID control is almost an industry standard approach for feedback-based motor speed regulation.