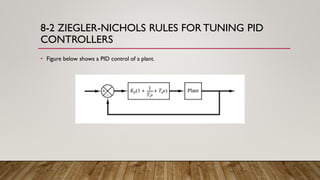

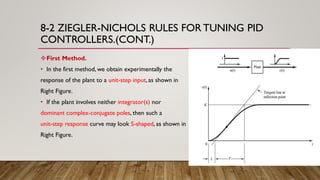

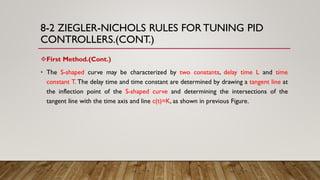

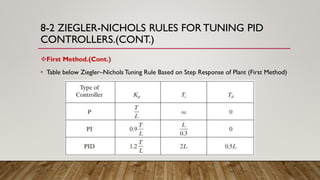

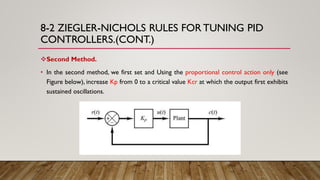

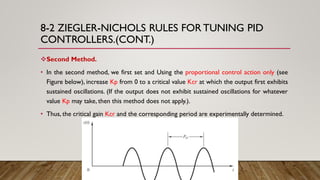

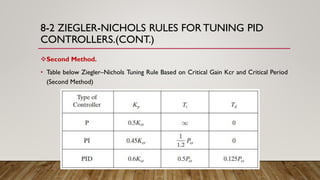

Chapter 8 discusses PID controllers, highlighting their prevalence in industry and various tuning methods including Ziegler-Nichols rules for tuning based on experimental step responses. The chapter emphasizes the utility of PID controls in scenarios where a plant's mathematical model is not known, and outlines both first and second methods for determining optimal controller parameters. It concludes that while Ziegler-Nichols rules provide a useful starting point for tuning PID controllers, further adjustments are often necessary to achieve desired performance.