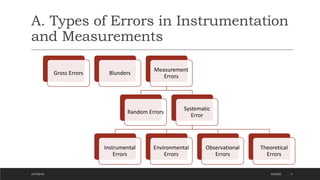

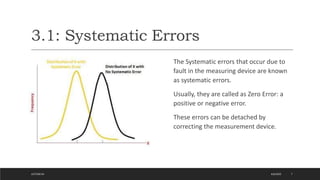

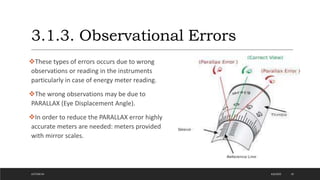

The document discusses various types of errors in instrumentation and measurements, including gross errors, blunders, and systematic errors such as instrumental, environmental, observational, and theoretical errors. It provides methods for reducing systematic errors and outlines the statistical analysis of measurements subject to random errors, emphasizing that averages can help mitigate these errors. Additionally, it covers the aggregation of errors from separate measurement system components.