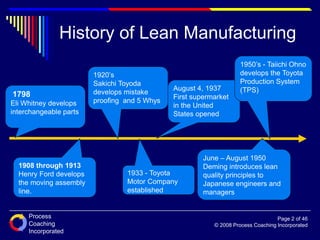

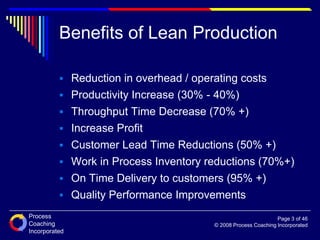

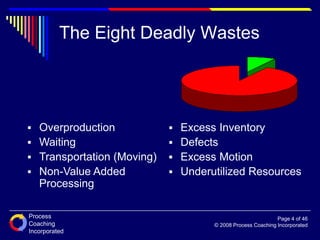

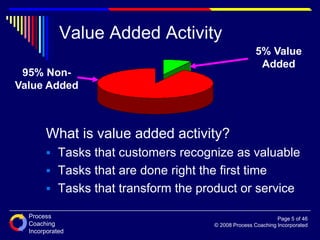

The document outlines lean thinking as a systematic approach aimed at continuous improvement and waste elimination in production processes. It highlights the history of lean manufacturing, key principles, and benefits such as increased productivity and reduced costs, while also identifying the eight deadly wastes. Additionally, the importance of specifying value and understanding value-added activities is emphasized to enhance overall efficiency.