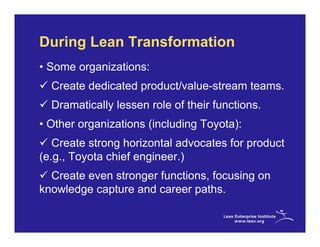

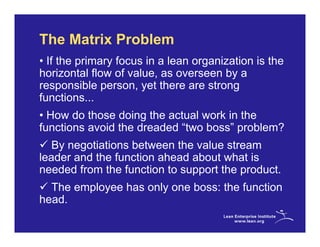

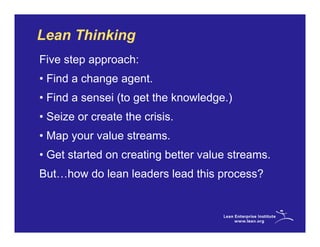

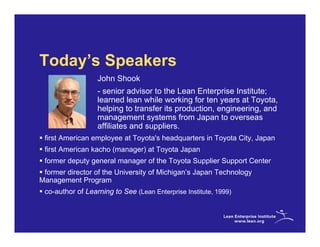

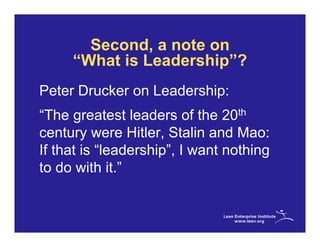

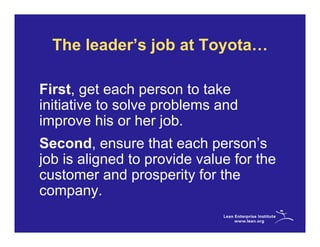

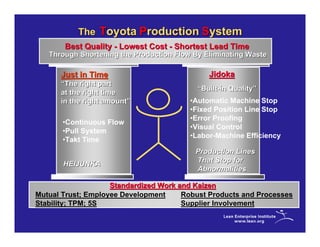

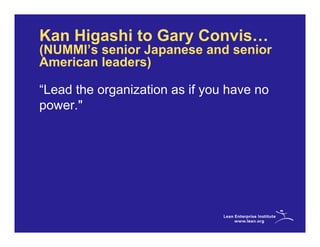

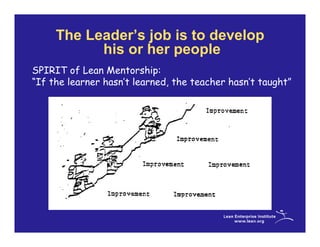

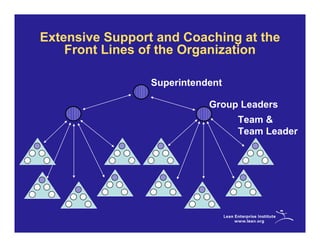

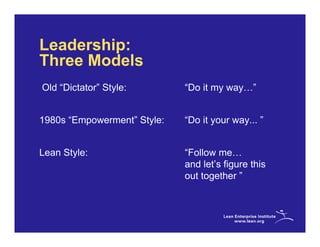

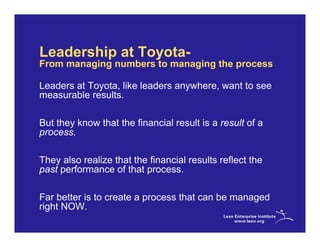

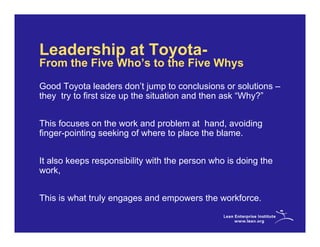

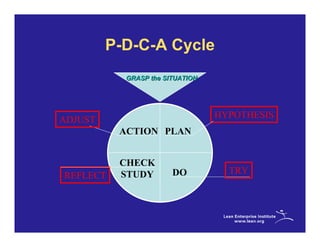

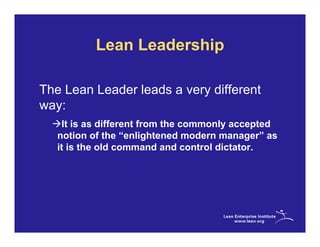

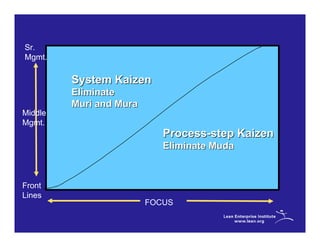

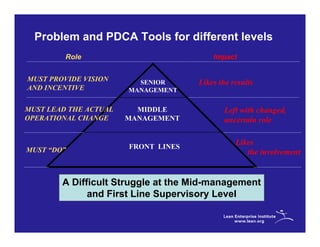

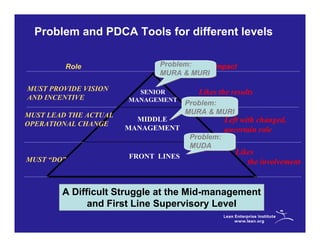

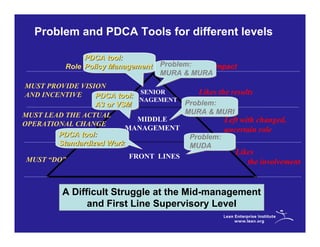

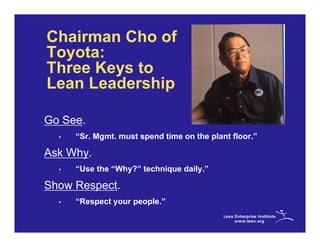

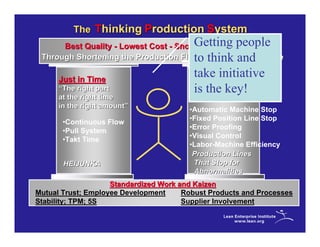

The document discusses lean management and the role of lean leadership. It begins by introducing James Womack and John Shook, who will be presenting. It then discusses some of the key principles of lean management, including focusing on value streams to clearly define purpose and optimize processes. Lean management addresses appointing leaders responsible for each value stream. The presentation then contrasts vertical versus horizontal thinking in organizations and discusses the matrix structure used in some lean organizations. John Shook's portion focuses on what lean leadership entails, such as developing people, aligning jobs to create value, and using tools like standard work and continuous improvement. The presentation emphasizes problem-solving, flexibility, and engaging employees in a way that provides direction while allowing autonomy.