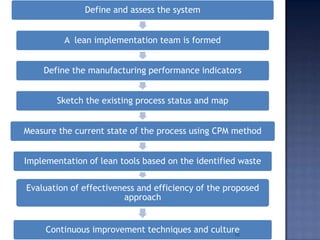

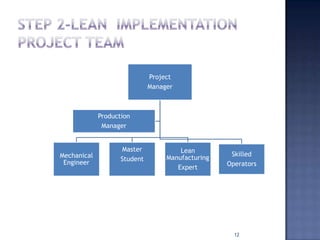

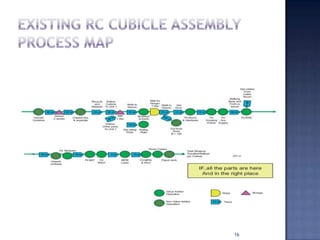

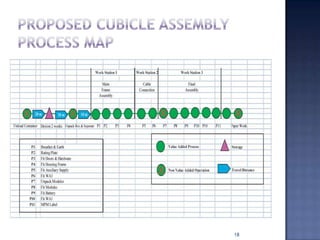

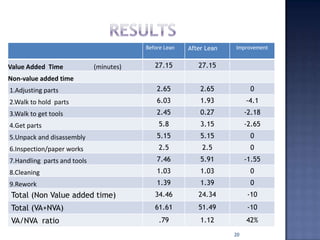

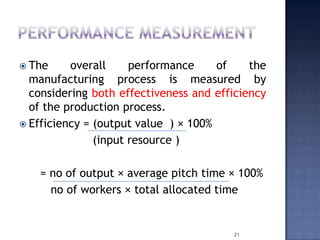

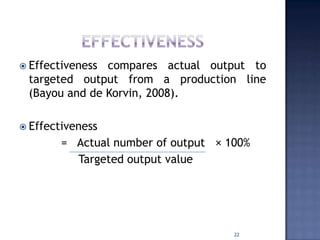

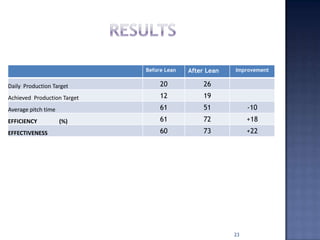

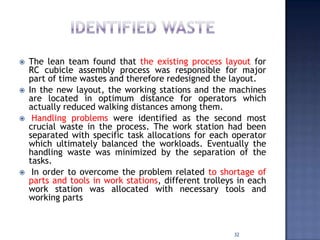

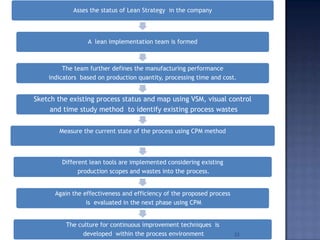

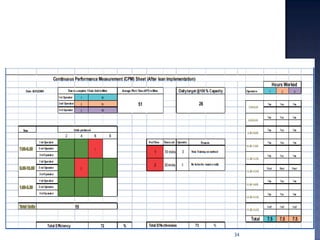

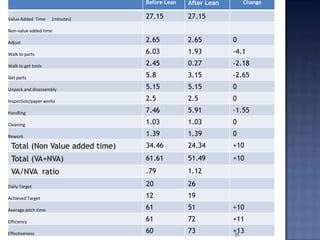

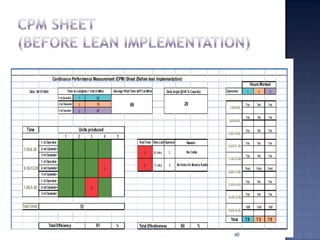

The lean team assessed the status of lean strategy implementation in an assembly unit of a company that specializes in low and medium voltage switchgear products. They formed a lean implementation team and defined key performance indicators like processing time. The existing assembly process was mapped and current performance was measured using Continuous Performance Measurement. Major wastes identified included long walk times, improper layout, and lack of tools at workstations. The lean tools implemented included redesigning the layout to reduce walking, separating tasks among operators to balance work, and providing necessary tools and parts at each station. After implementation, non-value added time decreased by 10 minutes, efficiency increased by 18%, and effectiveness increased by 22%, showing the methodology effectively improved operational performance.