The document summarizes new OSHA standards for fall protection that will take effect in 2017 and beyond. Key points include:

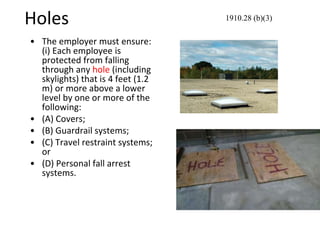

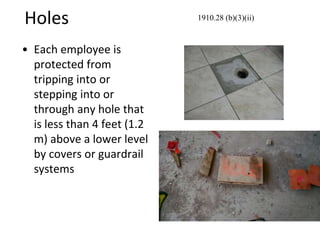

- The new standards will require fall protection for workers 4 feet or more above a lower level, clarifying previous construction standard of 6 feet.

- Effective dates are staggered over several years for things like training, inspections, and equipment upgrades.

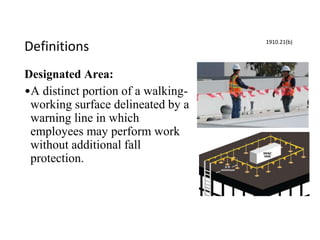

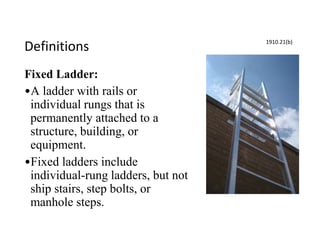

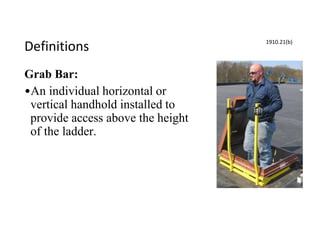

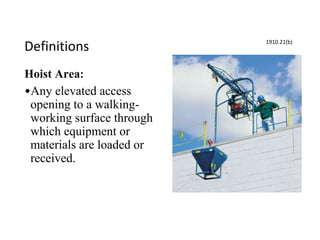

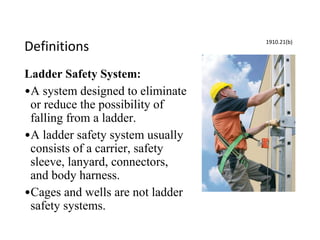

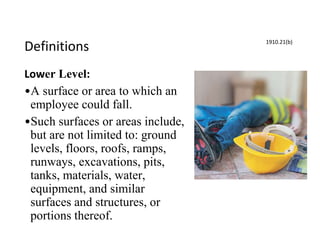

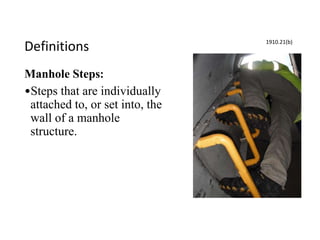

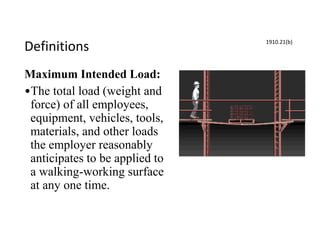

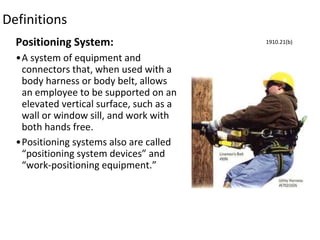

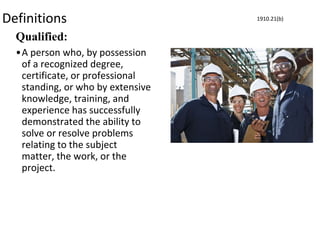

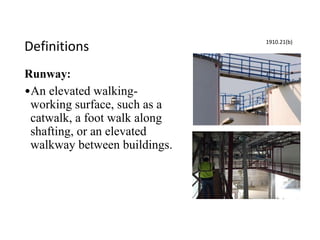

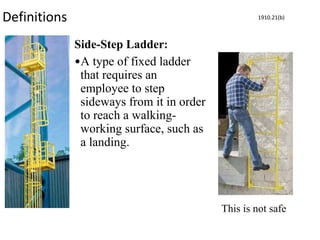

- Definitions are provided for terms like designated area, temporary, infrequent, and dockboards.

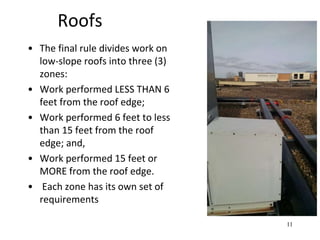

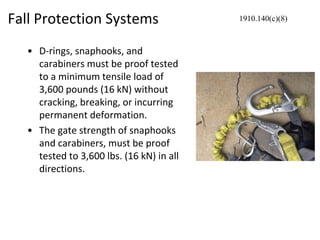

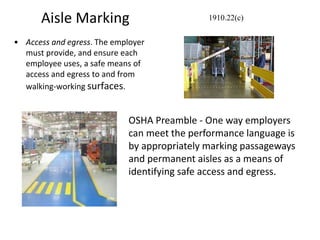

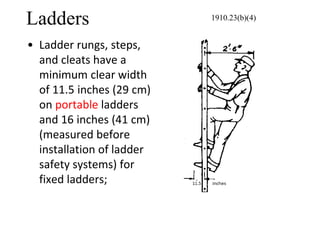

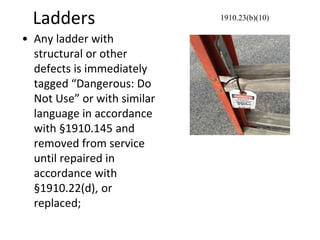

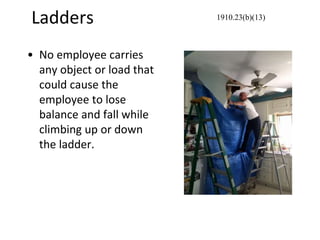

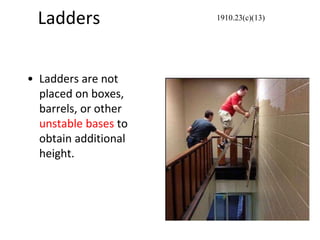

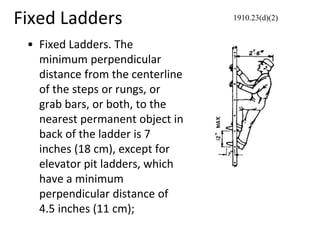

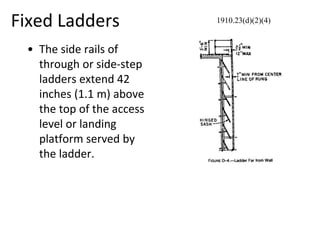

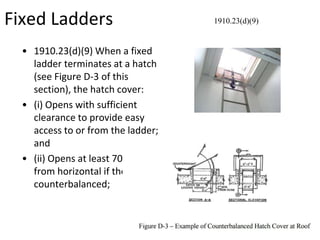

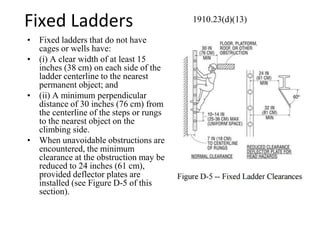

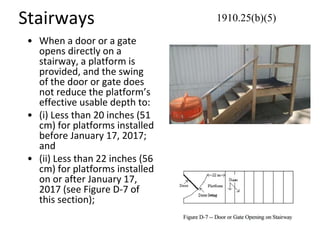

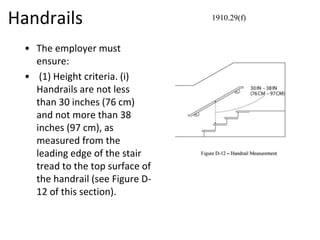

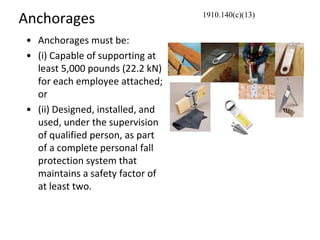

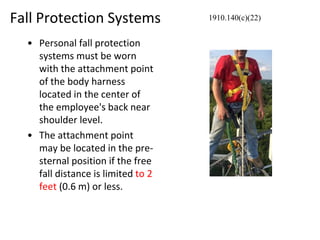

- Requirements address specific areas like roofs, ladders, fall protection systems, and general walking-working surfaces.