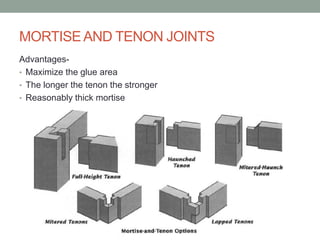

This document provides instructions for making mortise and tenon joints. It discusses the advantages of mortise and tenon joints, including maximizing glue area and strength from a longer tenon. It also mentions offset tenons having a fourth shoulder. The document then outlines a 3-step process for making a mortise and tenon joint from selecting materials to cutting the tenons and mortise and fitting the joints together through a trial and error process.