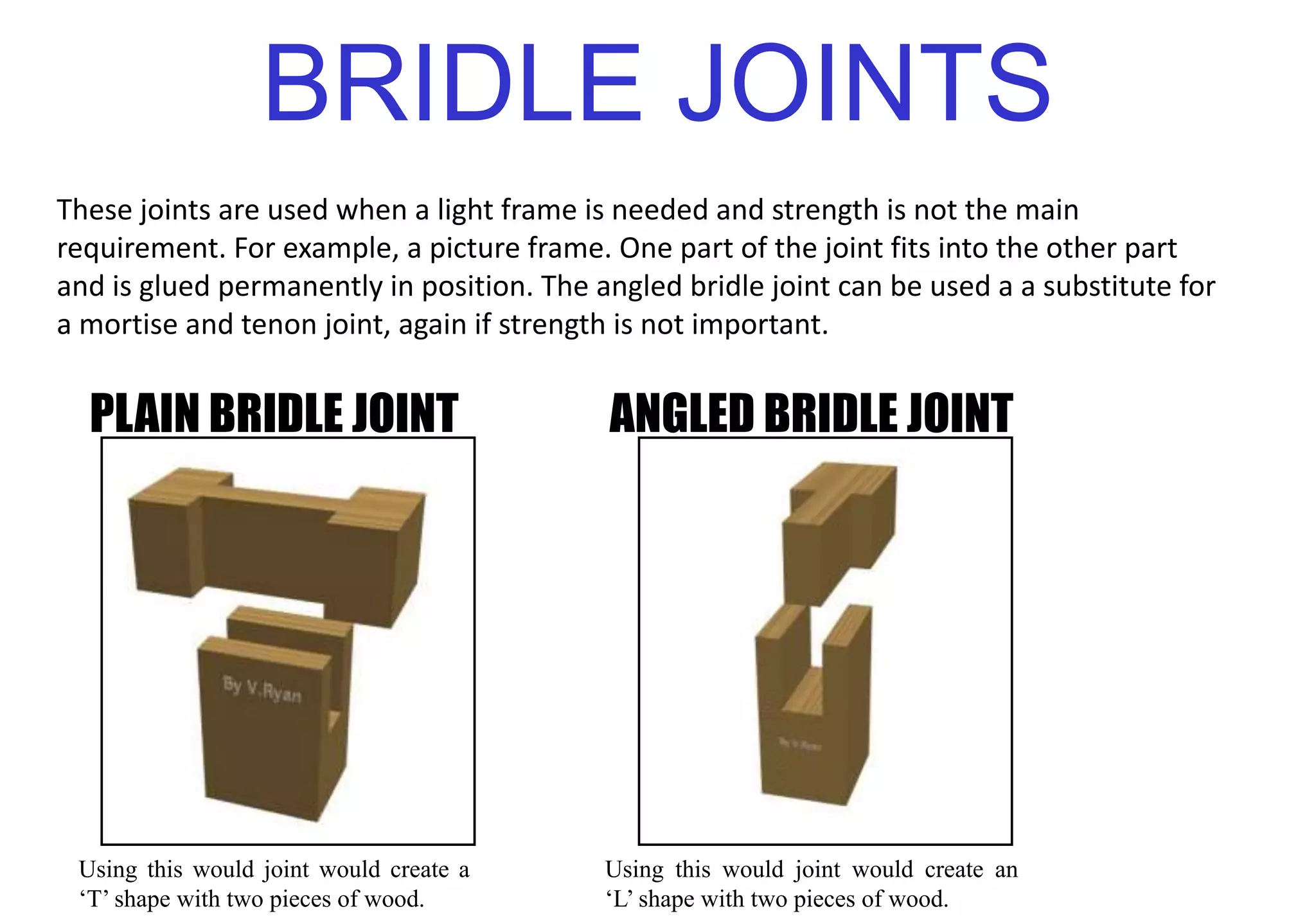

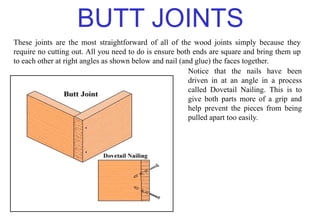

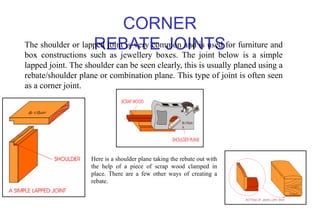

This document discusses and illustrates different types of wood joints used in light frame construction including bridle joints, butt joints, and corner rebate joints. Bridle joints are used when strength is not critical and come in plain and angled variations to form a 'T' or 'L' shape. Butt joints simply bring two ends together at a right angle and nail them for basic connections. Corner rebate joints use a shoulder or lapped configuration common for furniture and boxes, where a rebate plane or combination plane creates flush shoulders at the corners.